Method for producing nitrogen-doped porous biochar from waste biomass and application of nitrogen-doped porous biochar

A technology for waste biomass and biomass charcoal, which is applied in the field of environmental materials and biomass recycling, can solve problems such as pollution and heavy metal pollution, and achieve the effects of wide sources, high adsorption performance, and difficulty in secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

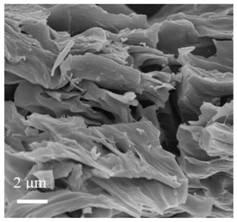

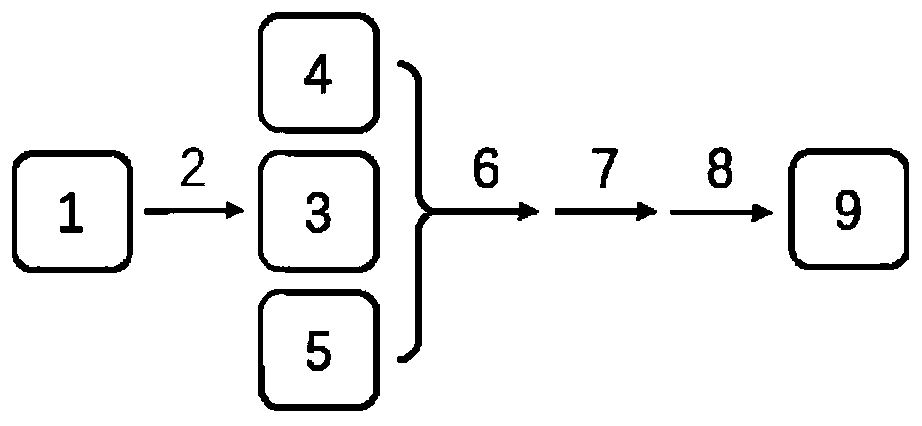

[0032] Example 1: This example provides a method for preparing a nitrogen-doped porous biomass carbon material that adsorbs heavy metals

[0033] (1) Dry the mangosteen bark first, then grind it into powder with a crusher and a ball mill, weigh 1 g of the powder, add 10 mL of an aqueous solution containing 0.2 g of urea, 5 mL of an ethanol solution containing 0.02 g of P123, and ultrasonically After 1 h, stir for 12 h.

[0034] (2) The solution in step (1) was transferred to a hydrothermal reactor for hydrothermal treatment at 140 °C and maintained for 6 h. After taking it out, it was cooled to room temperature and the mixture was dried in a vacuum oven.

[0035] (3) Cool the solid in step (2) to room temperature, grind it into powder, and then raise the temperature to 400 °C at a rate of 2 °C / min under nitrogen atmosphere, keep it for 2 h, and then cool it to room temperature.

[0036] (4) The sample was ground into powder, washed three times with ethanol and water respecti...

Embodiment 2

[0037] Example 2: This example provides a method for preparing a nitrogen-doped porous biomass carbon material that adsorbs heavy metals

[0038] It includes the following steps:

[0039] (1) Dry the lemon peel first, then grind it into a powder with a crusher and a ball mill, weigh 1 g of the powder, add 10 mL of an aqueous solution containing 0.5 g of urea, 5 mL of an ethanol solution of 0.05 g P123, and sonicate for 1 h and then stirred for 12 h.

[0040] (2) The solution in step (1) was transferred to a hydrothermal reactor for hydrothermal treatment at 140 °C and maintained for 6 h. After taking it out, it was cooled to room temperature and the mixture was dried in a vacuum oven.

[0041] (3) The solid in step (2) was cooled to room temperature, ground into powder, and then heated to 400 °C at a heating rate of 5 °C / min under nitrogen atmosphere, kept for 2 h, and then cooled to room temperature.

[0042] (4) The sample was ground into powder, washed three times with e...

Embodiment 3

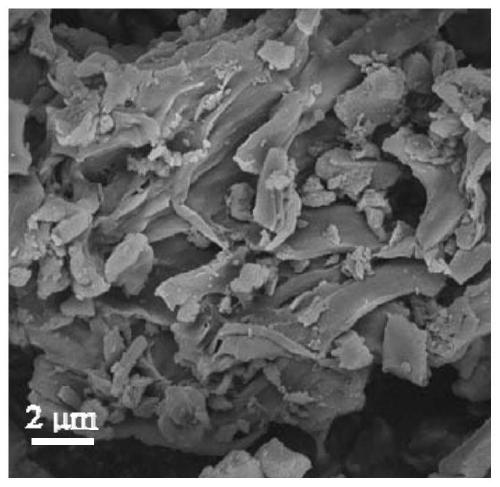

[0043] Example 3: This example provides a method for preparing a nitrogen-doped porous biomass carbon material that adsorbs heavy metals

[0044] It includes the following steps:

[0045] (1) Dry the watermelon rind first, then grind it into powder with a crusher and a ball mill, weigh 1 g of the powder, add 10 mL of an aqueous solution containing 0.5 g of ethylenediamine, 5 mL of an ethanol solution containing 0.02 CTAB, Sonicate for 1 h and then stir for 12 h.

[0046] (2) The solution in step (1) was transferred to a hydrothermal reactor for hydrothermal treatment at 140 °C and maintained for 6 h. After taking it out, it was cooled to room temperature and the mixture was dried in a vacuum oven.

[0047] (3) The solid in step (2) was cooled to room temperature, ground into powder, and then heated to 700 °C at a heating rate of 10 °C / min under nitrogen atmosphere, kept for 2 h, and then cooled to room temperature.

[0048] (4) The sample was ground into powder, washed three ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com