Patents

Literature

57results about How to "Increase heat radiation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ceramic coating used for heating furnace

InactiveCN102020475AExtended service lifeHas high temperature oxidation resistanceEmissivityRadiance

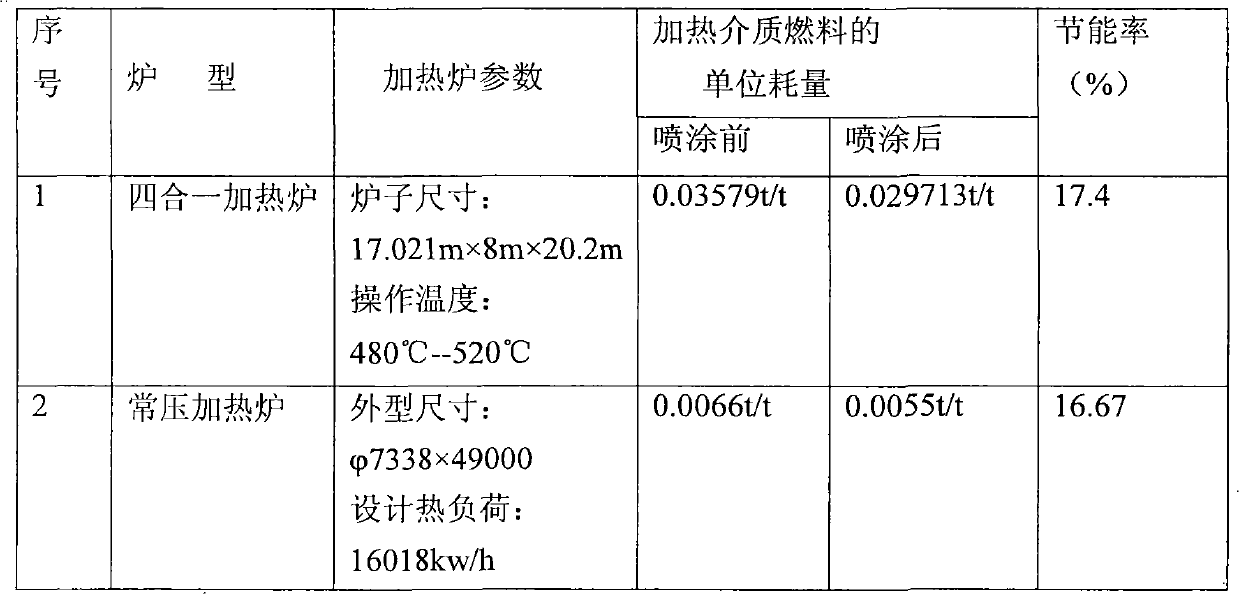

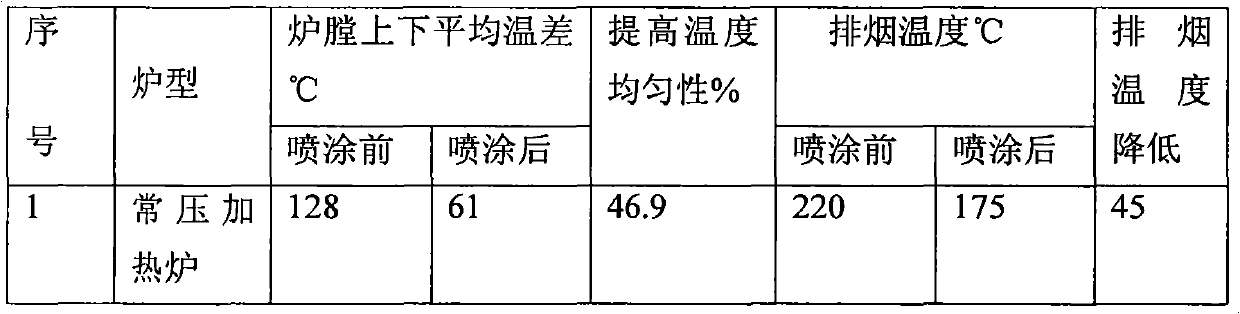

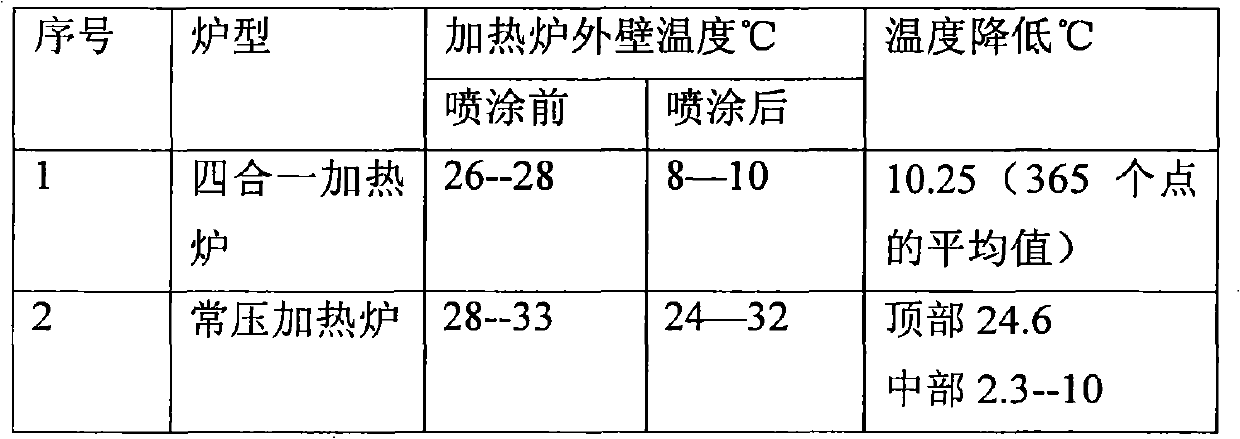

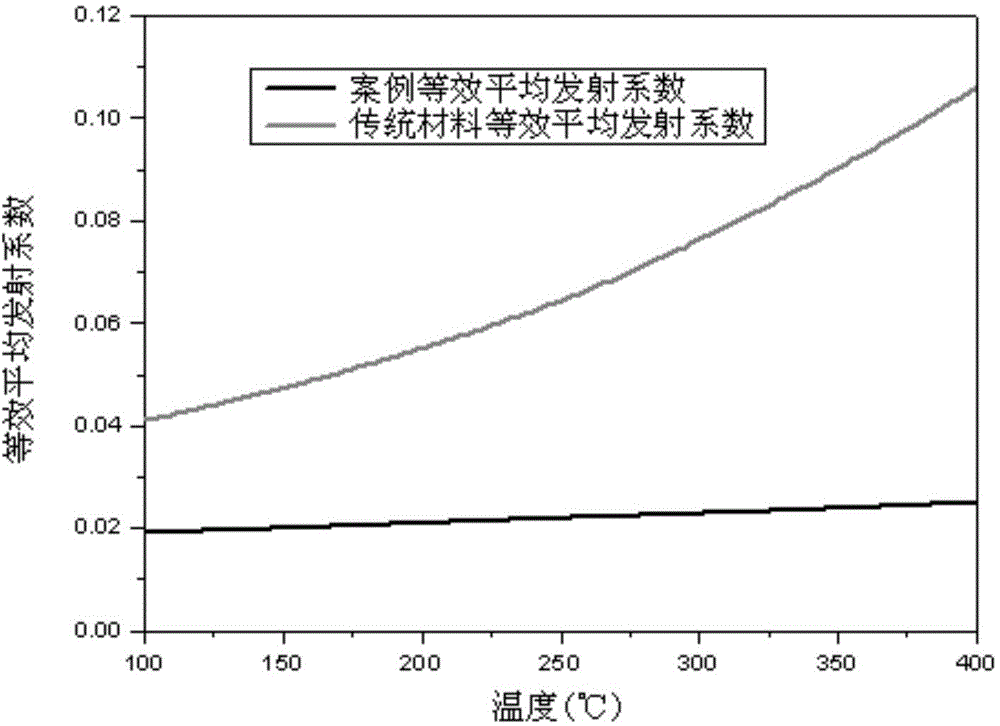

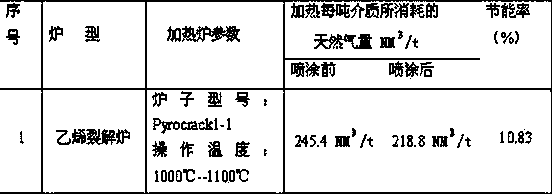

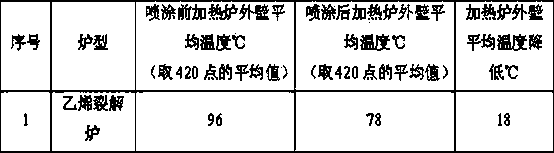

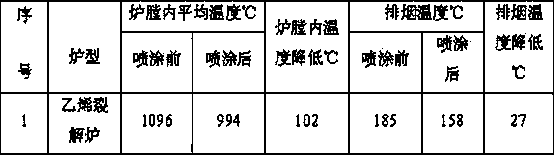

The invention relates to ceramic coating used for a heating furnace. The ceramic coating comprises the following components: ceramic micro powder, an inorganic bonding agent and a linear thermal expansivity regulator. The invention also provides a method for preparing the ceramic coating for the heating furnace. The ceramic coating has the characteristics of having improved radiance and thermal shock resistance, being efficient and energy-saving, prolonging the service life of furnace linings and furnace tubes, improving temperature uniformity and the like, as defined below: (1) the energy consumption is reduced, the energy is saved by more than 3 percent and pollutant discharge is reduced; (2) the temperature uniformity in the heating furnace is improved: (3) the metallurgy stability of the furnace tube of the heating furnace is improved, the coking and scaling of the furnace tub are delayed, and the absorbing capacity of the furnace tube can be maximized; (4) the emissivity of the surface of the refractory lining layer can be maximized so as to increase the secondary radiation of radiant heat (energy) and increase the efficiency of the radiant section; and (5) the outer wall temperature and the exhaust gas temperature of the heating furnace can be reduced by more than 5 percent.

Owner:北京安泰恒业科技有限公司

Nickel-picotite type infrared radiation ceramic powdered material for thermal spraying and preparation method

InactiveCN1762893AShort manufacturing processProcess parameters are easy to controlThermal sprayingAdhesive

The Ni-Cr spinel type infrared radiation powder material is prepared by using Cr2O3 and NiO with stable high performance as main components and TiO2, Nb2O5, TiN and TiB2, or Fe2O3 and MnO2, or SiO2 and ZrO2 as supplementary material, and through the steps of mixing powdered solid materials, adding adhesive and water to compound slurry, spray drying to form aggregate powder, and final plasma nodulizing or sintering to densify. The Ni-Cr spinel type infrared radiation powder material has heat radiation factor as high as 0.89-0.93, and may be molten and sprayed via plasma spraying, oxygen-acetylene flame spraying or fuel gas expansion spraying to surface of base body to form firm mechanically combined coating, which has controllable thickness, chemical performance stable in 500-700 deg.c, high heat shock resistance and low heat radiation factor attenuation in long term use.

Owner:WUHAN UNIV OF TECH

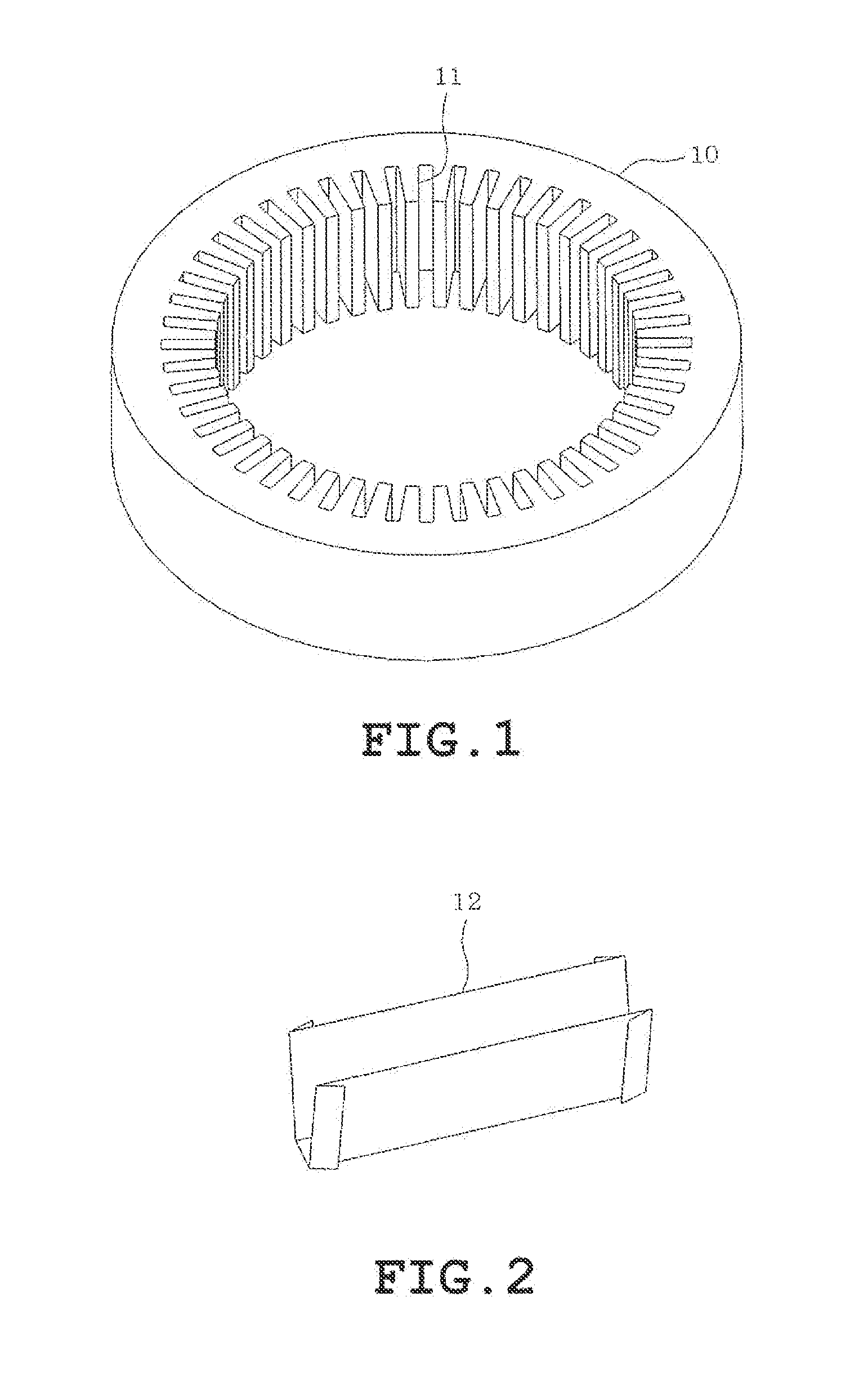

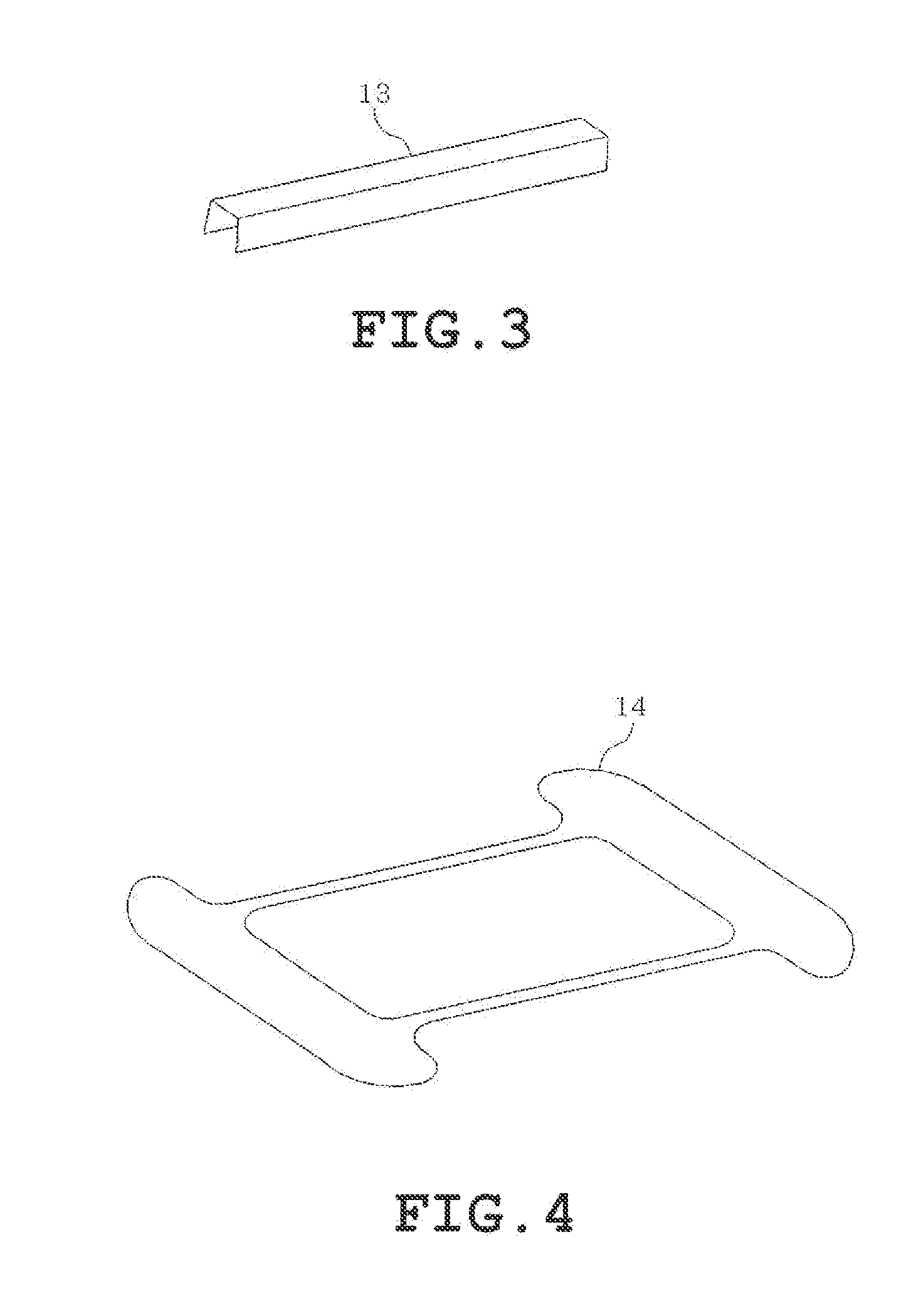

Electric motor insulating sheet and a manufacturing method therefor

InactiveUS20120128988A1Thinner laminateImprove performanceWindings insulation shape/form/constructionLamination ancillary operationsSlot insulationEmissivity

An insulation sheet for electric machine that forms slot insulation sheet is configured by an aramid paper and a PPS film directly pressure laminated without use of an adhesive. This means that no adhesive layer interposes the aramid paper and PPS film. PPS film is less costly as compared to a polyimide film and possesses better thermal properties such as higher heat emissivity and is highly resistant to heat. Thus, high strength is maintained even when subjected to high temperature over extensive time. Further, because the aramid paper and PPS film are laminated directly without an adhesive layer, the laminate is reduced in thickness. This allows further thinning of the laminate.

