Technique for preparing high-purity praseodymium from industrial praseodymium raw material

A process method and process technology, which is applied in the field of preparing high-purity praseodymium from industrial grade praseodymium raw materials, and achieves a good cohesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Industrial grade praseodymium feed liquid

[0029] The industrial-grade praseodymium feed solution is a rare earth chloride aqueous solution with a rare earth concentration of 1.0 M and a pH value of 2.5. The mole fraction of cerium in the feed solution is 0.005, the mole fraction of praseodymium is 0.985, and the mole fraction of neodymium is 0.01.

[0030] (2) Organic phase

[0031] The organic phase is a kerosene solution of 2-ethylhexylphosphonic acid mono-2-ethylhexyl ester (that is, P507), and the concentration of P507 is 1.0 M. In the cerium-praseodymium / praseodymium-neodymium separation process and the cerium / praseodymium separation process, the organic phase of the P507 extractant is saponified by conventional methods.

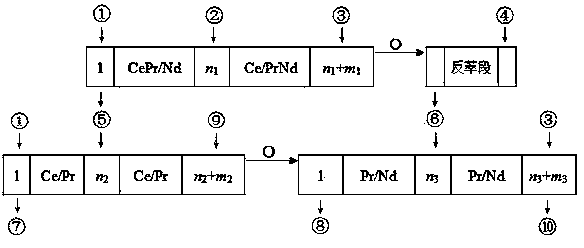

[0032] (3) Cerium-praseodymium / praseodymium-neodymium group separation fractionation extraction process

[0033] The group separation process of cerium-praseodymium / praseodymium-neodymium adopts a fractional distillation extraction system...

Embodiment 2

[0053] (1) Industrial grade praseodymium feed liquid

[0054] The industrial-grade praseodymium feed solution is a rare earth chloride aqueous solution with a rare earth concentration of 1.2 M and a pH value of 2.5. The mole fraction of cerium in the feed solution is 0.001, the mole fraction of praseodymium is 0.995, and the mole fraction of neodymium is 0.004.

[0055] (2) Organic phase

[0056] The organic phase is a kerosene solution of 2-ethylhexylphosphonic acid mono-2-ethylhexyl ester (that is, P507), and the concentration of P507 is 1.2 M. In the cerium-praseodymium / praseodymium-neodymium separation process and the cerium / praseodymium separation process, the organic phase of the P507 extractant is saponified by conventional methods.

[0057] (3) Cerium-praseodymium / praseodymium-neodymium group separation fractionation extraction process

[0058] The group separation process of cerium-praseodymium / praseodymium-neodymium adopts a fractional distillation extraction syste...

Embodiment 3

[0078] (1) Industrial grade praseodymium feed liquid

[0079] The industrial-grade praseodymium feed solution is a rare earth chloride aqueous solution with a rare earth concentration of 1.5 M and a pH value of 3. The mole fraction of cerium in the feed solution is 0.005, that of praseodymium is 0.98, and that of neodymium is 0.015.

[0080] (2) Organic phase

[0081] The organic phase is a sulfonated kerosene solution of 2-ethylhexylphosphonic acid mono-2-ethylhexyl ester (that is, P507), and the concentration of P507 is 1.5 M. In the cerium-praseodymium / praseodymium-neodymium separation process and the cerium / praseodymium separation process, the organic phase of the P507 extractant is saponified by conventional methods.

[0082] (3) Cerium-praseodymium / praseodymium-neodymium group separation fractionation extraction process

[0083] The group separation process of cerium-praseodymium / praseodymium-neodymium adopts a fractional distillation extraction system, with P507 as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com