High-efficiency oil displacement agent

An oil-displacing agent, high-efficiency technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of surfactant loss of activity, poor salt resistance, etc., achieve high activity, good oil displacement effect, and solve the problem of The effect of poor salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

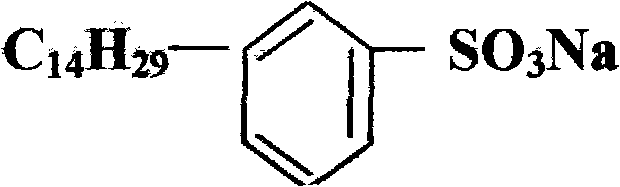

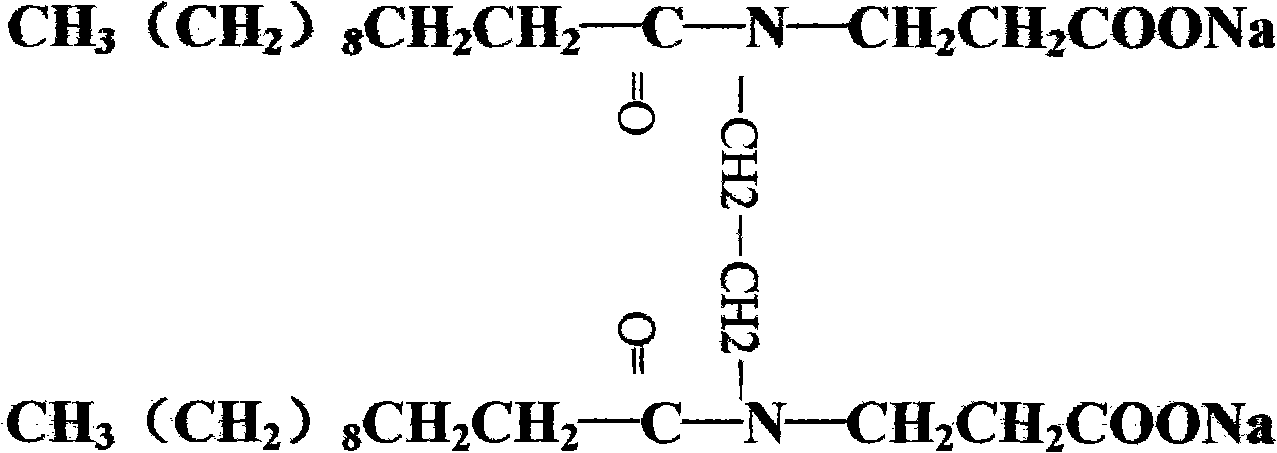

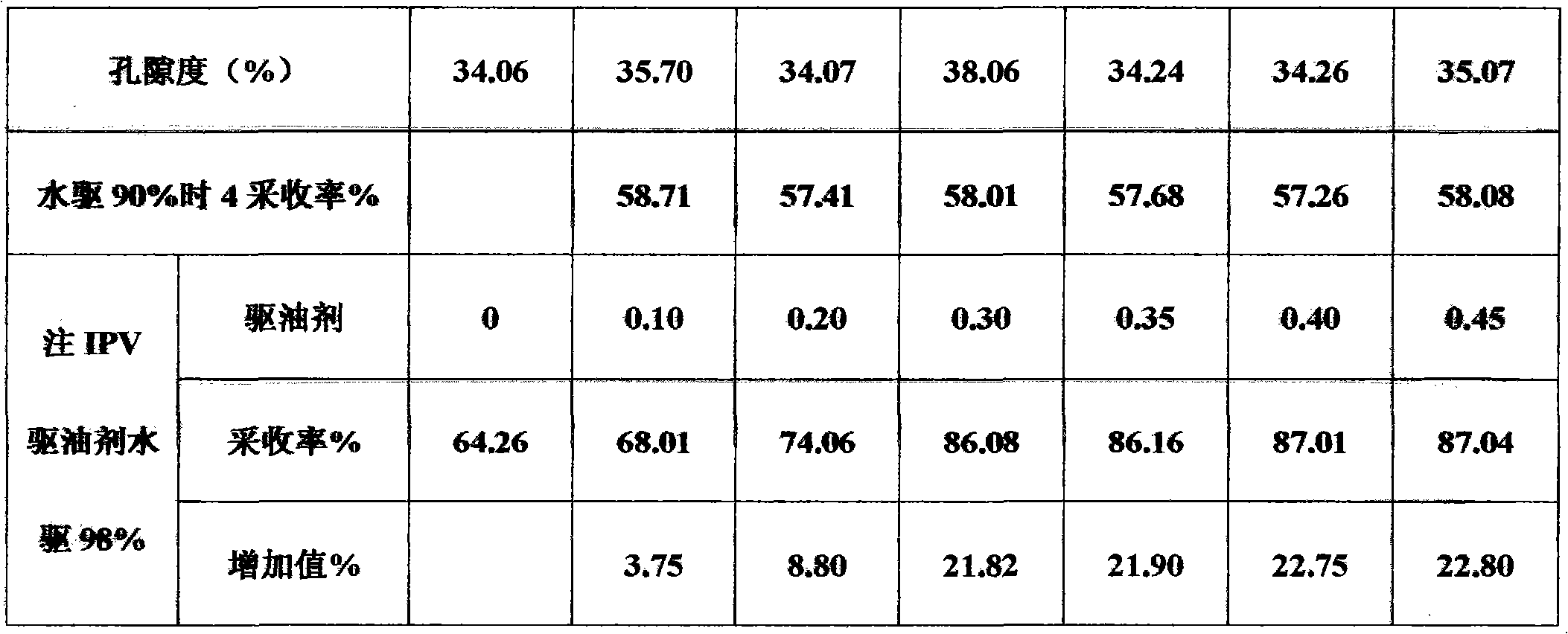

[0047] in 2M 3 Add 500kg of tap water (or oilfield reinjection water), stir at room temperature, and at the same time add 3kg of N,N'-dilauroylethylenediamine dipropionate sodium at one time, OP-103kg after stirring for 30 minutes, add 454kg sodium tetradecylbenzene sulfonate, stirring continuously for 30 minutes is the oil displacing agent product of the present invention. The result of detecting the surface tension of its 0.3% aqueous solution is: 37.

Embodiment 2

[0049] in 2M 3 Add 500kg of tap water (or oil field reinjection water) to the reaction volume, stir at room temperature, and at the same time add 5kg of N,N'-dilauroylethylenediamine dipropionate sodium at one time, OP-105kg after stirring for 30 minutes, add 400kg sodium tetradecylbenzene sulfonate, continuously stirred for 30 minutes is the oil displacement agent product of the present invention. The result of detecting the surface tension of its 0.3% aqueous solution is: 34.2.

Embodiment 3

[0051] in 2M 3 Add 500kg of tap water (or oil field reinjection water) to the reaction volume, stir at room temperature, and at the same time add 7kg of N,N'-dilauroylethylenediamine dipropionate sodium at one time, OP-107kg after stirring for 30 minutes, add 436kg sodium tetradecylbenzene sulfonate, stirring continuously for 30 minutes is the oil displacement agent product of the present invention. The result of detecting the surface tension of its 0.3% aqueous solution is: 39.

[0052] Conclusion: Example 2 is the preferred solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com