Patents

Literature

56results about How to "Solve the problem of efficient utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing mineral wool by using early-stage molten-state steel slag of converter

ActiveCN106045301AReduce manufacturing costImprove comprehensive benefitsGlass making apparatusBrown iron oxideFerrosilicon

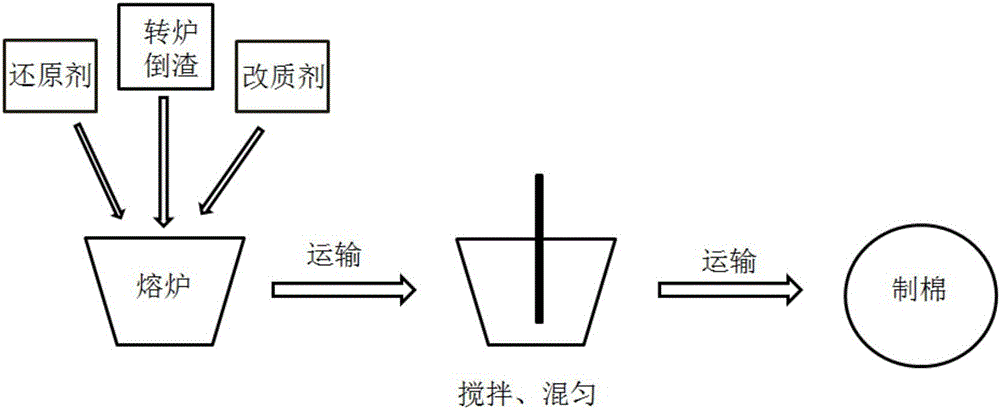

The invention discloses a method for producing mineral wool by using early-stage molten-state steel slag of a converter, and belongs to the technical field of production of mineral wool. The method comprises the following steps: pouring the early-stage molten-stage steel slag of the converter in a smelting furnace, adding a reducing agent and a modifier in a pouring process, and carrying out reducing and modifying; and after stirring, mixing evenly and standing for 0.5-1.5 hours, feeding slag at the temperature between 1,380 DEG C and 1,430 DEG C to wool producing equipment and processing into the mineral wool. Double advantages of 'residues' and 'heat' of the molten-state steel slag are played fully, ferrosilicon and aluminum granules are used as reducing agents, reaction of silicon, aluminum and iron oxide is silicothermal reaction and aluminothermal reaction, a large amount of thermal can be produced along with the reaction, and heat supply in a whole reducing and modifying process can be satisfied. After valuable elements are recycled, residues are directly prepared into the mineral wool with high additional value, the molten-state steel slag is comprehensively recycled, the problem of emission of the steel slag is solved, furthermore, the production cost of the mineral wool can be reduced, and the economic benefit and the environment benefit are good.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY +1

Method for extracting titanium from vanadium-titanium magnetite

InactiveCN105112689AEfficient and reasonable useSolve the technical problems of efficient separation and extractionProcess efficiency improvementElectric furnaceAluminateSmelting process

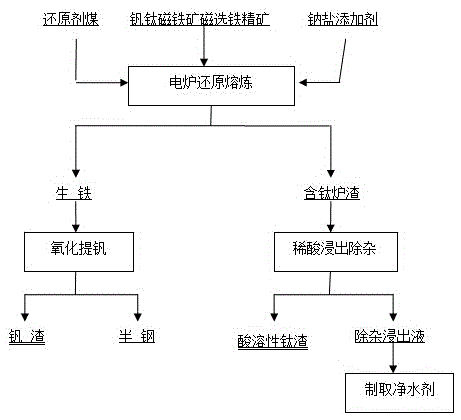

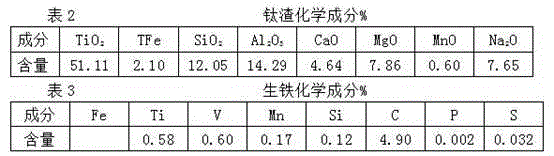

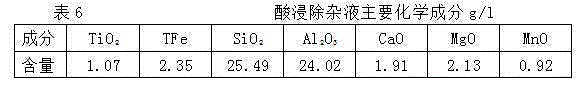

The invention discloses a method for extracting titanium from vanadium-titanium magnetite. The method comprises the following steps: adding sodium or potassium salt additive in the reduction smelting of an iron ore concentrate electric stove to obtain liquid iron and titanium-containing slag, wherein vanadium and iron are reduced to enter liquid iron, under a smelting high temperature condition, silicon and aluminum impurities form sodium aluminosilicate capable of being dissolved in dilute acid with the sodium or potassium salt additive, and enabling the sodium aluminosilicate and titanium and aluminum magnesium impurities to remain in the titanium-containing slag; purifying the titanium-containing slag by virtue of a wet-method metallurgical impurity removal method, to acquire a titanium slag product with TiO2 content more than 75 percent. For the application problem of titanium in the iron ore concentrate, the slag modification additive is added in the reduction smelting process, so that not only is the mobility of the slag improved, but also a condition is created for removing the later silicon-aluminum impurities of the slag, the high-efficiency separation and extraction problem of the titanium in the iron ore concentrate can be well solved, the resource utilization rate of the iron, titanium and vanadium is greatly increased, and the utilization rate of the titanium is increased about 3 times compared with the flow of a blast furnace.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

