Patents

Literature

310results about How to "Increase crude protein content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

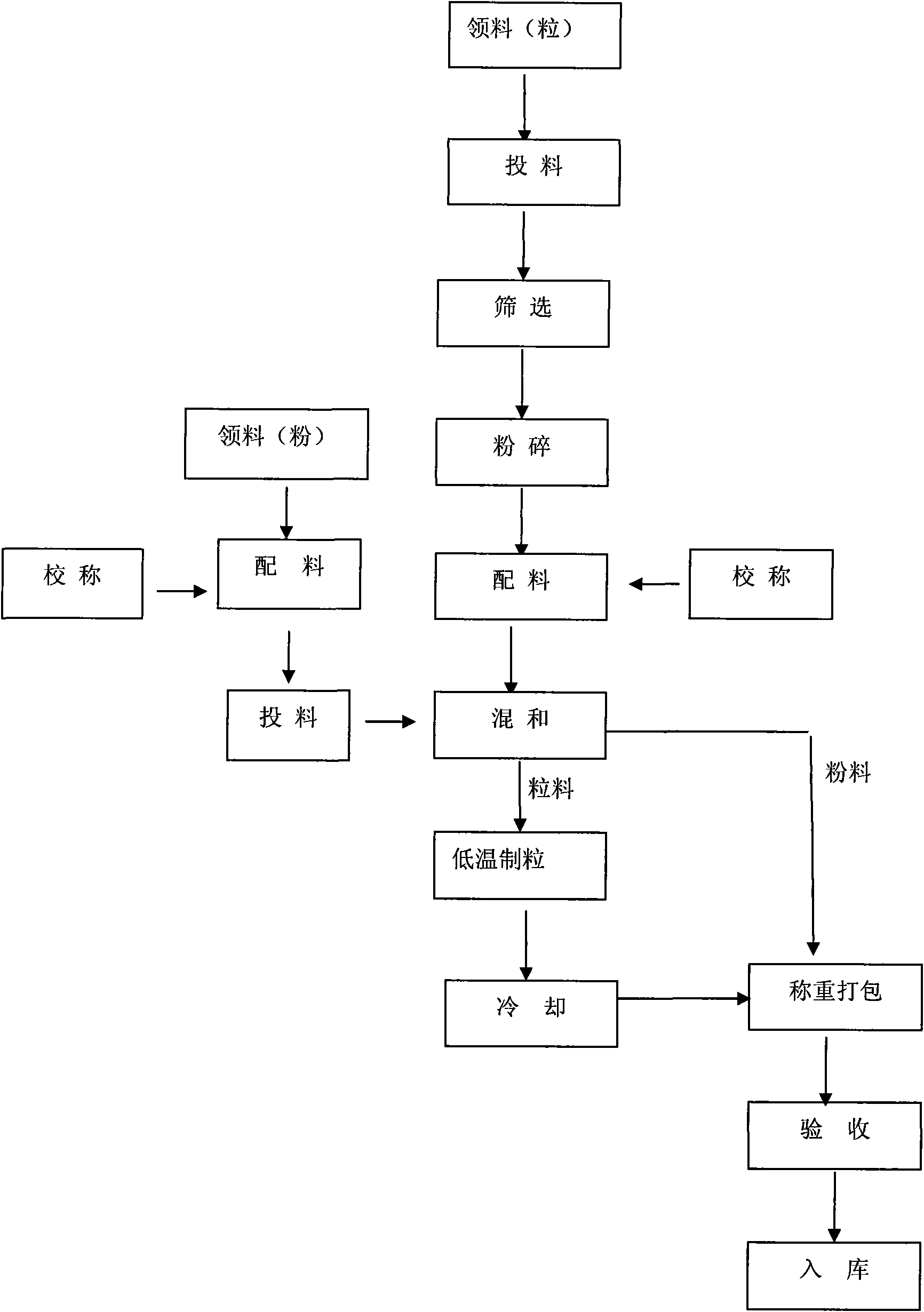

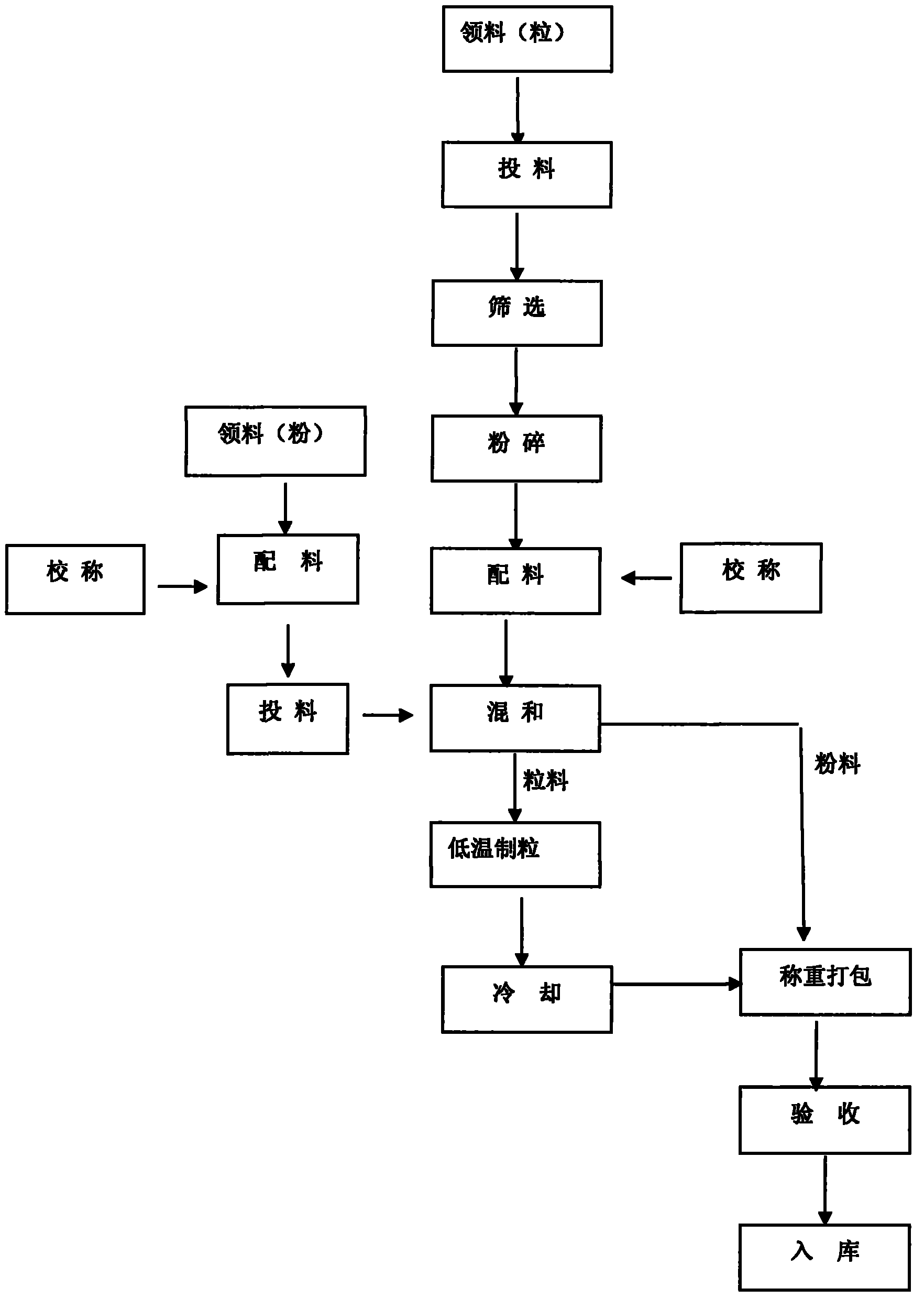

Method for processing inapplicable tobacco leaves by musca domestica larva to prepare biological protein feed