Owner:KAWAMURA SANGYO KK

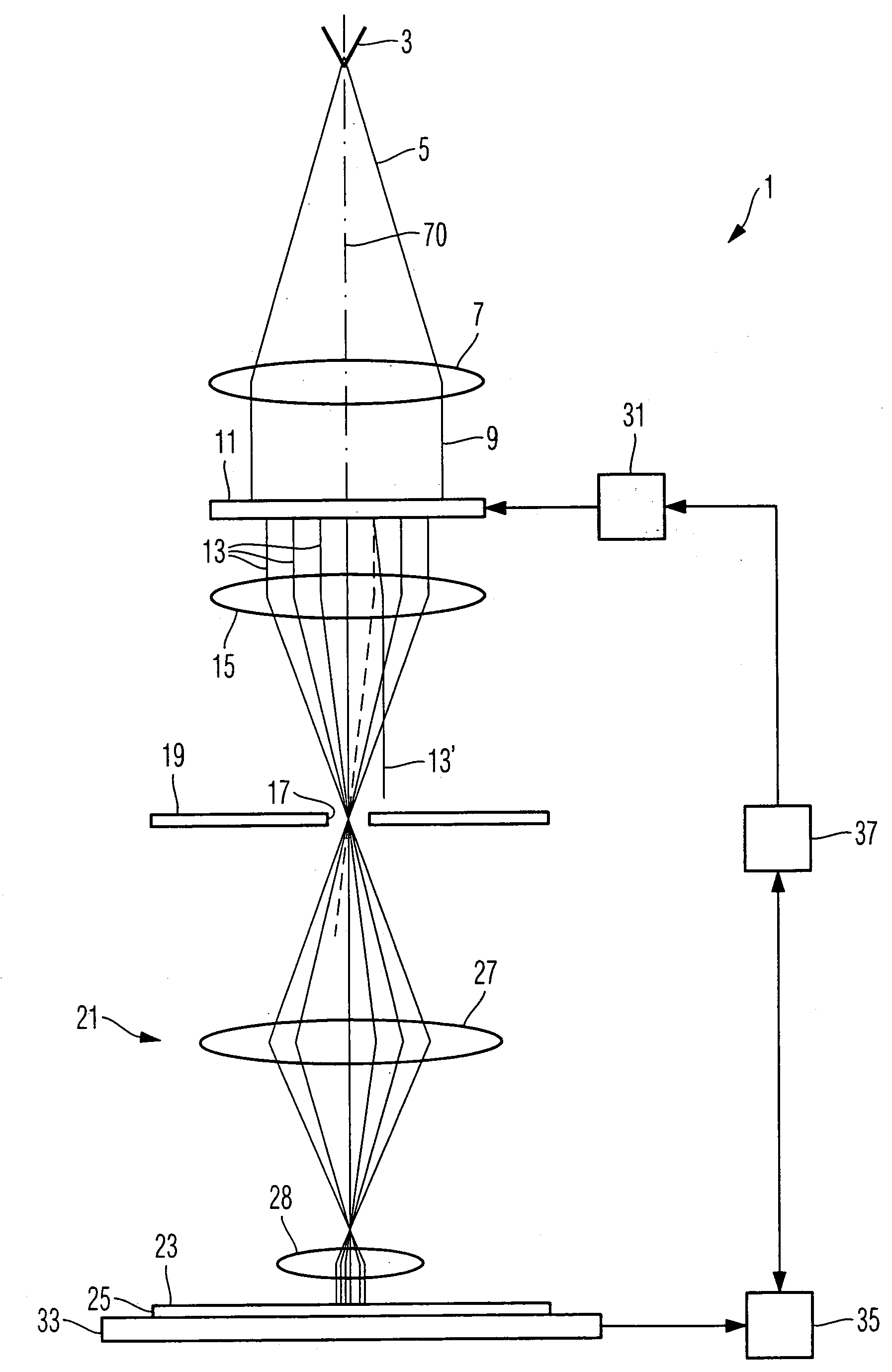

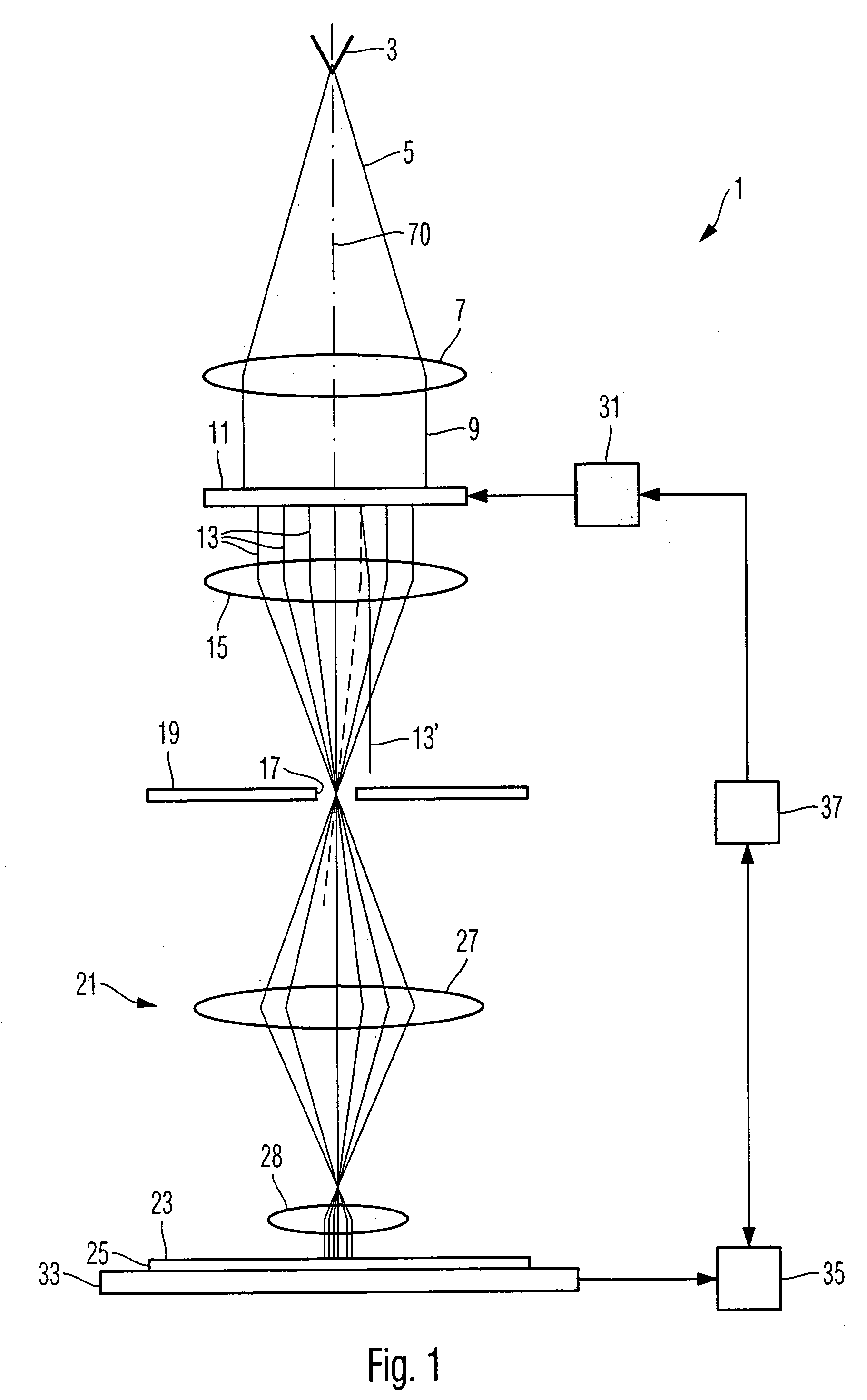

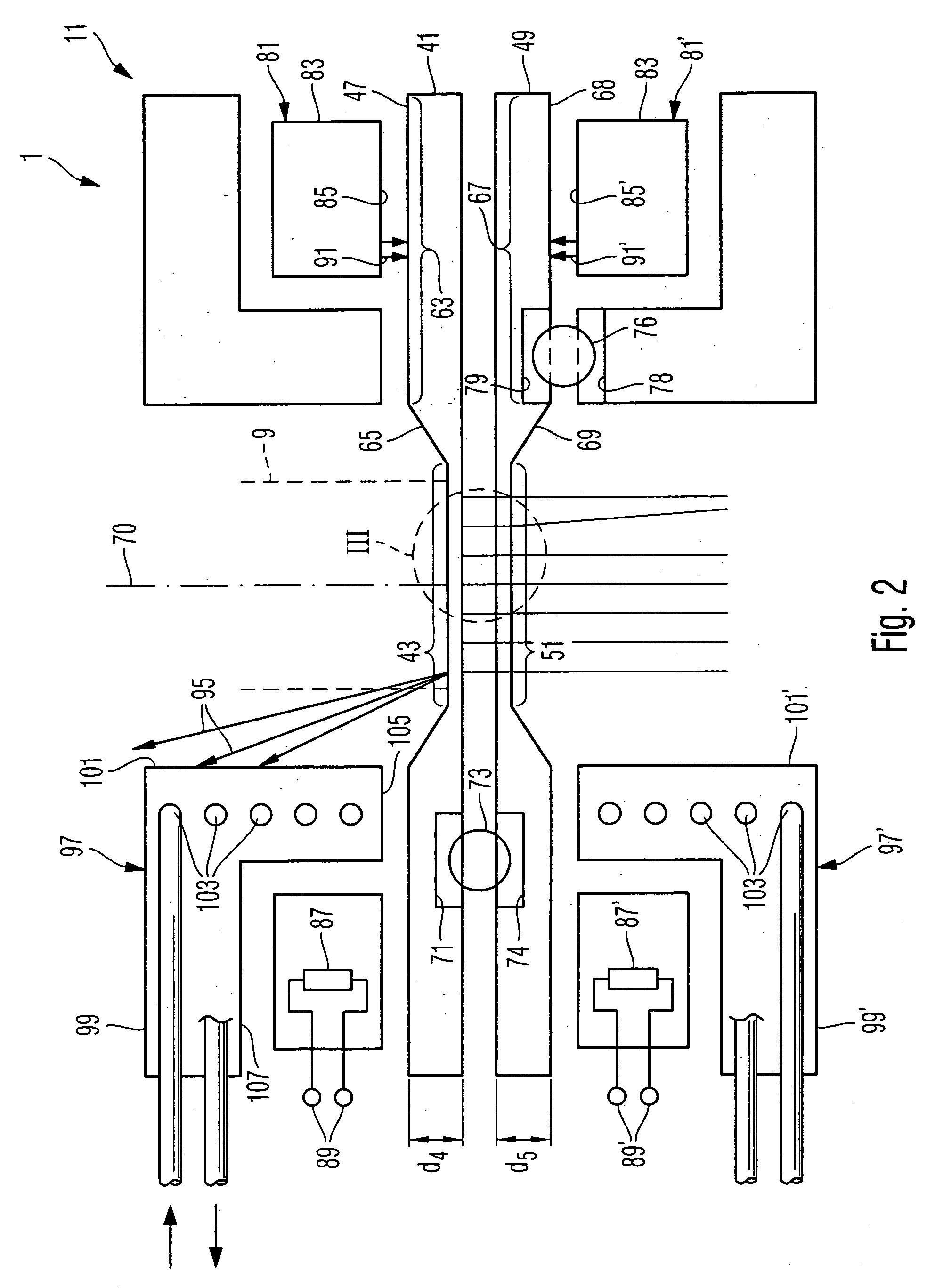

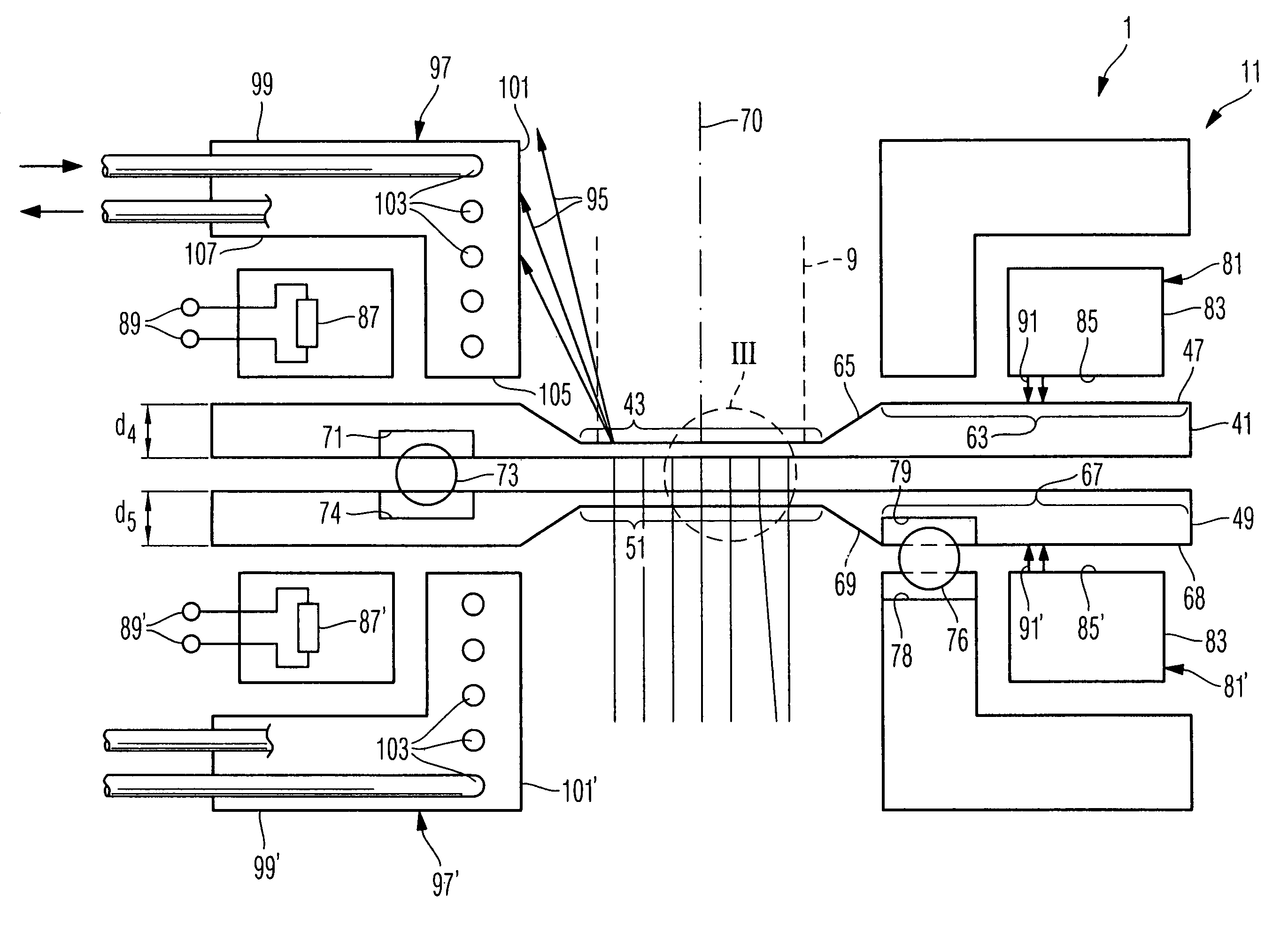

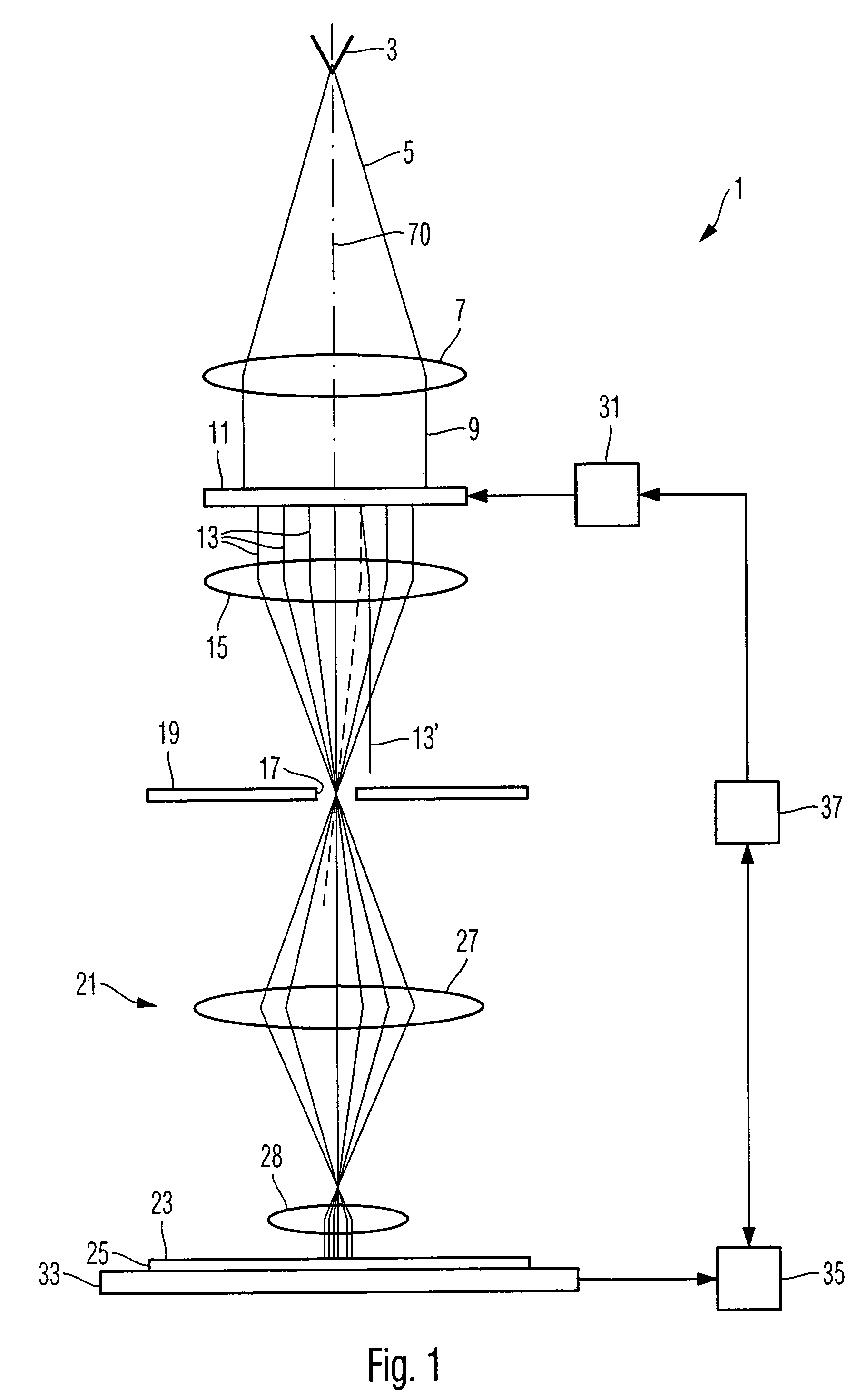

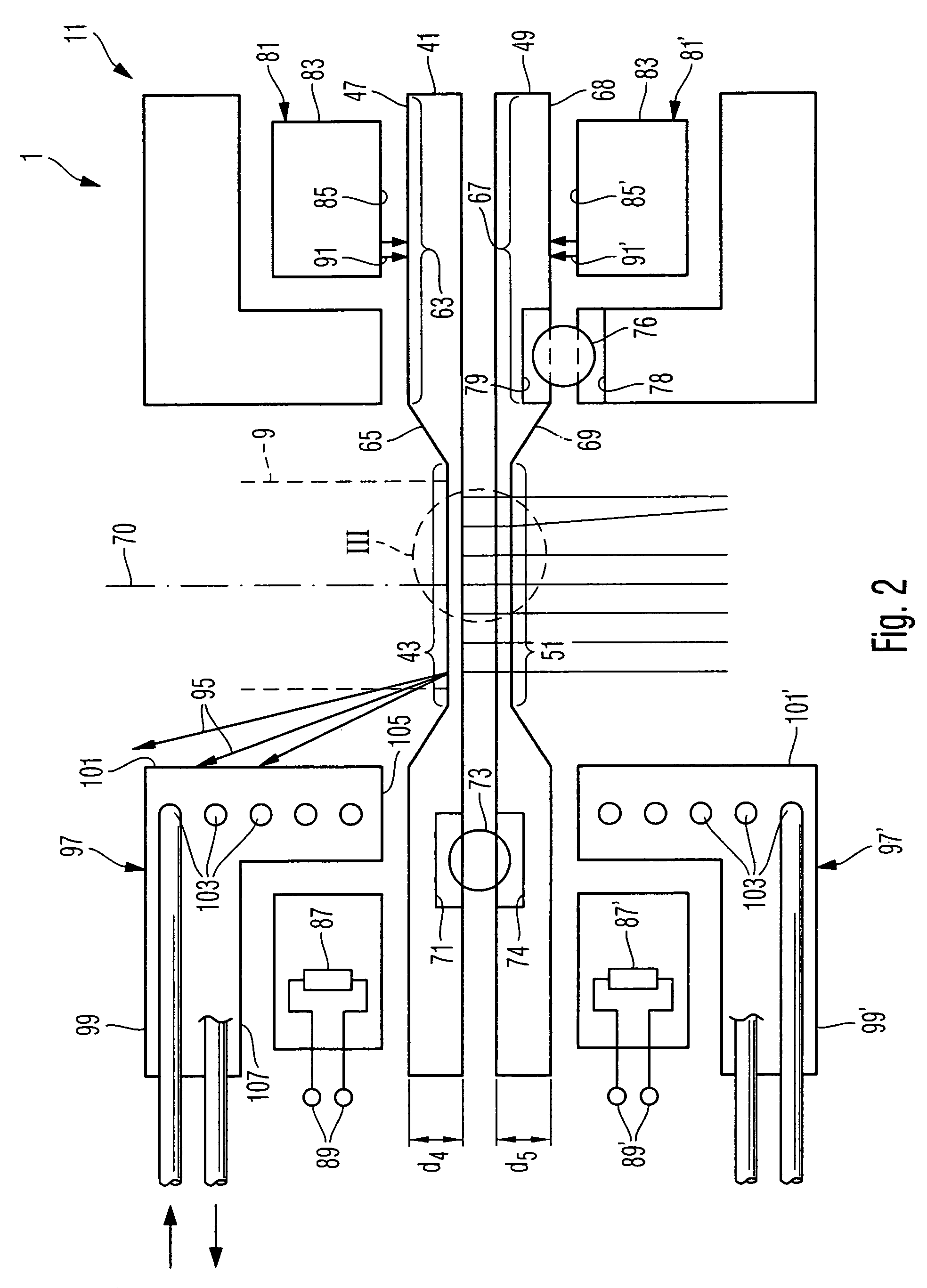

Charged particle beam exposure system and beam manipulating arrangement

ActiveUS20090140160A1Reduce transferTemperature gradientThermometer detailsStability-of-path spectrometersEmissivityLight beam

A beam manipulating arrangement for a multi beam application using charged particles comprises a multi-aperture plate having plural apertures traversed by beams of charged particles. A frame portion of the multi-aperture plate is heated to reduce temperature gradients within the multi-aperture plate. Further, a heat emissivity of a surface of the multi-aperture plate may be higher in some regions as compared to other regions in view of also reducing temperature gradients.