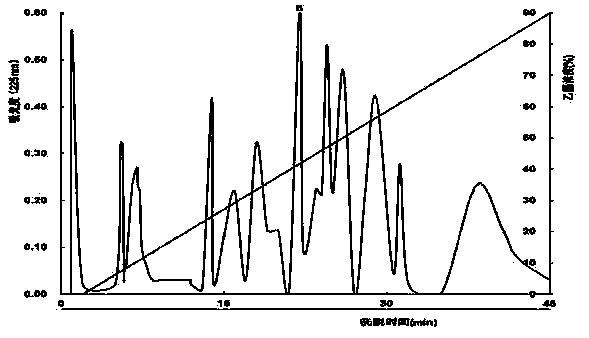

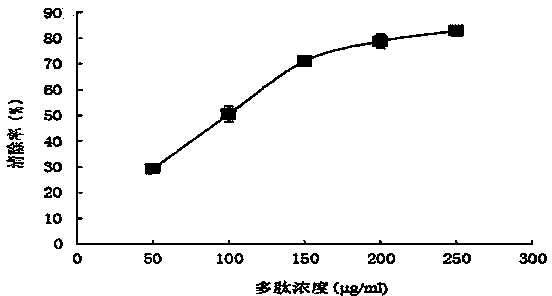

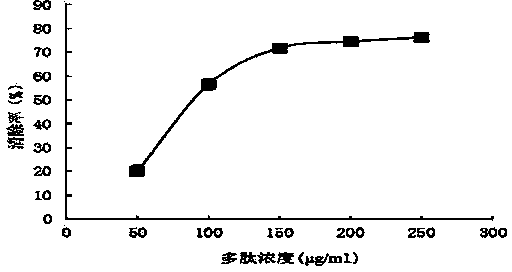

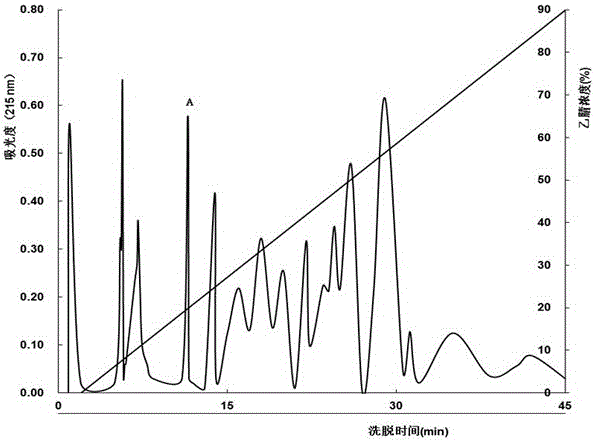

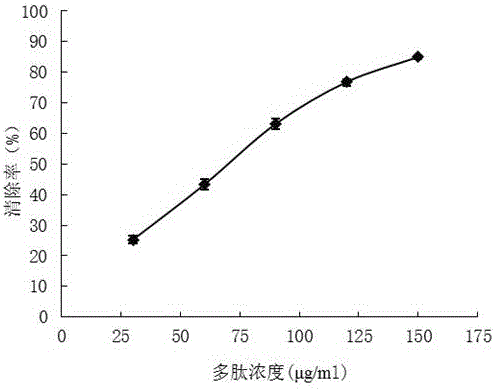

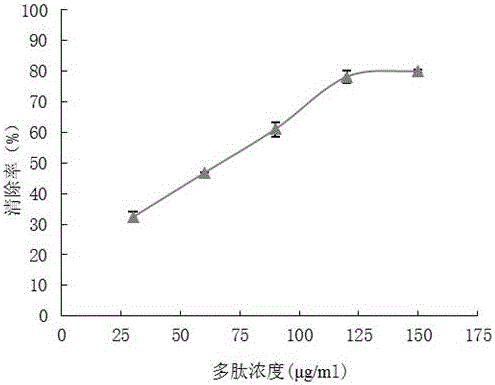

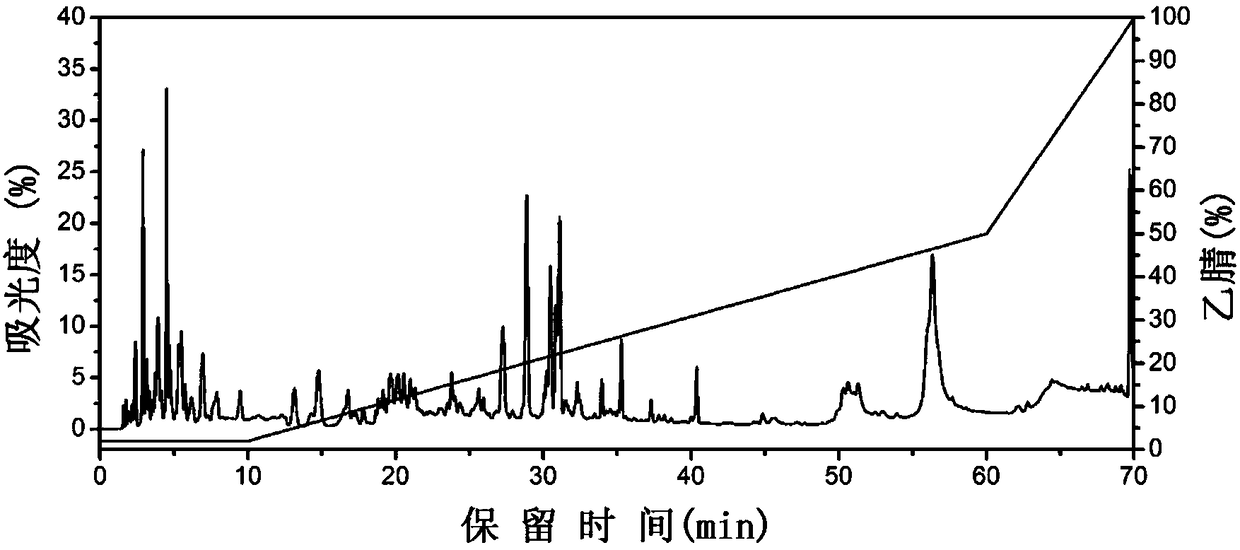

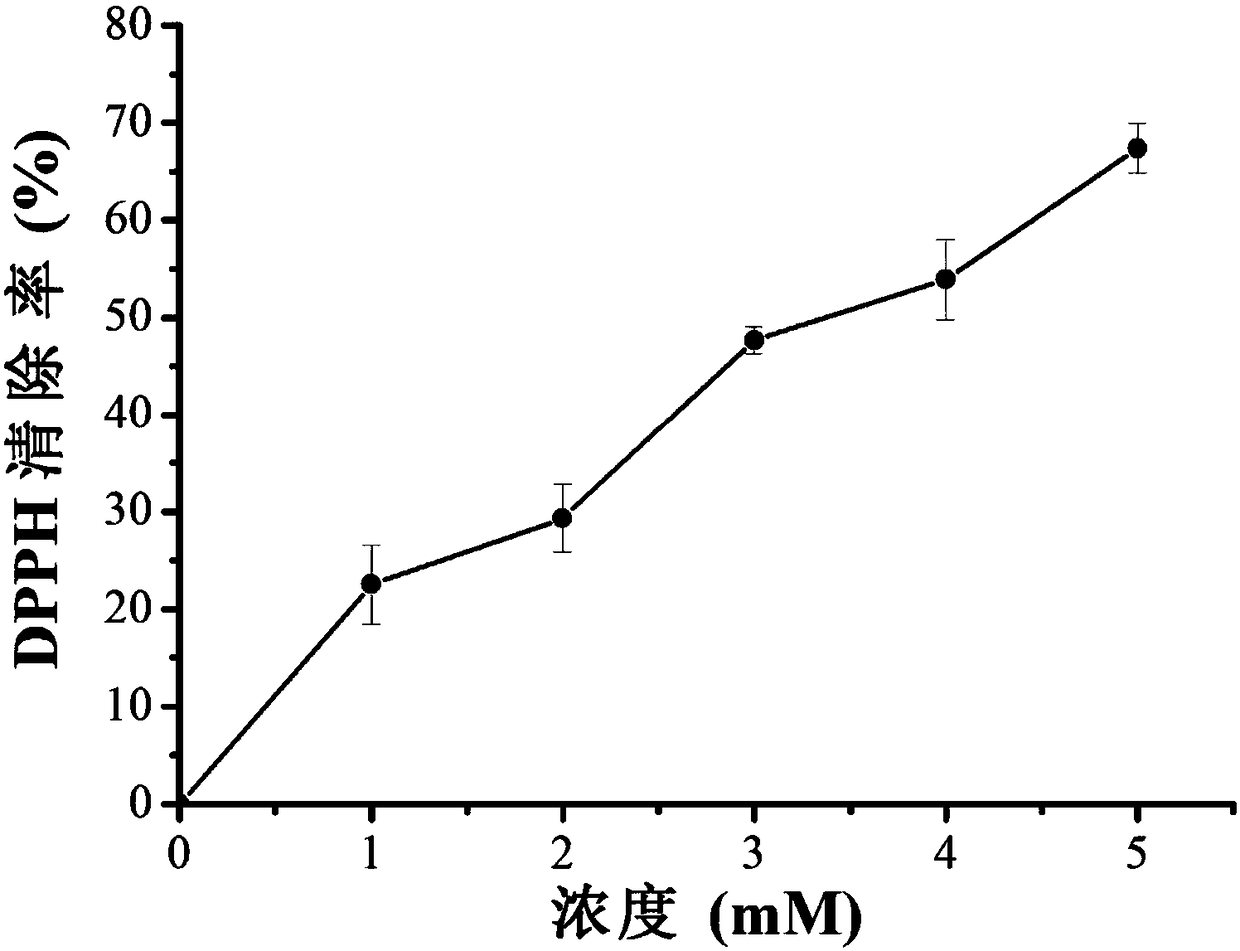

Anti-oxidative peptide and preparation method thereof

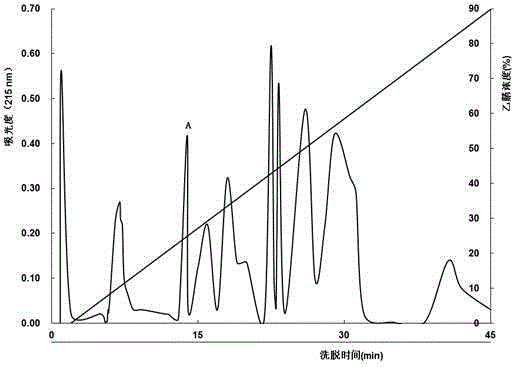

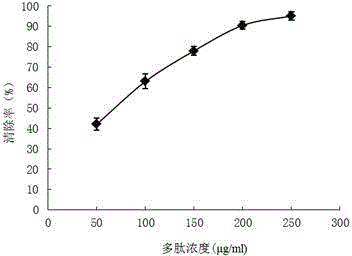

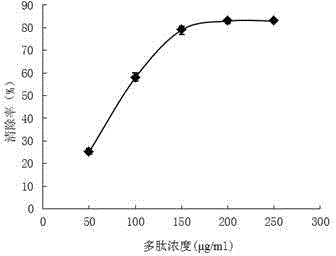

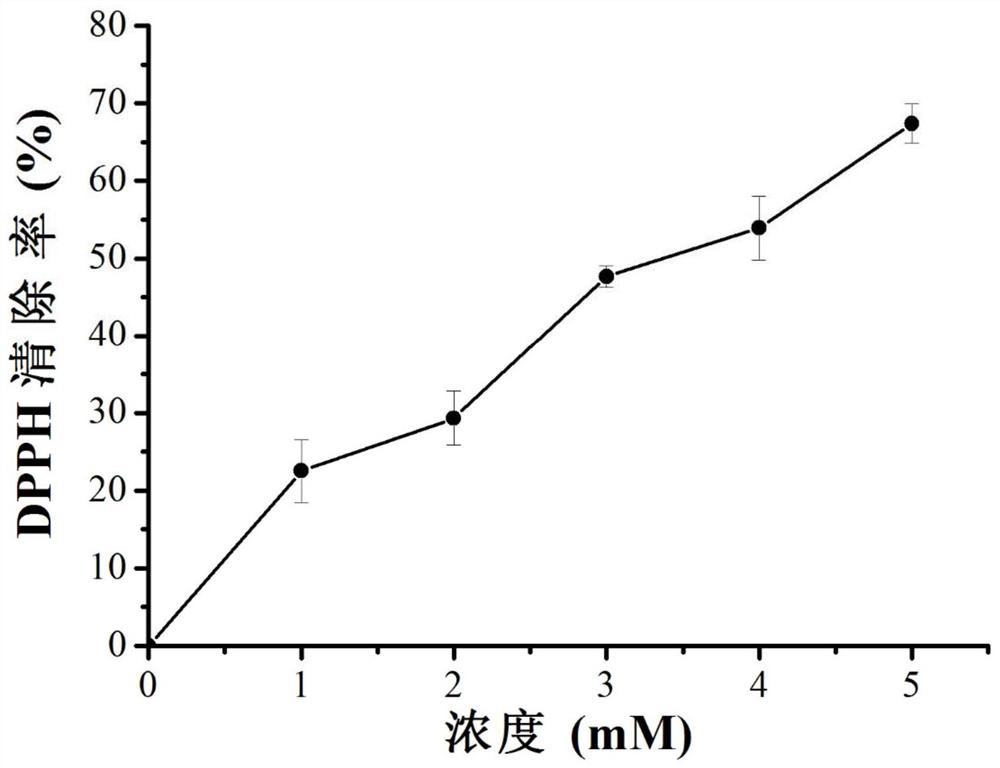

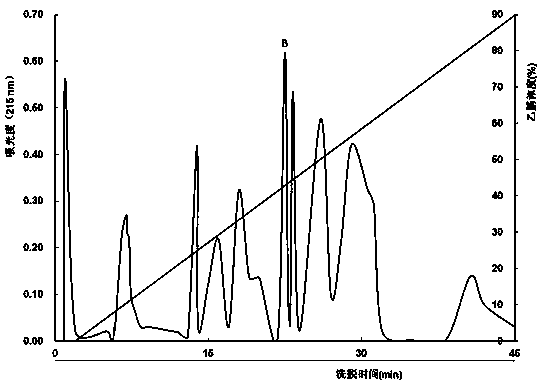

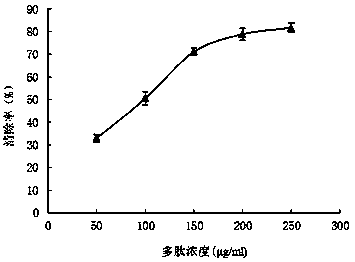

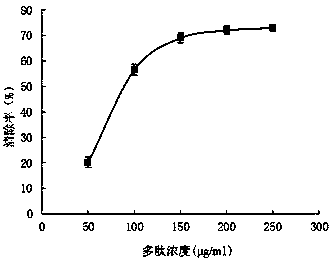

ActiveCN104356200AResolve concernsImprove low utilizationPeptide preparation methodsFermentationOrganic chemistryAnti oxidant

The invention provides an anti-oxidative peptide and a preparation method thereof. The preparation method comprises the steps of performing zymolysis, separation and purification on acid protease by using sea cucumber meat or sea cucumber visceral protein as the raw material to obtain the specific anti-oxidative peptide. The complete sequence of amino acid is gavlgty. The anti-oxidative peptide disclosed by the invention makes up the defects of natural antioxidants, reduces anxiety of the public about artificially synthesized antioxidants, and lays the foundation for developing the anti-oxidative peptide based on a food source and widely applying the anti-oxidative peptide based on the food source to foods and medicine.

Owner:FUZHOU UNIV

Antioxidative peptide

ActiveCN103880933AImprove low utilizationSolve the problem of efficient utilizationPeptide preparation methodsAlgae/lichens peptidesMedicineChlorella sp.

The invention provides an antioxidative peptide and a preparation method thereof. The method is used for obtaining the specific antioxidative peptide from chlorella protein as the raw material by virtue of enzymolysis of an acid proteinase, separation and purification; the amino acid complete sequence of the specific antioxidative peptide is aetiglap. The shortcomings of a natural antioxidant are overcome and the worry of the public on an artificially synthetic antioxidant is eliminated, and a foundation is laid for developing the antioxidative peptide based on food sources and exploring the wide application of the antioxidative peptide in foods and medicines.

Owner:FUZHOU UNIV

Method for producing phosphorus-potassium-silicone-calcium multi-element microporous mineral fertilizer (soil conditioner)

InactiveCN104844302ASolve the problem of efficient utilizationFertilizer mixturesPhosphateFree cooling

A method for producing phosphorus-potassium-silicone-calcium multi-element microporous mineral fertilizer (soil conditioner) by a hydrothermal chemical method comprises the following steps: uniformly mixing finely ground potassium-rich rock, lime and phosphate ore according to the mass percent ratio of (38.5%-52.25%):(31.5%-42.7%):(30%-5%) with water, wherein the water-solid ratio is (1:1)-(3:1); then transferring the slurry into a reaction kettle to make the slurry react for 8-24h under saturated vapor pressure at 160-250DEG C, and naturally cooling a reaction product to room temperature; and drying and crushing the reaction product to obtain the phosphorus-potassium-silicone-calcium multi-element microporous mineral fertilizer (soil conditioner).

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

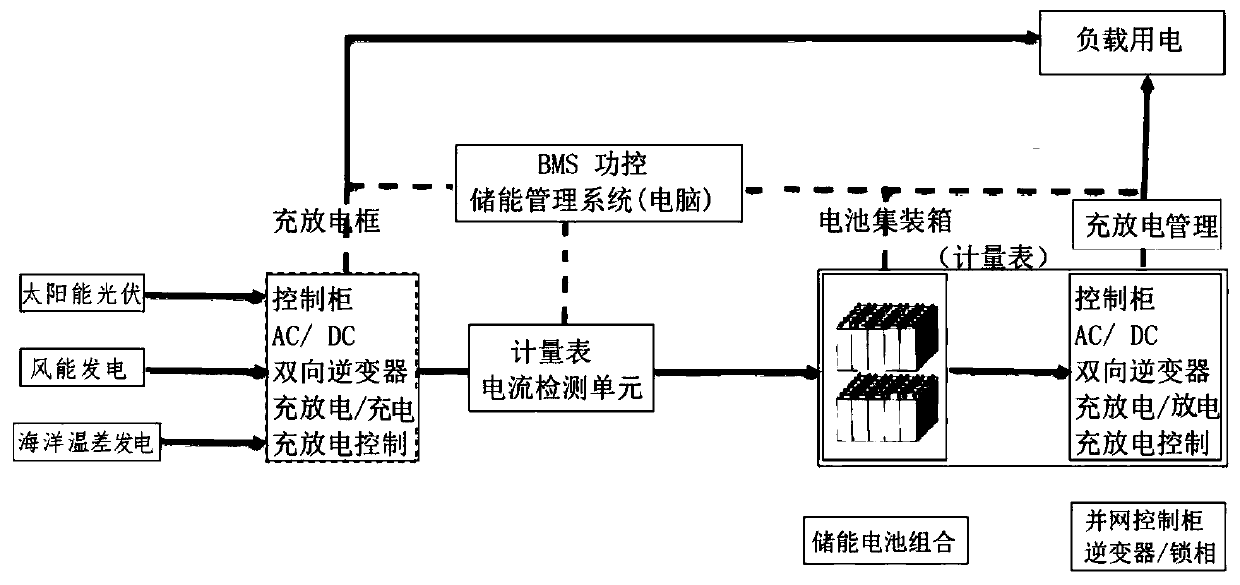

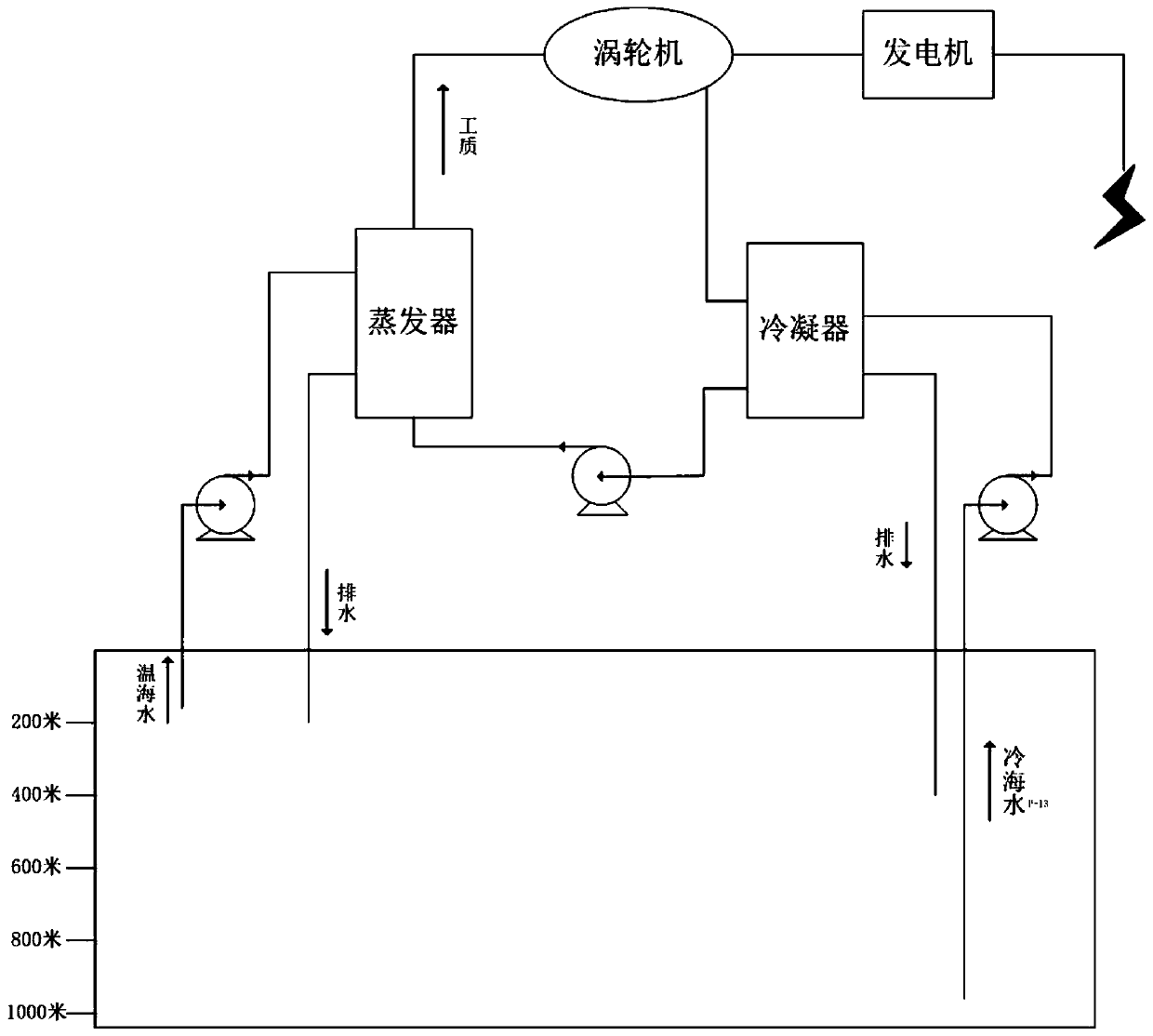

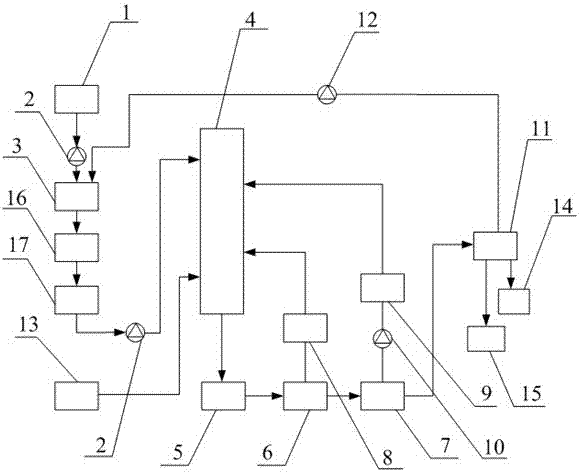

Multi-energy complementary offshore energy integrated power generation system

ActiveCN110649861ASolve the problem of efficient utilizationEfficient use ofGeneral water supply conservationPV power plantsControl theorySeawater

The invention discloses a multi-energy complementary offshore energy integrated power generation system, which comprises a wind power generation system, a photovoltaic power generation system and an ocean temperature difference energy power generation system, and is also equipped with an energy storage system and a seawater desalination system. The output voltage of the ocean temperature difference energy power generation system is subjected to voltage stabilization, voltage regulation and constant current treatment through an AC / DC bidirectional inversion device, and the output voltage is stable. An energy storage battery pack is charged through a charging and discharging module, and charging is stopped when the electric quantity of the battery pack reaches a set upper limit. When the AC / DC bidirectional inversion device charges the energy storage battery pack, if a load needs electric energy, a DC / AC inserter carries out conversion and outputs electricity suitable for the load to theload. According to the scheme, more types of energy are integrated for multi-energy complementation, offshore energy is fully utilized, and the light energy power generation system, the wind energy power generation system and the ocean temperature difference energy power generation system are coupled to solve the problem of comprehensive and efficient utilization of energy is.