ActiveCN103109972ARealize resource utilizationIncrease profitAnimal feeding stuffAnimal scienceResource utilization

The invention discloses a method for processing inapplicable tobacco leaves by musca domestica larvae to prepare a biological protein feed, and belongs to the technical field of environmental protection. The method for processing the inapplicable tobacco leaves by the musca domestica larvae to prepare the biological protein feed comprises the steps of: crushing fresh inapplicable tobacco leaves until the grain size of the crushed leaves is 1-5mm; adding bran, mixture of rice chaff and husk, feather meal and spray-dried animal blood cells to prepare compost; and inoculating housefly eggs at the surface of the compost, cultivating the housefly eggs for 5 days at 25-35 DEG C, collecting the compost containing the musca domestica larvae, drying and preparing the biological protein feed. The method disclosed by the invention is strong in handling capacity, small in floor area, and low in energy consumption in the processing process, achieves the resource utilization of the inapplicable tobacco leaves, changes waste into precious resources, improves the environmental health, simultaneously produces the biologic protein feed, and has a good application prospect.

Owner:胡新军 +2

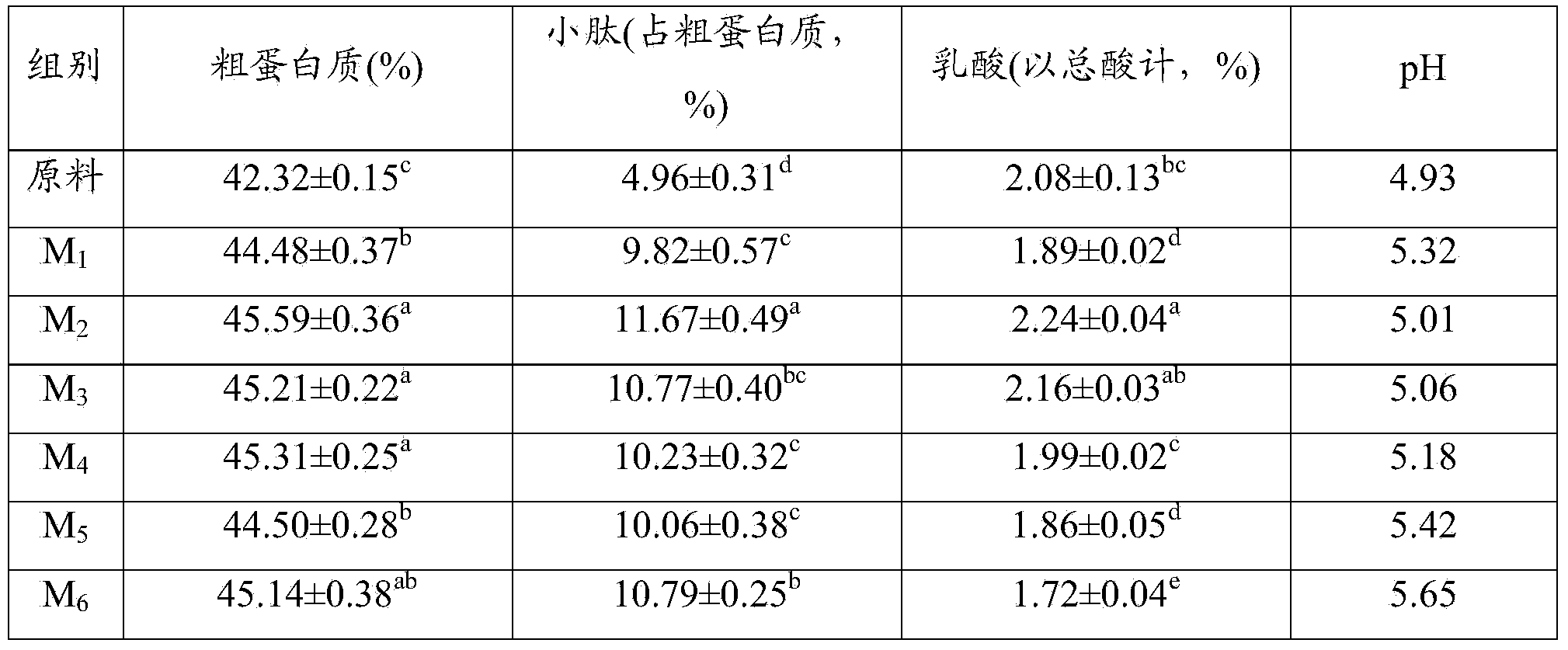

Complex bacterium for bean pulp fermentation and application of complex bacterium

The invention provides a complex bacterium for bean pulp fermentation. The complex bacterium is composed of bacillus subtilis, bacillus coagulans, aspergillus niger, aspergillus oryzae, lactobacillus plantarum and saccharomyces cerevisiae. The complex bacterium provided by the invention is obtained through repeated scientific experiment and reasonable combination based on physiological metabolism feature of the microorganism, the complex bacterium is vigorous in growth metabolism, is capable of secreting a plurality of enzymes, acids and other metabolites, and is capable of efficiently decomposing macromolecule protein, anti-nutritional factors and sensitization factors in the bean pulp, obviously increasing content of soluble protein, small peptide, organic acid, protease and vitamin and the number of probiotics and antibacterial peptide, improving the digestion utilization rate, inhibiting the growth of pathogenic bacteria and reducing the use of antibiotic; and meanwhile, the complex bacterium has acid fragrance of fermentation and is good in food attractant effect. The bacteria strains forming the complex bacterium are included in a feed additive variety catalogue (2013) issued by the department of agriculture, the complex bacterium is safe and reliable, and can be directly used for the industrial production for the bean pulp fermentation.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

