Method for preparing methyl isobutyl ketone from industrial by-product effluent acetone

A kind of technology of methyl isobutyl ketone and industrial by-product, which is applied in the field of preparing methyl isobutyl ketone from industrial by-product waste liquid acetone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

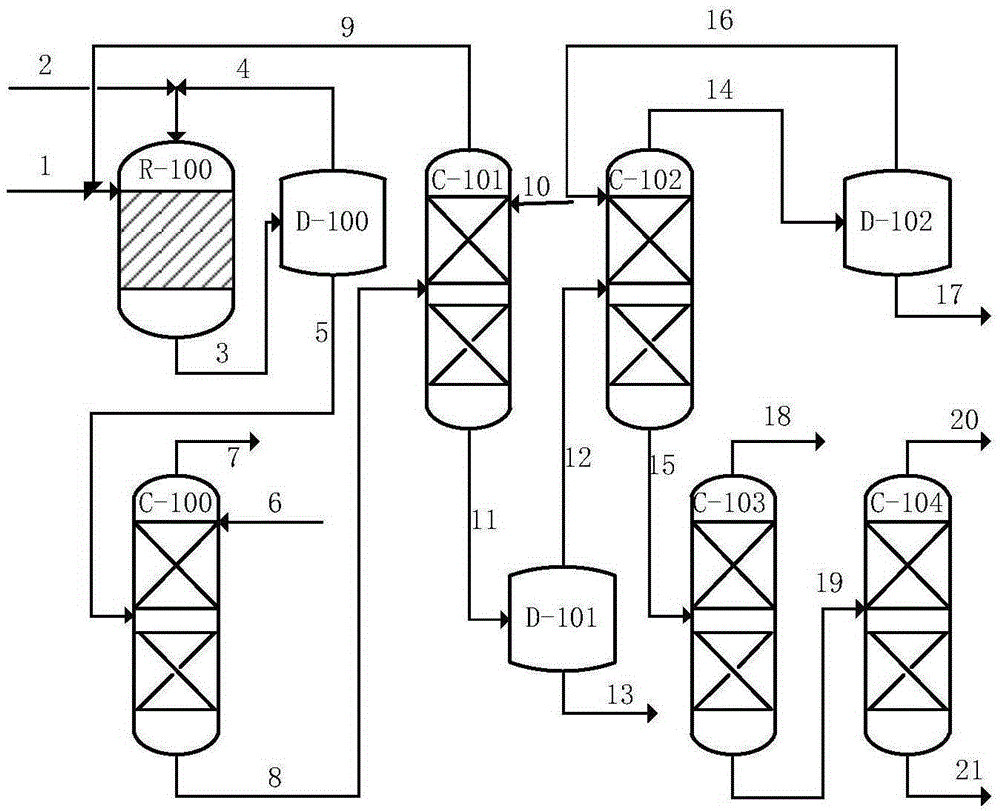

Method used

Image

Examples

Embodiment 1

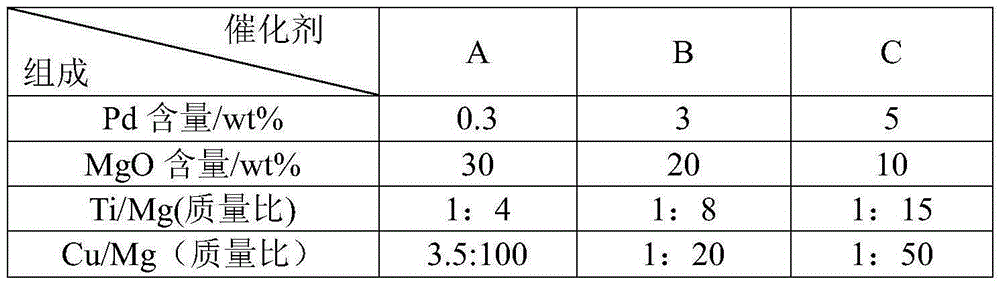

[0066] Preparation of modified loaded Pd / activated carbon catalyst: 2.08g commercial powdered coconut shell activated carbon, particle size 150 mesh, specific surface area 2500m 2 / g, first at 10Mpa, 600k, H 2 / N 2 Reduced activated carbon 12h, H 2 , N 2 The molar ratio is 1:3. 6.47g Mg(NO 3 ) 2 ·6H 2 O, 0.10gCu(NO 3 ) 2 ·6H 2 O. Dissolve 0.89g of isopropyl titanate into 70.92g of deionized water, and divide the solution into three parts with a weight ratio of 4:2:1. Add ammonia water dropwise to the three solutions respectively to control PH = 9, immerse the above-mentioned activated carbon in the above-mentioned solution three times for 5 hours respectively, after each immersion, age for 12 hours and then perform the next immersion, and continuously evaporate the solvent while immersing, When the impregnation is completed, the remaining solution volume is less than 1% of the original solution volume. In vacuum condition N 2 Dry at 80°C for 12h, then 20Pa, N 2 Roa...