Owner:宁波莲腾智慧能源科技有限公司

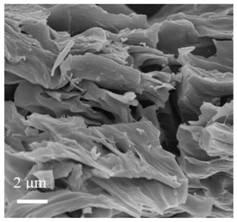

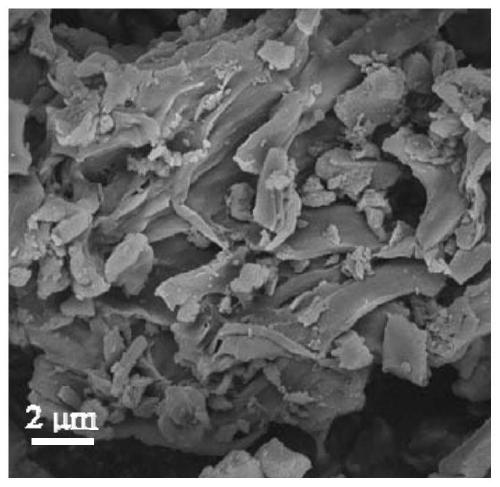

Method for producing nitrogen-doped porous biochar from waste biomass and application of nitrogen-doped porous biochar

InactiveCN110142024AImprove adsorption capacityWide variety of sourcesOther chemical processesWater contaminantsVacuum dryingBiochar

The invention discloses a method for producing nitrogen-doped porous biochar from waste biomass and application of the nitrogen-doped porous biochar. The material produced by using a wide range of biomass of mangosteen peel, lemon peel, watermelon peel, banana peel and the like as raw materials through a template method and a hydrothermal method can efficiently remove heavy metal in water. The method for producing the nitrogen-doped porous biochar from the waste biomass comprises the following steps of (1) thoroughly washing, drying and crushing the peel, sequentially adding an aqueous solution in which a nitrogen source is dissolved and an ethanol solution in which a template agent is dissolved, and conducting stirring after ultrasonic treatment is conducted; (2) transferring a solution in the step (1) into a hydrothermal reactor, heating the hydrothermal reactor to 140 DEG C, maintaining the temperature for 6 h, and after a mixture is taken out, conducting cooling and vacuum drying;(3) grinding solid into powder, then heating the powder to 400-700 DEG C in a nitrogen atmosphere at the heating speed of 2-10 DEG C / min, maintaining the temperature for 2 h, and then cooling the powder to room temperature; and (4) washing a sample with ethyl alcohol three times, then washing the sample with water three times, and conducting vacuum drying to obtain the nitrogen-doped biochar material high in adsorption performance. According to the material, a production cycle is short, the process is simple and convenient, when the material is used for adsorbing the heavy metal of lead (Pb[II]), copper (Cu[II]), chromium (Cr[VI]), cadmium (Cd[II]) and the like, the adsorption efficiency is high, and the material can be recycled.

Owner:SUN YAT SEN UNIV

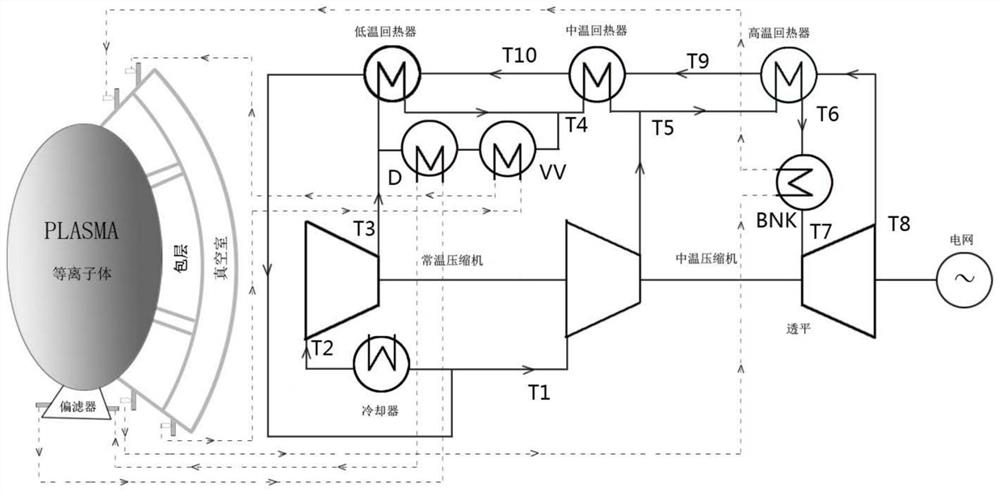

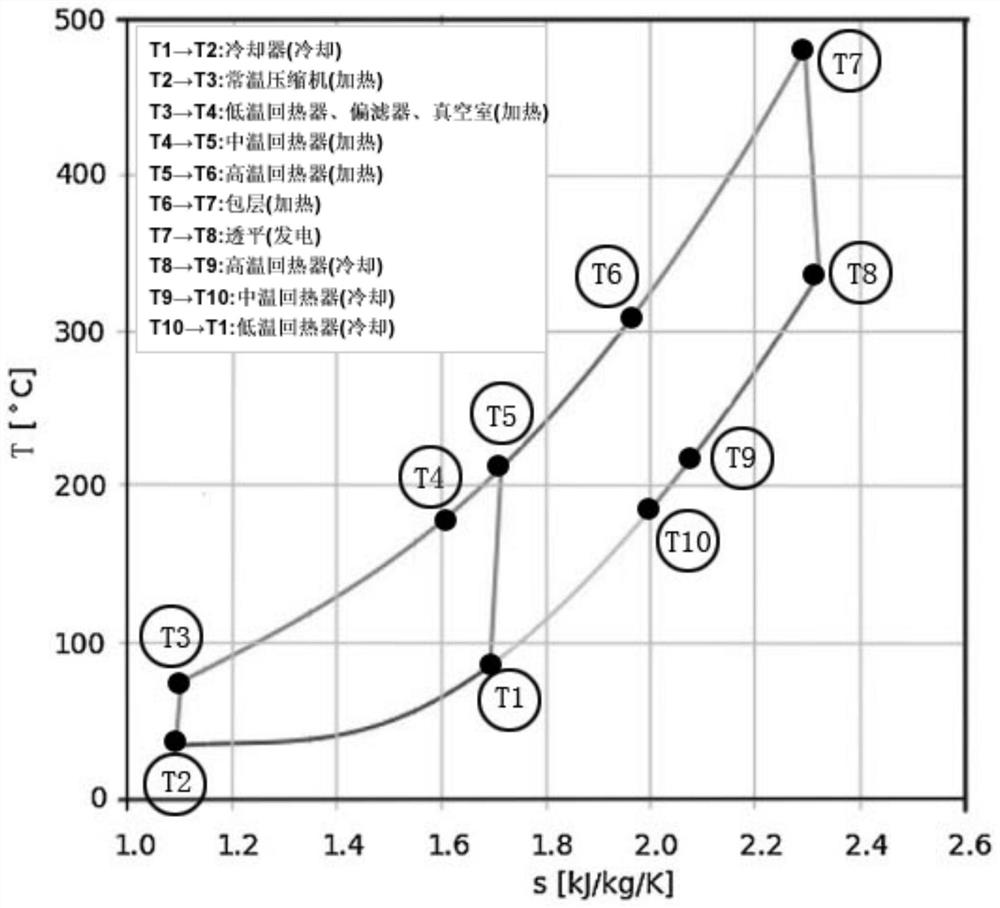

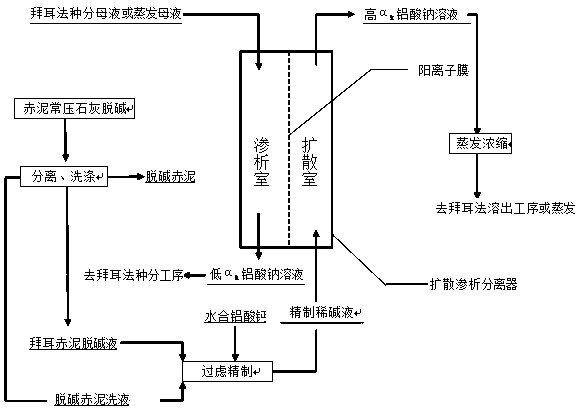

Supercritical carbon dioxide power circulating system and method for fusion reactor

ActiveCN111963267AHigh thermoelectric efficiencyEfficient use ofNuclear energy generationSteam useProcess engineeringDivertor

The invention discloses a supercritical carbon dioxide power circulating system and method for a fusion reactor. Aiming at different working medium conditions of different nuclear heat sources of a fusion reactor cladding layer, a divertor and a vacuum chamber, S-CO2 is heated by stage-by-stage heat regeneration on the high-pressure side and cooled by stage-by-stage heat regeneration on the low-pressure side through three stages, namely a low-temperature heat regenerator, a middle-temperature heat regenerator and a high-temperature heat regenerator; 20 percent of S-CO2 is selected to be cooledand then pressurized and heated so as to be used for heat regeneration of a low-temperature heater and cooling of the divertor and the vacuum chamber, so that the operation requirements of differentcooling media for different heat sources of three components in the reactor are met, a negative temperature effect during heat regeneration is avoided, the heat sources of all components in the reactor are effectively utilized, and the heat energy utilization efficiency is greatly improved; and compared with the current designs only using helium gas carrying cladding layer core heat and a Rankinecirculatory system with two-loop pressure water heat exchange to generate electricity, the thermoelectricity efficiency of the fusion reactor is improved to 41 percent from 30 percent, and the supercritical carbon dioxide power circulating system for the fusion reactor has the remarkable advantages of simple structure, low cost, high heat efficiency and the like.

Owner:ANHUI UNIVERSITY

Multistage high-efficiency flash evaporation sludge dewatering treatment system and method thereof

PendingCN107010809AImprove heat drying effectSolve pyrolysisSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisMulti-stage flash distillationProcess engineering

The invention discloses a multistage high-efficiency flash evaporation sludge dewatering treatment system and a method. The utilization problem of sludge pyrolysis multistage flash evaporation secondary steam is solved in the invention. The system comprises a pretreatment unit, a boiling unit, a multistage flash evaporation unit and a dewatering and backmixing unit, the pretreatment unit comprises a mixer for mixing the sludge through a rotor pump, the boiling unit comprises a heater connected with the sludge mixer and a boiler connected with the heater, the multistage flash evaporation unit comprises a flash evaporation device and a heat energy recovery device for conveying steam in the flash evaporation device to the heater, the dewatering and backmixing unit comprises a screw dewaterer for conveying separated water to the sludge mixer through a reuse water pump, the screw dewaterer is connected with a secondary flash evaporation device. The method sequentially comprises: sludge mixing, heating treatment, continuous flash evaporation and dewatering separation. The system and the method are adopted to recover the flash evaporation secondary steam, so the heat energy utilization rate in the sludge treatment process and the reliability of a sludge treatment device are increased.

Owner:四川省科学城中心科技有限公司

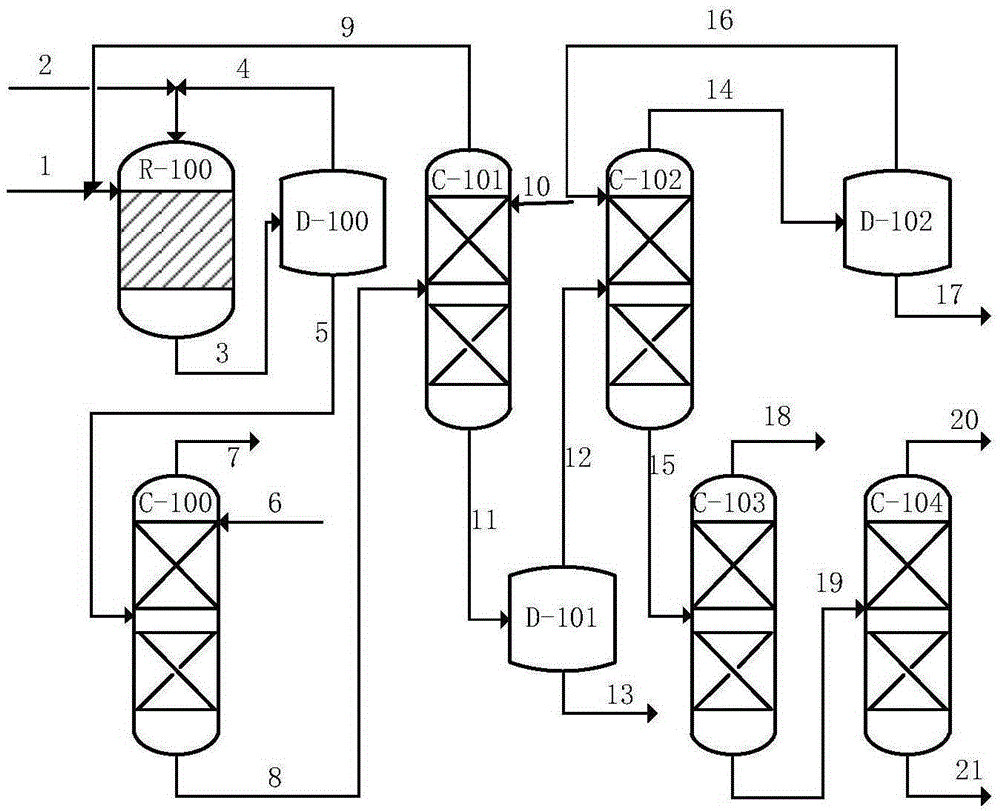

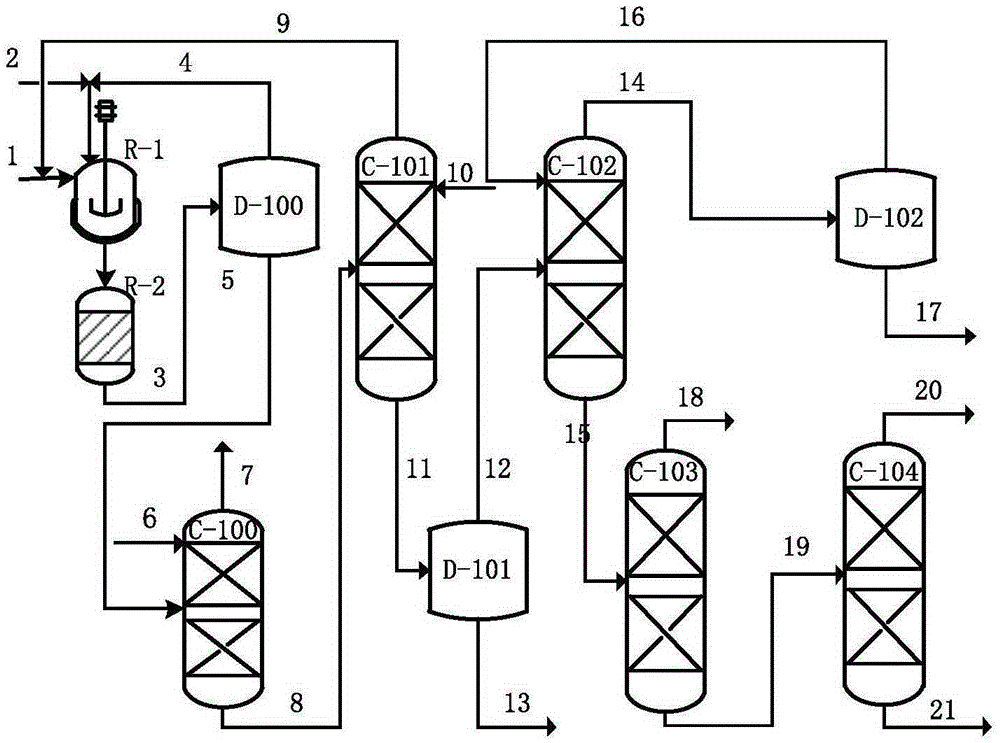

Method for preparing methyl isobutyl ketone from industrial by-product effluent acetone

ActiveCN106565446ASolve the problem of efficient utilizationAvoid wastingOrganic compound preparationChemical industryAlcoholMethyl isobutyl ketone

A method for preparing high-purity methyl isobutyl ketone (MIBK) from an industrial by-product effluent acetone comprises the following steps: converting epoxide impurities in the effluent acetone into corresponding tertiary alcohol during the process section I; converting acetone into MIBK during the process section II; and realizing conversion of the above tertiary alcohol and separation from MIBK through reactive distillation. In cooperation of optimal refining process, a high-purity MIBK product can be easily prepared. By the technology, the byproduct effluent acetone is converted into an MIBK product with high added value. The equipment has remarkable economical benefit.