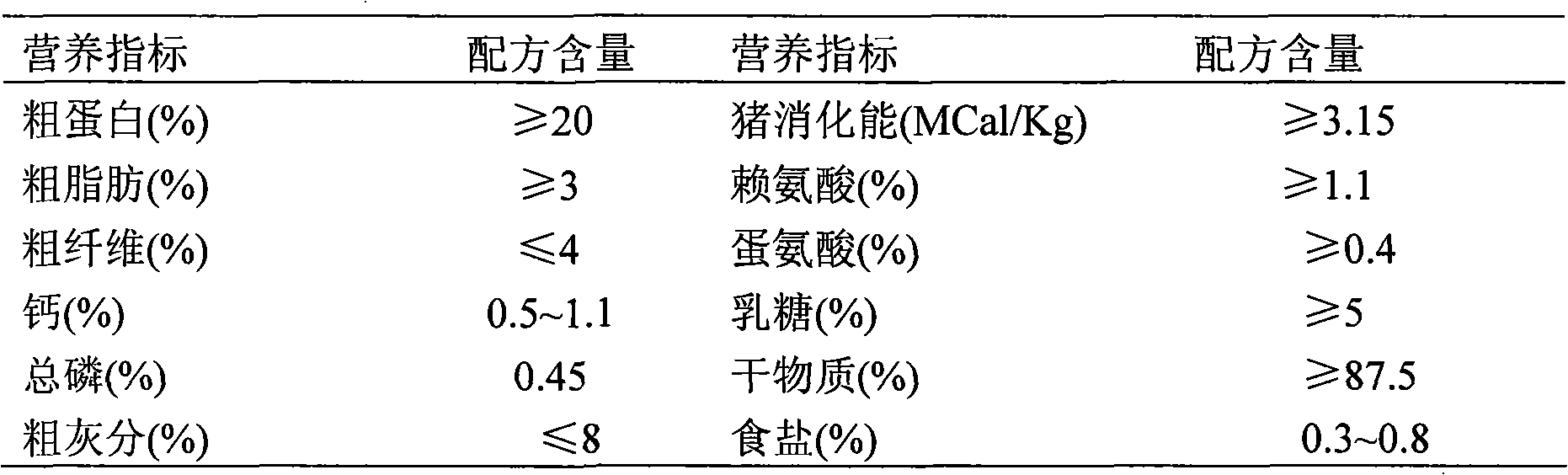

Creep, early weaned porket feeding and preparation method thereof

ActiveCN101773210AImprove digestibilityImprove digestion efficiencyAnimal feeding stuffAntigenAnimal science

The invention discloses a creep and an early weaned porket feeding. The early weaned porket feeding comprises the following components by weight part: 350 to 550 parts of Alpha-grain; 0.5 to 1 parts of choline chloride; 50 to 100 parts of peeled soybean meal; 1 to 5 parts of acidulant; 50 to 100 parts of antigen-extracted soybean meal; 0.5 to 0.75 parts of flavouring agent and masking agent; 25 to 75 parts of fish mel; 0.5 to 1 parts of lysine; 0.1 to 0.5 parts of methionine; 0.1 to 0.25 parts of probiotic (lactic acid bacteria and saccharomycetes); 1 to 4 parts of calcium hydrophosphate; 25 to 50 parts of oil meal; and 5 to 10 parts of mountain meal. A preparation method for the feeding includes the following steps: (a) the peeled soybean meal and the grain are first ground, and preferably, all the ground grain sizes can pass through a 40-mesh sieve; (b) the ground grain is cured by adopting a wet extrusion technique; (c) the materials are accurately weighed according to a formula, and the large materials and then the small materials are sequentially added in the mixer and sufficiently mixed; (d) the mixed material is dedusted; (e) the mixed material is palletized under the low temperature of less than 65 DEG C, and the powdery material directly enters the packaging process; (f) a conventional counterflow type feeding cooler is adopted for cooling.

Owner:ANYOU BIOTECH GRP

Open type method for producing fermentated lacitc acid and feedstuff using kitchen residue

InactiveCN1843152AIncrease productionLow crude protein contentFood processingSolid waste disposalLactic acid bacteriumOrganic acid

The invention relates to a method for preparing lactic acid and feed stuff with kitchen refuse in open type. The invention saves steps in current close-type process of strict sterilization and zymogeneous bacteria inoculation, nutrient addition and improves the lactic acid yield and protein content in prepared feed stuff. The lactic acid preparation comprises following steps: (1) drying and disintegrating kitchen refuse; (2) adding water; (3) adding cellulase and amylase; (4) open fermenting; (5) solid-liquid separating; (6) purifying and getting the lactic acid in fermentation liquor. The feed stuff preparation comprises following steps: (1) drying and disintegrating kitchen refuse; (2) adding water; (3) adding cellulase and amylase; (4) open fermenting; (5) solid-liquid separating; (6) sterilizing and drying the leavings, getting the feed stuff. The lactic acid content percent in organic acid is 94-98%, and its yield amounts to 64-75 g / l. The coarse protein content percent in feed stuff is 25-35% of the total feed stuff.

