System and method for preparing synthesis gas by electrolyzing low-cost CO2 in solid oxide electrolytic tank

A technology of solid oxides and electrolytic cells, applied in chemical instruments and methods, separation methods, electrolysis processes, etc., can solve the problems of cathode material oxidation and deactivation, reduce energy consumption, reduce overpotential and power consumption, and improve The effect of energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

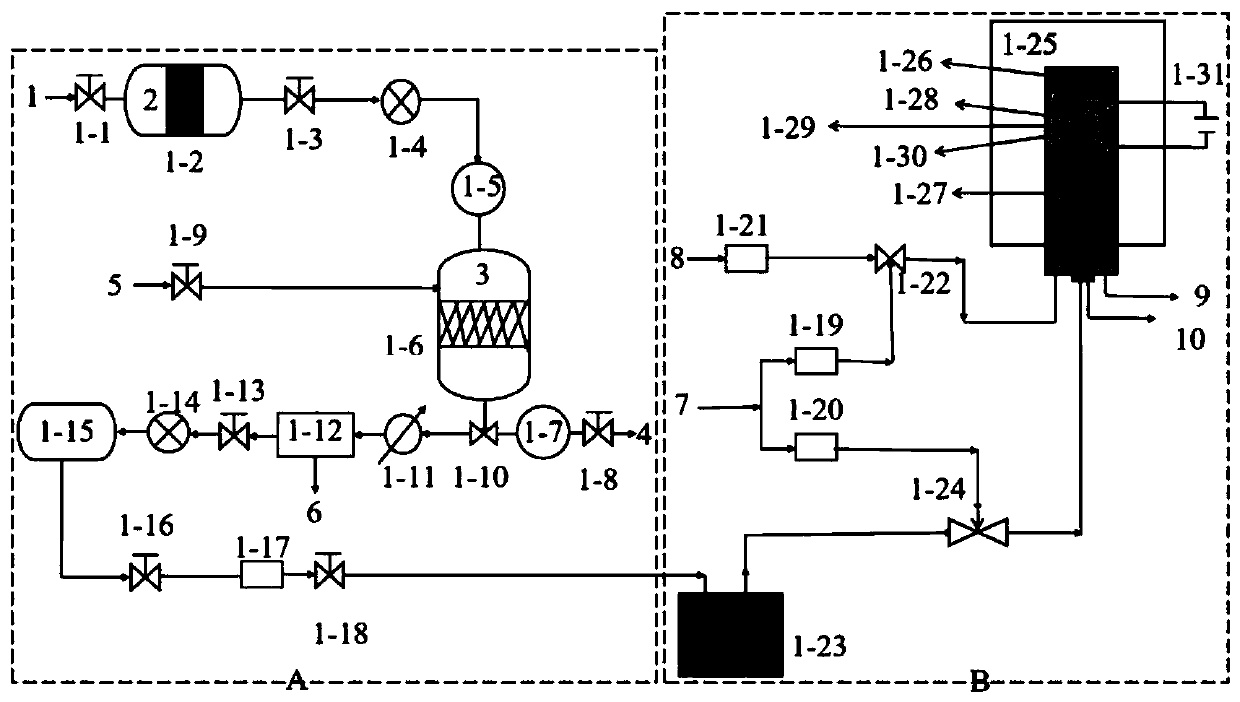

[0040] like figure 1 As shown, a solid oxide electrolytic cell of the present invention electrolyzes low-cost CO 2 Systems for the production of syngas, including direct capture of CO 2 Unit A and solid oxide electrolytic cell unit B;

[0041] The direct capture of CO 2 Unit A includes a dryer 1-2 for filtering and drying air or flue gas 1, and the inlet of the dryer 1-2 is connected with a high concentration of CO 2 The gas source 1 is connected, and the gas outlet is connected to CO 2 The gas inlet at the top of the adsorption chamber 1-6 is connected, CO 2 A second flow regulating valve 1-3, a first air pump 1-4 and a first CO 2 Concentration detector 1-5, CO 2 The gas outlet at the bottom of the adsorption chamber 1-6 is divided into two roads through the first three-way valve 1-10, one branch road is provided with the second CO 2 Concentration detector 1-7, the third flow regulating valve 1-8, the first CO 2 Concentration detector 1-5 and the second CO 2 Concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com