Owner:WANHUA CHEM GRP CO LTD

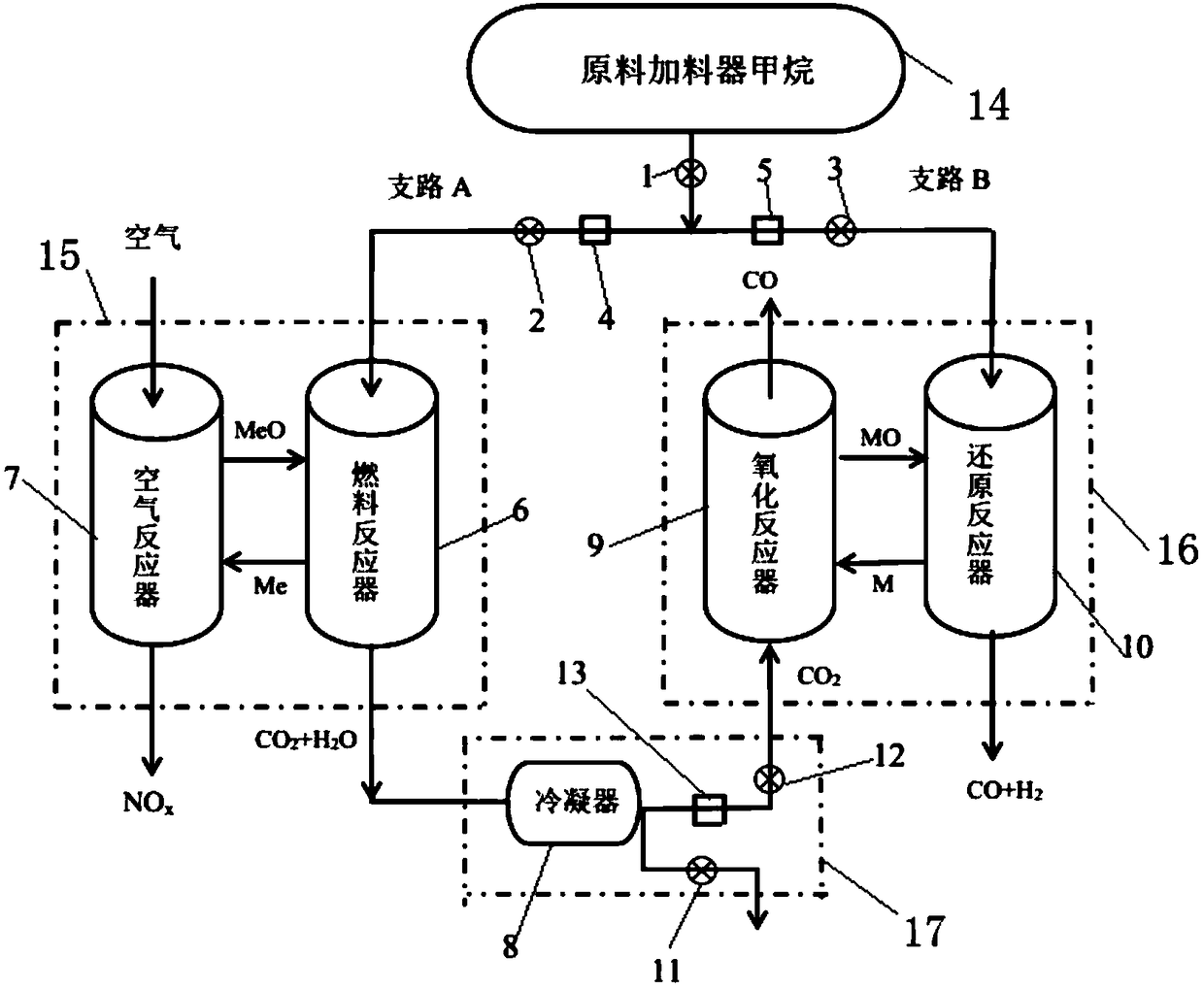

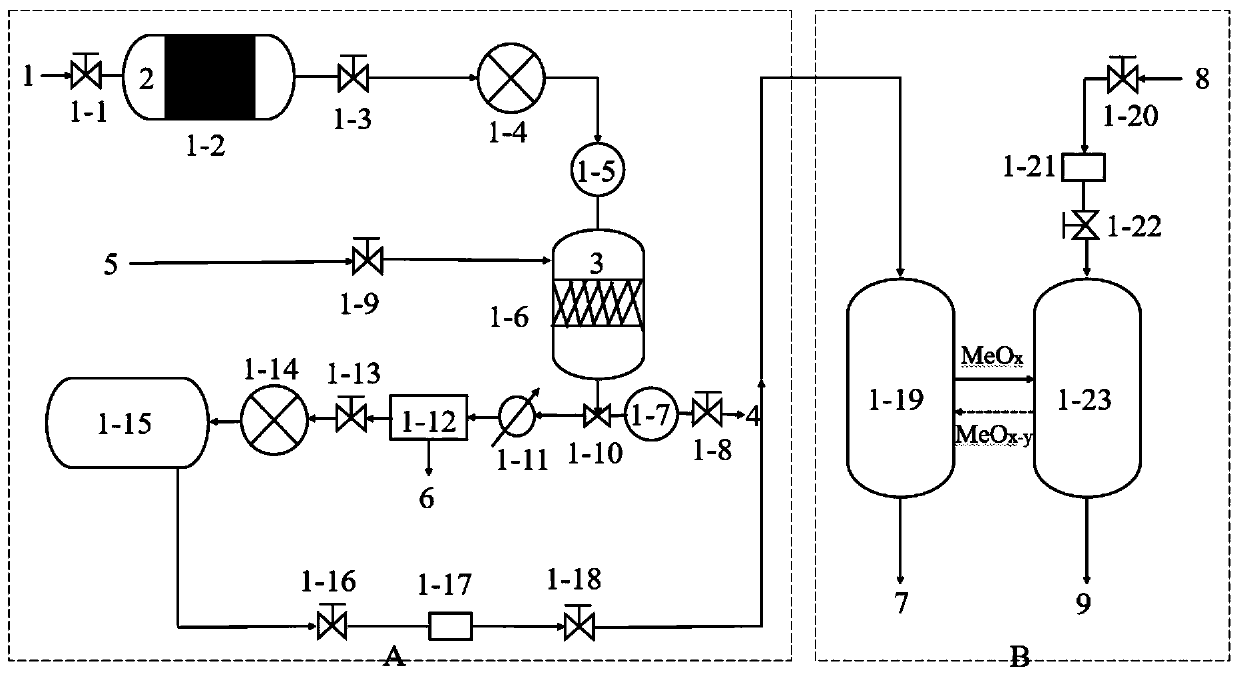

Device and method for coproducing synthesis gas through coupling of carbon dioxide capturing process and methane reforming process

ActiveCN108117045ASimple structureSimple compositionHydrogenHydrogen/synthetic gas productionSyngasCombustion

The invention relates to a device and method for coproducing synthesis gas through the coupling of a carbon dioxide capturing process and a methane reforming process. The method comprises the following steps: reacting by virtue of methane and a first oxygen carrier in a fuel reactor so as to generate CO2 and H2O, transferring the reduced first oxygen carrier into an air reactor to react with air to supplement lattice oxygen, after oxidation restoring, and returning the first oxygen carrier to the fuel reactor for supplying lattice oxygen to the combustion reaction of methane, so as to realizecycle use; introducing methane into a reduction reactor to react with a second oxygen carrier in the reduction reactor, so as to generate synthesis gas CO and H2; and separating, introducing obtainedhigh-purity CO2 into an oxidation reactor, transferring the reduced second oxygen carrier in the reduction reactor into the oxidation reactor to be oxidized again, introducing the oxidized second oxygen carrier into the reduction rector, so as to realize cycle use. According to the method, the low-cost capturing and local conversion utilization of CO2 are realized, meanwhile, the quality and selectivity of the synthesis gas are improved, and the structure and constitution of the reactors are optimized; and the method meets the requirements of a circular economy conception.

Owner:NORTHWEST UNIV

Snapper anti-oxidation polypeptide and preparation method thereof

ActiveCN106589068AEliminate side effectsResolve concernsPeptide preparation methodsFermentationProteinase activityEnzymatic hydrolysis

The invention provides a snapper anti-oxidation polypeptide and a preparation method thereof. The method is characterized in that using the enzymatic hydrolysis of acidic protease to the pure anti-oxidation polypeptide is obtained through acid proteinase hydrolysis of snapper skins or fish scale proteins used as a raw material, separation and purification, and the amino acid sequence of the polypeptide is ASTSNLKKAVHL. The snapper anti-oxidation polypeptide eliminates the defects of natural antioxidants, eliminates public concerns about synthetic antioxidants, and lays a foundation for the development of food-based anti-oxidation polypeptides and exploring of the wide application of the anti-oxidation polypeptide in foods and medicine science.

Owner:FUZHOU UNIV

Method for preparing compound microbial inoculant by microbially decomposing Bayan Obo potassium-rich slate

ActiveCN103667143AReduce energy consumptionReduce consumptionFungiBacteriaRare-earth elementMinor element

The invention discloses a method for preparing a compound microbial inoculant by microbially decomposing Bayan Obo potassium-rich slate, which comprises the following steps: decomposing Bayan Obo potassium-rich slate ores in a liquid fermentation culture medium by using Bacillus megaterium (AS1.459, GIMCCGIM1.14), thus obtaining a leach solution containing potassium, phosphorus, sulfur, minor elements, rare-earth elements and other minerals required by plants; and mixing the leach solution and a commercially available EM microbial inoculant according to a volume ratio of 1:1, thus obtaining the compound microbial inoculant containing multiple mineral elements (potassium, phosphorus and sulfur). The method causes less pollution and is low in energy consumption; and the Bayan Obo potassium-rich slate ores are used as raw materials, thus lowering the cost and eliminating the pollution of rejected ores to environment. The raw materials (Bayan Obo potassium-rich slate ores) in the method can be sufficiently decomposed, thereby greatly improving the utilization ratio of the ores.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Preparation method of rabbit manure biological feed

InactiveCN104472858AGood for digestion and absorptionImprove the use effectAnimal feeding stuffWater contentChemistry

The invention belongs to the field of biological feed processing, and particularly discloses a preparation method of rabbit manure biological feed. The preparation method comprises the following steps: preparing slurry from rabbit manure powder and a water extraction concentrate of residue of edible mushrooms at the weight ratio of 1:(5-15), placing the slurry at the temperature of 80-90 DEG C, carrying out the Maillard reaction for 36-50 hours, adding a compound microorganism bacterium accounting for 4-8 percent by weight of the slurry, culturing and fermenting for 72-150 hours under the conditions that the temperature is 26-40 DEG C, the stirring speed is 50-180 rpm and the ventilatory capacity is 1:(0.3-1.5)V / V / min, carrying out vacuum concentration on the fermented slurry into thick paste under the conditions that the temperature is 33-36 DEG C and the pressure is -0.065-0.095 MPa, then carrying out low-temperature vacuum drying till the water content is 6-8%, smashing and screening, carrying out dry-type vertical compression pelletizing to obtain the rabbit manure biological feed. According to the preparation method, the efficient utilization of the residue of the edible mushrooms can be achieved, the application value of the rabbit manures as the feed is improved, waste resources are used to the hilt, the industrial chain is expanded, the comprehensive utilization benefits of edible mushrooms cultivation and the meat rabbit breeding industry waste are increased, the economic benefits are increased, and the ecological environment is protected.