Owner:HARBIN INST OF TECH

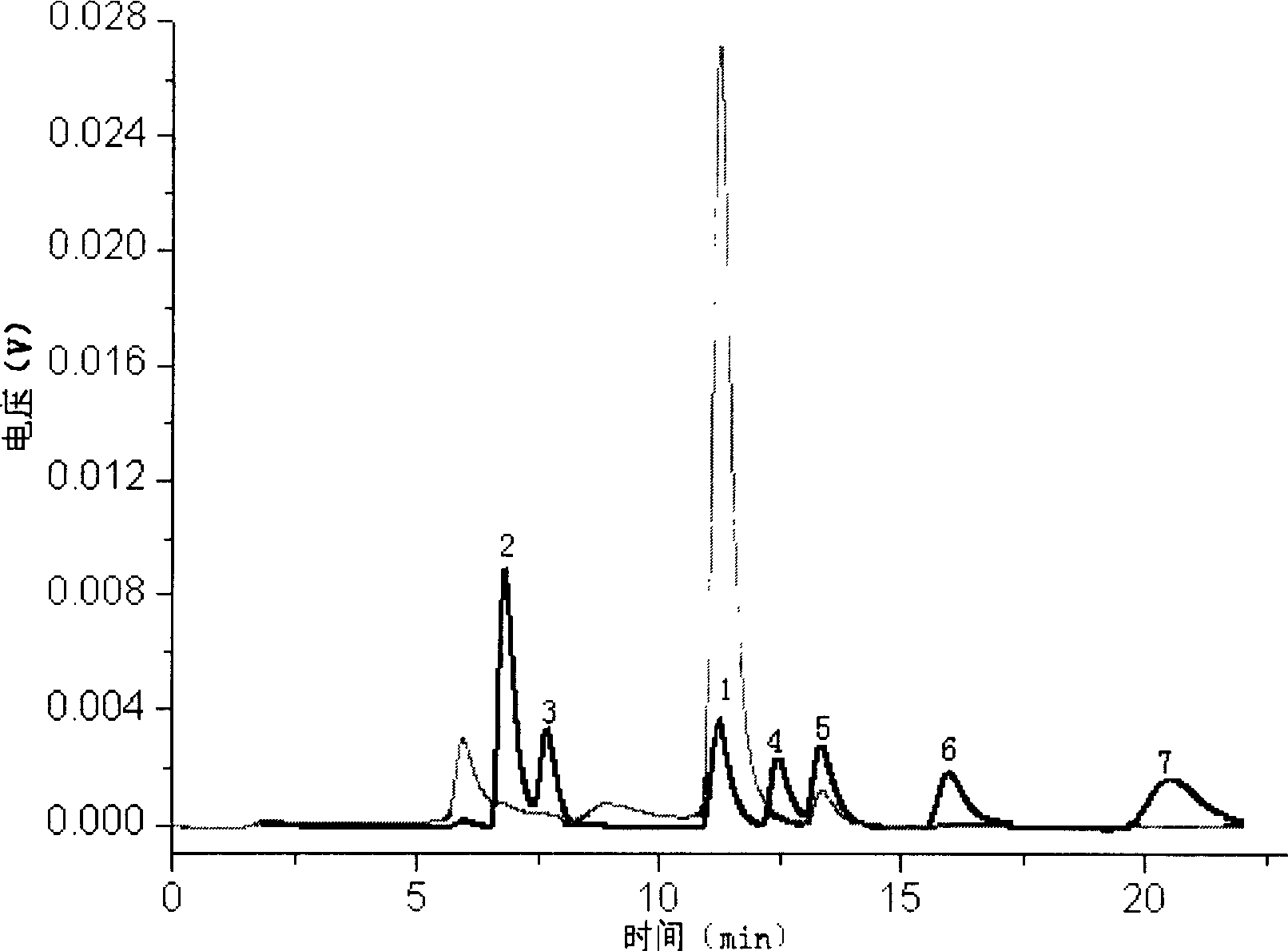

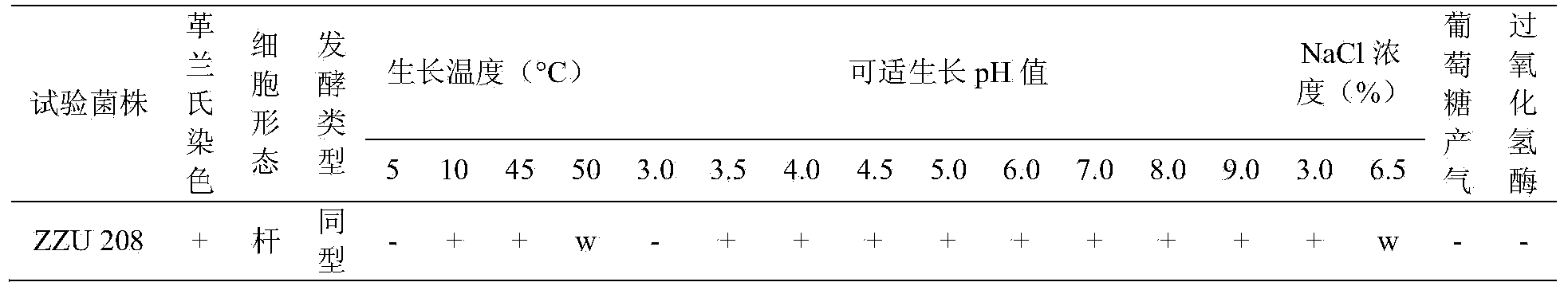

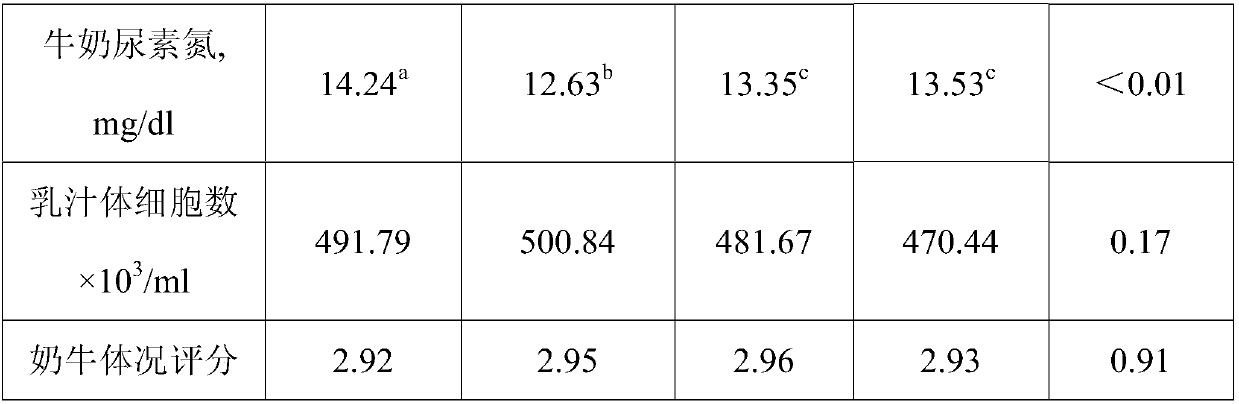

Lactobacillus plantarum and application thereof to alfalfa silage

ActiveCN104336416AHigh antibacterial activityLower pHBacteriaMicroorganism based processesMicrobiologySugar

The invention discloses lactobacillus plantarum and application thereof to alfalfa silage. The invention provides application of lactobacillus plantarum ZZU 208 CGMCC No.8990 or a fermentation product thereof or a bacterium suspension thereof or a culture solution thereof as an alfalfa silage additive or to preparation of the alfalfa silage additive. As proved by experiments, lactobacillus ZZU 208 which is separated from a corn silage fodder and is purified can grow and produce acid in an environment of low soluble sugar content, and has high bacteriostatic activity to pathogenic bacterium. In the alfalfa silage, the pH can be effectively lowered, the fiber content is lowered, and crude fat and crude protein content are increased; the lactobacillus plantarum has a potential application value on the aspect of silage additives.

Owner:ZHENGZHOU UNIV +1

Alpine area oat-common vetch mixed sowing method

InactiveCN102428820AIncrease productionHigh in proteinFertilising methodsHorticulturePastoralismWood pasture

The invention relates to an oat-common vetch mixed sowing method which is suitable for the alpine areas of the Tibetan plateau. The method is as follows: from the mid-May to the early June per year, seeds are sowed, the sowing depth of the seeds of oat and common vetch is 2-4cm; the seeding rate of the gramineous pasture oat is 150-165kg / hm<2>, the seeding rate of the leguminous pasture common vetch is 75-82.5kg / hm<2>, and oat and common vetch are sowed in a mixed sowing ratio of 2:1. By adopting the mixed sowing method, the yield of the pasture can be increased, the protein content of the pasture can be increased, the palatability of the pasture can be optimized, the soil structure can be improved, the soil fertility can be increased and the bottleneck that the leguminous pasture is lack in the alpine pasturing areas of the Tibetan plateau during the development of the animal industry can be effectively alleviated.

Owner:CHINA ACAD OF SCI NORTHWEST HIGHLAND BIOLOGY INST +1

Method for preparing high-moisture fermented granular feed for poultry

InactiveCN102178092AHigh densityHigh nutrient concentrationAnimal feeding stuffWorking-up animal fodderDiseaseBiotechnology

The invention relates to a method for preparing high-moisture fermented granular feed for poultry. The feed is composed of 60-70wt% of corn and 30-40wt% of fermented protein feed, firstly the fermented protein feed is prepared by utilizing composite bacterium liquid to ferment soybean meal, cottonseed meal and vinasse, and then the fermented protein feed is mixed with the corn to finally obtain the high-moisture fermented granular feed. The granular feed prepared by the method provided by the invention is convenient to store, package and transport; since the density of the granular feed is high, the volume is reduced, and the nutrient concentration is high, the feed intake of animals is correspondingly increased; and the composite flora is used for fermenting soybean meal and cottonseed meal to increase the content of crude protein and promote generation of the beneficial flora, thereby improving the beneficial flora in an intestinal canal, reducing the incidence of disease, improving the physicochemical properties of certain nutrient components in the feed, and enhancing the digestion absorption rate and the utilization rate of nutrient substances to a certain degree.

Owner:河南宏翔生物科技有限公司

Mixed feed for sea-bass fish and preparation method thereof

The invention discloses a mixed feed for sea-bass fish and a preparation method thereof. The mixed feed is made from the following raw materials in parts by weight: 35 to 45 of insect powders, 20 to 30 of a compound fermented material, 0.5 to 1 of fish oil, 10 to 20 of flour, 1.5 of calcium dihydrogen phosphate, 2 of a vitamin-mineral salt mixture, and 0.5 of choline chloride, wherein the compound fermented material is a fermented product of castor cake, rape cake and cotton cake with compound dry microbial inocula. The mixed feed is prepared by the steps as follows: mixing castor cake, rape cake and cotton cake according to a weight ratio of 1:1:1, and adding the compound dry microbial inocula composed of at least two of lactic acid bacteria, saccharomycetes, bacillus and geotrichum candidumlink strain for fermentation 2-24h, wherein the additive amount of the compound dry microbial inocula is 1% of the total weight of the fermentation raw material; and thoroughly mixing the raw materials, compounding, pelletizing and oven-drying to obtain the final product. The preparation method is simple and low in cost. The mixed feed for sea-bass fish is good in palatability and nutrition and can enhance disease resistance and stress resistance of sea-bass fish.