Owner:CARL ZEISS SMT GMBH

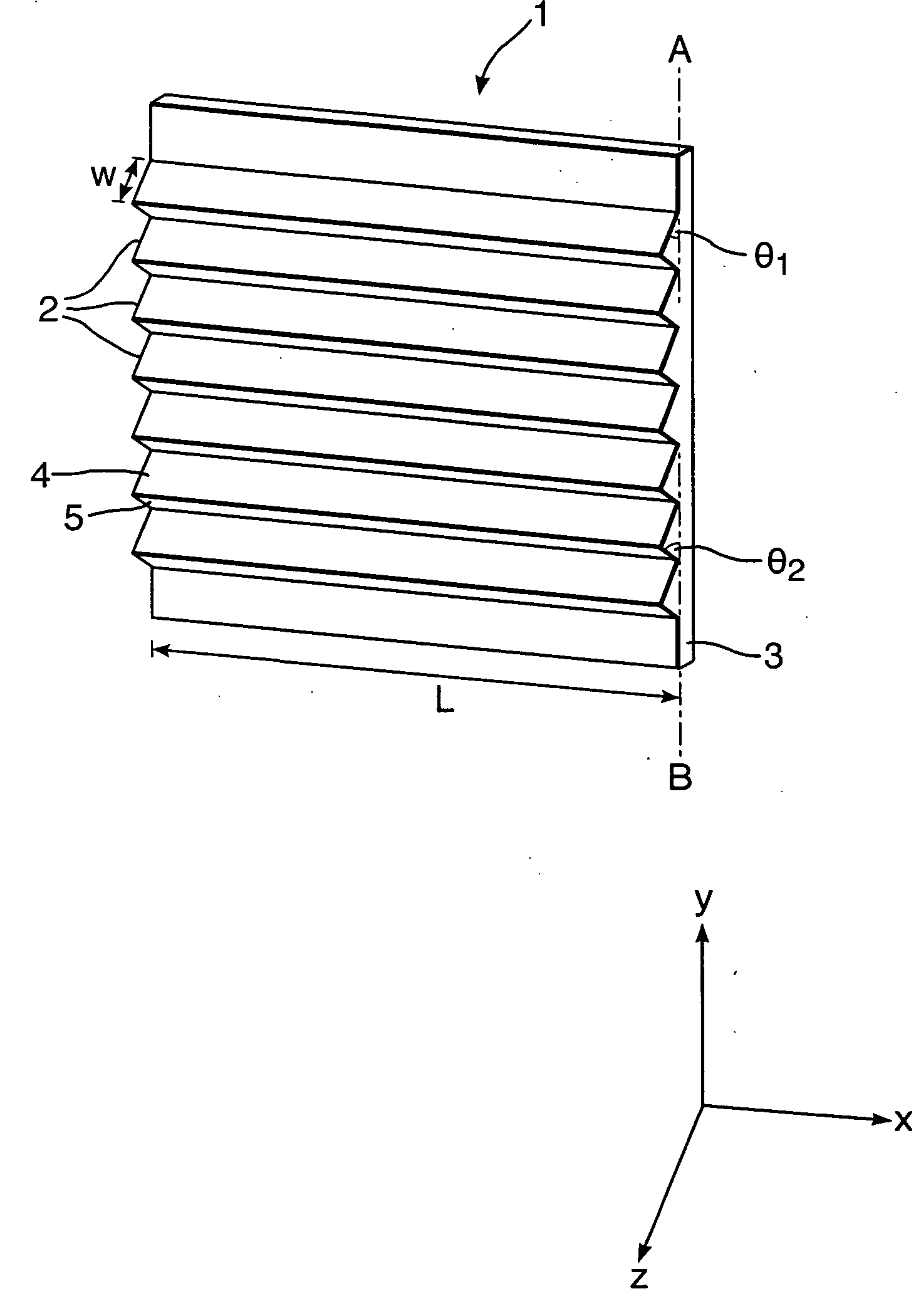

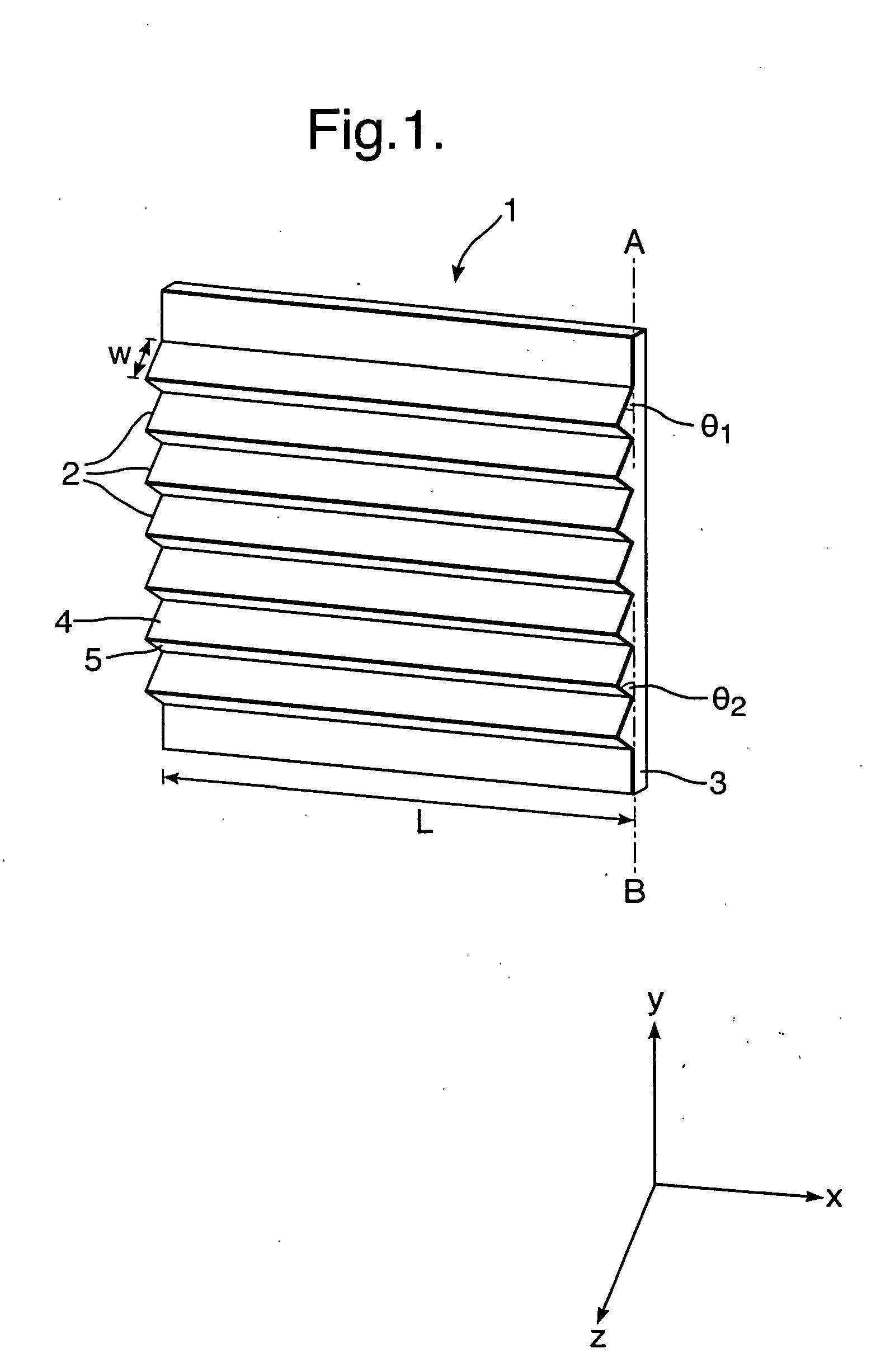

Indentification device

InactiveUS20090252982A1Easy to useEasy to handleStampsLayered productsThermographic cameraIdentification device

A sheet of thermally reflective material (1) has a surface texture comprising a plurality of reflecting elements (2), wherein each element has a first facet (4) which is substantially reflective at thermal infrared wavelengths and wherein the respective first facets (4) form an angle θ with the plane of the sheet (A-B) (0°<θ<90°). Preferably, the first facets (4) are aligned such that, in use, thermal radiation is reflected from a common direction. By orienting the sheet of thermally reflective material to reflect cold regions of the sky, a marking material exhibiting a cold spot in a thermal imager can be provided.

Owner:QINETIQ LTD

Graphene high temperature resistant corrosion-resistant coating for metallic material and preparation method of graphene high temperature resistant corrosion-resistant coating

InactiveCN108276866AReduce coagulationImprove anti-corrosion performanceAnti-corrosive paintsPolyvinyl butyralPolyvinyl alcohol

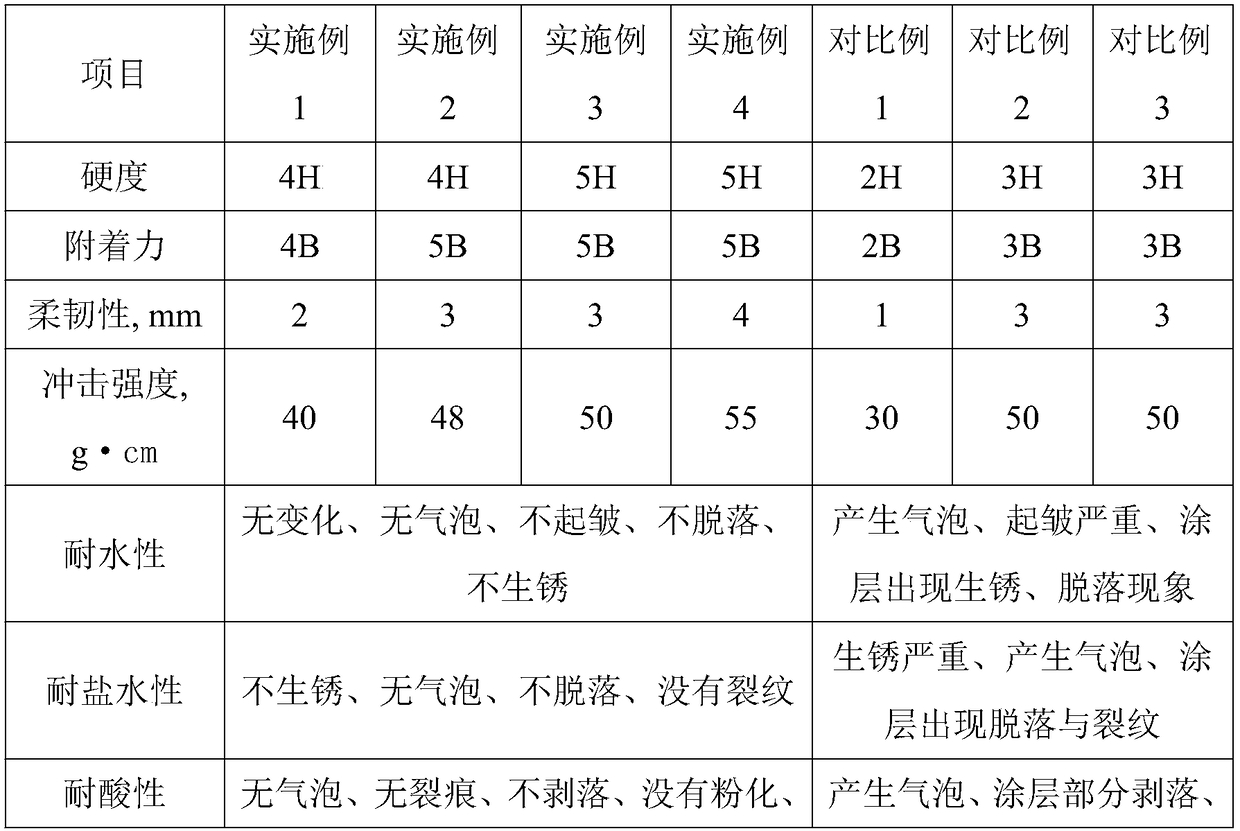

The invention relates to a graphene high temperature resistant corrosion-resistant coating for a metallic material and a preparation method of the graphene high temperature resistant corrosion-resistant coating. The graphene high temperature resistant corrosion-resistant coating consists of the following components in parts by weight: 6-12 parts of graphene oxide, 20-45 parts of a phenolic resin,2-6 parts of polyvinyl butyral, 1-4 parts of rare earth chloride, 12-30 parts of graphene quantum dots, 2-5 parts of a heat conduction metallic powder, 3-6 parts of carbon nanotubes, 12-30 parts of asolvent, 2-6 parts of an antioxidant, 5-9 parts of a curing agent and 12-18 parts of a defoaming agent, wherein the graphene quantum dots is 2-4nm in size; the solid content of the phenolic resin is 45-55%. According to the graphene high temperature resistant corrosion-resistant coating provided by the invention, by the virtue of the good dispersibility of the graphene quantum dots in solvents andrelatively good non-covalent functions of the graphene quantum dots with graphene sheets, two-dimensional sheet structures of the graphene can be overlapped layer by layer in the coating, a compact physical insulating layer can be formed, and the corrosion resistance of the coating can be improved.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

