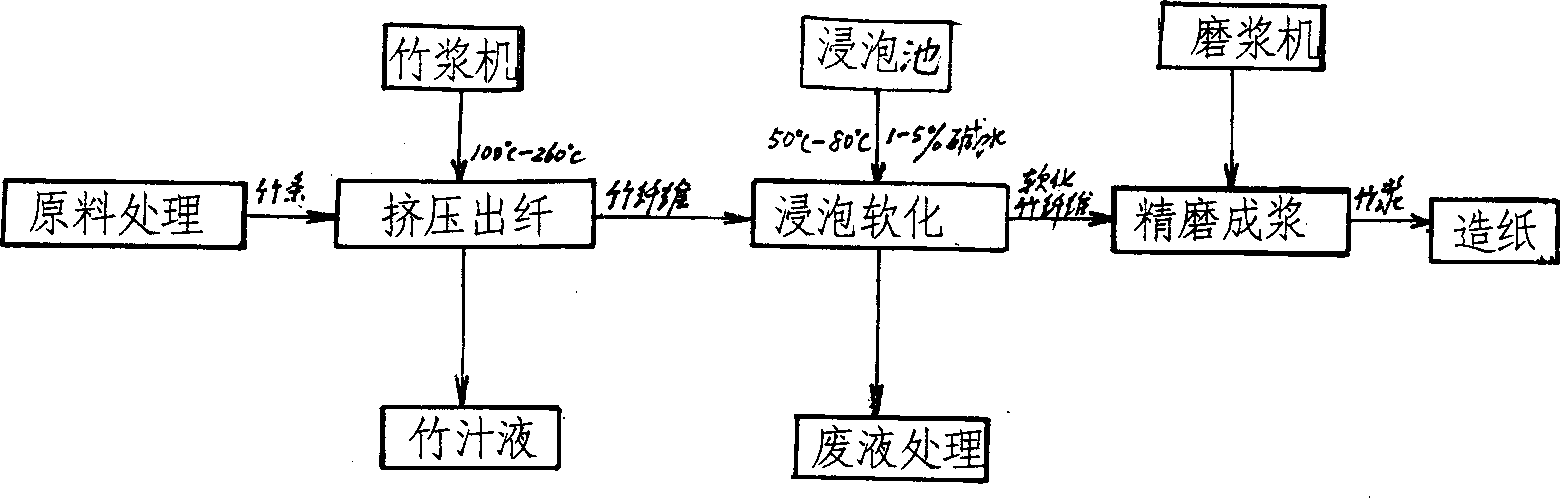

Technological process of mechanically making bamboo pulp

A process method, the technology of bamboo pulp, applied in the field of pulp manufacturing, can solve the problems of large energy consumption, long cooking time, and environmental pollution, and achieve the effects of reducing production costs, saving time in the extraction process, and high fiber acquisition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0007] Specific embodiments ①Bamboo pulp machine: power of 15-30 kilowatts to produce extruded bamboo material at a temperature of 100°C to 260°C ②Soaking tank: ③ refiner: power of 30 kilowatts, refining speed of 1500-3000 rpm The specific pulping process: ①Crush the bamboo into long strips ②Send the bamboo strips into the bamboo pulp machine ③After 10 seconds, the bamboo fiber will be discharged from the discharge port of the bamboo pulp machine ④The soaking tank is filled with 60 degrees hot water, and NaoH is added. Make alkaline hot water with a concentration of 3%, put the bamboo fiber into the hot alkaline water in the soaking tank for 2 hours, ⑤ send the soaked slurry to the refiner for fine grinding, and the output is the bamboo for paper making Pulp, paper machine can make paper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com