Owner:宁波天邦饲料科技有限公司

Straw feed fermented by white rot fungus and preparation method thereof

InactiveCN101606579AReduce crude fiber contentImprove digestibilityFungiFood processingBiotechnologyRumen

The invention relates to a straw feed fermented by white rot fungus and a preparation method thereof, and strain is the combination of white rot fungus Tf1 (pleurotus sajor-caju) and JG1 (pleurotus cornucopiae) which are screened in an oriented way, so that solid fermentation fungicide is cultured and prepared by three-stage propagation. Straw is pretreated by quicklime instead of being processed by high temperature sterilization without being washed by water or neutralized by acid. The obtained straw is accessed with white rot fungus composite fungicide to be fermented for 15-20 days, thus being taken as a first step of fermentation for degrading lignin in the straw and improving the straw digestion utilization rate of ruminant. After that, the fermented straw is accessed with yeast to be fermented for 3-4 days, thus being taken as a second step of fermentation for improving the crude protein content of the straw and further enhancing the nutritional value of the straw feed. After the two steps of fermentation, the crude fiber content of the straw is reduced by over 25%, the dry matter rumen (nylon bag technique) digestion rate is improved by over 20%, the crude protein content is increased by more than 50%, and the straw feed has no safety risk when being fed for animals. The invention has the characteristics of no energy consumption, no pollution, low cost, easy operation, high feeding value of the straw, and being suitable for local production of villages in China.

Owner:AGRO ENVIRONMENTAL PROTECTION INST OF MIN OF AGRI

Method for producing livestock and poultry feed by using fermentation of sugar cane tips

ActiveCN102106453AReduce slightly crude fiber contentFor long-term storageAnimal feeding stuffEffective microorganismProtein content

The invention provides a method for producing a livestock and poultry feed by using fermentation of sugar cane tips, which comprises the following steps of: taking chopped fresh sugar cane tips, adding urea or effective microorganism (EM) bacteria stock solution and molasses, and performing proper mixing; and then performing compaction, sealing, anaerobic fermentation and unsealing for use. According to the method, the crude fiber content of the sugar cane tips is effectively reduced, the crude protein content is improved, the digestive utilization rate of cattle on the sugar cane tips is further improved, the weight increment of the cattle is remarkably improved, the economic benefit is increased, and meanwhile, the sugar cane tips can be stored for a long term.

Owner:云南金草地牧业科技开发有限公司

Method for preparing high-moisture fermented granulated feed for pigs

InactiveCN102178093AEasy storageAvoid moisture cakingFood processingAnimal feeding stuffNutrientChemistry

The invention discloses a method for preparing a high-moisture fermented granulated feed for pigs. The feed is prepared from the following raw materials in percentage by weight: 65-70% of corn and 30-35% of fermented protein feed; and the method comprises the following steps: firstly, fermenting bean pulp, bran and a vinasse protein feed by using compound microbial liquid so as to obtain a fermented protein feed; and then, mixing the fermented protein feed with the corns. The feed prepared by using the method is a granulated feed which is easy to store, package and transport; because the density of the granulated feed is large, the volume thereof is reduced, and the nutrient concentration thereof is high, so that the feed intake of animals is correspondingly increased; and the crude protein content of the feed and the generation of beneficial microorganisms can be increased by simply fermenting the bean pulp and bran by using complex microorganisms, thereby improving the beneficial microorganisms in intestinal canals, reducing the occurrence of diseases, improving the physicochemical properties of some nutrients in the feed, and enhancing the digestibility of the feed and the utilization rate of nutrients in the feed to some extent.

Owner:河南宏翔生物科技有限公司

Method for preparing probiotics leaven used for plant-derived albumen

InactiveCN101240255AIncrease crude protein contentReduce morbidityBacteriaHydrolasesAquatic animalNutrition

A method for preparation of living-benefiting bacterium leaven of plant source albumen belongs to biofermentation technology field. The process of the invention comprises culture selecting, activating, culturing, anticentripetal concentrating, drying and mixing with enzyme to produce composite leaven containing activity living-benefiting bacterium and enzyme. Adapting the leaven, macro molecule albumen in material is degraded into small peptides, the number of living-benefiting bacterium viable bacteria of fermentation producers stock is up to 10 million, the content of crude protein is increased by 3 to 5, the proteolysis degree is achieved 12 to 15, Ph value is reduced to 3.8 to 4.0, the content of lactic acid is 5 to 6 The fermentation producers can be used for human beings health care and nutrition tonic, various critters dialy feeder, fish and shrimp daily feeder or other breed aquatics animals daily feeder.