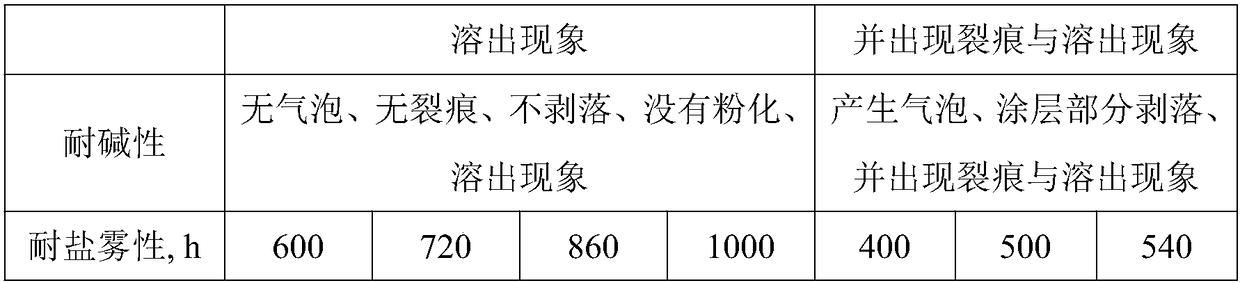

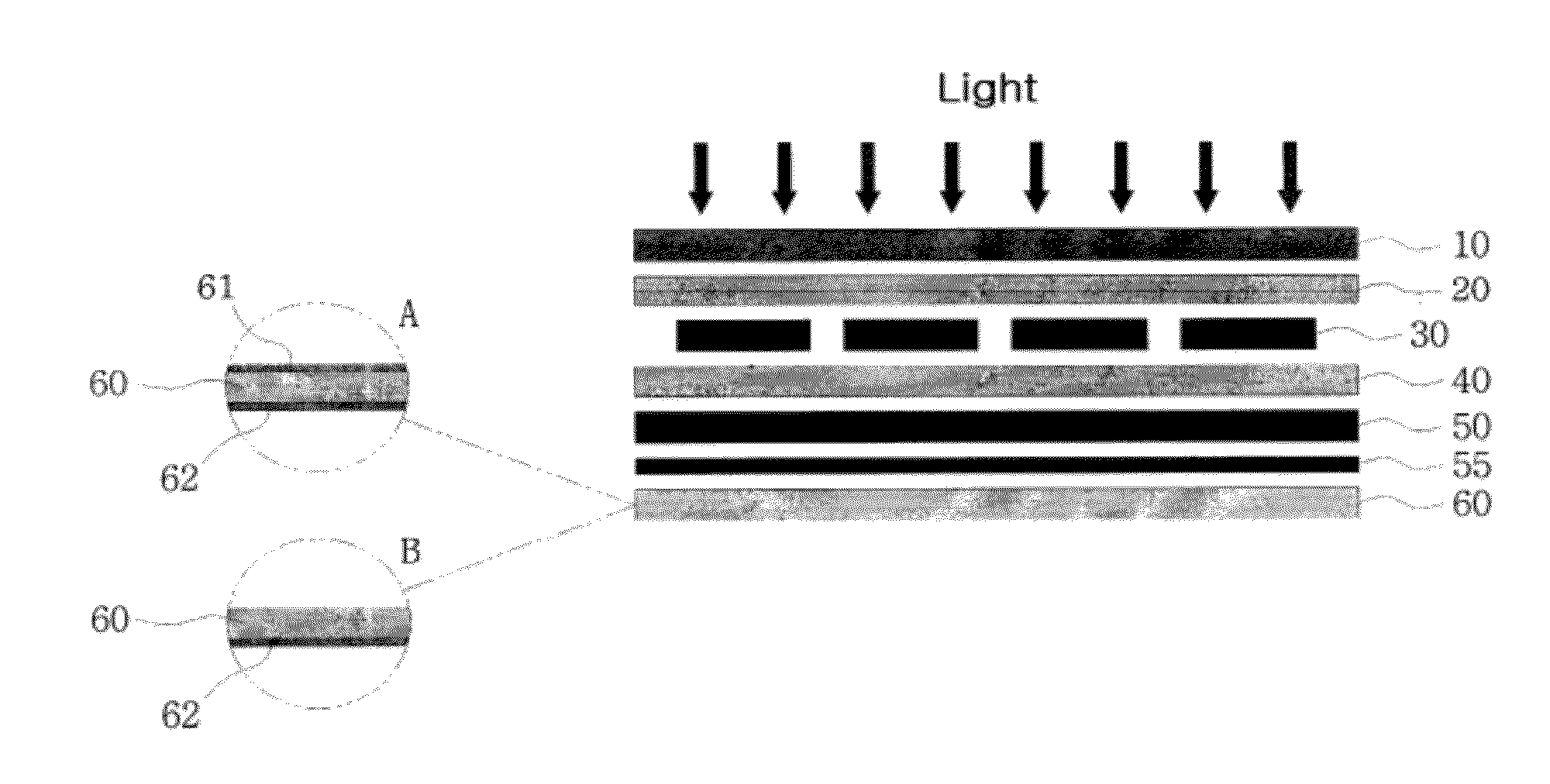

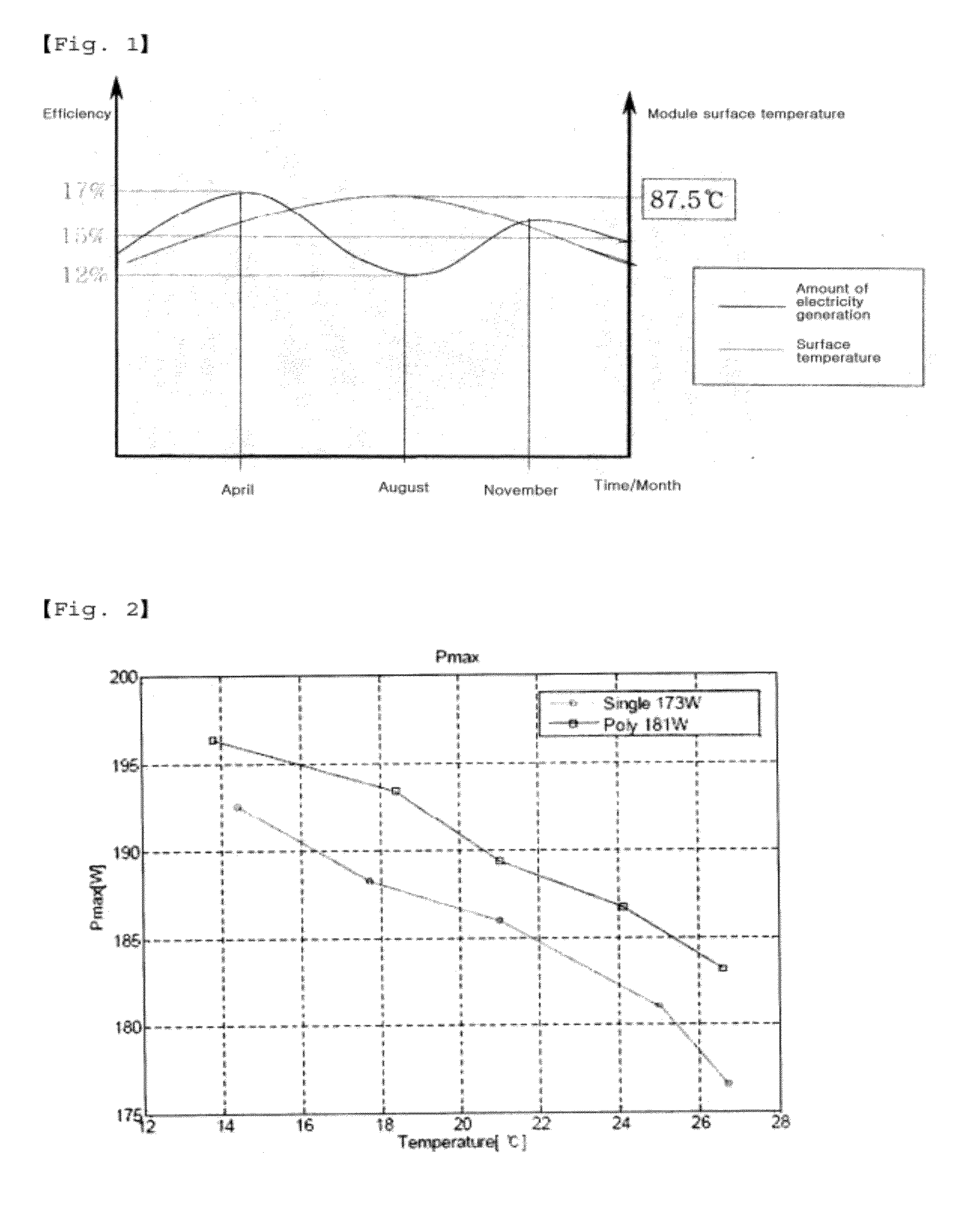

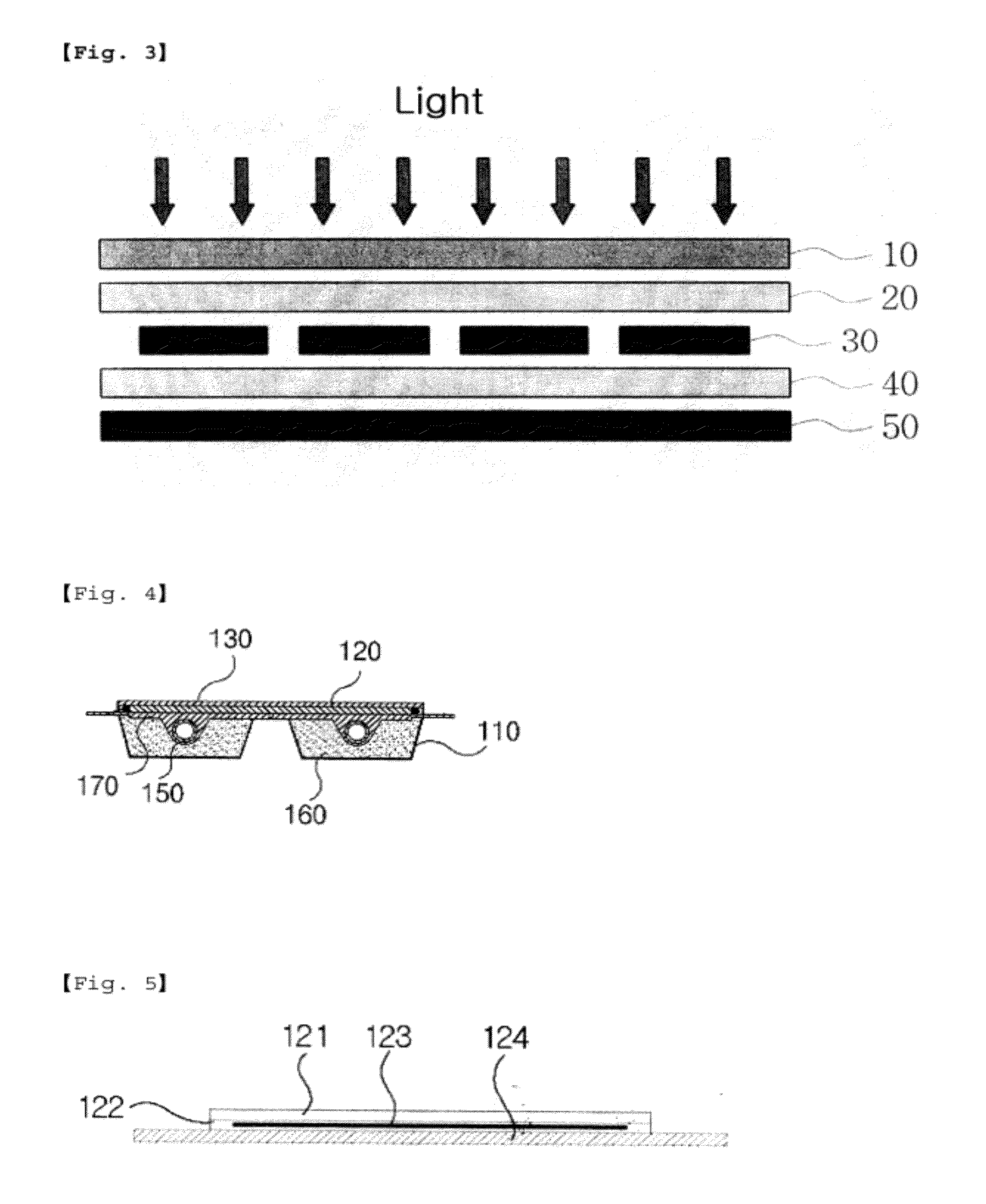

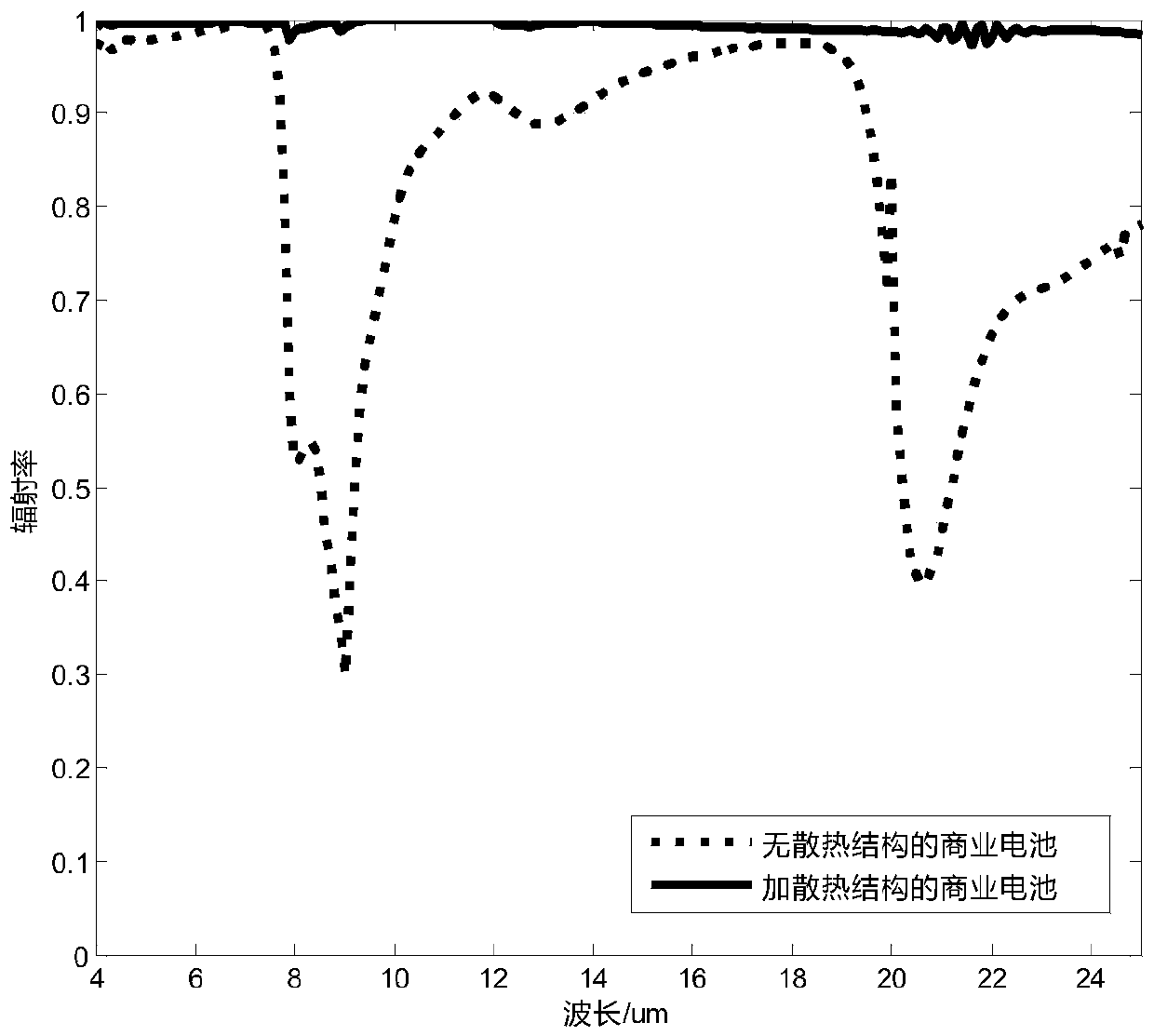

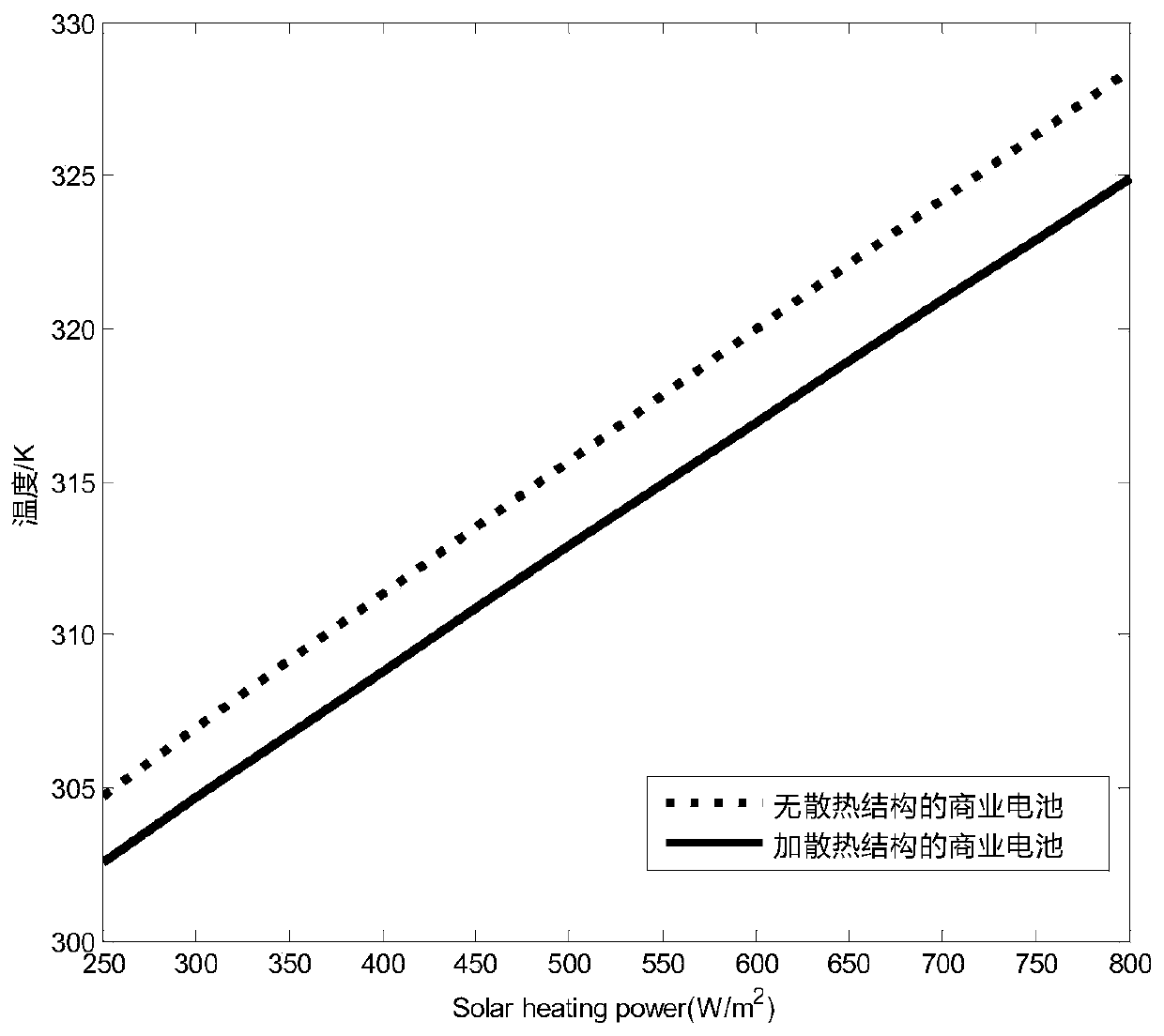

Photovoltaic module with ceramic coating heat radiating sheet

InactiveUS20120067399A1Increase heat dissipation efficiencyHigh thermal emissivityPV power plantsPhotovoltaic energy generationHeat sinkMaterial transfer

The present invention relates to a photovoltaic module characterized by comprising a heat radiating sheet overlaid with a ceramic coating layer, which is attached to a conventional photovoltaic module. In a method of increasing heat radiation with the aid of the ceramic coating layer provided on both sides or one side of the heat radiating sheet, heat generated by a solar cell due to the differences in thermal emissivity, thermal shear rate and surface area of a material is transferred to a solar EVA and then a heat radiating sheet thin plate that serves as a carrier, and returns back to the ceramic coating layer for emission. A high thermal emissivity is obtained by having a so-called heat transfer phenomenon in one direction, which resultantly improves a heat radiation performance and increases the refrigeration efficiency of the photovoltaic module and its peripheral devices to thus lower the internal temperature. As such, the power generation rate and efficiency through a module to which the heat radiating sheet is applied can be maximized, and a photovoltaic module with such a heat radiating sheet can maintain a change in the power generation rate traditionally due to a change in the surface temperature at a constant level, thereby increasing the annual power generation rate by 3-5% compared to that of the conventional one and improving the power generation effect during the summer season by 5-10%. Further, wide applicability can be ensured by equally applying the photovoltaic module of the present invention to areas having severe heat or high-temperature and high-humidity tropical weather as well as desert areas. In addition, the photovoltaic module according to the present invention is advantageous in that it is applicable not only to a new module but also to an already existing module, which makes it possible to manufacture those photovoltaic modules under the same process conditions as with the conventional ones without modifying the existing equipment.