Owner:邳州市小河科技发展有限公司

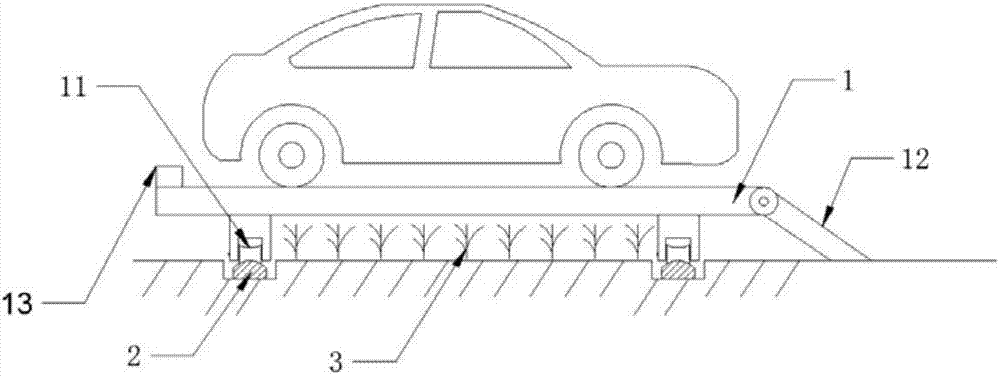

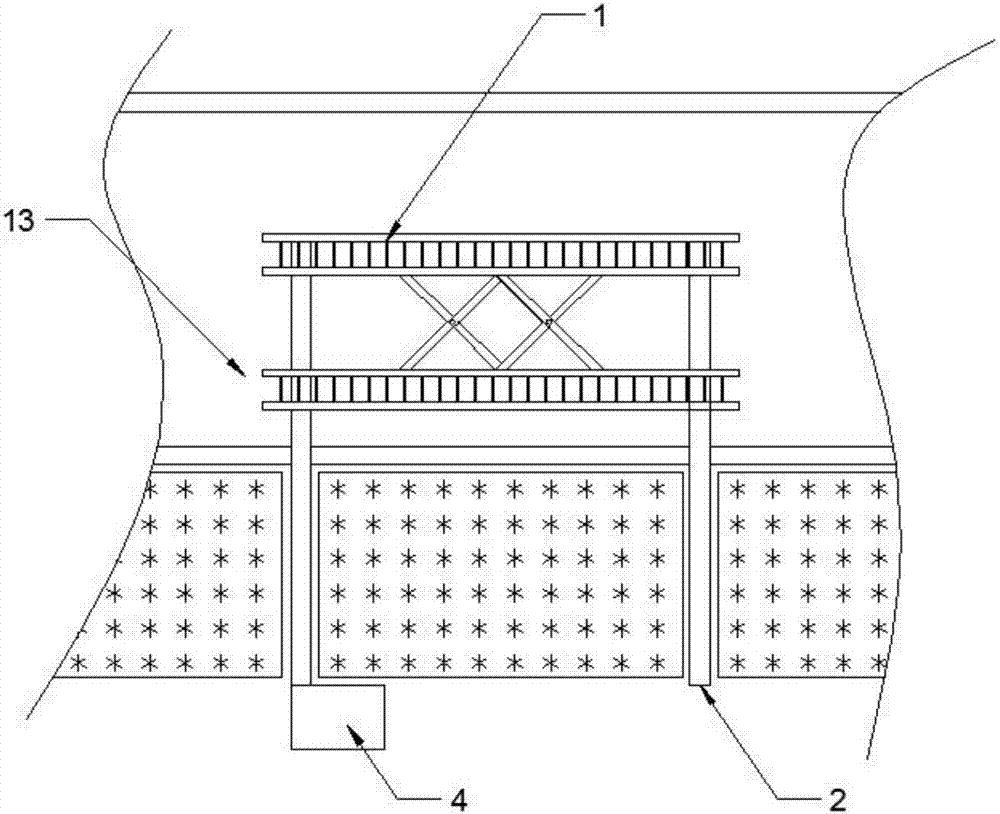

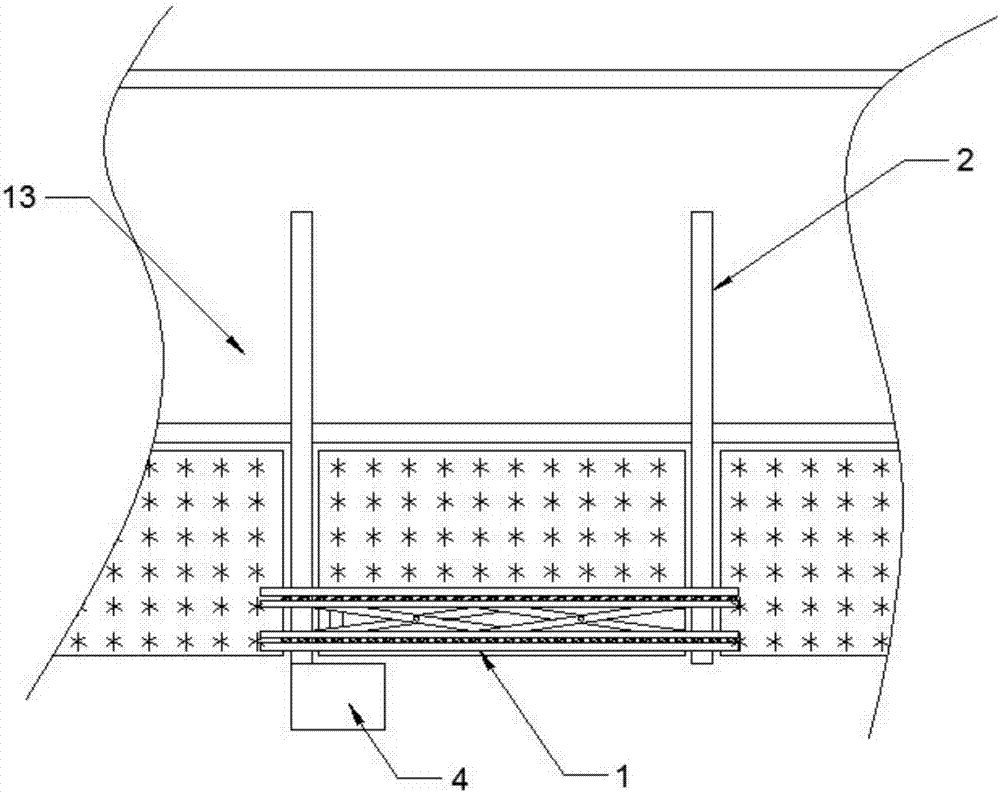

Green belt parking device

PendingCN106894660ASolve the problem of efficient utilizationTake advantage ofParkingsStructural engineeringPower apparatus

The invention provides a green belt parking device and belongs to the field of parking devices. Aiming at the problem that an existing green belt parking device is large in occupied area or complex in construction, the invention provides the green belt parking device which is simple in structure and small in occupied area. The green belt parking device comprises a slide rail located on a green belt and laid perpendicular to a curbstone; and the slide rail stretches out of a street through the green belt by the distance of at least one car body width on the street, and a parking platform is installed on the slide rail, moves on the slide rail through rollers at the bottom of the parking platform and a power unit, is of a folding structure and comprises at least two supporting girders parallel to the curbstone and retractable net structures connected with every two adjacent supporting girders. According to the green belt parking device, though the structure similar to a retractable door, the conditions that when being used, the parking platform stretches, and when being unused, the parking platform contracts are achieved; and the occupied area is reduced as far as possible, and the influence on the green belt is reduced.

Owner:CHIZHOU VOCATIONAL & TECHN COLLEGE

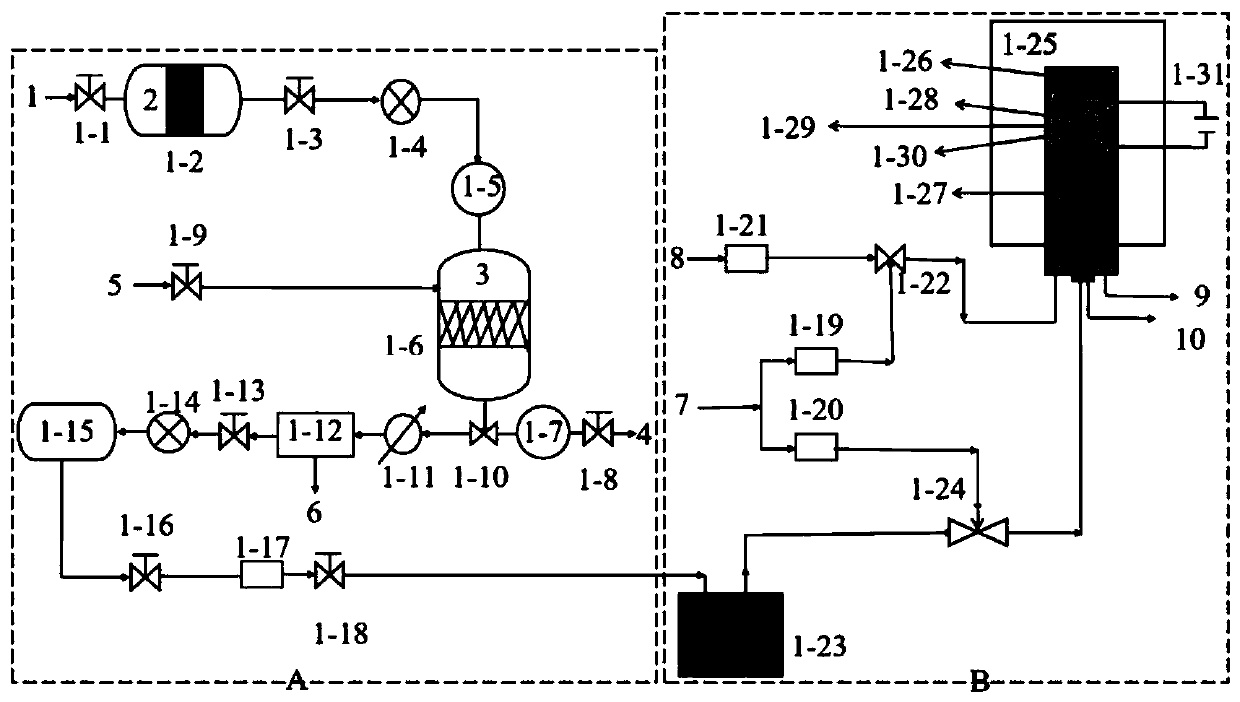

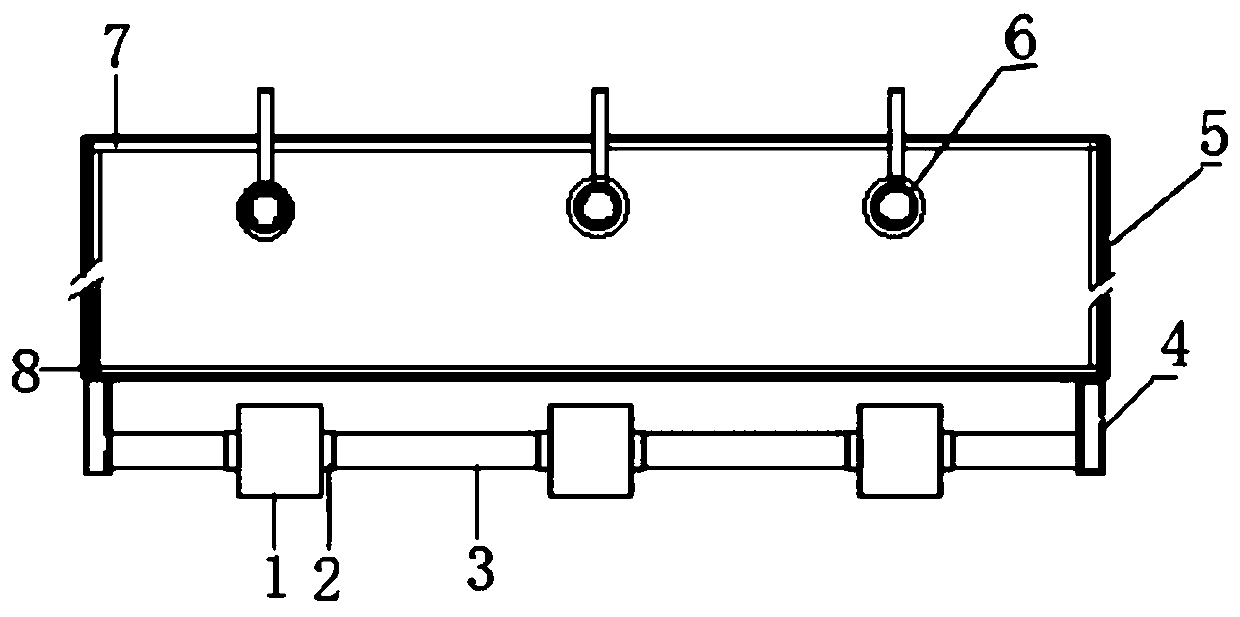

System and method for preparing synthesis gas by electrolyzing low-cost CO2 in solid oxide electrolytic tank

PendingCN111549355AReduce energy consumptionReduce overpotential and power consumptionCellsProductsGreenhouse gasFlue gas

The invention discloses a system and a method for preparing synthesis gas by electrolyzing low-cost CO2 in a solid oxide electrolytic tank. The system is composed of a direct CO2 capture unit and a solid oxide electrolytic tank unit, wherein the direct CO2 capture unit comprises a dryer, a CO2 adsorption chamber, a condenser, a gas-liquid separator, a gas pump, a gas tank, a CO2 concentration detector and the like; the solid oxide electrolytic tank unit comprises a steam generator, a heating furnace, a solid oxide electrolytic tank and the like. According to the system, low-concentration CO2 in air or high-concentration CO2 in flue gas is directly captured by regulating and controlling the humidity of the CO2 capturing unit; the CO2 containing air captured at a low cost is introduced intothe solid oxide electrolytic cell unit, H2O and the CO2 containing air are co-electrolyzed by the cathode of the electrolytic cell to generate synthesis gas, and methane is introduced into the anode of the electrolytic cell to reduce the overpotential of the reaction and generate the synthesis gas. According to the invention, not only is negative emission of CO2 realized, but also resource utilization of greenhouse gas is achieved, so that environmental and economic benefits are obtained.

Owner:NORTHWEST UNIV

System and method for coupling co-production of synthetic gas

InactiveCN109718630AReduce energy consumptionSolve energy efficient utilization and environmental protectionHydrogenProductsChemistryCarbon dioxide

The invention discloses a system and a method for coupling co-production of synthetic gas. The system is composed of a unit for directly capturing carbon dioxide in air and a unit for preparing the synthetic gas by chemically circularly reforming methane, wherein the unit for directly capturing carbon dioxide in air comprises a dryer for drying air, a carbon dioxide adsorption chamber for capturing carbon dioxide, a condenser, a gas-liquid separator, a gas pump, a gas tank for storing desorbed carbon dioxide and a carbon dioxide concentration detector; and the unit for preparing the syntheticgas by chemically circularly reforming methane includes a reduction reactor and an oxidation reactor. The system controls the adsorption and desorption process of carbon dioxide in the air by adjusting the humidity of the carbon dioxide capturing unit, and a mixed gas composed of the desorbed carbon dioxide and the air is stored in the gas tank, and enters the methane chemical circular reforming unit through a gas tank gas discharge valve under the control of a mass flow meter. The method realizes the integration of the negative emission of carbon dioxide and the conversion and regeneration ofenergy, and improves the economic benefit of the carbon dioxide in the air.

Owner:霖和气候科技(北京)有限公司

Production method of super-selenium-enriched tenebrio molitor

ActiveCN109496992ASolve the problem of efficient utilizationTo achieve the purpose of enriching seleniumFood processingAnimal feeding stuffAnimal scienceEconomic benefits

The invention relates to a production method of super-selenium-rich tenebrio molitor, and straw, leftovers of agricultural production and selenium-containing raw materials are directly subjected to fungal conversion so as to become a nutritional feed loved by tenebrio molitor. According to the method, the cost of the breeding feed is reduced to be less than one third of that of an original feed, the purpose of selenium enrichment is achieved, the breeding economic benefit is increased by more than three times, and the problem that the crop straw is efficiently utilized is solved.