Owner:江苏云海辰龙生物科技有限公司 +1

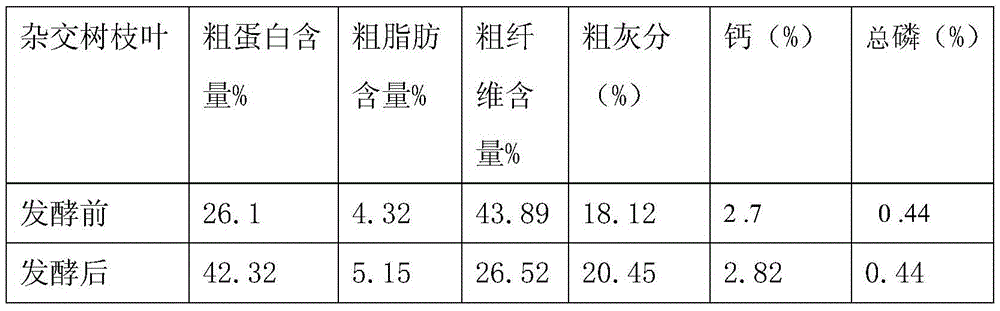

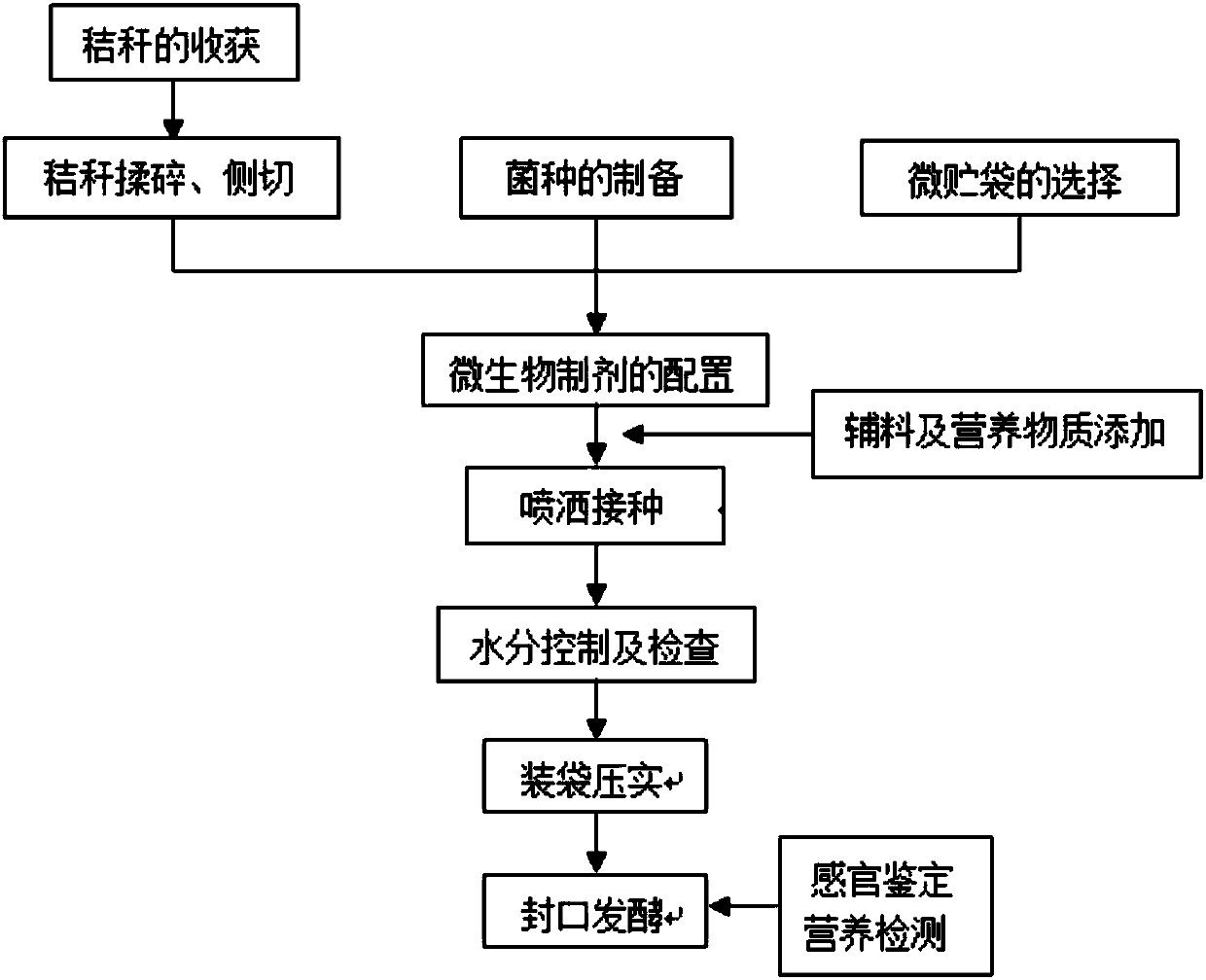

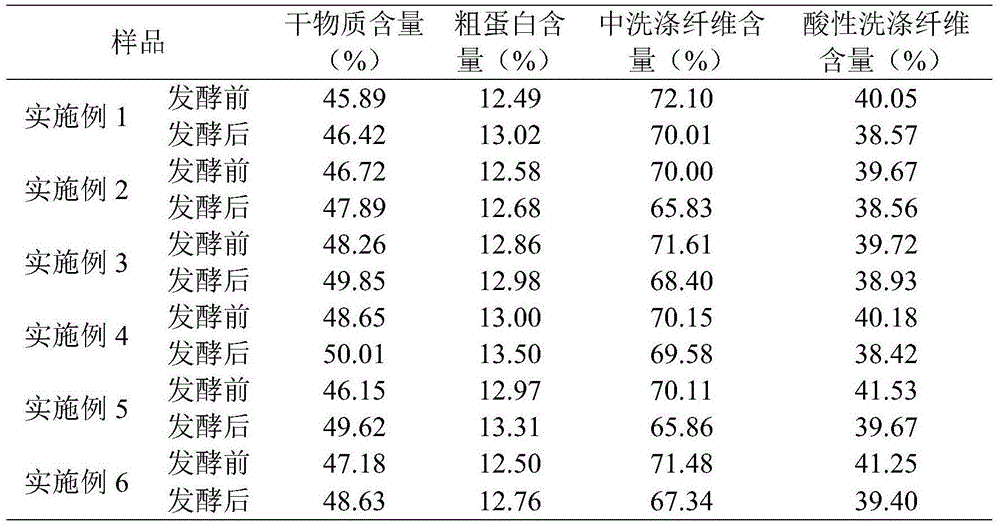

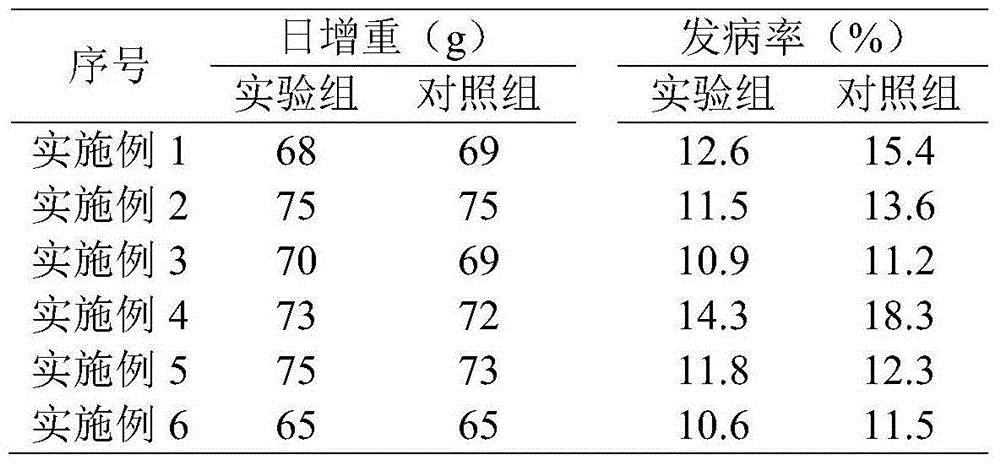

Hybrid paper mulberry tree leaf and shoot fermentation feed and preparation method thereof

InactiveCN105533160AIncrease crude protein contentReduce crude fiber contentAnimal feeding stuffAccessory food factorsAnimal feedPaper mulberry tree

The invention provides a preparation method of a hybrid paper mulberry tree leaf and shoot fermentation feed. The preparation method comprises the following steps of firstly crushing raw materials, performing soaking treatment with alkali, then performing high-temperature boiling, performing cooling and enzymolysis, and finally performing microbial fermentation so as to obtain finished products. The method disclosed by the invention is short in fermentation time, the obtained fermentation feed is high in the content of crude protein, reduced in the content of crude fibers, high in raising efficiency and environmentally-friendly, and animals fed with the fermentation feed grow quickly and are low in attack rate.