Owner:PARK CHUNG KWON +1

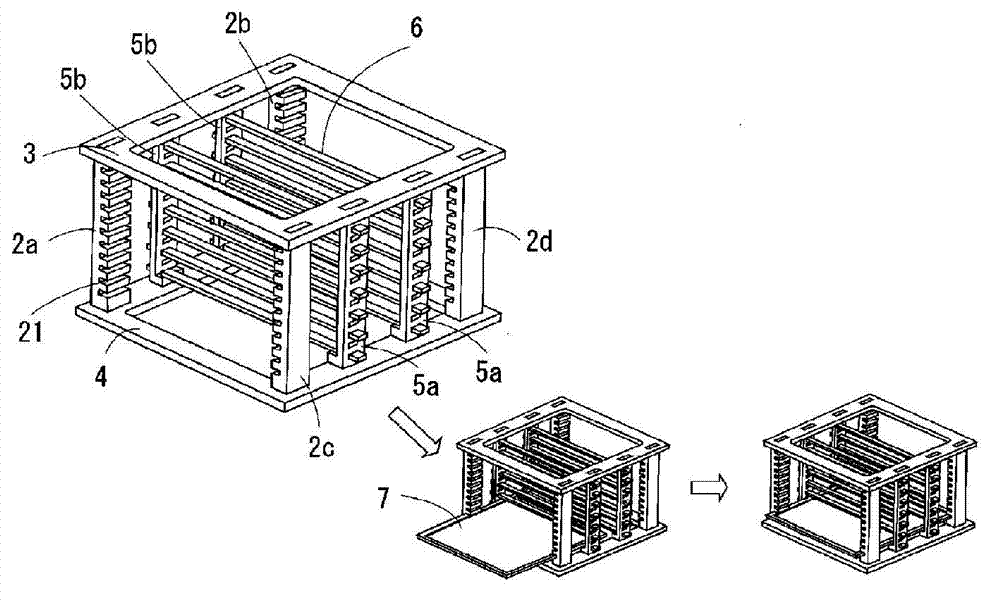

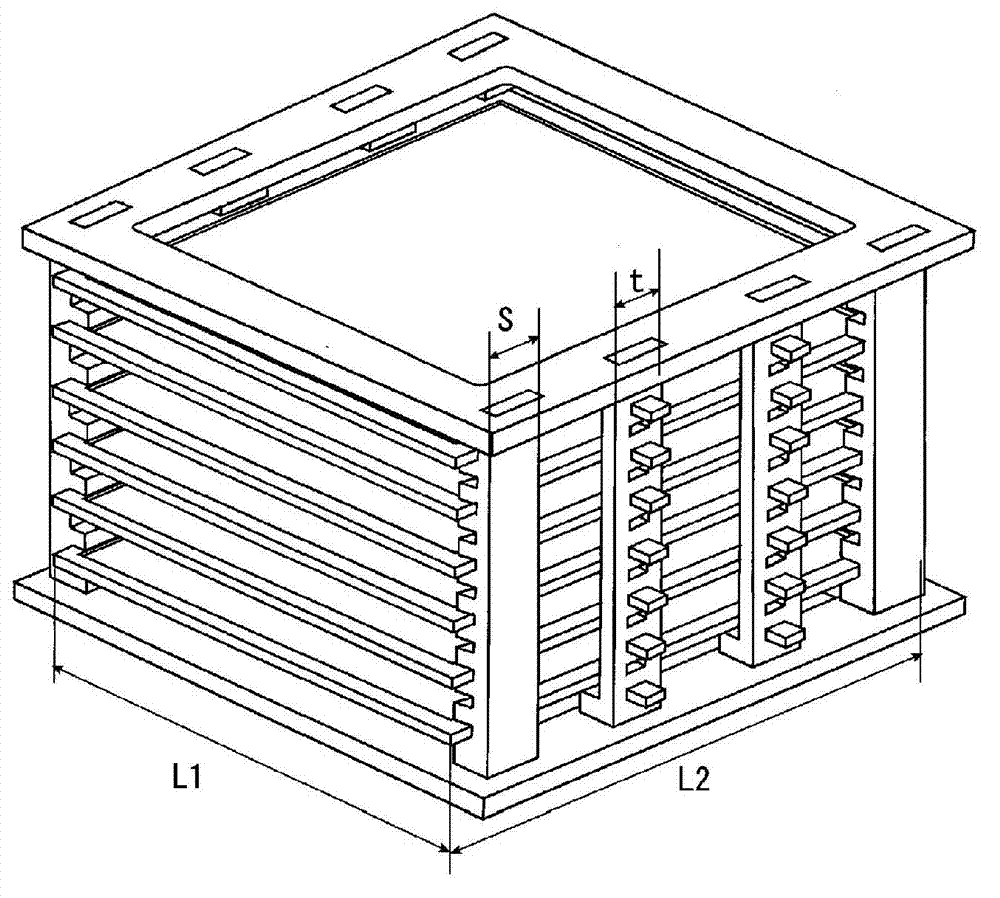

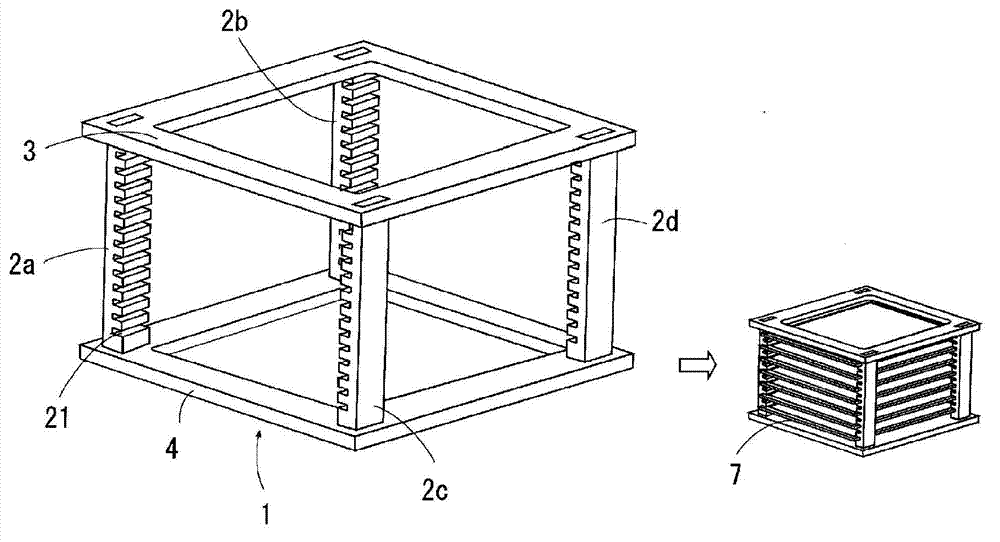

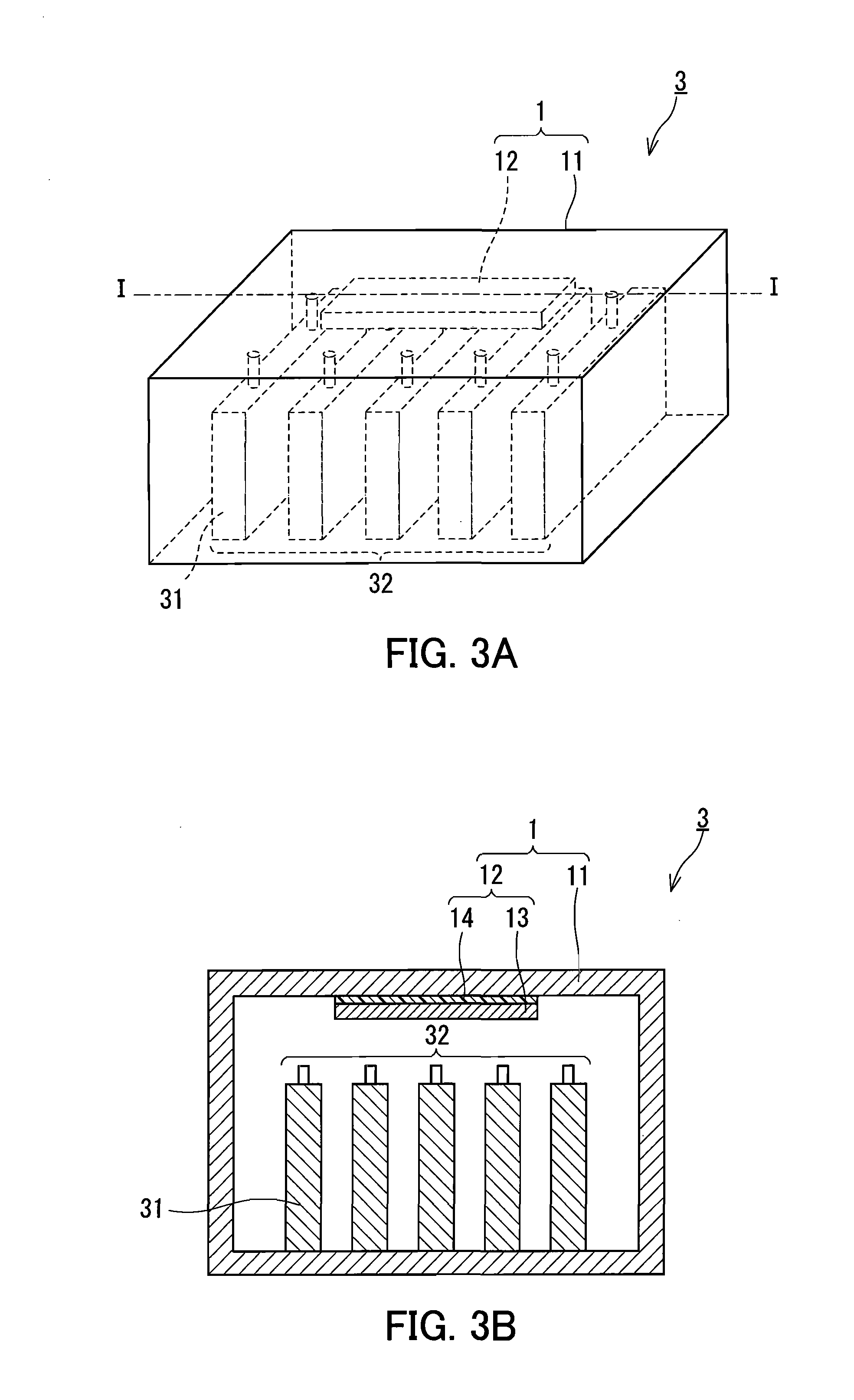

Rack for firing

ActiveCN103097845AEasy to passIncrease heat radiation rateCharge supportsCharge manipulationSetterEngineering

Provided is a rack for firing which holds a plurality of flat board-like setters at multiple levels in the perpendicular direction by means of a setter holding means, and fires electronic ceramic elements at multiple levels. The setter holding means is composed of a material composed of Si-SiC containing 0.01-30 % of Si or recrystallized SiC or Si3N4-SiC, and the setter holding means holds each of the flat board-like setters with 70-100 % of the outer circumferential side surface thereof exposed. Consequently, the rack has excellent energy efficiency, mass-production efficiency, and uniform heating characteristics at each of the multiple levels in the multiple-level firing.

Owner:NGK INSULATORS LTD +1

Charged particle beam exposure system and beam manipulating arrangement

ActiveUS8368030B2Temperature gradientReduce gradientStability-of-path spectrometersMaterial analysis using wave/particle radiationEmissivityLight beam

A beam manipulating arrangement for a multi beam application using charged particles comprises a multi-aperture plate having plural apertures traversed by beams of charged particles. A frame portion of the multi-aperture plate is heated to reduce temperature gradients within the multi-aperture plate. Further, a heat emissivity of a surface of the multi-aperture plate may be higher in some regions as compared to other regions in view of also reducing temperature gradients.

Owner:CARL ZEISS SMT GMBH

Method for preparing heat-dissipating and antistatic polyaniline epoxy organosilicone graphene coating

InactiveCN107746654AImprove heat resistanceImprove anti-corrosion performanceEpoxy resin coatingsElectrically-conductive paintsGraphene coatingSolvent

The invention provides a method for preparing a heat-dissipating and antistatic polyaniline epoxy organosilicone graphene coating. The method comprises the following steps of: (1) preparation of a main agent A: the preparation of the main agent A comprises the steps of adding organosilicone-modified epoxy resin and a dispersing agent into a solvent according to the amount of a formula, performingeven stirring, adding conductive titanium dioxide, carbon nanotubes, graphene and polyaniline into the stirred mixture sequentially, after the added materials are dispersed evenly, putting the obtained mixture into a grinding machine for grinding until the grinding fineness is less than or equal to 20 microns, putting the ground color paste into a clean stirring kettle, adding a defoaming agent, aleveling agent, a matting agent and a surface modifier sequentially with stirring, performing even mixing, and performing filtration and package to obtain the main agent A; and (2) preparation of a curing agent B: the preparation of the curing agent B comprises the steps of weighing an amine curing agent according to the amount of the formula, and performing filtration and package to obtain the curing agent B. The heat-dissipating and antistatic polyaniline epoxy organosilicone graphene coating has high heat emissivity, high thermal conductivity and low thermal resistance, and has propertiesof both polyaniline and epoxy organosilicone at the same time and a high practical value.

Owner:TIANJIN MEISHIBANG PAINT CHEM IND

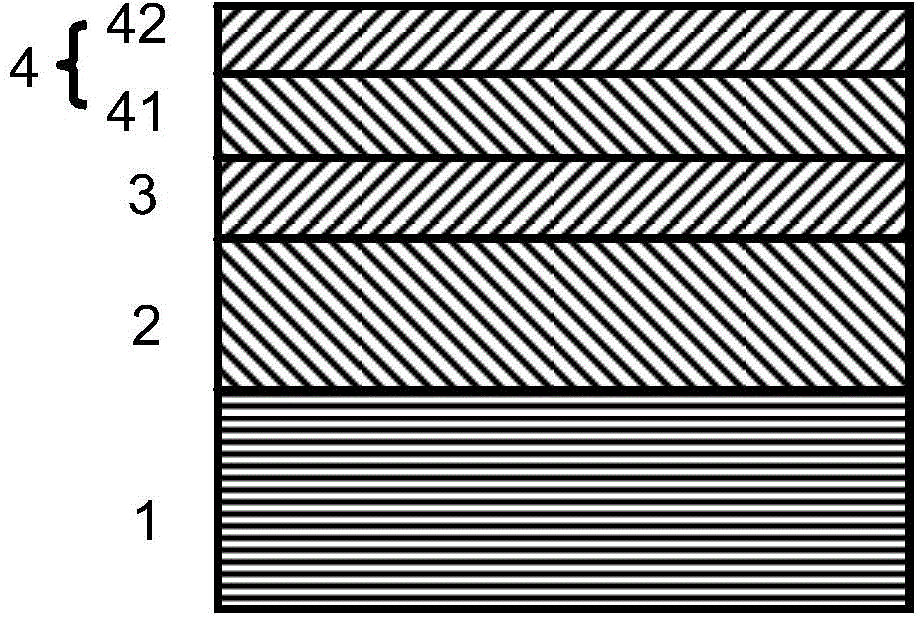

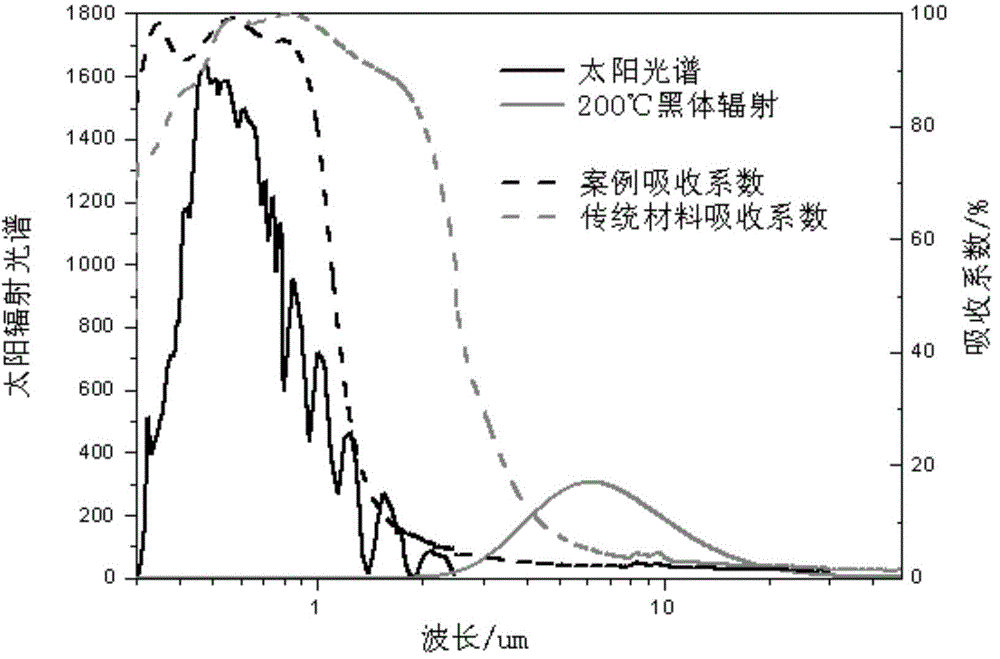

Solar spectrum selective absorbing coating and preparation method thereof

InactiveCN104976803AEffective absorptionReduce reflectionSolar heat devicesVacuum evaporation coatingAir interfaceRefractive index

The invention discloses a solar spectrum selective absorbing coating. The coating structure comprises a substrate 1, an infrared reflecting layer 2, a semiconductor absorbing layer 3 (germanium) and an anti-reflection layer 4 which is composed of a medium layer 41 with a high refractive index and a medium layer 42 with a low refractive index from the substrate to an air interface in sequence. The solar spectrum selective absorbing coating has excellent spectrum selectivity, and has a steep absorbing-reflecting transition region; absorptivity alpha within a solar spectrum range (0.3-2 microns) is relatively high, absorptivity / radiance epsilon in a thermal-radiation infrared area (2-50 microns) is extremely low, and alpha / epsilon of the coating is much higher than that of a current commercial product, so that the coating is suitable for a low-power optical focusing medium-temperature solar heat collector; and the preparation process is simple, low in requirement on film coating equipment, and suitable for large-scale low-cost production.

Owner:TAHOE TECH

High-temperature nano radiation coating for heating furnace and preparation process thereof

The invention provides a high-temperature nano radiation coating for a heating furnace and a preparation process thereof. The coating comprises radiation function powder particles, an inorganic adhesive and an expansion coefficient regulator. The preparation process comprises the following steps: preparing the radiation function powder particles, preparing the expansion coefficient regulator, synthesizing the inorganic adhesive, mixing the radiation function powder particles, the inorganic adhesive and the expansion coefficient regulator, and filtering and grinding the obtained mixture so as to obtain the high-temperature nano radiation coating for the heating furnace. The high-temperature-resistant nano radiation coating disclosed by the invention has the characteristics of capability of increasing the radiance and the thermal shock stability, energy conservation and environmental friendliness, corrosion resistance, and capability of prolonging the service life of the heating furnace and raising the temperature uniformity, and the like. The technical indexes of the products provided by the invention are as follows: a temperature of 1800 DEG C can be resisted, the radiance epsilon is greater than or equal to 0.92, the thermal shock resistance (1300 DEG C) is greater than or equal to 5 times, the thickness of the coating is 0.1-0.2 mm, and the service life is greater than or equal to 6 years.

Owner:BDES BEIJING ENERGY SAVING TECH SERVICE

Heating element with porous ceramic coating

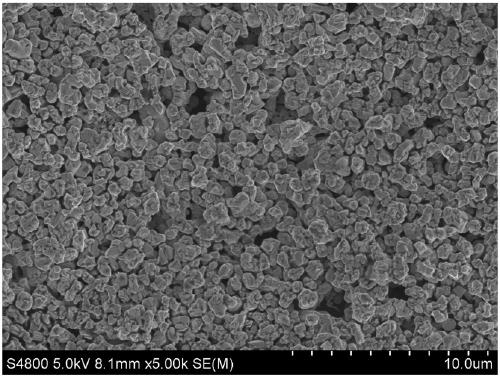

ActiveCN109321803ALarge heat radiation areaIncrease heat radiation rateChemical vapor deposition coatingNiobiumCeramic coating

The invention provides a heating element with a porous ceramic coating. The heating element with the porous ceramic coating comprises a metal base body and the porous ceramic coating composited on thesurface of the metal base body; the porous ceramic coating comprises a metal phase and a ceramic phase; the mass percentage of the metal phase in the porous ceramic coating is 0-50%; the metal phaseis composed of one or more of tungsten, molybdenum, tantalum, zirconium, niobium and hafnium; and the ceramic phase is one or more of carbide of rare metal, nitride of rare metal, oxide of rare metal,carbide of boron, nitride of boron, oxide of boron, aluminum oxide and magnesium oxide. The coating body in the heating element is ceramic powder, metal powder serves as an adhesion agent, and the porous ceramic coating is prepared. The coating with the ceramic material as the body can increase the heat radiation rate of the element, meanwhile, due to the fact that the ceramic coating is of a loose porous structure, the heat stress generated due to the heat expanding coefficient difference of the base body and the coating can be effectively reduced, and the coating is not prone to cracking orfalling.

Owner:SUZHOU IMOTECH MATERIALS TECH CO LTD

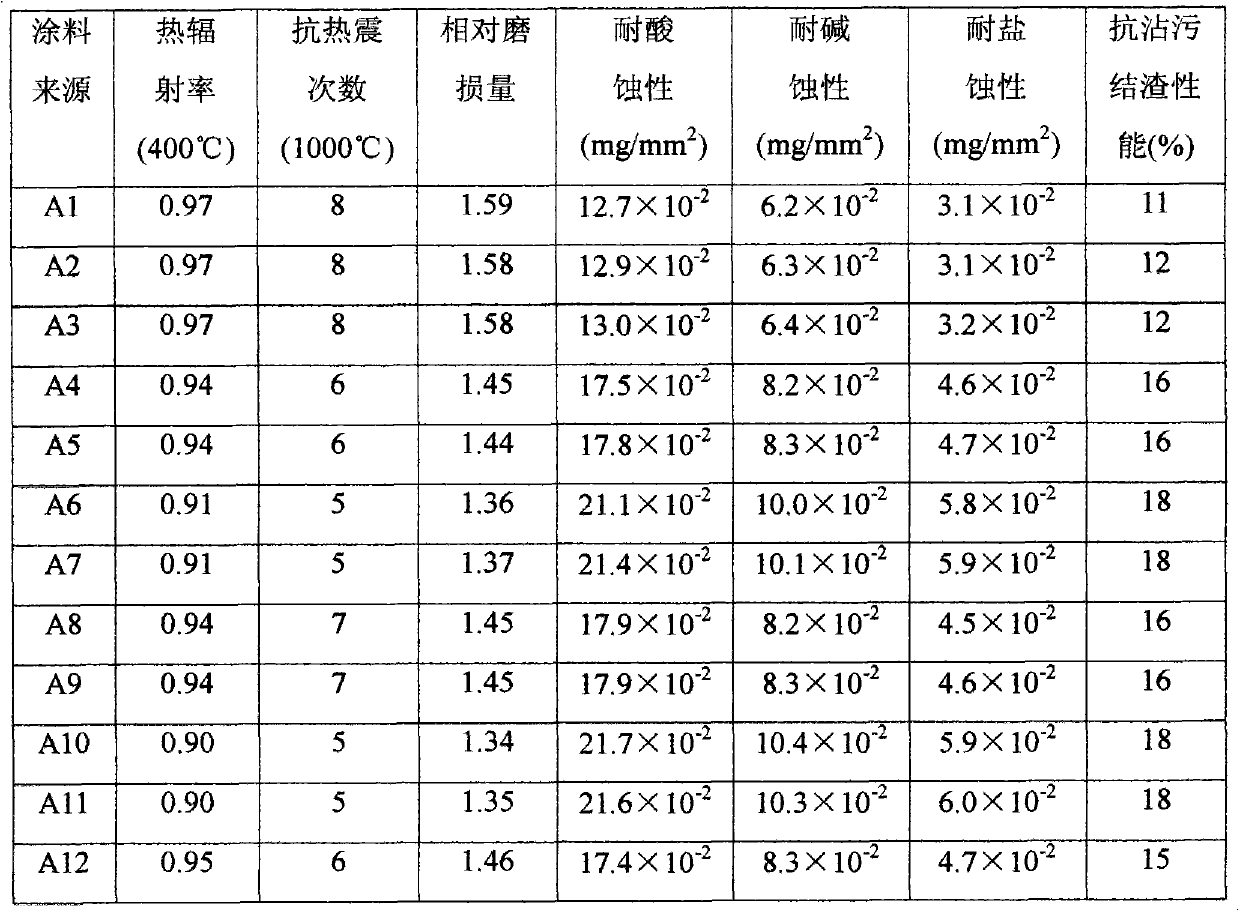

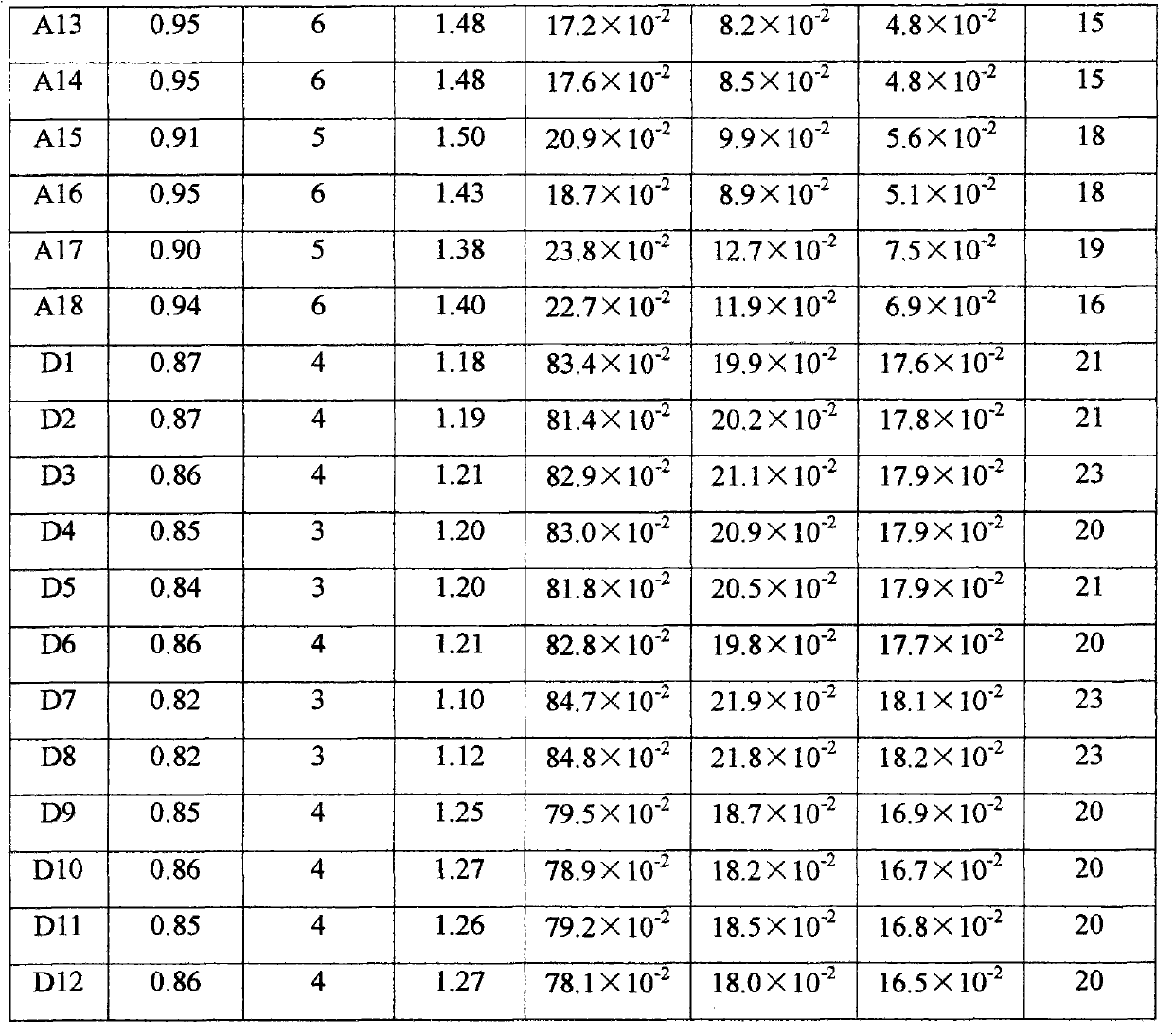

Ceramic coating and its preparation method and use

InactiveCN103342563AImprove wear resistanceImprove anti-fouling and slagging performanceFurnace componentsSlagCeramic coating