Owner:湖南袁禾农业科技有限公司

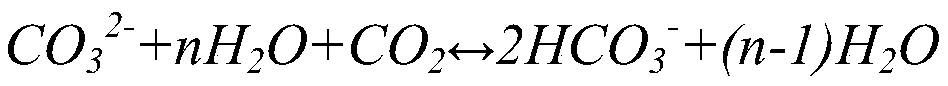

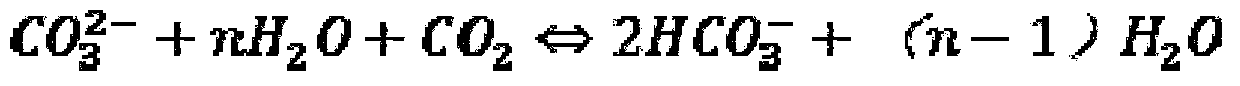

Method for systematically reducing process alkali consumption and improving process efficiency of Bayer process

InactiveCN108946777AReduce alkali consumptionSolve the problem of efficient utilizationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationDecompositionSodium aluminate

The invention discloses a method for systematically reducing process alkali consumption and improving the process efficiency of a Bayer process. The method comprises the following steps: refining diluted alkali liquor generated in a Bayer red mud dealkalization process to obtain refined diluted alkali liquor, and treating the refined diluted alkali liquor with decomposing mother liquor or evaporating mother liquor in the Bayer process in a volume ratio of 1.0-2.0 by adopting a cationic membrane diffusion dialysis separator to obtain a low alpha-k sodium aluminate solution having alpha-k beingless than 2.00 or a high alpha-k sodium aluminate solution having alpha-k being more than 6.50; and decomposing the low alpha-k sodium aluminate solution in a seed precipitation process, and evaporating the high alpha-k sodium aluminate solution for dissolving bauxite, or directly dissolving bauxite in the dissolving process of the Bayer process. According to the method, the diluted alkali liquorgenerated in the red mud dealkalization process can be recycled, the seed precipitation decomposition rate of the Bayer process can be increased by 65 percent or more, and the aim of greatly improvingthe efficiency of the Bayer process is achieved.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

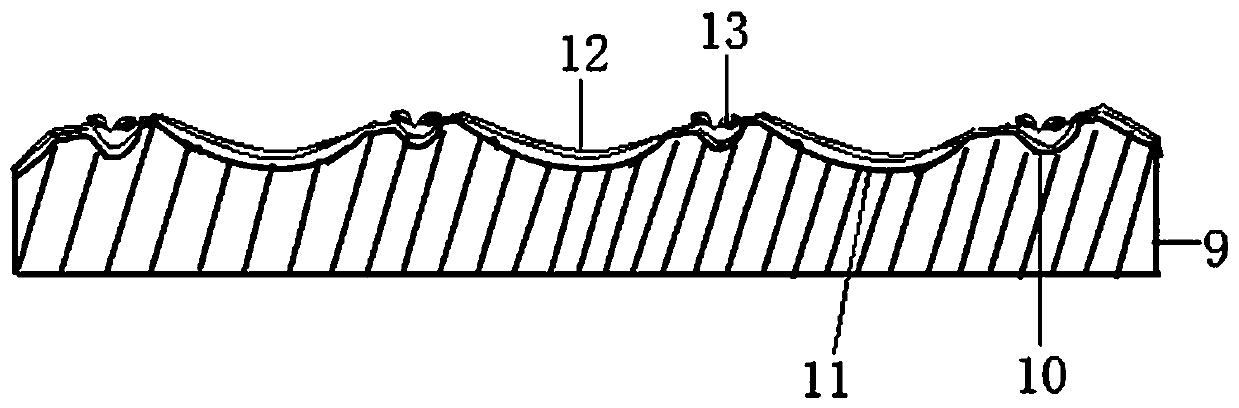

Biodegradable water-permeable mulching film ridge back microgroove multi-row mechanical film-mulching and sowing method

The invention discloses a biodegradable water-permeable mulching film ridge back microgroove multi-row mechanical film-mulching and sowing method and aims to solve the problem of efficient utilizationof drizzle resource and nutrient by dry land in semiarid areas and the problem that full-biodegradable mulching films are too fast in breaking and disintegrating in the crop seedling period. The method includes: making a steel roller compacting and shaping module which is structurally characterized in that a cylindrical steel roller is mounted on a steel shaft in a sleeved manner, and steel ringsfor fixing the steel roller sleeve two sides of the steel roller; mounting a ditching disc at a position, corresponding to the middle of a sowing ground ridge back, of a front crossbeam of a rack ofa film-mulching sowing machine, connecting two ends of the steel shaft at positions, 150mm away from the rear end, of longitudinal beams on two sides of the rack of the film-mulching sowing machine through hanging plates in a hanging manner, and enabling the ditching disc and the steel roller to be on a same straight line; starting the film-mulching sowing machine to work, wherein the ditching disc forms a microgroove in the middle of each ridge back, the steel roller rolls along the microgroove in the middle of each ridge back to compact and shape to form a ridge back microgroove, the ridge back microgrooves and planting ditches form a wavy rain collection terrain, and then the machine automatically completes film mulching, earthing and punch dibbling processes.

Owner:山西省农业科学院农业资源与经济研究所 +2

Anti-oxidization bone collagen polypeptide and preparation method thereof

ActiveCN108250291AImprove low utilizationSolve the problem of efficient utilizationFood ingredient as antioxidantConnective tissue peptidesChymaseImmunogenicity

The invention relates to anti-oxidization bone collagen polypeptide and a preparation method thereof, aiming at solving the technical problems of an existing product that the source is single and theimmunogenicity exists. An amino acid sequence is shown as a sequence table 1. The invention also provides a preparation method of the anti-oxidization bone collagen polypeptide; collagen is extractedby taking tuna bones as a source; then the collagen is subjected to enzymolysis by adopting a tyrisin-chymase complex enzyme and then is separated and purified, and frozen and dried to obtain the anti-oxidization bone collagen polypeptide. The anti-oxidization bone collagen polypeptide can be used for the field of preparation of the anti-oxidization polypeptide.

Owner:BEIJING UNIV OF CHEM TECH

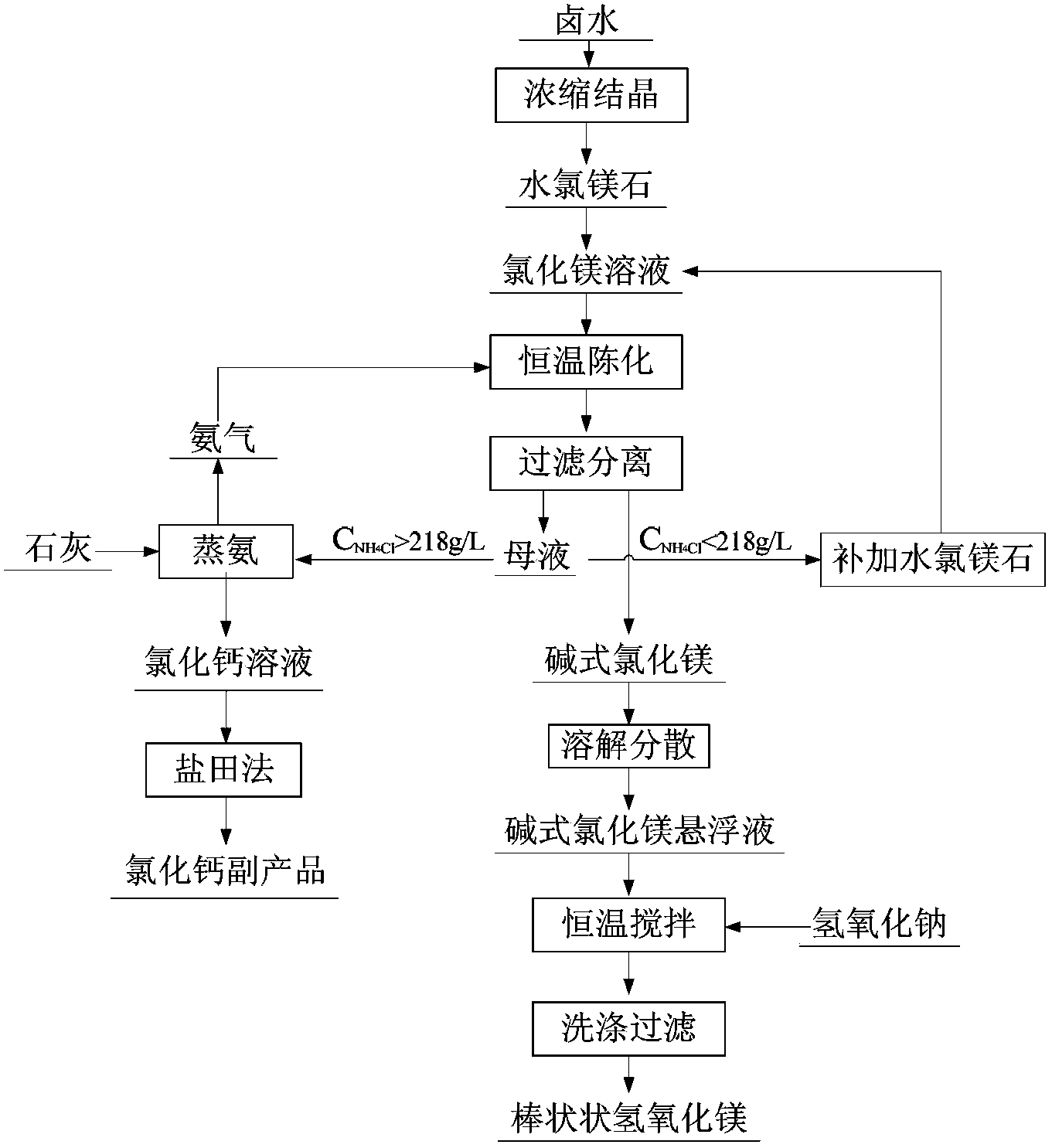

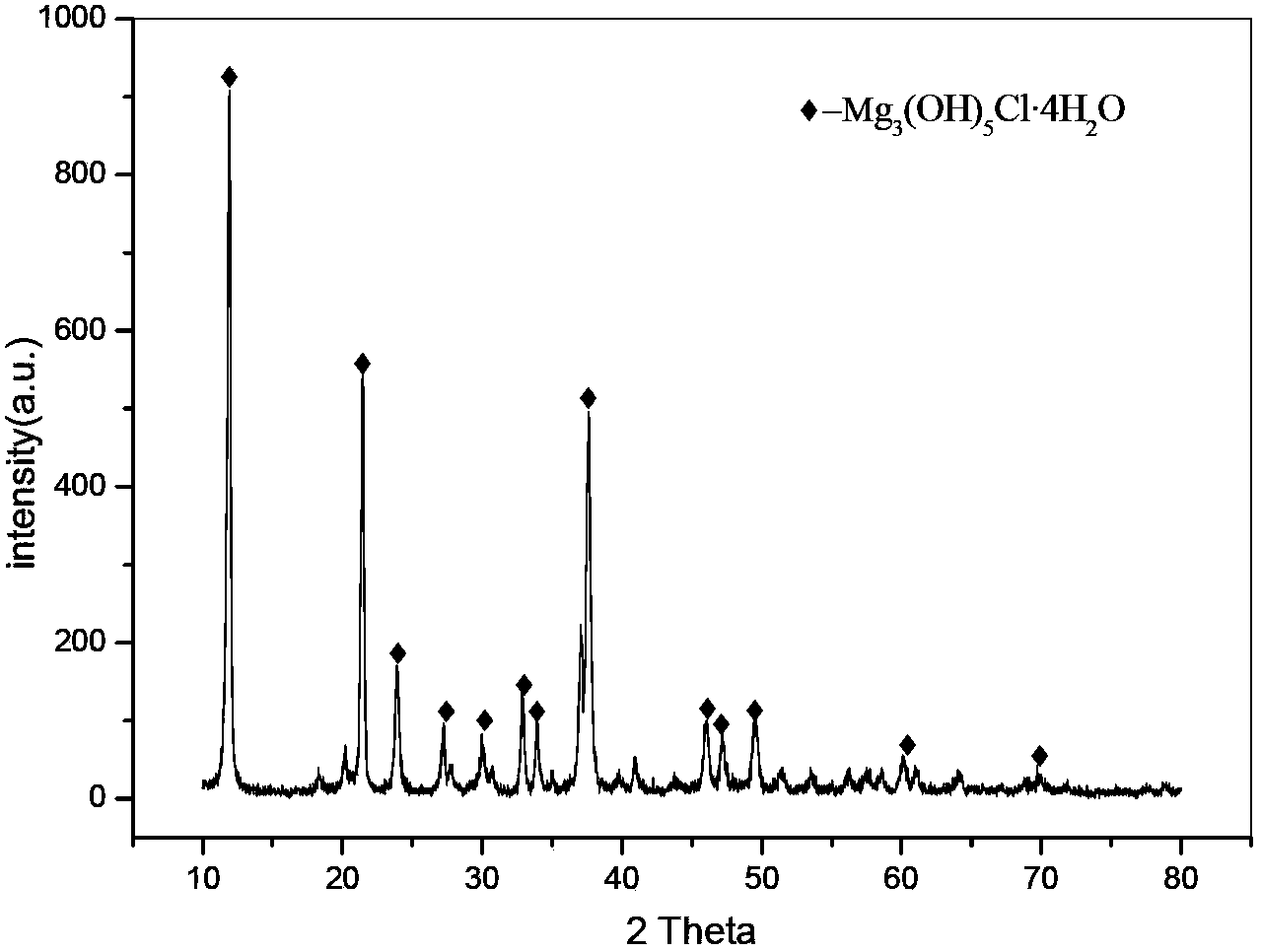

Method for preparing rod-like magnesium hydroxide from salt lake brine

InactiveCN102674409BLarge particlesImprove filtering effectCalcium/strontium/barium chloridesMagnesium hydroxidePotassiumSodium hydroxide

The invention discloses a method for preparing rod-like magnesium hydroxide from salt lake brine. The method comprises the following steps of: concentrating and crystallizing salt lake brine, from which elements such as potassium and lithium are extracted, serving as a raw material to obtain bischofite; dissolving the bischofite separated by crystallization into water to prepare magnesium chloride solution; introducing ammonia gas to perform magnesium precipitation reaction; when the pH value reaches 7-8, stopping introducing the ammonia gas, reacting at the temperature of 30-50 DEG C for 0.5-2 hours, aging and filtering to obtain alkaline magnesium chloride and magnesium precipitation mother liquor; dispersing the alkaline magnesium chloride in mixed solution of ethanol and water to obtain alkaline magnesium chloride suspension; adding sodium hydroxide to further precipitate to obtain rod-like magnesium hydroxide; filtering and separating to obtain magnesium precipitation mother liquor; replenishing the bischofite and circulating for precipitating the alkaline magnesium chloride; feeding to an ammonia still process along with concentration enrichment of magnesium precipitation mother liquor in ammonia chloride; performing ammonia still with lime; and circulating the produced ammonia gas to precipitate the alkaline magnesium chloride of a next batch and producing byproduct calcium chloride, wherein the magnesium content in the brine is not less than 93.4 g / L. The method has the advantages of high product purity, good economic benefit, no environmental pollution, high operability and easiness for industrial production.