Owner:ANHUI ZHONGKE ANYUE FORESTRY TECH DEV CO LTD

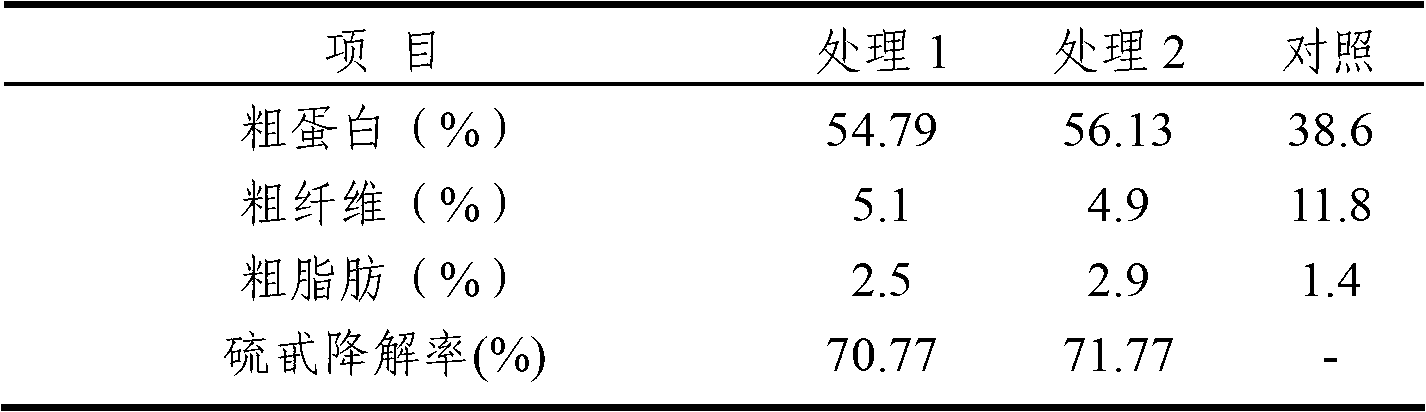

Composite microbial preparation as well as preparation method and application thereof

The invention discloses a composite microbial preparation as well as a preparation method and an application thereof. The composite microbial preparation comprises Bacillus subtilis, Lactobacillus plantarum and Saccharomyces cerevisiae. The composite microbial preparation is used for fermentation process of microbial silage forage, and can be used for effectively improving fiber degradation rate and biotransformation rate of the forage, improving NDF digestibility, increasing crude protein content, inhibiting breeding of harmful bacterium, and shortening fermentation period with wide application prospects and market values.

Owner:TIANJIN BIOFEED TECH CO LTD

Broussonetia papyrifera fermented feed and preparation method thereof

InactiveCN106387341AHigh protein contentIncrease crude protein contentAnimal feeding stuffAccessory food factorsNutrientBroussonetia

The invention relates to a broussonetia papyrifera fermented feed and a preparation method thereof, and belongs to the technical field of feed production. The broussonetia papyrifera fermented feed disclosed by the invention comprises the following components in parts by weight: 15-25 parts of a plant ferment, 450-600 parts of broussonetia papyrifera, 40-60 parts of stevia rebaudianum herb, 400-500 parts of energy accessories, 2-5 parts of compound trace elements and 2-5 parts of calcium and phosphate supplements. The broussonetia papyrifera fermented feed is prepared by performing sealed fermentation on the components, wherein the fermentation humidity is 60-70% and the fermentation temperature is 25-35 DEG C. The broussonetia papyrifera fermented feed disclosed by the invention is high in protein content, low in lignin and fibrin contents, high in broussonetia papyrifera nutrient utilization rates, and good in palatability. The broussonetia papyrifera fermented feed provided by the invention is high in broussonetia papyrifera whole plant utilization efficiency and high in Nutritive values.

Owner:汪金小

Biological feed for sheep and preparation method thereof

InactiveCN104054967AImprove digestibilityPromote fermentationFood processingAnimal feeding stuffDiseaseAnimal science

The invention provides a biological feed for sheep. The feed comprises the following components by weight: 40-60 parts of bagasse, 10-15 parts of dry cassava dregs, 10-15 parts of sugar cane tail leaf, 1-2 parts of dicalcium phosphate, 4-6 parts of urea, 4-6 parts of molasses and 0.4-0.9 parts of a feed additive. The invention also provides a preparation method of the biological feed for sheep. The biological feed for sheep provided by the invention makes full use of raw materials including waste bagasse, sugarcane tail leaf and cassava dregs, which are not originally consumed by the sheep; through the fermentation of microorganism, the feed has enhanced palatability and is easy for sheep to eat; the feed improves the utilization rate of nutrient contents and improves digestion capability of the sheep; the fermented feed contains a large amount of beneficial microorganisms and nutrients for the growth of sheep; and sheep fed with the feed has enhanced disease resistance and improved lamb quality and taste.

Owner:TROPICAL CORP STRAIN RESOURCE INST CHINESE ACAD OF TROPICAL AGRI SCI

Combined bacteria fermented bran high protein predigesting feed and preparation method

InactiveCN102178033AHigh densityHigh nutrient concentrationAnimal feeding stuffAccessory food factorsDiseaseBiotechnology

The invention discloses combined bacteria fermented bran high protein predigesting feed and a preparation method. The combined bacteria fermented bran high protein predigesting feed consists of 30 to 70 weight percent of fermented wheat bran and 30 to 70 weight percent of composite bacteria culture material. The preparation method comprises: preparing the fermented wheat bran and the composite bacterial culture material by using dry corn pulp fermented by solution of combined bacteria and wheat bran; and mixing the fermented wheat bran and combined bacteria culture material. The prepared granulated feed is convenient to store, package and transport, has high density, small volume and high nutrient concentration, and thereby improves the feed intake of animals; and the addition of the dry corn pulp fermented by the solution of the combined bacteria and the wheat bran increases the coarse protein content and beneficial bacterium colonies in the feed, improve the beneficial bacterium colonies in intestinal tracts, reduce diseases, improve physical properties of some nutrients in the feed and improve digestion and absorption rates and nutrient utilization rate to a certain degree.

Owner:河南宏翔生物科技有限公司

Probiotics leavening agent suitable for fermenting cake dreg type feed raw materials and preparation method of probiotics leavening agent

InactiveCN102934735AHigh viable countHigh nutritional valueAnimal feeding stuffProtein qualityLeavening agent

The invention discloses a probiotics leavening agent suitable for fermenting cake dreg type feed raw materials and a preparation method of the probiotics leavening agent. The leavening agent comprises composite probiotics powder and auxiliary materials. The composite probiotics powder is candida tropicalis powder, aspergillus niger agent, bacillus licheniformis powder and lactobacillus plantarum powder. The probiotics leavening agent can be used for cake dreg type feed raw material fermentation, can effectively degrade anti-nutritional factors in cake dregs, improves taste and protein quality of cake dreg feed, and accordingly effectively improve use ratio of the cake dregs in various livestock feed.

Owner:BEIJING DABEINONG TECH GRP CO LTD +2

Fermented feed and production process thereof

InactiveCN101756019AReduce isothiocyanateReduced oxazolidinethione contentAnimal feeding stuffBiotechnologyRapeseed

The invention provides a fermented feed and a production process thereof, wherein the fermented feed forms composite fermentation strains by three groups of lactic acid bacteria, yeast and bacillus which have more than ten bacterial strains, the composite fermentation strains are mixed with molasses according to the ratio of 1:1 and are mixed with fermentation zymolyte (cottonseed meal is mixed with rapeseed meal with the grain size of 1.0 to 2.0mm according to the ratio of 90:10-60:40) to form fermentation material according to the ratio of 0.1 percent, after the moisture content of the material is adjusted to 40-60 percent, fermentation of 30 plus or minus 2 DEG C is carried out for 48 hours, and expansion drying under 80 DEG C is carried out after completing the fermentation. Compared with non fermentation, a fermentation miscellaneous meal product produced by the production process reduces the gossypol, isothiocyanate and oxazolidinethione contents by more than 80 percent, improves the crude protein content by more than 5 percent, and has the lactate content larger than 2.5 percent and pH value about 4.5. The product can substitute soya bean meal of 30 to 50 percent in small, medium and large pig feed, the feed cost is lowered by 20 to 50 yuan / ton, feed intake is improved by about 10 percent, the feed meal has close phase comparison, daily gain is improved by about 4 percent, the morbidity is greatly reduced, and the ammonia odour of a colony house is obviously reduced.