The invention relates to a ceramic coating and its preparation method and use. The ceramic coating comprises ceramic powder, titanium nitride, zirconium nitride, rare-earth oxides and a binder. Based on 100 weight parts of the ceramic powder, in the ceramic coating, the content of titanium nitride is in a range of 10-80 weight parts, the content of zirconium nitride is in a range of 10-80 weight parts, the content of the rare-earth oxides is in a range of 5-50 weight parts, and the content of the binder is in a range of 5-80 weight parts. The ceramic powder is a calcium hydrogen phosphate-calcium carbonate compound. The rare-earth oxides comprise yttrium oxide, lanthanum oxide and cerium oxide. The invention also relates to a use of the ceramic coating in forming of a coating layer on an inner wall of a heating furnace. The ceramic coating layer prepared from the ceramic coating has obviously improved wear resistance, corrosion resistance and contamination and slag-bonding resistance, and also has a high thermal radiation rate and thermal shock resistance.

Owner:BEIJING BEIRUIDA PHARMA TECH

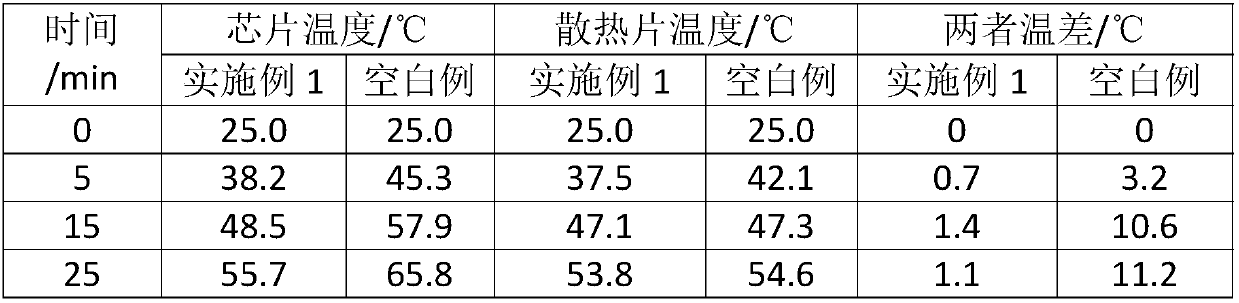

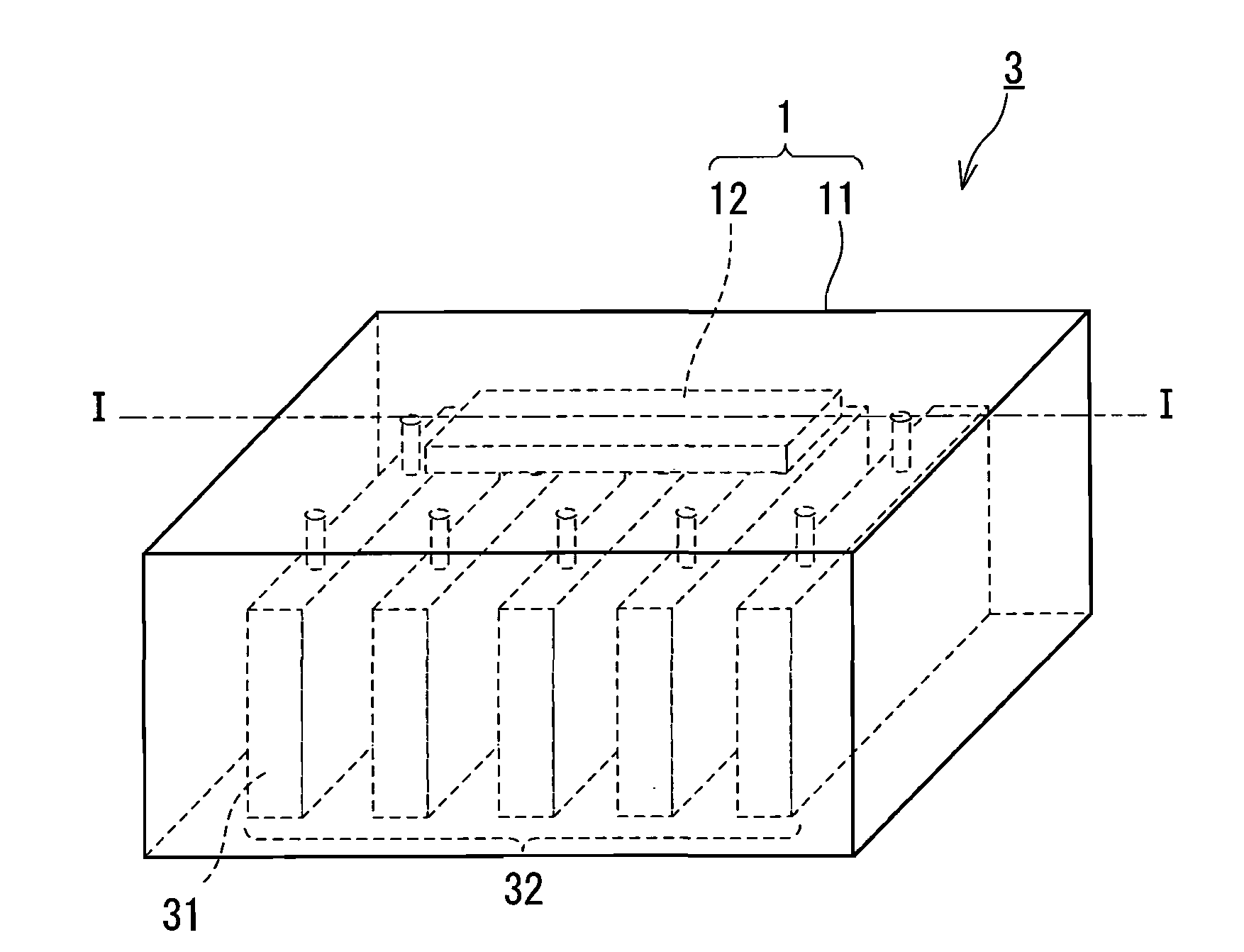

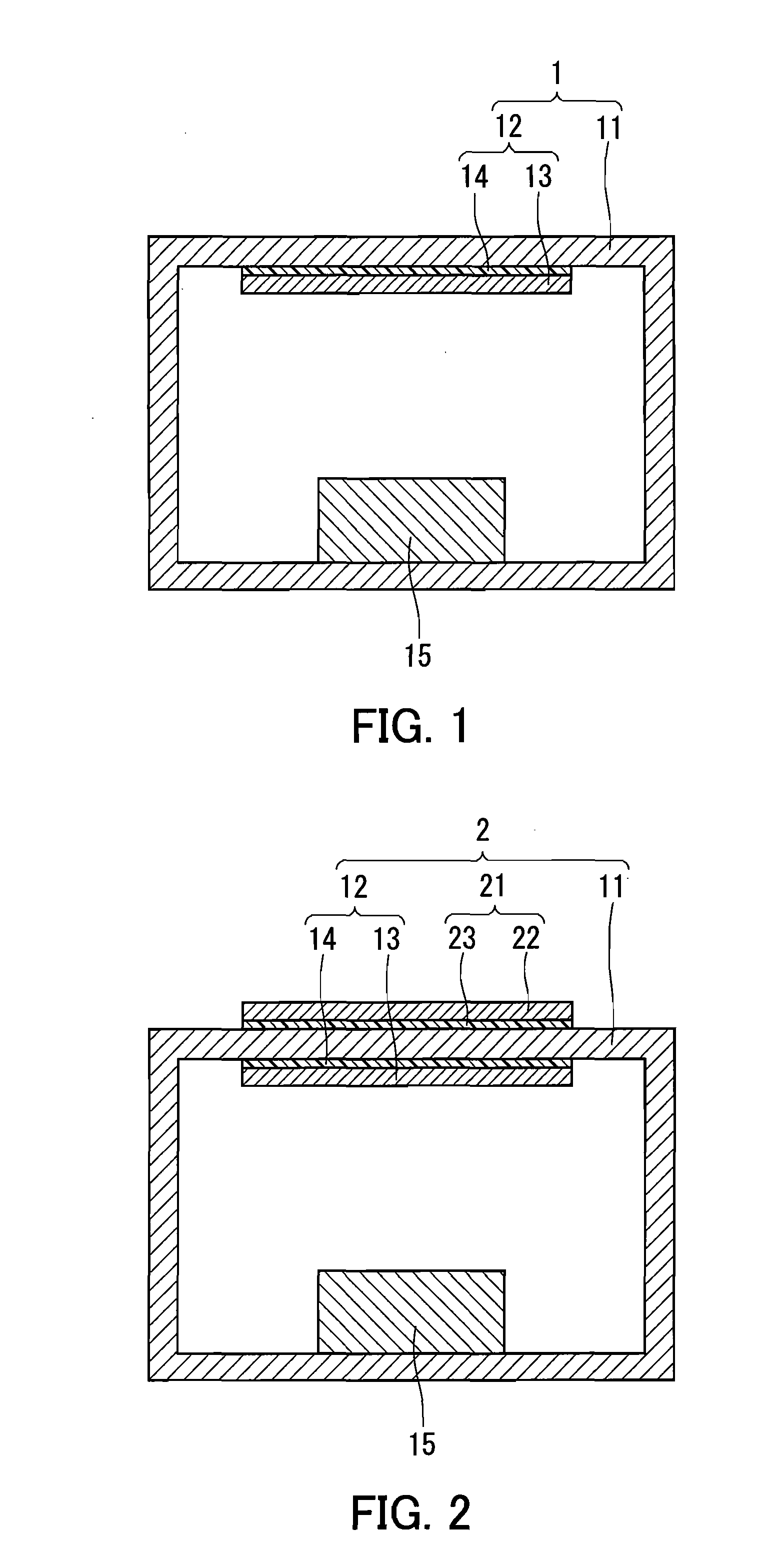

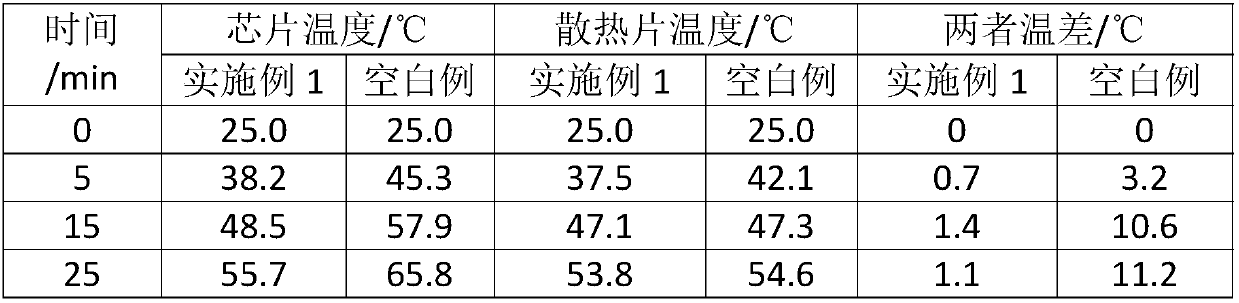

Heat dissipating housing and lithium battery pack using the same, and semiconducting tape for heat dissipation

InactiveUS20120171546A1High heat emissivityHigh effectCell temperature controlBattery isolationCarbon blackSemiconductor

The heat dissipating housing (1) of the present invention includes a housing body (11) made of metal, and a first semiconducting tape for heat dissipation (12) attached to at least a part of the inner wall of the housing body (11). The first semiconducting tape for heat dissipation (12) includes a fluoropolymer substrate (13) containing carbon black, and an adhesive layer (14) formed on the fluoropolymer substrate (13).

Owner:NITTO DENKO CORP

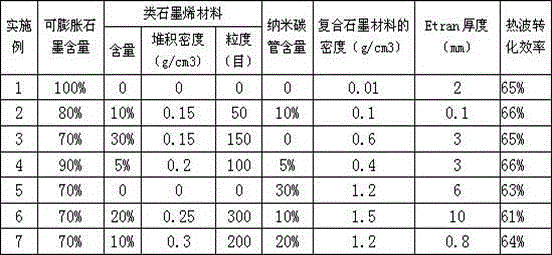

Composite graphite material and its application as heat wave conversion material

InactiveCN104909355AIncrease heat radiation rateHigh heat wave conversion efficiencyCovering/liningsChemical industryInfraredHeat wave

A composite graphite material comprises 70-100wt% of expandable graphite, 0-30wt% of a graphene-like material and 0-30wt% of carbon nanotube, wherein the bulk density of the graphene-like material is 0.15-0.3g / cm<3>, and the granularity of the graphene-like material is 50-300 meshes. The invention also relates to an application of the composite graphite material as a heat wave conversion material. The composite graphite material has a very high heat wave conversion efficiency at a low temperature of 10-50DEG C, uses the directional heat conduction performance of graphite, and also has the advantages of high heat conduction efficiency, fast speed and low cost; and the composite graphite material can realize bidirectional low temperature conversion of infrared ray wave and heat energy as a heat wave conversion material, and realizes heating and refrigeration in spaces.

Owner:NINGBO SINYUAN IND GRP CO LTD

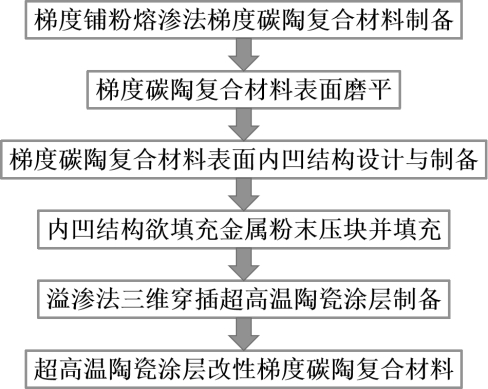

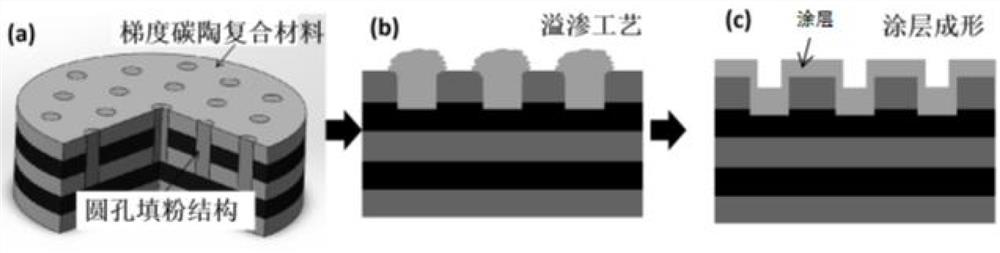

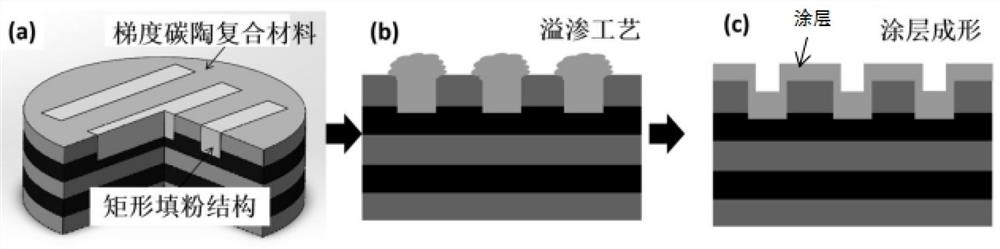

Ceramic coating protection gradient carbon-ceramic composite material and preparation method thereof

ActiveCN113582713AStable high temperature mechanical propertiesImprove high temperature mechanical propertiesCeramic compositeCarbide coating

The invention discloses a ceramic coating protection gradient carbon-ceramic composite material and a preparation method thereof. The ceramic coating protection gradient carbon-ceramic composite material comprises: a gradient carbon-ceramic composite material which is provided with a concave structure on the surface thereof and is a gradient C / C-ZrC-SiC composite material; and an ultrahigh-temperature ceramic coating which is continuously arranged along the surface of the gradient carbon-ceramic composite material and the inner wall surface of the concave structure. The ultrahigh-temperature ceramic coating is an indissolvable metal carbide coating formed by diffusing and infiltrating indissolvable metal along the surface of the gradient carbon-ceramic composite material and reacting the indissolvable metal with the surface of the gradient carbon-ceramic composite material. Therefore, the formed ceramic coating is a three-dimensional jack structure coating, the interfacial strength of the ceramic coating is far higher than that of a two-dimensional plane coating, the surface area of the coating is greatly increased due to the arrangement of the concave structure, meanwhile, the flow resistance of melt on the surface of the composite material can be improved, then the overall temperature resistance of the composite material can be improved, and the risk of coating stripping is reduced.

Owner:CENT SOUTH UNIV

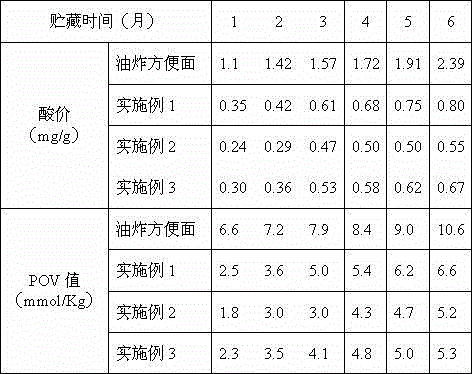

Low-oil-temperature instant noodles subjected to far infrared drying and preparation method thereof

The invention relates to low-oil-temperature instant noodles subjected to far infrared drying and a preparation method thereof. The preparation method comprises the steps of kneading a dough prepared from wheat flour, starch, water chestnut flour, raw peanut pulp, a mixed thickener, salt and an edible emulsifier, boiling, rolling, shredding, cooking, cutting off, uniformly spraying low-temperature frying oil on the upper and lower sides of the noodles, carrying out secondary far infrared drying and shaping and obtaining an instant noodle lump after cooling. The preparation method has the advantages that the instant noodles have high nutritive value; the oil content of the pastry is controlled; and the reconstitution property, taste and flavor of the fried instant noodles are maintained.

