In-situ leaching and leachate treatment method with co2 and o2 added to heavy carbonic acid type groundwater

A treatment method and leachate technology, applied in the direction of earthwork drilling, mining fluid, wellbore/well components, etc., to achieve the effects of low production cost, omission of high-temperature heating equipment, and refined control parameters

Active Publication Date: 2014-01-08

BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

View PDF0 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Login to View More

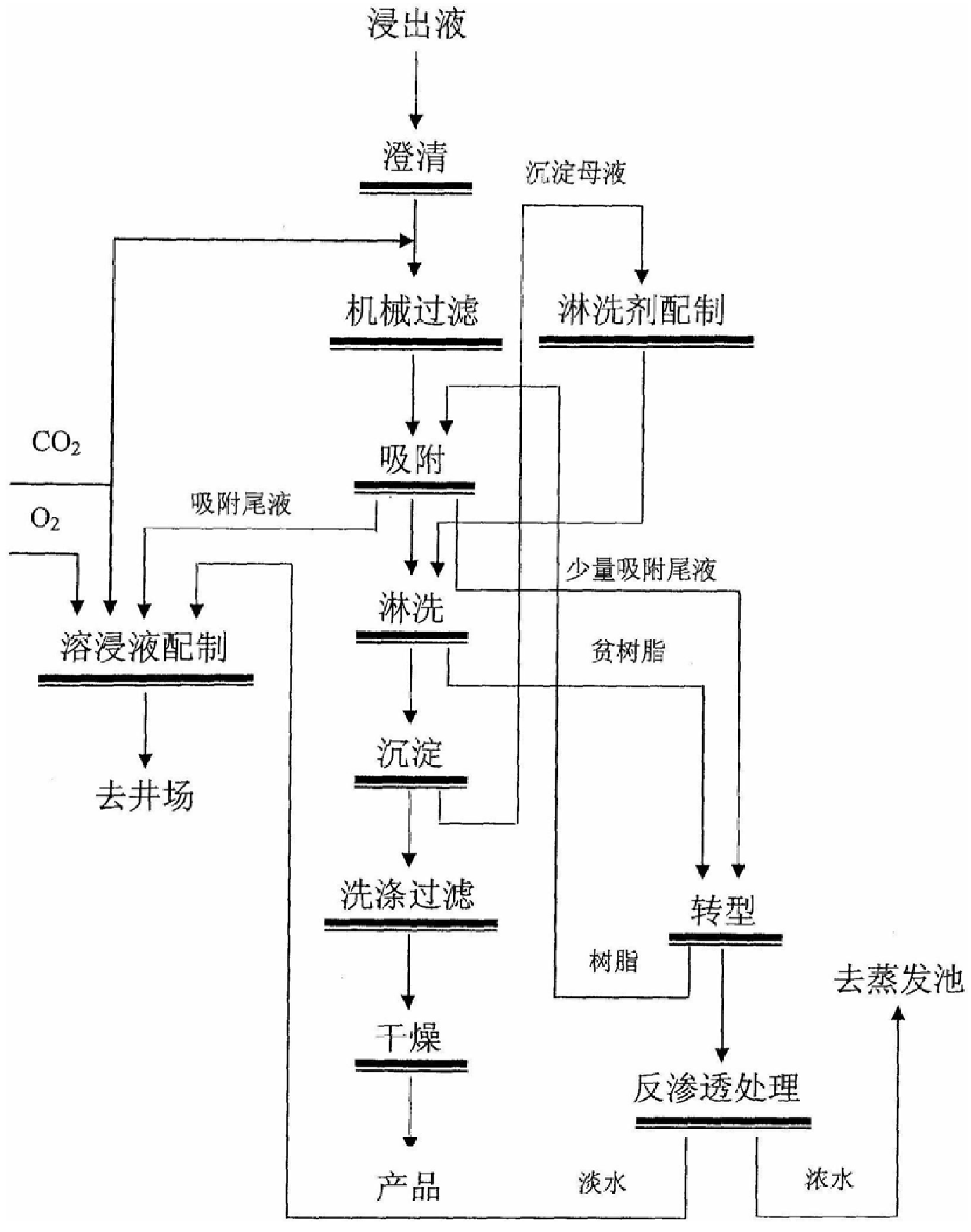

Abstract

The invention provides a method for adding CO2 and O2 in-ground leaching in heavy carbonic acid type ground water and leachate, which comprises the following steps: (1) adding CO2 and O2 into the leaching solution to leach uranium underground to obtain uranium leachate; (2) adding uranium to the uranium Add CO2 to the leaching solution to adjust the pH value of the uranium leaching solution, and then filter it mechanically; (3) perform ion exchange adsorption on the uranium leaching solution in the adsorption tower; (4) perform leaching on the saturated resin to obtain Cl-type poor resin and leaching qualified solution (5) transforming the Cl-type poor resin with the adsorption tail liquid; (6) acidifying the eluting qualified liquid, adding alkali and aging precipitation at room temperature, washing, filtering and drying the precipitated slurry to obtain uranium products. The method of the invention only adds O2 and CO2 without adding other reagents, which will not cause blockage of ore beds and pollution of underground water; at the same time, the preparation process is integrated, the operation is simplified, and the cost is saved.

Description

Adding CO to bicarbonate groundwater 2 and O 2 In-situ leaching and leachate treatment methods technical field The present invention relates to a kind of in-situ leaching mining uranium leaching method and leachate treatment method, be specifically related to a kind of in heavy carbonic acid type A method for extracting uranium by in-situ leaching with adding CO2 and O2 to groundwater and a method for treating leachate. The technical feature lies in the novelty of lean resin after leaching The transformation method and the technology of reusing the transformed wastewater after reverse osmosis treatment. Background technique Ground leaching mining uranium (in situ leaching mining uranium) is that the liquid injection well drilled into the ore-bearing layer from the surface will be prepared in a certain proportion. A good leaching solution is injected into the ore layer, and the injected leaching solution contacts with the useful components in the ore to undergo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E21B43/28C22B60/02C22B3/42C22B3/46

Inventor 刘乃忠苏学斌郭忠德杜志明苏艳茹王晓东程宗芳杨少武沈红伟向秋林邓慧东

Owner BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com