Owner:CENT SOUTH UNIV

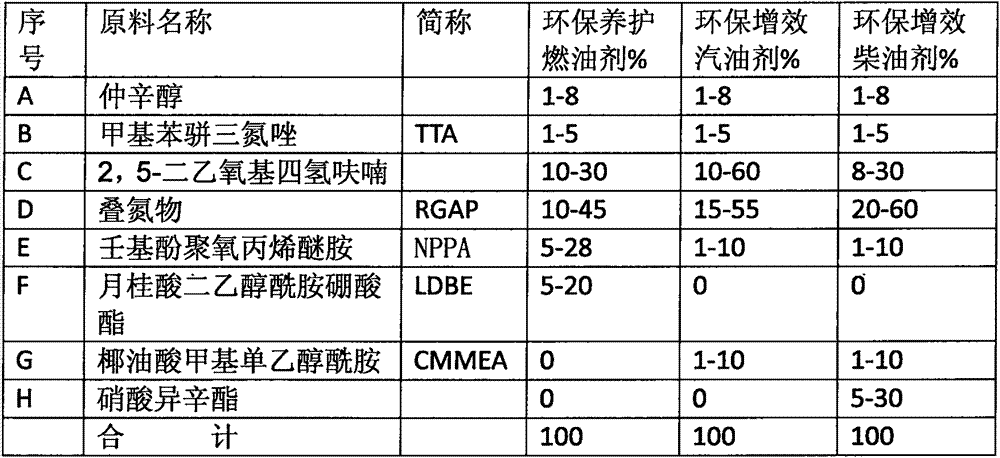

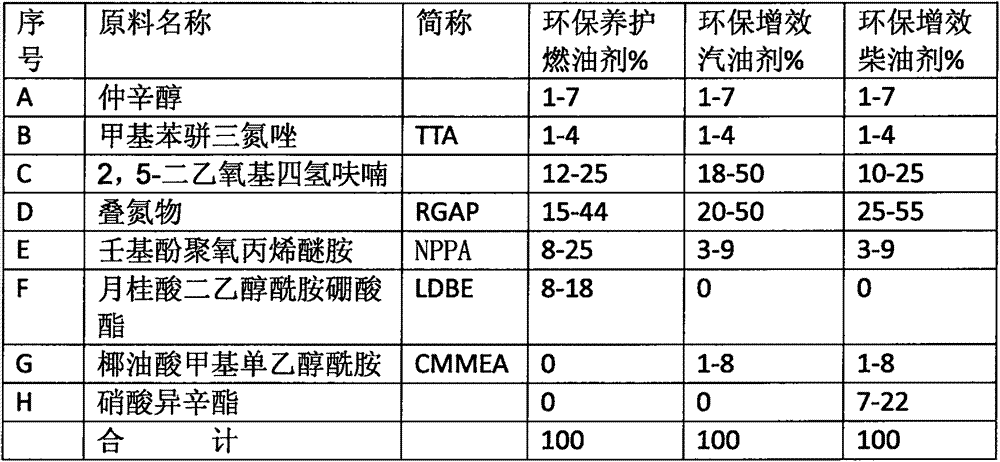

Environment-friendly fuel oil agent for promoting quality and effect of fuel oil and environment-friendly fuel oil

InactiveCN106957700ASolve temperature problemsSolve the problem of efficient utilizationLiquid carbonaceous fuelsThermal energyEnvironmental resistance

The invention relates to an environment-friendly fuel oil agent for promoting quality and effect of fuel oil. The environment-friendly fuel oil agent comprises the following materials by weight percent: 1-9% of octanol, 1-5% of tolyltriazole, 8-60% of 2,5-diethoxy tetrahydrofuran, 10-60% of azide, 1-28% of nonyl phenol polyoxy propylene ether amine, 0-20% of diethanolamide borate laurate, 0-10% of coconut oleate methyl monoethanolamide and 0-30% of isooctyl nitrate. According to the invention, the clean combustion, catalytic combustion and control combustion techniques are organically combined for efficiently removing and preventing scale of an oil-way system and an exhausting system in chemical and physical modes; the surface metal in an engine can be activated to form a powerful catalytic field and a 'flame combustion' mode is converted into 'flameless combustion'; the starting / ending temperature of the control combustion is reduced, the speed is increased, the photo-thermal energy is effectively converted and the thermal radiation rate is increased; and a new mode of instantly breaking liquid oil molecules into gaseous micro-molecule residues and then quickly, thoroughly and cleanly combusting with the stimulated oxygen is realized and the optimization of the quality of the fuel oil and the upgrading of the effect differentiation are realized.

Owner:聂志守

Method for interplanting of luffa, dry raised seedlings and radishes

InactiveCN103733847ALarge content effectSolve nurturingHorticultureLuffa aegyptiacaSoil organic matter

The invention discloses a method for interplanting of luffa, dry raised seedlings and radishes. The method comprises the steps of land preparation and bedding, luffa cultivation, dry raised seedling cultivation and radish cultivation. Quite a number of easily thoroughly decomposed vegetable fresh stem leaves can remain while plenty of vegetables are produced, the effect for improving soil fertility and increasing the content of soil organic matters is extremely high, rice seeding can be directly performed only by simply turning over land, and rice drought seedling pool cultivation and efficient utilization can be achieved well.

Owner:林雪桃

Method for processing fermented brown rice nutrition powder

The invention relates to a method for processing fermented brown rice nutrition powder. The method comprises the following steps: by using a brown rice processing byproduct, namely brown rice nutrition powder as a main raw material, adding a cold solution containing an antioxidant and a flavoring agent for real-time anti-oxidation processing, then adding fresh milk and direct-vat type lactic acid bacteria powder for sealed fermentation, and finally cooling and drying. Through an anti-oxidation technology and a fermentation technology, the method effectively realizes the whole flour utilization and efficient utilization of rice byproducts and fully utilizes the nutritional ingredients of rice lost during processing. The prepared fermented brown rice nutrition powder is rich in major nutrients in rice, good in safety, unique in flavor and convenient to eat, conforms to national food safety standards, and is good for health of people after being often eaten.

Owner:湖南米珍宝生物高科技有限公司

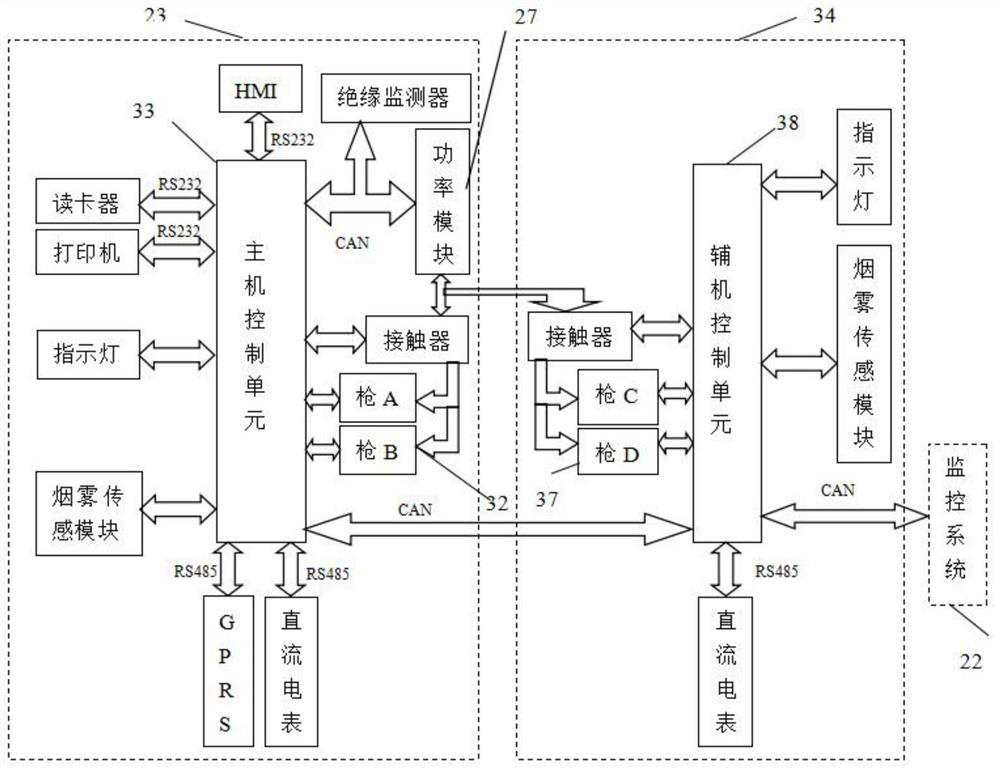

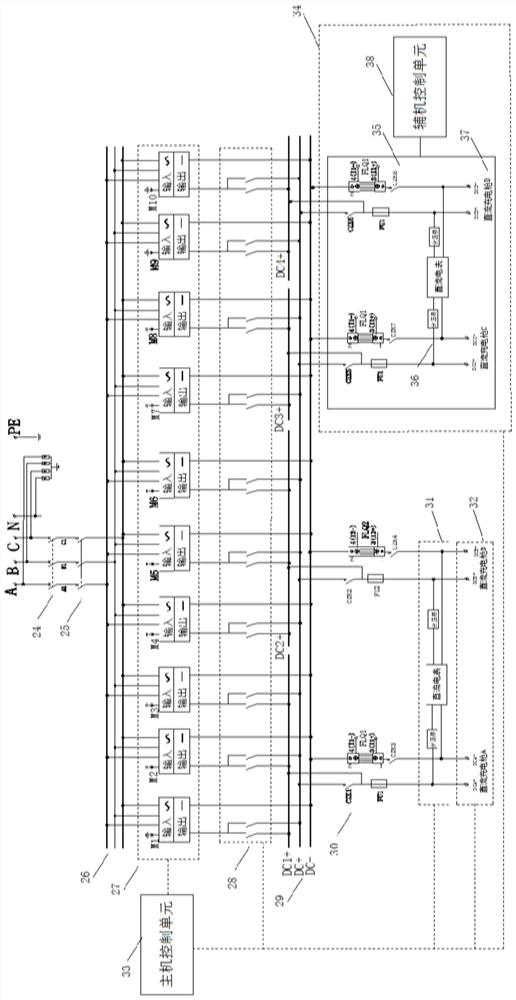

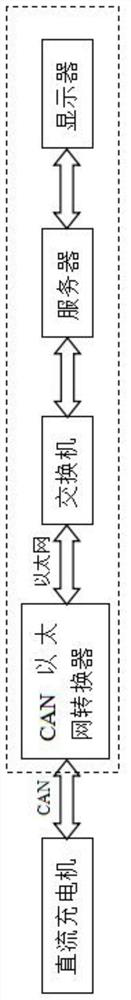

Intelligent power distribution quick charger and control method thereof

ActiveCN113022342AImprove work efficiencyImprove rationalityCharging stationsElectric vehicle charging technologyDC - Direct currentDc current

The invention relates to the field, in particular to an intelligent power distribution direct-current charger which comprises at least two direct-current charging guns used for charging an electric vehicle; each direct-current charging gun is provided with at least two rectification power modules, and each rectification power module is used for being coupled with an external power supply and outputting direct current; each direct-current charging gun is provided with a sampling unit which is used for collecting the charge state quantity of a power supply of the corresponding electric vehicle when the direct-current charging gun works; and a control unit, wherein when the charge state quantity of any direct-current charging gun is greater than a first preset value, the control unit is used for connecting at least one rectification power module connected to the direct-current charging gun to the other direct-current charging guns in the working state. The system has multiple charging modes: a single-gun full-power charging mode, a multi-gun simultaneous charging mode and an intelligent power distribution charging mode. The control unit can control the action of the rectifier module output contactor according to different SOC values of the vehicle storage battery under the condition of not influencing the continuous charging of the current channel.

Owner:博格华纳新能源(襄阳)有限公司

Forage mulberry, microbial fermentation method, mutton sheep concentrate supplement and preparation method

InactiveCN110074255AReduce contentIncrease crude protein contentFood processingAnimal feeding stuffBiotechnologyCellulose