Owner:福家欢食品股份有限公司

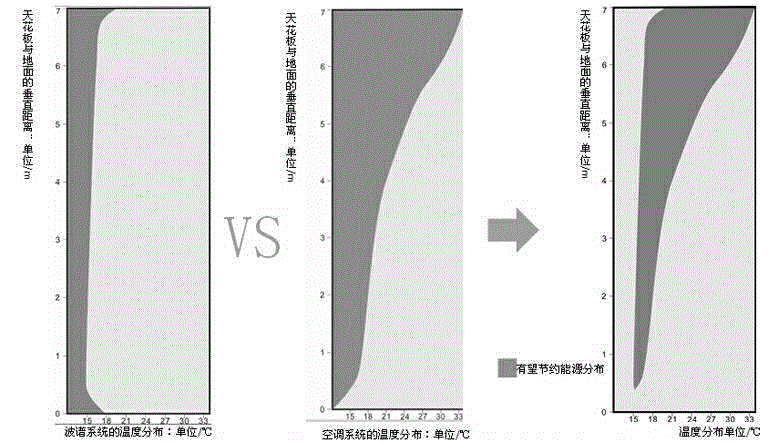

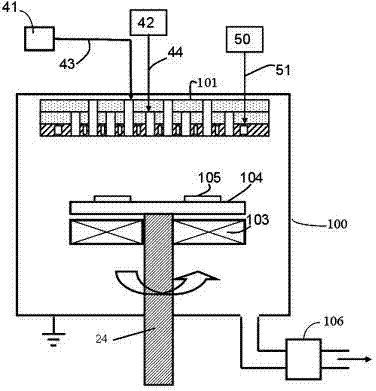

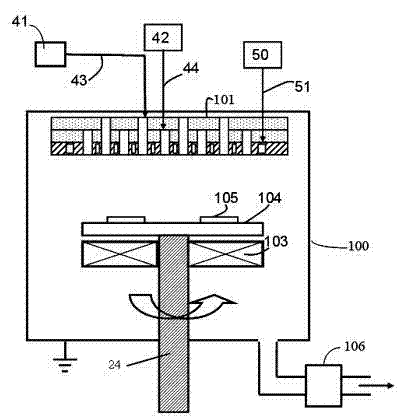

Thermochemical vapor deposition reactor and method for improving thermal radiance in reactor

ActiveCN102409318AIncrease heat radiation rateThermal emissivity is stableChemical vapor deposition coatingThermal chemical vapor depositionRadiance

The invention discloses a thermochemical vapor deposition reactor and a method for improving the thermal radiance in the reactor. Before a reaction, a device in a reaction cavity is subjected to surface pretreatment, so as to change the roughness of the surface of the device or the material composition on the surface of the device to passivate the surface of the device, thereby improving the thermal radiance value of the device. According to the invention, the surface of the device in the reaction cavity can reach stable thermal radiance before a reaction, thereby ensuring processing uniformity and effect.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA +1

Polyaniline epoxy silicone graphene heat dissipation electrostatic conductive paint

InactiveCN107746655AImprove thermal stabilityImprove conductivityEpoxy resin coatingsElectrically-conductive paintsEpoxyCarbon nanotube

The invention provides a polyaniline epoxy silicone graphene heat dissipation electrostatic conductive paint. The coating mainly consists of epoxy silicone resin, graphene, carbon nanotubes, conductive titanium dioxide, polyaniline and other additives, wherein the epoxy silicone resin is coating resin with strong weather resistance and heat resistance, the polyaniline resin can greatly improve theheat radiation value and the electric conductivity of the coating, the graphene and the carbon nanotubes can further accelerate heat transfer, the conductive titanium dioxide has the effects of heatresistance, weather resistance, electric conduction and heat conduction, and the polyaniline, the carbon nanotubes, the graphene and the conductive titanium dioxide finally form a full three-dimensional network structure distribution of combination of points, lines and planes in fluid. The polyaniline epoxy silicone graphene heat dissipation coating provided by the invention has the characteristics of high heat radiation rate, high heat conductivity and low heat resistance, and simultaneously has the characteristics of polyaniline and epoxy silicone, thereby having a strong practical value.

Owner:TIANJIN MEISHIBANG PAINT CHEM IND

Photocuarable resin composition

InactiveCN101059652AImprove adhesion strengthFunction increasePhotosensitive materials for photomechanical apparatusEpoxyLiquid-crystal display

The invention discloses a photocureable resin composition which comprises: (A) 100 parts of epoxide resin by weight; (B) 0.01 to 20 parts of photopolymerization initiator by weight; (C) 0.01 to 10 parts of coupling agent by weight; and (D) 0.01 to 120 parts of mineral filler by weight. The photocureable resin composition can also comprise (E) 0.05 to 10 parts of photo-acid-generator by weight. The photocureable resin composition has improved heat conductibility and a damp insulation function, thereby can be used for producting display devices, such as organic light emitting diode (OLED), liquid crystal displays (LCD) and pliability displays.

Owner:DONGJIN SEMICHEM CO LTD

Nickel-picotite type infrared radiation ceramic powdered material for thermal spraying and preparation method

InactiveCN1296314CShort manufacturing processProcess parameters are easy to controlThermal sprayingAdhesive

The Ni-Cr spinel type infrared radiation powder material is prepared by using Cr2O3 and NiO with stable high performance as main components and TiO2, Nb2O5, TiN and TiB2, or Fe2O3 and MnO2, or SiO2 and ZrO2 as supplementary material, and through the steps of mixing powdered solid materials, adding adhesive and water to compound slurry, spray drying to form aggregate powder, and final plasma nodulizing or sintering to densify. The Ni-Cr spinel type infrared radiation powder material has heat radiation factor as high as 0.89-0.93, and may be molten and sprayed via plasma spraying, oxygen-acetylene flame spraying or fuel gas expansion spraying to surface of base body to form firm mechanically combined coating, which has controllable thickness, chemical performance stable in 500-700 deg.c, high heat shock resistance and low heat radiation factor attenuation in long term use.

Owner:WUHAN UNIV OF TECH

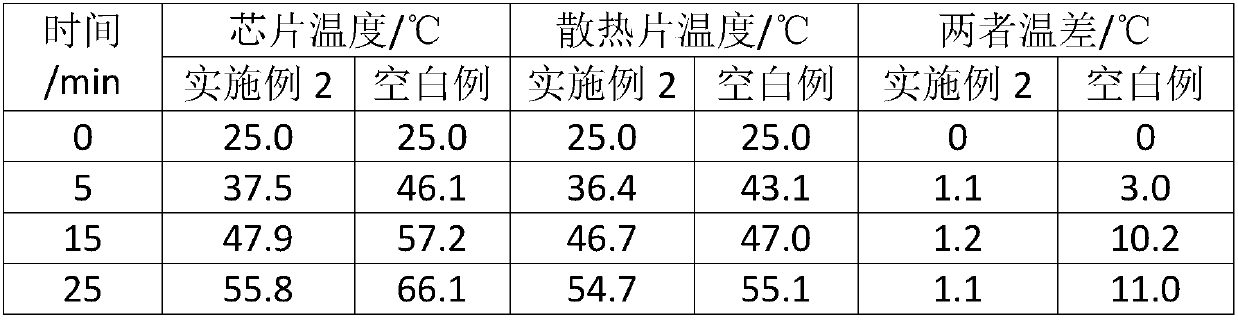

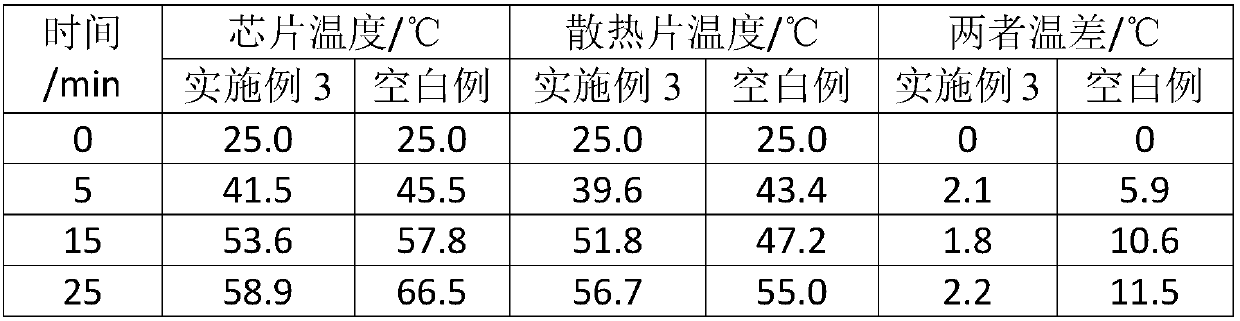

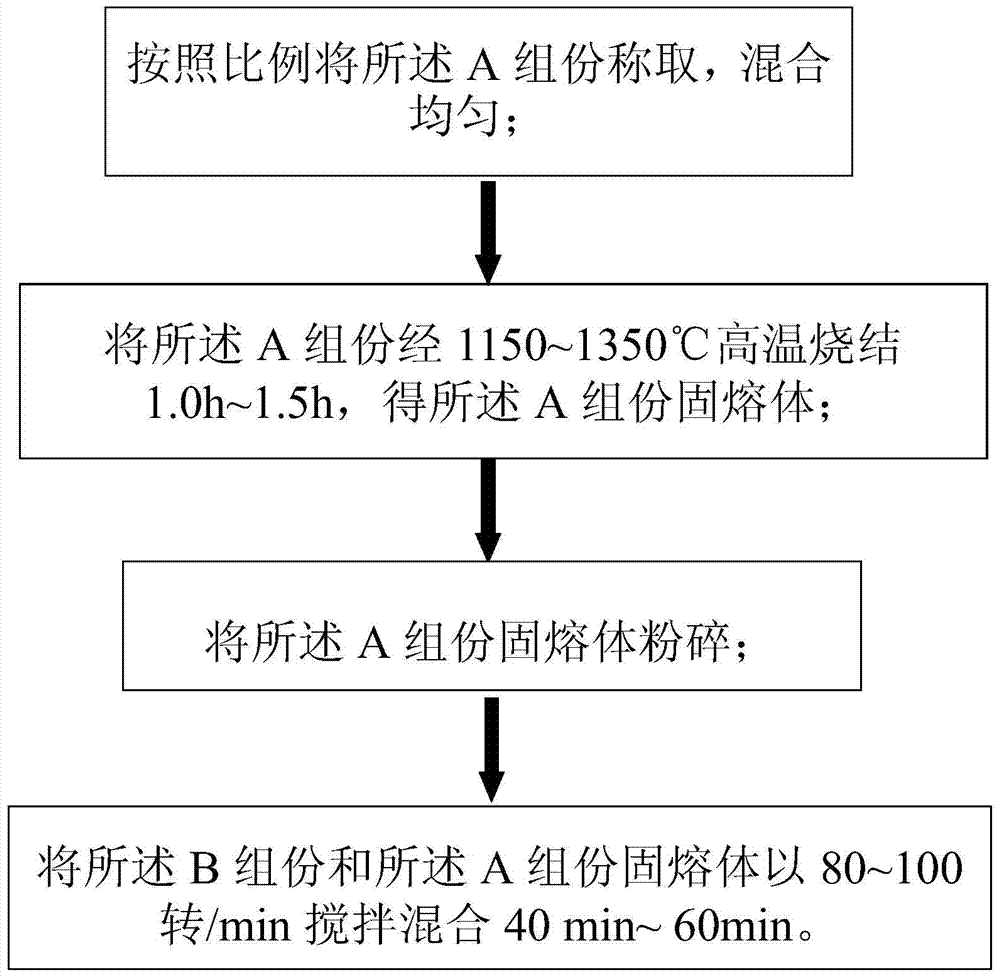

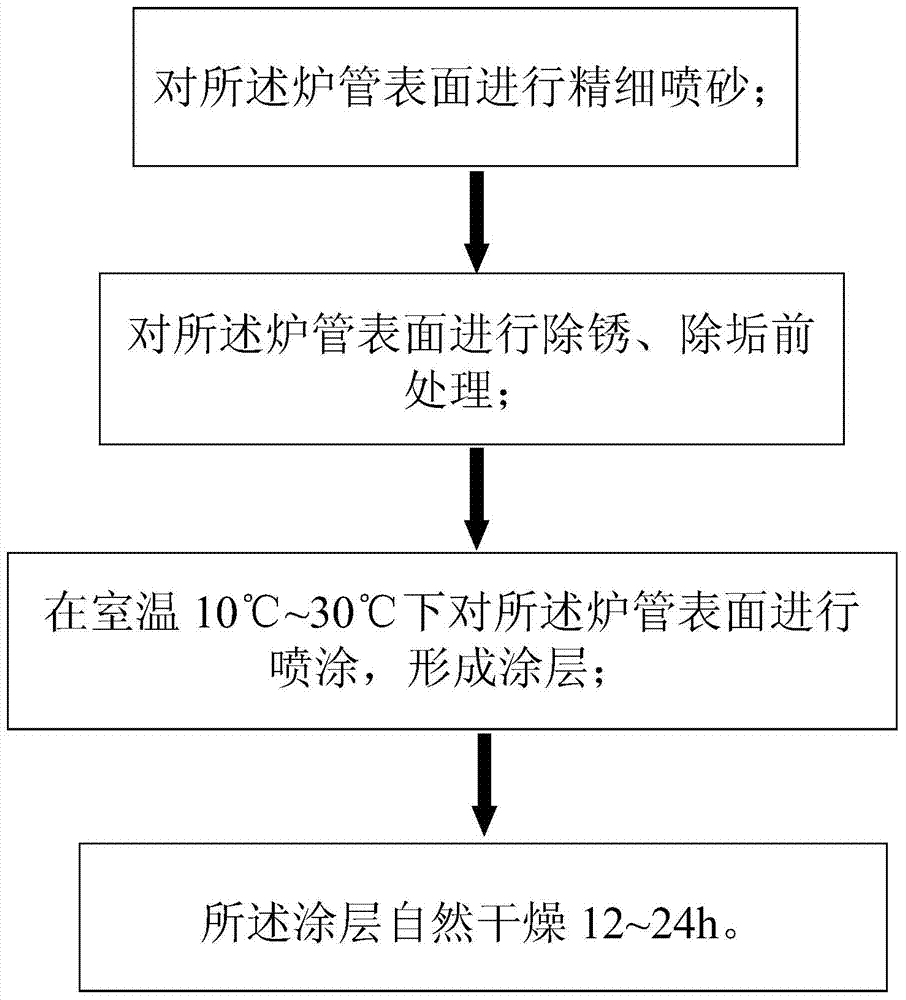

High radiant ceramic coating for heating furnace tube as well as preparation method and using method thereof

InactiveCN104744973AHigh temperature oxidation resistanceCorrosion resistantChemical industryPretreated surfacesRadiative transferCeramic coating

The invention discloses a high radiant ceramic coating for a heating furnace tube as well as a preparation method and a using method thereof. The high radiant ceramic coating for the heating furnace tube comprises a component A and a component B, wherein the component A is a metallic oxide mixture which is 30-35% of the total amount and the component B is a temperature resistant bonder which is 65-70% of the total amount. The high radiant ceramic coating provided by the invention has the functions of anti-high temperature oxidation and anticorrosion, prolongs the service life of the furnace tube, increases the heat transfer on the surface of the furnace tube, increases the heat exchange efficiency, reduces the fuel consumption of the heating furnace and reaches the energy saving purpose; under the condition of not changing the device structure, the high radiant ceramic coating reinforces the radiative transfer, is few in investment, rapid in effect, simple in construction and good for industrial popularization.

