Method for systematically reducing process alkali consumption and improving process efficiency of Bayer process

A technology of Bayer process and Bayer process red mud, which is applied in the fields of chemical instruments and methods, preparation of alkali metal aluminate/alumina/aluminum hydroxide, inorganic chemistry, etc. Low-level problems, to achieve the effect of improving efficiency and solving high-efficiency utilization problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

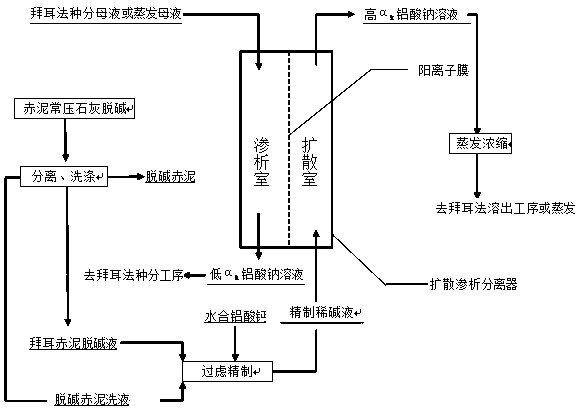

Image

Examples

Embodiment 1

[0033] N k The concentration is 150g / L and α k The decomposed stock solution of 1.45 can get N k The concentration is 160g / L and α k It is the decomposition mother liquor of 2.80. Lower the temperature of the above decomposed mother liquor to 50°C and make it flow at 1.0L / m 2 The flow rate of h (relative to the membrane area, the same below) enters the dialysis chamber of the cationic membrane diffusion dialysis separator to obtain a low α k Sodium aluminate solution, the low alpha k Sodium aluminate solution N k 80g / L, Al 2 o 3 The concentration is 70.14g / L, α k is 1.88; add 2g / L calcium aluminate hydrate to the dilute lye solution of Bayer red mud dealkalized with normal pressure lime as filter aid, and obtain the caustic alkali concentration N k It is 3g / L refined dilute lye, the refined dilute lye is cooled to 50°C, with 1.0L / m 2 The flow rate of h enters the diffusion chamber on the other side of the cationic membrane, and flows countercurrently with the decompo...

Embodiment 2

[0035] N k 158g / L, α k After the decomposed stock solution of 1.40 is decomposed by the Bayer method seed crystal, the caustic alkali concentration N k 169g / L, Al 2 o 3 The concentration is 101.46g / L and α k It is the decomposition mother liquor of 2.74. Lower the temperature of the above decomposed mother liquor to 70°C and make it flow at 2.0L / m 2 The flow rate of h enters the dialysis chamber on the side of the cation membrane in the cation membrane diffusion dialysis separator to obtain low α k Sodium aluminate solution, the low alpha k Sodium aluminate solution N k 62g / L, Al 2 o 3 The concentration is 65.10g / L, α k It is 1.56; add 1g / L calcium aluminate hydrate to the dilute alkaline solution of Bayer red mud and normal pressure lime dealkalization as a filter aid, and obtain the caustic alkali concentration N k It is 20g / L refined dilute lye, and the refined dilute lye is cooled to 70°C, at 3.0L / m 2 The flow rate of h enters the diffusion chamber on the othe...

Embodiment 3

[0037] N k 168g / L, α k After the decomposed stock solution of 1.45 is decomposed by the Bayer method seed crystal, the caustic alkali concentration N k 179g / L, Al 2 o 3 The concentration is 101.19g / L and α k It is the decomposition mother liquor of 2.91. Evaporate the above decomposition mother liquor to the caustic alkali concentration N k 309g / L, after cooling down to 70°C, make it 3.6L / m 2 The flow rate of h enters the dialysis chamber on the side of the cation membrane in the cation membrane diffusion dialysis separator to obtain low α k Sodium aluminate solution, the low alpha k Sodium aluminate solution N k 90g / L, Al 2 o 3 The concentration is 94.62g / L, α k It is 1.56; add 1g / L calcium aluminate hydrate to the dilute alkaline solution of Bayer red mud and normal pressure lime dealkalization as a filter aid, and obtain the caustic alkali concentration N k 20g / L of refined dilute lye, the refined dilute lye is cooled to 70 ° C, with 5.8L / m 2 The flow rate of h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com