Embodiment 2

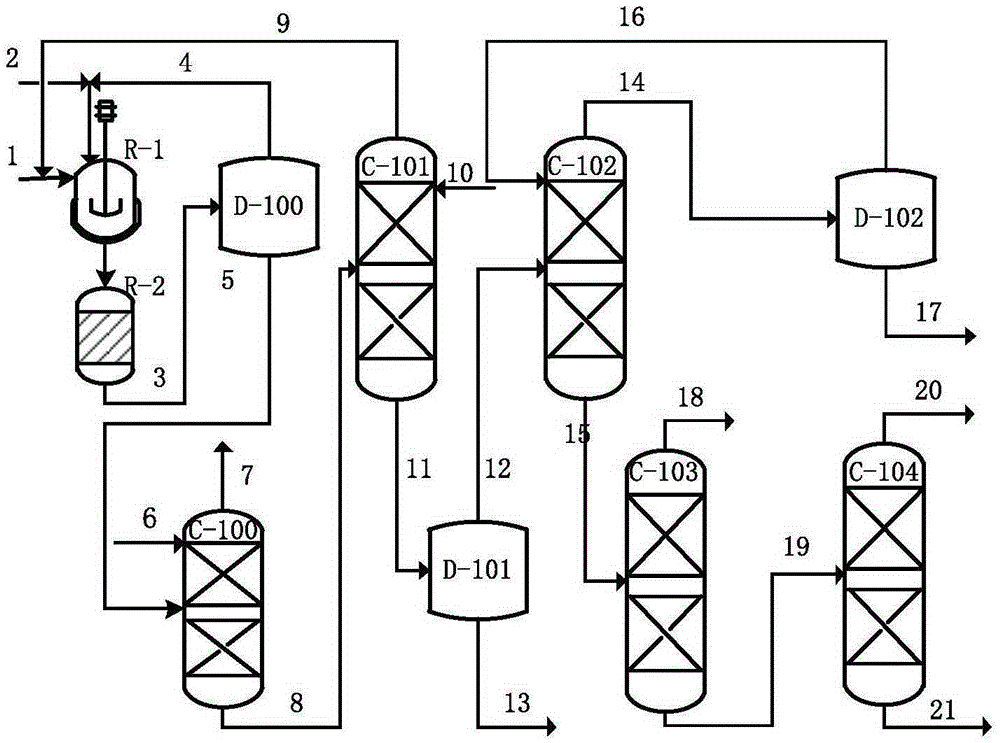

[0072] as attached figure 2 Shown, the CSTR reactor R-1 of series connection and fixed-bed reactor R-2, wherein R-1 loads the modified Pd / activated carbon catalyst A2.5g prepared by embodiment 1, R-2 loads Pd / ion exchange resin Composite functional catalyst, the catalyst is spherical particles with a diameter of Ф0.5-1.3, and the filling volume is 300ml. Byproduct waste liquid acetone mixed solution (composition is as table 1) is passed through reactor, reactor R-1 volume 1.5L, overflow volume 1L, byproduct acetone feed rate 6ml / min, H 2 The pressure is 4Mpa, and the reaction temperature is 120°C. Reactor R-2 has an inner diameter of Ф20 and adopts a multi-stage heating insulation system, H 2 The pressure is 3.5Mpa, the flow rate is 120NL / h, and the catalyst bed temperature is 120-140°C. Liquid samples were collected for gas chromatographic analysis. The conversion rate of isobutylene oxide at the outlet of reactor R-1 is 99%, the mass ratio of TBA (tert-butanol) to IBA (...

Embodiment 3

[0081] Such as figure 1As shown, the tube-and-tube reactor R-100 is sequentially filled with 300 ml of Pd / ion exchange resin MIBK synthesis catalyst and 100 ml of molded catalyst B from bottom to top, and the conditions in the reactor are the same as those of R-2 in Example 2. device, other operations and conditions are also the same as in Example 2, and the results are shown in Table 5.

[0082] Table 5 The reaction results of synthesizing MIBK

[0083]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com