Owner:马麟

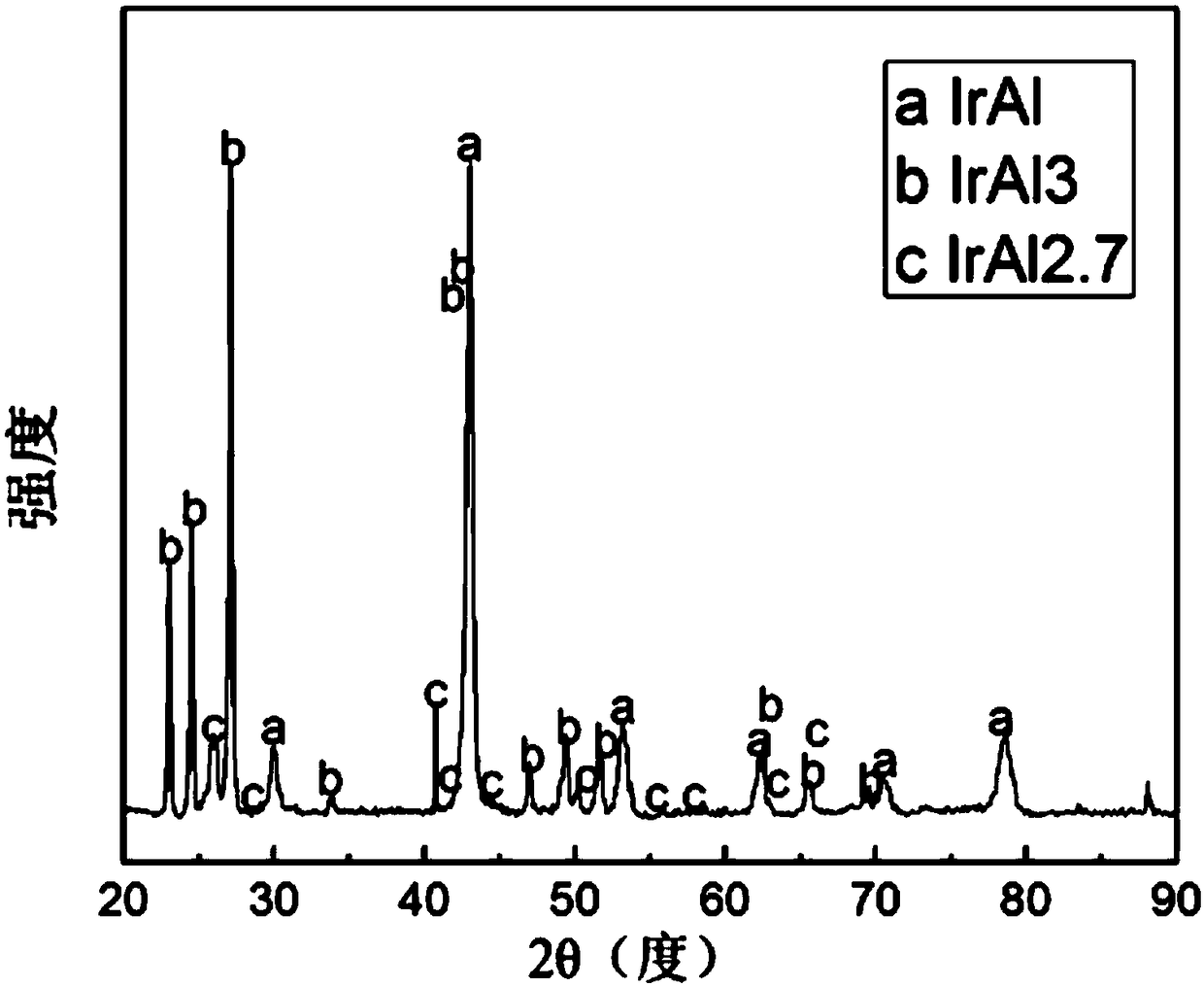

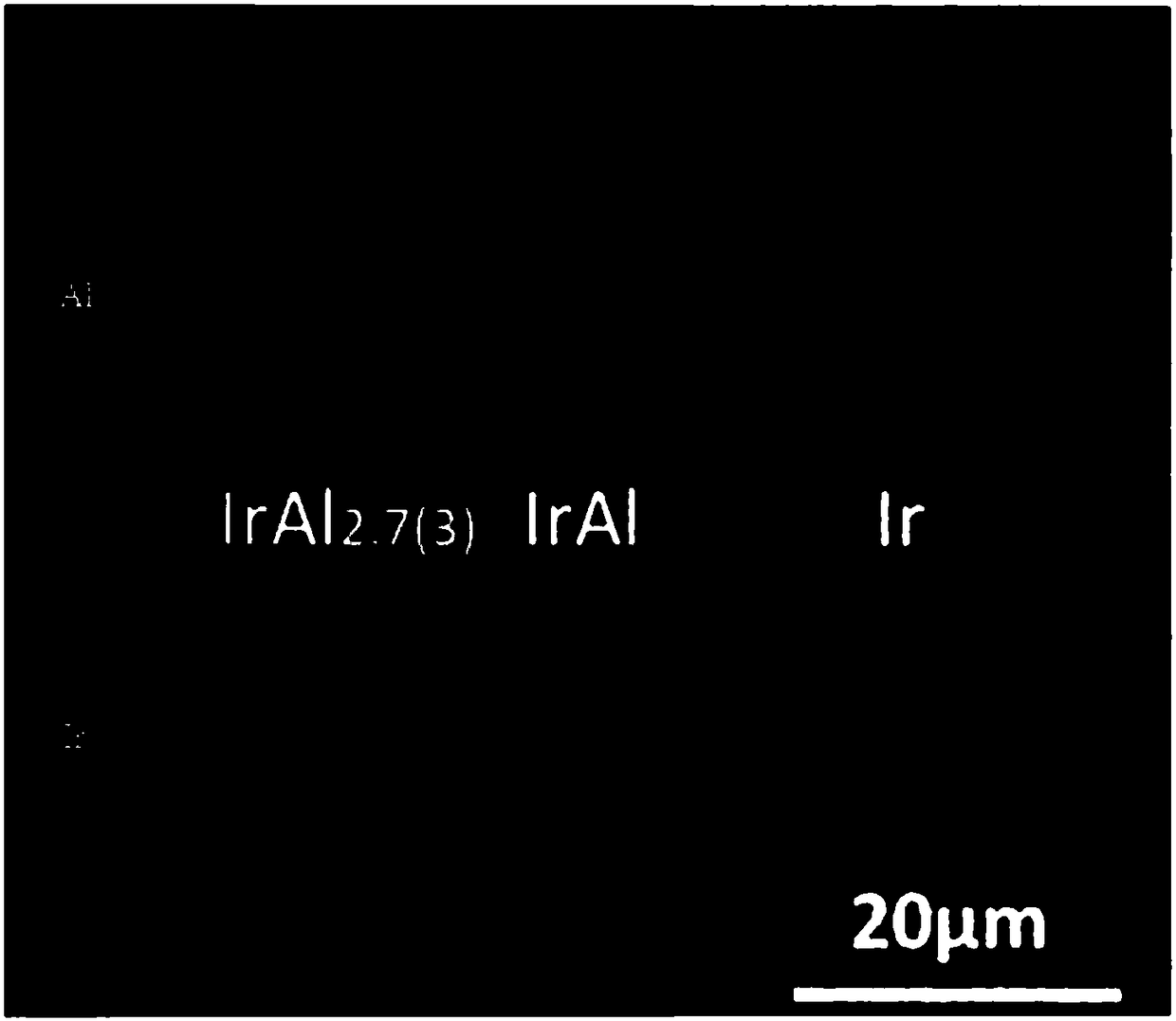

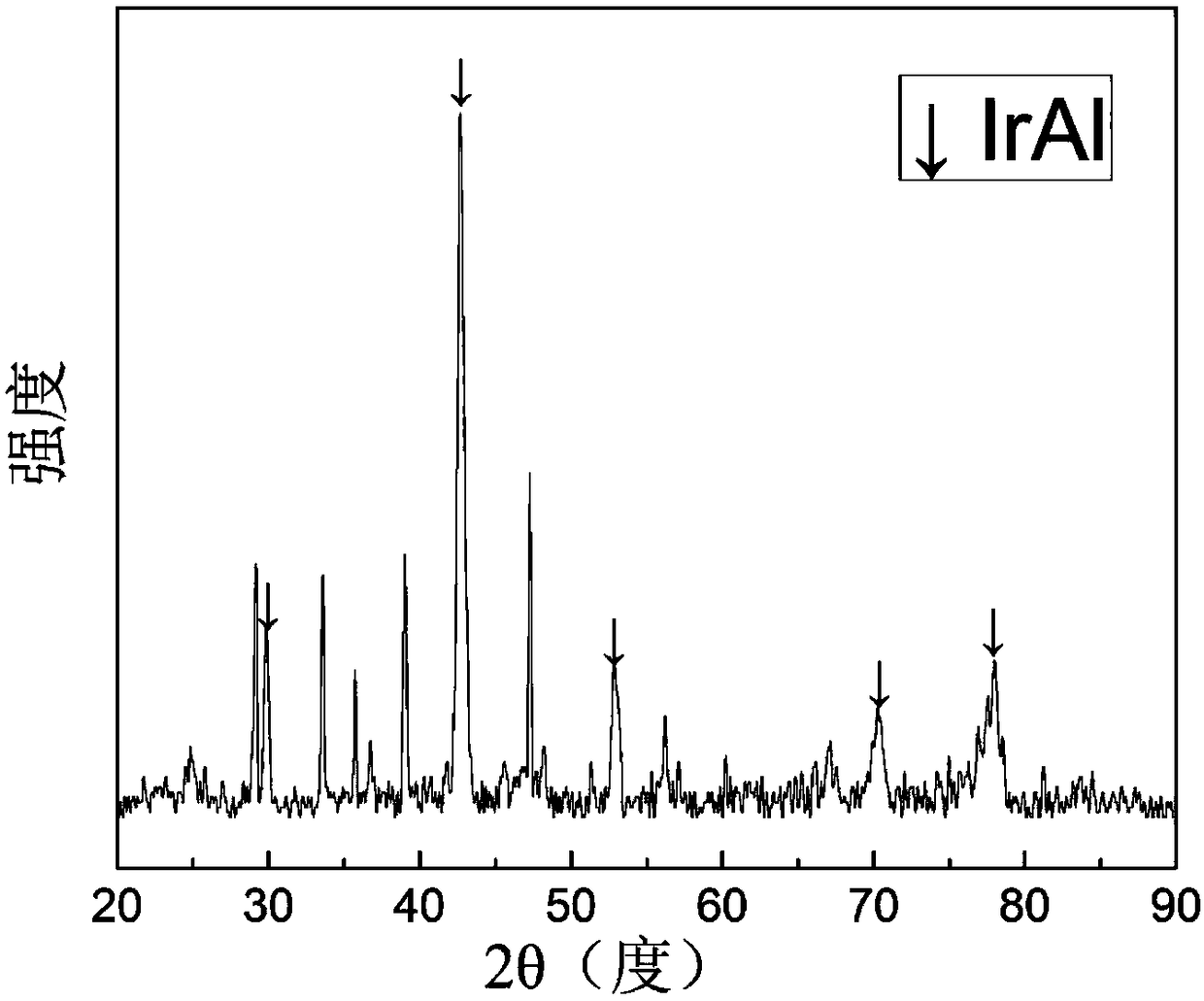

Multi-element gradient modified iridium coating layer and preparation method thereof

ActiveCN108588637AImprove service limitGuaranteed AntioxidantSolid state diffusion coatingSuperimposed coating processAl powderRhenium

The invention discloses a multi-element gradient modified iridium coating layer and a preparation method thereof. The multi-element gradient modified iridium coating layer comprises a Re layer, an Irlayer, an Ir-Al layer and an X permeating layer arranged on a graphite substrate in sequence from bottom to top, wherein X=Hf, Zr or Cr. The preparation method comprises the following steps: (1) the graphite substrate / rhenium / iridium system is prepared as an original material; (2) Al powder, Al2O3 powder and a halogen supply agent are firstly mixed to prepare an Al permeating agent; and then, metal X powder, metal oxide XO powder and the halogen supply agent are mixed to prepare an X permeating agent; (3) an Ir-Al coating layer is prepared by adopting powder embedding solid permeation; and (4)an Ir-Al-X gradient coating layer is prepared by adopting powder embedding solid permeation; and finally, the multi-element gradient modified iridium coating layer is obtained. The prepared multi-element gradient modified iridium coating layer is more excellent in high-temperature oxidation resistance, refractory metal oxide melting point and heat radiation rate compared with a traditional high-temperature oxidation resistant coating layer.

Owner:NAT UNIV OF DEFENSE TECH

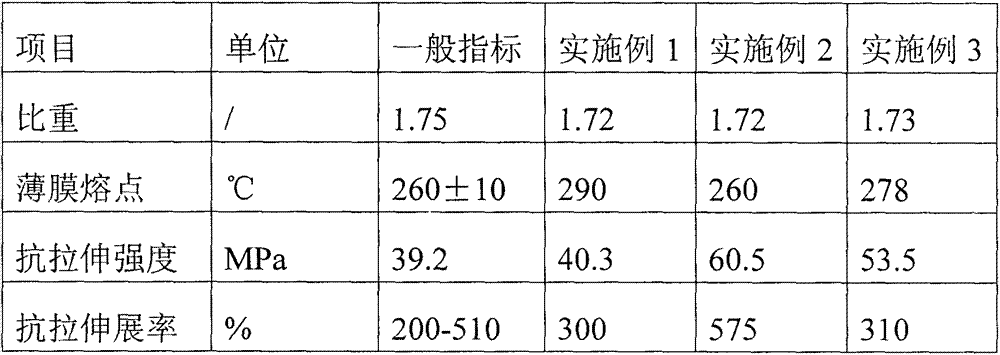

ETFE (ethylene-tetrafluoroethylene copolymer) film and preparation method thereof

The invention discloses an ETFE (ethylene-tetrafluoroethylene copolymer) film and a preparation method thereof. The film is prepared from the ETFE and an additive, wherein the processing temperature is 190 to 210 DEG C; the user amount ratio of the ETFE to the additive is 1:(10-20) percent according to the percentage by weight; the melt index of the ETFE is 20 to 25; and the functional additive comprises more than any one of the conventional fluoroplastic additive and the conventional engineering additive as well as graphene. The ETFE film provided by the invention has high thermal radiation ratio, high heat conductivity and low heat resistance value, has self-cleaning property, acid and alkali resistance and ultrahigh insulativity while cooling, and has strong practical value.

Owner:HUANGHE S & T COLLEGE

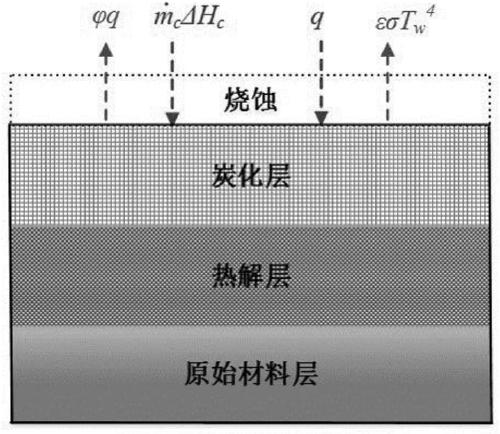

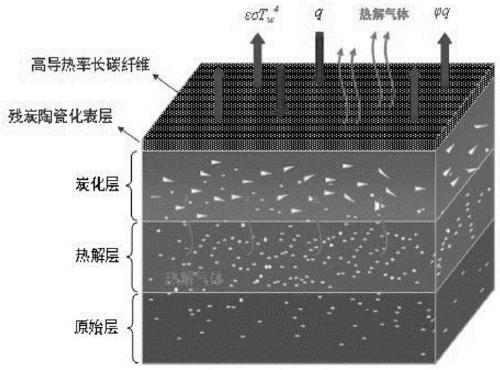

Light weight pyrolytic self-adaptive dimensional efficient heatproof material

The invention belongs to the field of aerospace thermal protection. Based on a light PICA heatproof composite material (a phenolic aldehyde impregnated carbon ablative material), the invention overcomes the contradiction of light weight and dimension of an existing heat protection material and discloses a light weight pyrolytic self-adaptive dimensional efficient heatproof material. Carbon fibersare coated with a ceramic, so that the carbon fibers are prevented from being in contact with oxygen. Residual carbon and ceramic filler are sintered to an antioxidant ceramic surface layer under theaction of aerodynamic heat, and the surface heat radiation rate is improved. The longer the aerodynamic heat action time is, the thicker the ceramic surface layer is and the higher the surface heat radiation rate is. The purpose of being self-adaptive to the environment is achieved. Based on pyrolytic heat absorption and a heat blocking effect of pyrolyzed gas, a heat leading heat-dissipating technique and a high radiation heat-dissipating technique of the ceramic surface layer of residual carbon, a synergistic effect of various heatproof mechanisms is achieved and the heatproof efficiency isimproved. The light weight pyrolytic self-adaptive dimensional efficient heatproof material can be applied to a heat protection system in medium and low heat flow heat environments of a hypersonic velocity near space aerocraft.

Owner:BEIJING JIAOTONG UNIV

Double-layer photothermal conversion composite material and preparation method thereof

InactiveCN104152848AIncrease working temperatureIncrease heat radiation rateSolar heat devicesVacuum evaporation coatingSputteringGas phase

The invention relates to a double-layer photothermal conversion composite material and a preparation method thereof, and belongs to the technical field of solar energy utilization. The composite material comprises a bottom transition layer and a top high-heat radiation rate layer, wherein the bottom transition layer and the top high-heat radiation rate layer of the composite material are prepared on a substrate material in sequence through a preparation method of vapor deposition or magnetron sputtering; the bottom transition layer and the substrate material are directly connected; and the top high-heat radiation rate layer and the bottom transition layer are also directly connected. The composite material has the characteristics of high working temperature, high heat radiation rate, strong heat shock resistance and long service life, and is a new high-performance photothermal conversion material.

Owner:赵骁

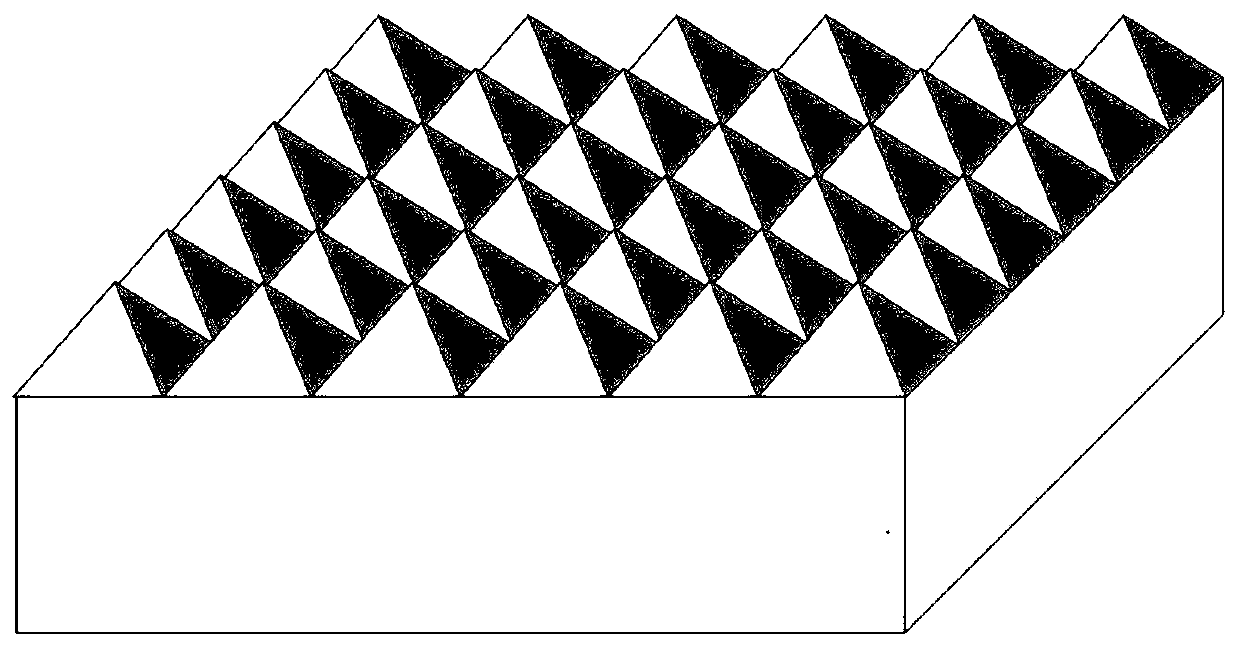

Photon radiation heat radiation structure

InactiveCN110350048AIncrease heat radiation rateReduce the temperatureLighting heating/cooling arrangementsSemiconductor/solid-state device manufacturingWorking temperaturePhotonics

The invention relates to the field of radiation heat radiation and particularly relates to a photon radiation heat radiation structure. The photon radiation heat radiation structure is composed of periodic unit photonic structures, the material is silicon dioxide, and each unit is composed of pyramid structures and is periodically arranged in a regular square lattice. The photon radiation heat radiation structure is advantaged in that no additional power consumption equipment is required, a production method is simple, the cost is low, the photon radiation heat radiation structure can be applied to solar cells, solar water heaters, solar LED lights, automobile glass windows, etc., the working temperature of the equipment is effectively reduced, and the aging rate is slowed down.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

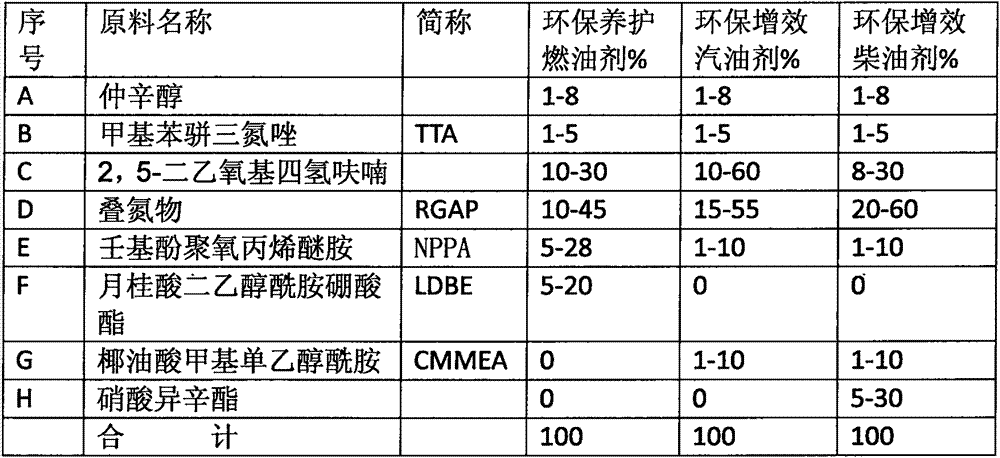

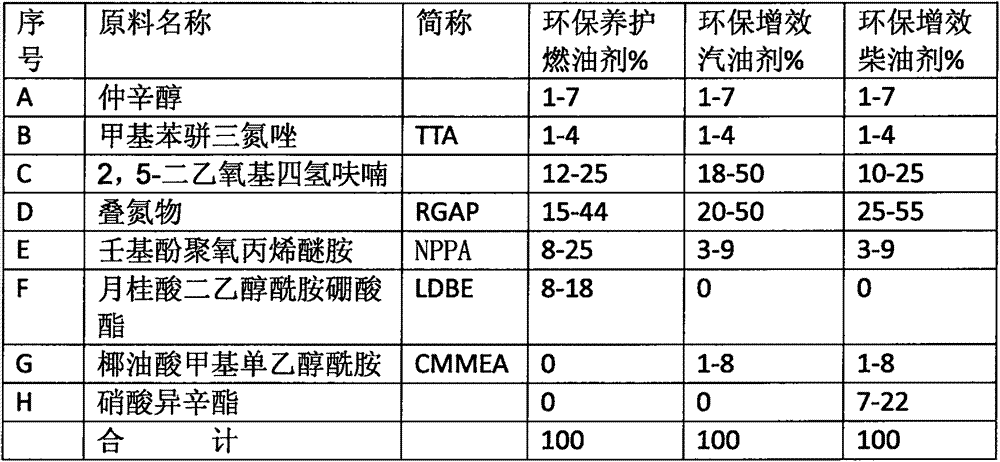

Environment-friendly fuel oil agent for promoting quality and effect of fuel oil and environment-friendly fuel oil

InactiveCN106957700ASolve temperature problemsSolve the problem of efficient utilizationLiquid carbonaceous fuelsThermal energyEnvironmental resistance

The invention relates to an environment-friendly fuel oil agent for promoting quality and effect of fuel oil. The environment-friendly fuel oil agent comprises the following materials by weight percent: 1-9% of octanol, 1-5% of tolyltriazole, 8-60% of 2,5-diethoxy tetrahydrofuran, 10-60% of azide, 1-28% of nonyl phenol polyoxy propylene ether amine, 0-20% of diethanolamide borate laurate, 0-10% of coconut oleate methyl monoethanolamide and 0-30% of isooctyl nitrate. According to the invention, the clean combustion, catalytic combustion and control combustion techniques are organically combined for efficiently removing and preventing scale of an oil-way system and an exhausting system in chemical and physical modes; the surface metal in an engine can be activated to form a powerful catalytic field and a 'flame combustion' mode is converted into 'flameless combustion'; the starting / ending temperature of the control combustion is reduced, the speed is increased, the photo-thermal energy is effectively converted and the thermal radiation rate is increased; and a new mode of instantly breaking liquid oil molecules into gaseous micro-molecule residues and then quickly, thoroughly and cleanly combusting with the stimulated oxygen is realized and the optimization of the quality of the fuel oil and the upgrading of the effect differentiation are realized.

Owner:聂志守

Application method of photocuring-based graphene heat-dissipating coating

InactiveCN108453029AGood dispersionEvenly dispersedLiquid surface applicatorsCoatingsUltraviolet lightsCvd graphene

The invention relates to the technical field of coatings, and discloses an application method of a photocuring-based graphene heat-dissipating coating. A graphene quantum dot is introduced as an additive so as to be added into a graphene heat-dissipating coating, so that the dispersibility of graphene is further improved, the agglomeration is prevented, and compared with a high molecular surfactant and a dispersing agent, no new impurities can be introduced to reduce the electrical conductivity; and through the action of a photocuring agent on an ultraviolet light or a laser beam, organic monomers are chemically crosslinked or physically crosslinked to form a three-dimensional network-shaped structure, and the graphene is immediately wrapped and isolated by a polymer molecule or a polymermonomer, so that the generation of self-agglomeration of the graphene is effectively avoided, and the heat conductivity and the heat dissipation of the coating are improved.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com