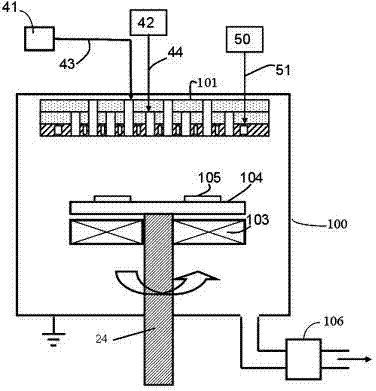

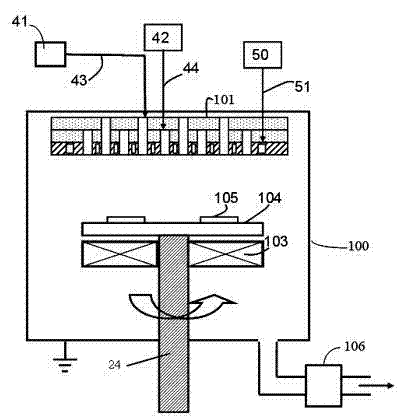

Thermochemical vapor deposition reactor and method for improving thermal radiance in reactor

A technology of vapor phase deposition and thermal radiation rate, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problem of affecting the thermal field distribution of the reaction chamber, the increase of the thermal radiation rate of the device, and the deviation of the processing effect from the ideal value, etc. Problems, to ensure the uniformity and effect, improve the effect of heat radiation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The surface preparation method includes the following steps:

[0022] Step 1, the device is oxidized;

[0023] Step 2, coating the soluble salt of the refractory metal on the surface of the device;

[0024] Step 3. Reduction of salts and oxides to metal form.

Embodiment 2

[0026] The surface preparation method includes the following steps:

[0027] Step 1, the device is oxidized;

[0028] Step 2, coating the surface of the device with alumina;

[0029] Step 3, heating the device;

[0030] Step 4, coating the soluble salt of the refractory metal on the surface of the device;

[0031] Step 5. Reduction of the salt to the metal form.

Embodiment 3

[0033] The surface preparation method includes the following steps:

[0034] Step 1. Heat the device at a temperature of 725°C for 5 minutes in an air atmosphere;

[0035] Step 2, coating the surface of the device with alumina;

[0036] Step 3, in H 2 Heat the device at 1650°C for 5 minutes in the atmosphere;

[0037] Step 4, immerse the device in ammonium tungstate solution;

[0038] Step 5, in H 2 The device was heated at 1000° C. for 10 minutes in the atmosphere.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com