Alkyl aryl alkyl-sulfonate surfactant composition and its application in tertiary oil recovery

A technology of alkyl aryl alkyl sulfonate and surfactant, which is applied in the field of novel alkyl aryl alkyl sulfonate type surfactant composition, can solve problems such as formation and oil well damage, and achieve low oil and water Interfacial tension, the best oil displacement effect, the effect of enhanced oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Embodiment one: the preparation of alkyl aryl alkyl sulfonate type surfactant

[0062] 1. m is 12, n is 4, p is 0, that is R 1 for C 12 h 25 Alkyl; R 2 for C 4 h 8 Alkyl; R 3 Be the preparation of the alkyl aryl alkyl sulfonate type surfactant of H group:

[0063] 10mol benzene (780g) is added in the reactor, stirs, in catalyst AlCl 3 Add 1 mol (168g) of linear dodecene dropwise at 58-60°C under the action to obtain 240g of dodecylbenzene. 3 1 mol (127 g) of dichlorobutane was added dropwise at 58-60° C. under the action to obtain 320 g of dodecylphenylbutyl chloride. Then add sodium bisulfite 126g, heat, stir, until the reactant is transparent. After concentration, m is 12, n is 4, p is 0, namely R 1 for C 12 h 25 Alkyl; R 2 for C 4 h 8 Alkyl; R 3 Sodium dodecylphenyl butyl sulfonate for H group.

[0064] 2. Preparation of alkyl aryl alkyl sulfonate type surfactant composition

[0065] Take the above m as 12, n as 4, and p as 0, which is R 1 for C 1...

Embodiment 2

[0066] Embodiment two: the preparation of alkyl aryl alkyl sulfonate type surfactant

[0067] 1. m is 14, n is 3, p is 0 or R 1 for C 14 h 29 Alkyl; R 2 for C 3 h 6 Alkyl; R 3 Be the preparation of the alkyl aryl alkyl sulfonate type surfactant of H group:

[0068] 10mol benzene (780g) is added in the reactor, stirs, in catalyst AlCl 3 Add 1 mol (196g) of linear tetradecene dropwise at 58-60°C under the action to obtain 270g of tetradecylbenzene. 3 Under action, 1 mol (77 g) of allyl chloride was added dropwise at 58-60° C. to obtain 311 g of tetradecylphenylpropene. Then add sodium bisulfite 126g, heat, stir, until the reactant is transparent. After concentration, m is 14, n is 3, p is 0, namely R 1 for C 14 h 29 Alkyl; R 2 for C 3 h 6 Alkyl; R 3 Sodium tetradecylphenylpropyl sulfonate for H group.

Embodiment 3

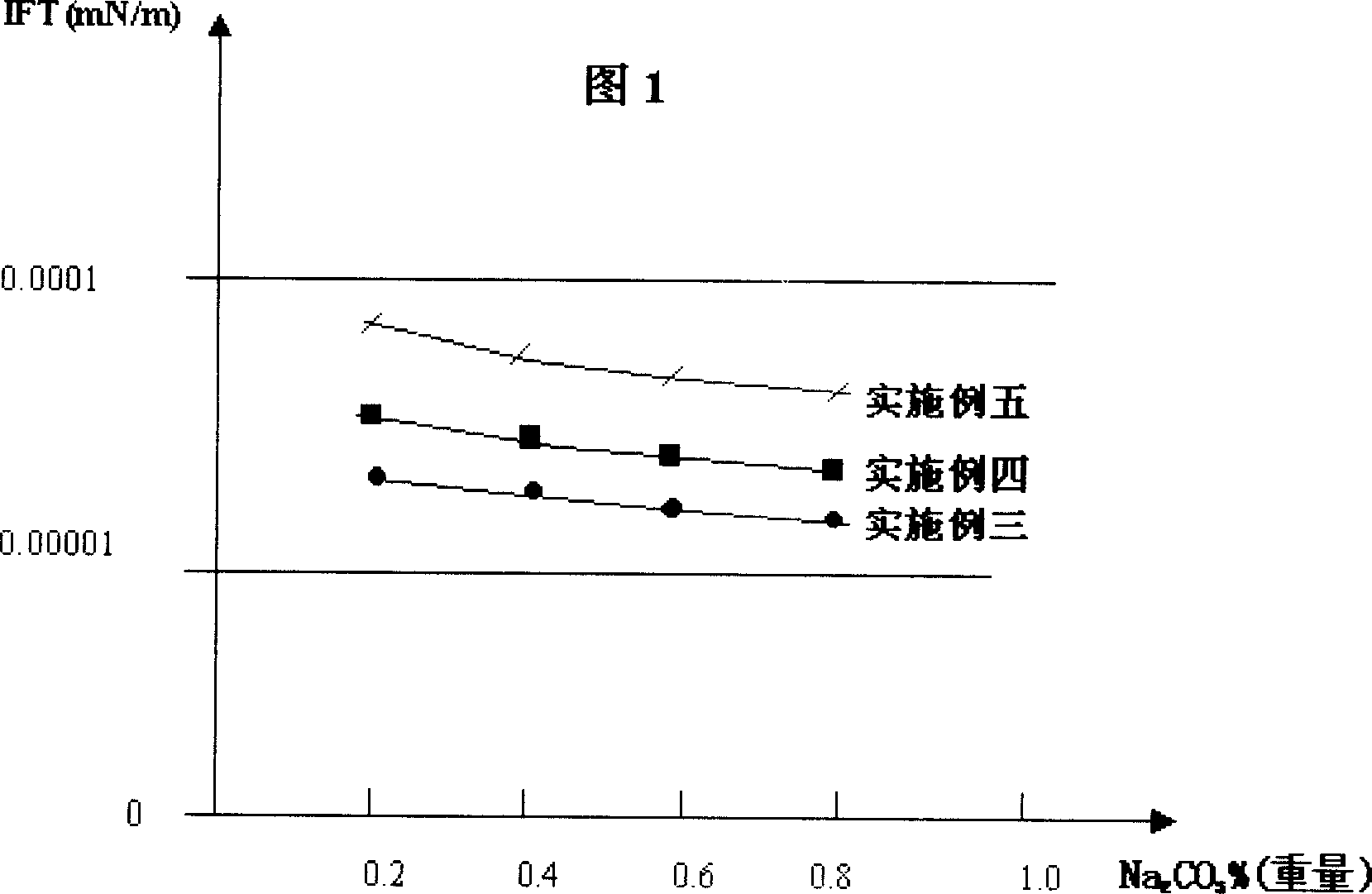

[0070] Alkylaryl alkyl sulfonate type surfactant composition, this composition comprises following several components:

[0071] ①The alkyl aryl alkyl sulfonate type surfactant is 0.3% (weight);

[0072] Among them, the surfactant is m is 12, n is 4, p is 0, namely R 1 for C 12 h 25 Alkyl; R 2 for C 4 h 8 Alkyl; R 3 Sodium dodecylphenyl butyl sulfonate as H group

[0073] 2. The polymer is 0.25% (by weight); the polymer is water-soluble polyacrylamide with a molecular weight of 21 million;

[0074] ③The balance is oilfield injected sewage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com