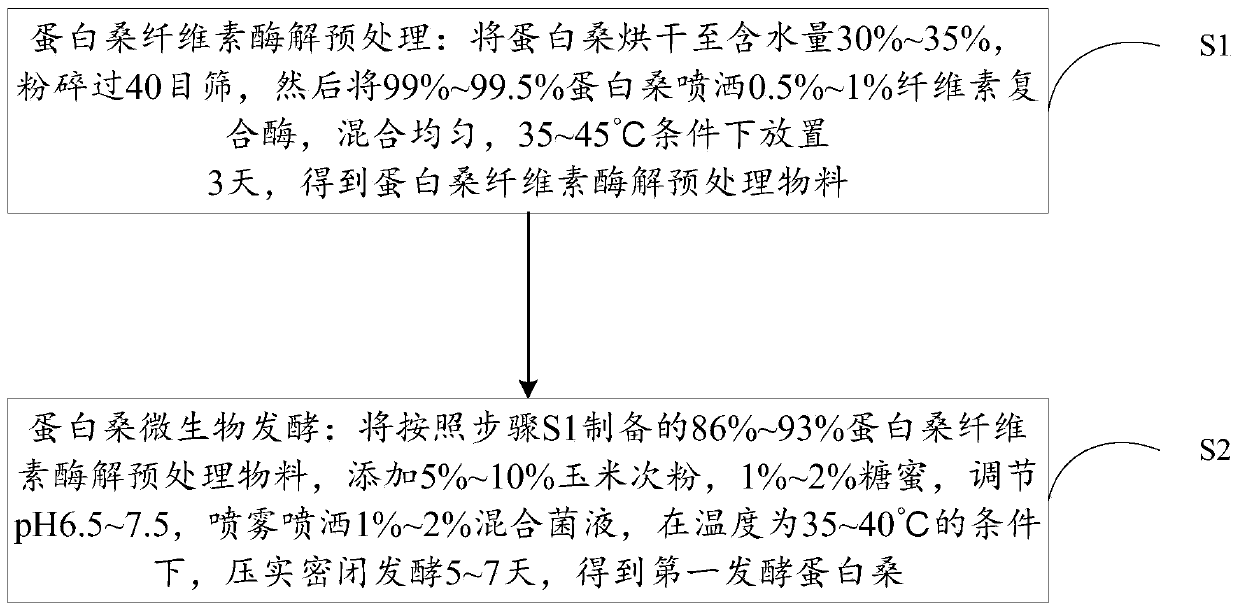

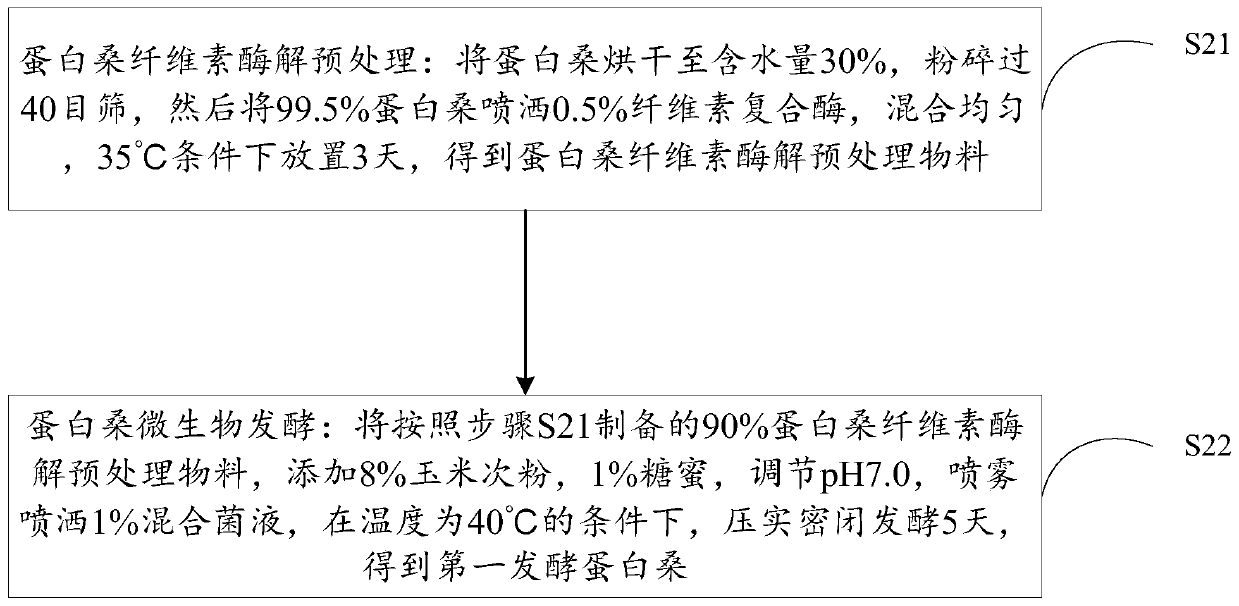

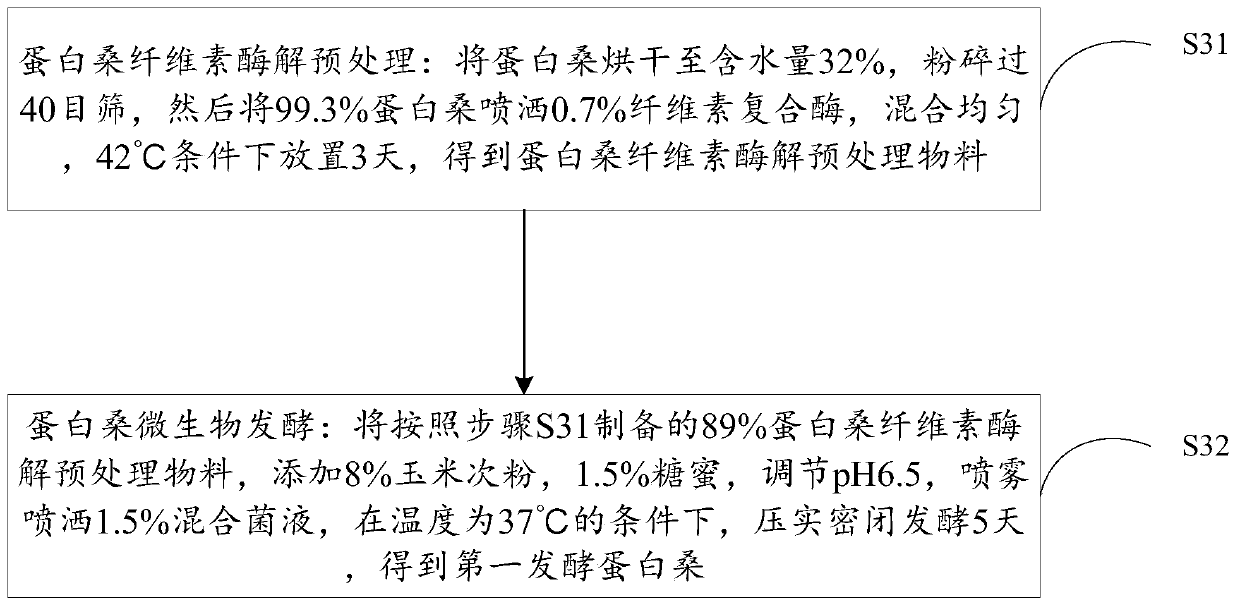

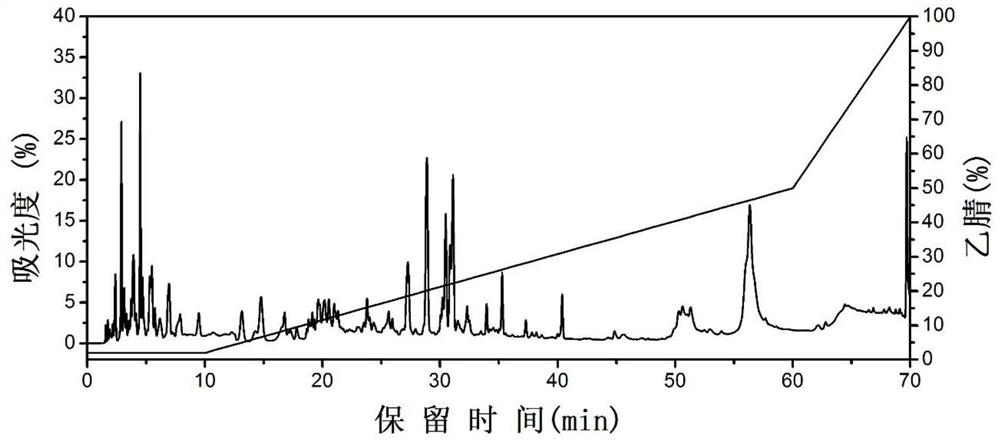

The invention provides forage mulberry, a microbial fermentation method, a mutton sheep concentrate supplement and a preparation method. The microbial fermentation method of the forage mulberry comprises the following steps that: S1, the forage mulberry is dried until the water content is 30 to 35 percent, and is crushed to pass through a 40-mesh sieve; then, 0.5 to 1 percent of cellulose compoundenzyme is sprayed on 99 to 99.5 percent of the forage mulberry; uniform mixing is performed; placement is performed for 3 days under the condition of 35 to 45 DEG C; a forage mulberry cellulose enzymolysis pretreatment material is obtained; S2, 5 to 10 percent of corn shorts and 1 to 2 percent of molasses are added into 86 to 93 percent of the forage mulberry cellulose enzymolysis pretreatment material prepared according to step S1; the pH is regulated to be 6.5 to 7.5; 1 to 2 percent of a mixed bacteria solution is sprayed in a mist spray way; under the condition that the temperature is 35 to 40 DEG C, compaction is performed, and closed fermentation is performed for 5 to 7 days; first fermented forage mulberry is obtained. Compared with forage mulberry in the prior art, the forage mulberry provided by the invention has the advantages that the content of crude fibers is reduced; the content of crude protein is increased.

Owner:ELION RESOURCE GROUP +1

A kind of antioxidant bone collagen polypeptide and preparation method thereof

ActiveCN108250291BImprove low utilizationSolve the problem of efficient utilizationFood ingredient as antioxidantConnective tissue peptidesChymaseEngineering

Owner:BEIJING UNIV OF CHEM TECH

Sea cucumber antioxidant peptide and preparation method thereof

ActiveCN104402972BResolve concernsImprove low utilizationPeptide preparation methodsFermentationAntioxidantHydrolysis

The invention provides a sea cucumber antioxidant peptide and a preparation method thereof. In the method, sea cucumber meat or sea cucumber visceral protein is used as a raw material, and the specific sea cucumber antioxidant peptide is obtained by enzymatic hydrolysis with acid protease, and the complete sequence of amino acids is as follows: :MALSVL. The sea cucumber antioxidant peptide prepared by the present invention makes up for the defects of natural antioxidants, and eliminates the public’s concerns about synthetic antioxidants. It is useful for the development of antioxidant peptides based on food sources and their wide application in food and medicine. Application lays the groundwork.

Owner:FUZHOU UNIV

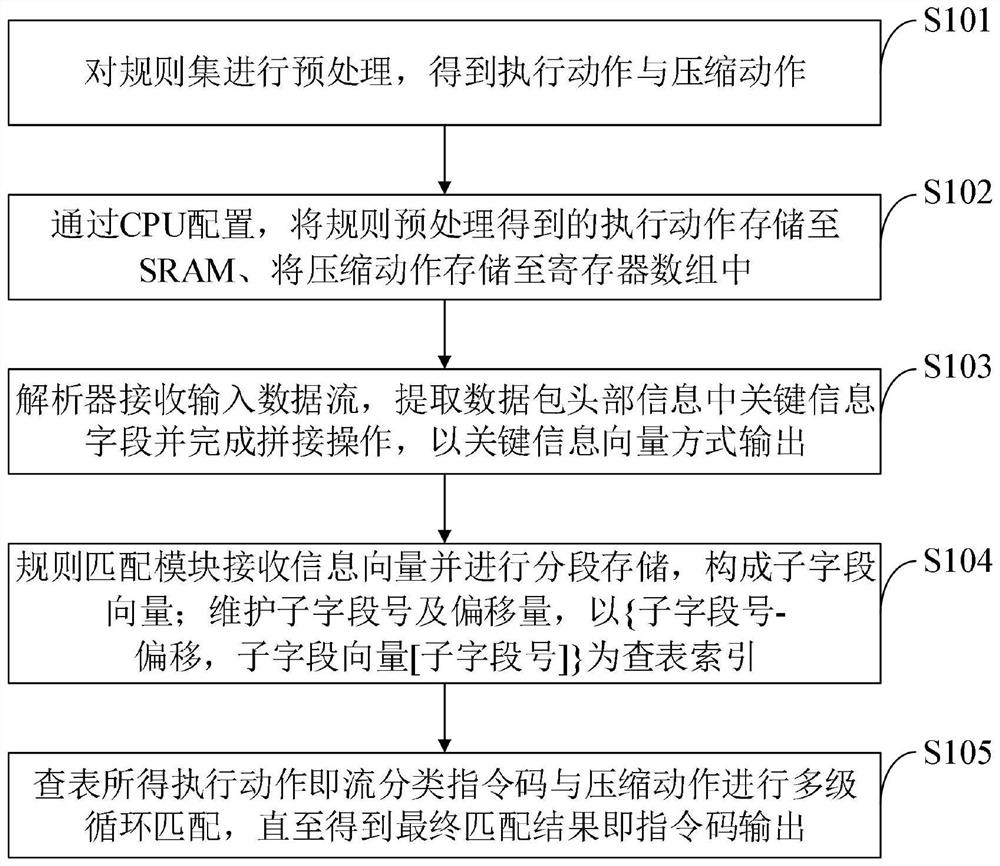

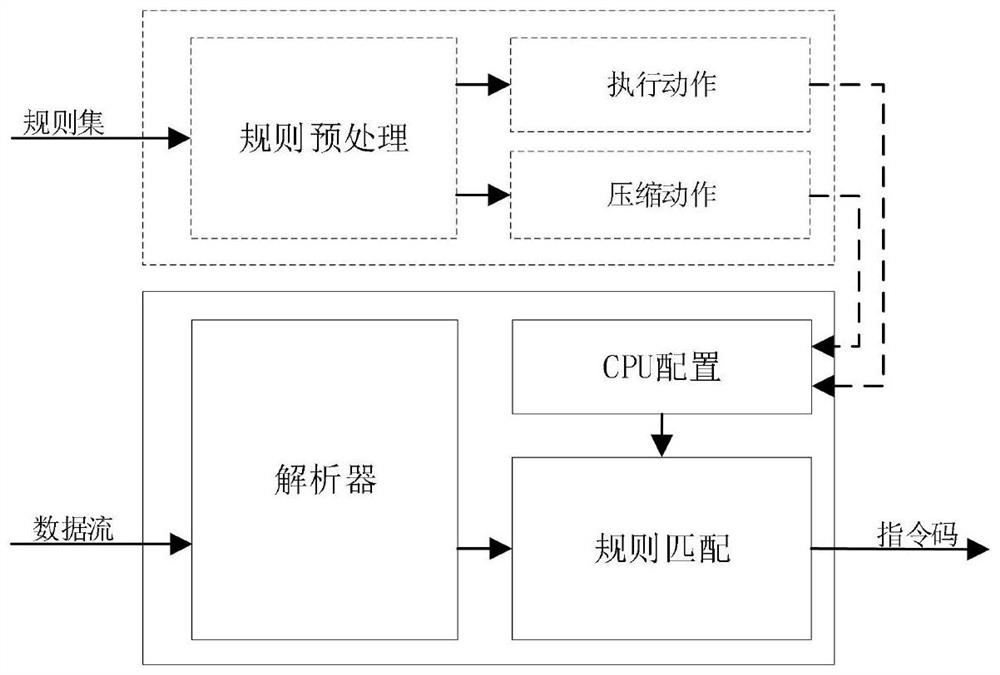

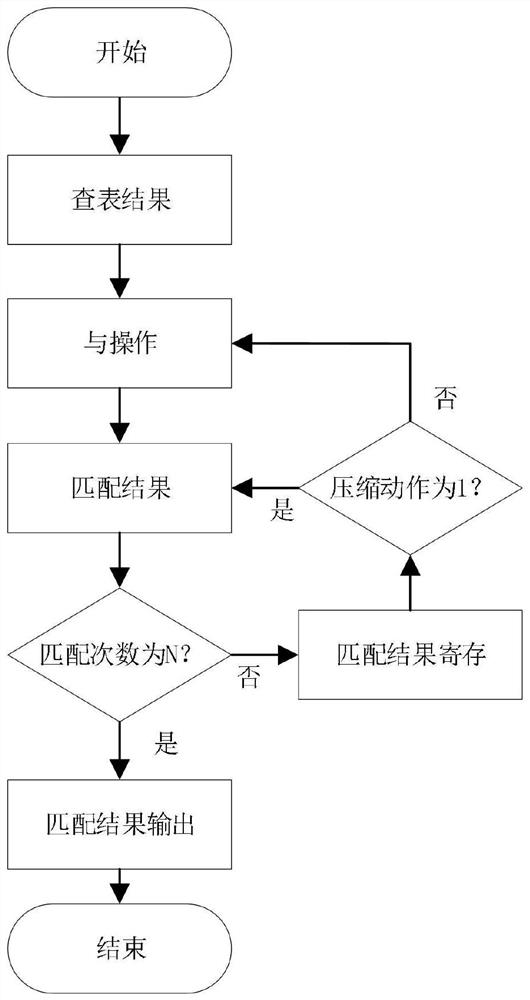

Stream classification device and table item compression method based on folded SRAM (Static Random Access Memory)

The invention belongs to the technical field of network communication, and discloses a flow classification device and a table item compression method based on a folded SRAM (Static Random Access Memory), which are characterized in that a rule set is preprocessed to obtain an execution action and a compression action; storing the execution action to an SRAM (Static Random Access Memory), and storing the compression action to a register vector; the analyzer receives an input data stream, extracts a key information field in header information of a data packet, completes splicing operation, and outputs the key information field in a key information vector mode; receiving a key information vector, and performing segmented storage on the key information vector; the rule matching module is based on a BV lookup mode of a folded SRAM, and an index address is corrected according to an offset value obtained by a compression action so as to complete table lookup operation; the execution action obtained by table look-up is multi-stage cyclic matching of the stream classification instruction code and the compression action until a final matching result is obtained and output. The method has the advantages of being suitable for hardware implementation, reducing cache overhead and having nothing to do with a protocol, and can be used for data flow identification and classification in a communication network.

Owner:XIDIAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com