Open-type spontaneously generating negative oxygen ion multifunctional water permeable brick and preparation method thereof

A negative oxygen ion and open technology, applied in clay products, ceramic products, and other household appliances, can solve the problems of difficult control of cellulose liquid viscosity, unstable viscosity, single function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

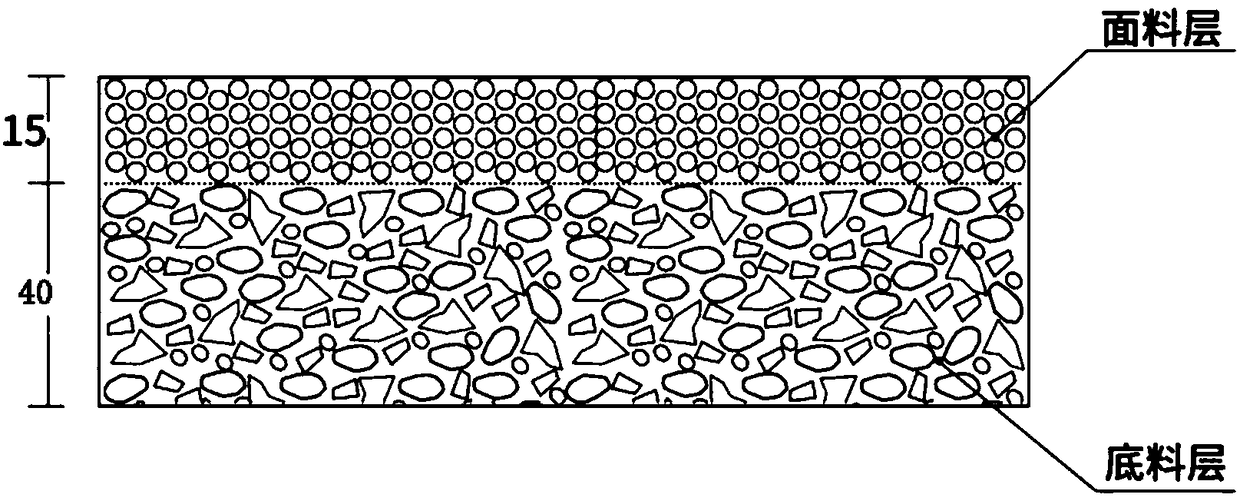

Method used

Image

Examples

Embodiment 1

[0094] Preparation of composite water solution for fabric: 50kg (A1)

[0095] Specific formula:

[0096]

[0097]

[0098] Preparation of composite water solution for primer: 50kg (B1)

[0099] Specific formula:

[0100] water

75%

37.5kg

7%

3.5kg

11.9%

5.95kg

6%

3.0kg

0.1%

0.05kg

[0101] The specific preparation method of the composite water solution A for the fabric layer and the composite water solution B for the bottom material layer (do not contain negative ion powder, then save the step of adding negative ion powder) is as follows:

[0102] 1) Prepare a high-speed fluid dispersing mixer, the speed can be adjusted at 1500-3000 rpm by frequency conversion, and adjusted according to needs;

[0103] 2) Mix water, modified starch and trisodium phosphate in proportion for 5-10 minutes, then add lithium carbona...

Embodiment 2

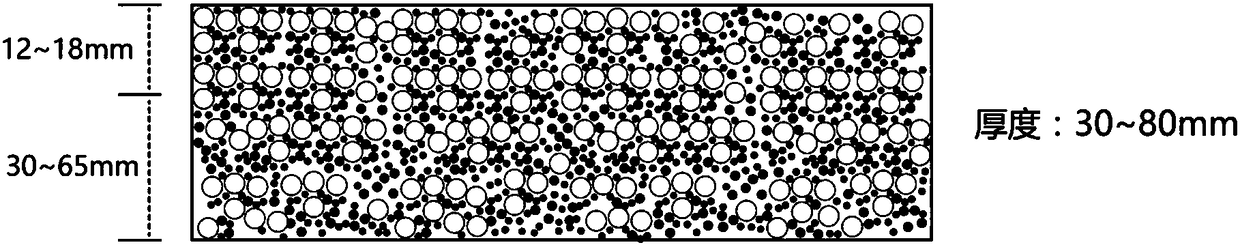

[0120] Take fabric aggregate 100kg

[0121] 10~16 mesh 82% 82kg

[0122] 16~60 mesh 18% 18kg

[0123] After horizontal stirring, 8kg of A1 composite water solution is sprayed by combining pressure atomization and compressed air secondary atomization, and horizontal dispersive crushing and stirring are carried out to break up the agglomeration caused by subdivision.

[0124] Take bottom material aggregate 400kg

[0125] 3~10 mesh 46% 184kg

[0126] 10~16 mesh 20% 80kg

[0127] 16~60 mesh 34% 136kg

[0128] After horizontal stirring, 32kg of B1 composite water solution was sprayed by combining pressure atomization and compressed air secondary atomization, and horizontal dispersion crushing and stirring were carried out to break up the agglomeration caused by subdivision.

[0129] Use a 100×200 mould: add 1.6kg to the bottom material and 0.45kg to the fabric, press with 5 tons of pressure for 8 seconds, demould and place on a high-temperature backing plate for a total of 60 ...

Embodiment 3

[0135] Composite water solution (A2) 50kg is used for preparing fabric layer, concrete formula:

[0136] water

60%

30kg

3.85%

1.925kg

3%

1.5kg

3%

1.5kg

0.15%

0.075kg

negative ion powder

30%

15kg

[0137] After being prepared according to the method and process of Example 1, it was left to stand for 24 hours and then stirred for use.

[0138] Prepare 50kg (B2) of composite water solution for primer, specific formula:

[0139]

[0140]

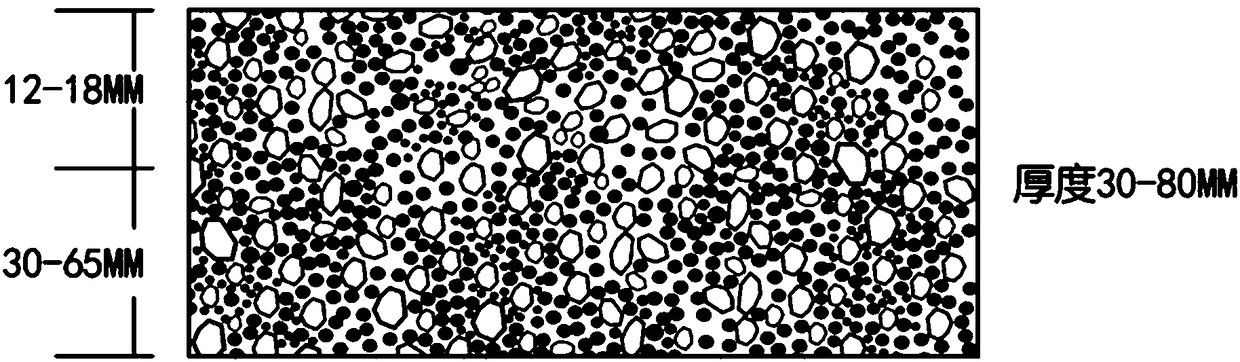

[0141] A total of 100kg of fabric aggregate

[0142] 10~16 mesh 80% 80kg

[0143] 16~60 mesh 20% 20kg

[0144] After horizontal stirring is carried out, 8kg of A2 composite water solution is sprayed by combining pressure atomization and compressed air secondary atomization, and horizontal dispersive crushing and stirring are carried out to break up the agglomeratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Water permeability coefficient | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com