Owner:北京资源亚太饲料科技有限公司

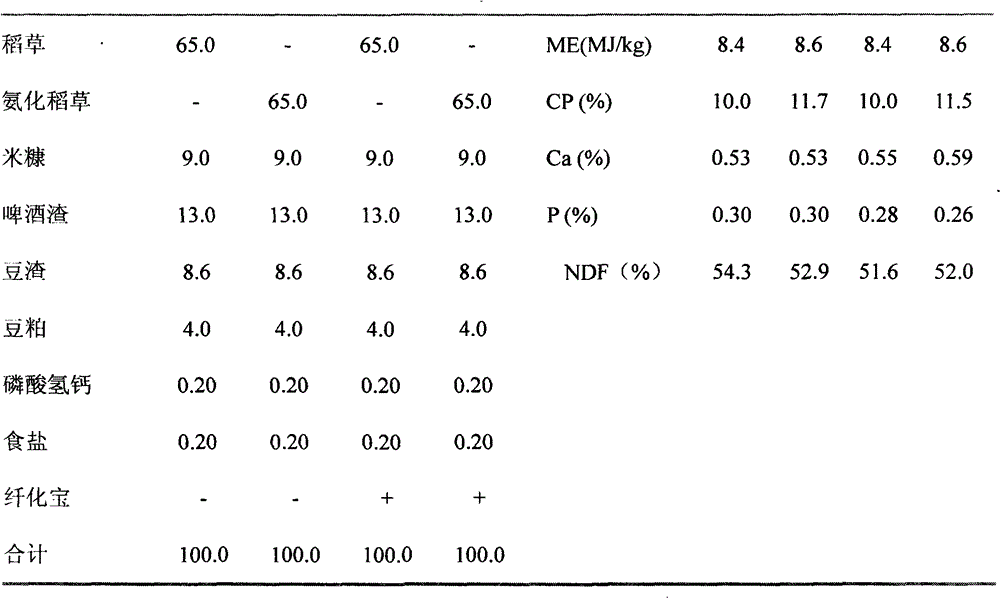

Hu sheep totaI mixed ration (TMR) feed and Hu sheep cultivation method

ActiveCN102715381AIncrease crude protein contentImprove palatabilityFood processingAnimal feeding stuffCell wall polysaccharideAgricultural science

The invention discloses a feed containing ammoniated straws and a cultivation method of a Hu sheep. By adopting the feed, the coarse protein contents of the straws can be effectively improved, cell wall polysaccharides components and the degree of lignifications of the straws are reduced, the palatability of the straws is improved, and the nutrition value of the straws is effectively improved. By comprehensively using the straws, folium mori and byproducts of subsidiary agricultural products as the feed resources of the Hu sheet, the poor agricultural product wastes are well utilized to realize the breakthrough of the technology.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Method for preparing crop straw feed based on composite puffing and biological processing technology

InactiveCN103798512ASimple processReduce energy consumptionAnimal feeding stuffBiotechnologyLactic acid bacterium

The invention relates to a method for preparing crop straw feed based on composite puffing and biological processing technology. The method is characterized by comprising the steps of crushing crop straws, chemically preprocessing the crushed crop straws, puffing the chemically preprocessed straws so as to destroy the wood fiber structure of the straws and to realize safety and no toxicity and side effect, and adding mixed strains such as yeast and lactic acid bacteria into the puffed material for solid fermentation so as to produce mycoprotein. Therefore, the content of crude protein of the straw feed can be increased from 2 to 4 percent to 8 to 12 percent, and the digestion rate can be increased from 30 to 45 percent to more than 60 percent. The method has the advantages of simplicity in process, low energy consumption, high applicability and easiness in industrialization.

Owner:NANJING AGRICULTURAL UNIVERSITY

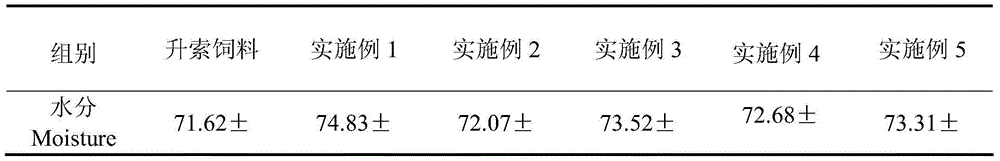

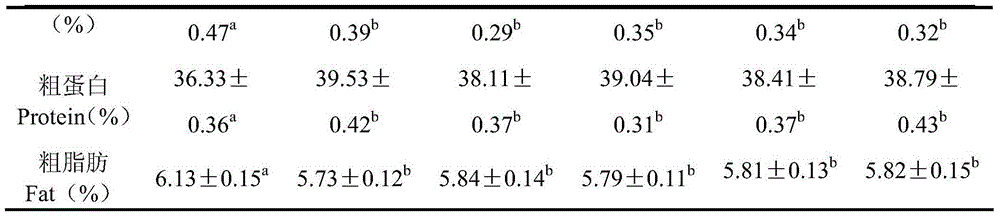

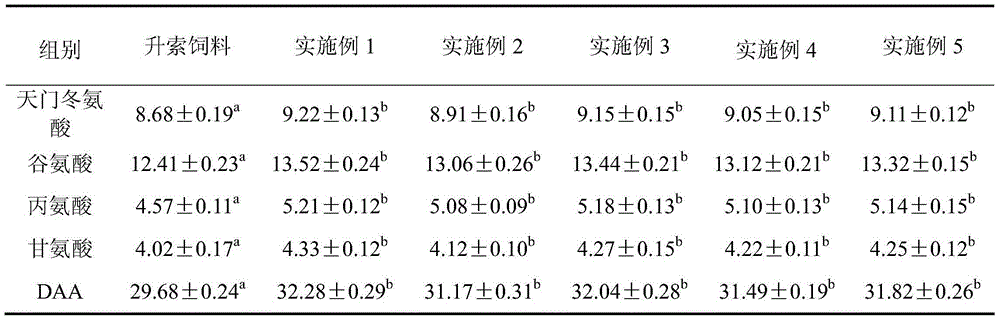

Compound feed for Pelteobagrus fulvidraco and preparation method of compound feed

InactiveCN104957437AMeet nutritional needsImprove qualityFood processingAnimal feeding stuffFish oilRapeseed

The invention relates to a fish feed and in particular relates to a compound feed for Pelteobagrus fulvidraco and a preparation method of the compound feed. The compound feed for Pelteobagrus fulvidraco is prepared from the following components in parts by weight: 20-30 parts of fish meal, 8-15 parts of barley, 7-14 parts of rapeseed meal, 5-9 parts of soybean meal, 6-10 parts of honeysuckle flower powder, 3-8 parts of Portulaca oleracea powder, 3-7 parts of licorice powder, 3-7 parts of green bean powder, 3-5 parts of Lycium barbarum powder, 2-6 parts of mulberry powder, 2-6 parts of fish oil, 1-5 parts of tangerine powder, 1-4 parts of shell powder, 1-4 parts of honey, 1-4 parts of olive oil and 1-4 parts of compound vitamin. Pelteobagrus fulvidraco fed by the Pelteobagrus fulvidraco compound feed has low feed coefficient, and has high crude protein content, low crude fat content and high flavor amino acid content in Pelteobagrus fulvidraco muscles.

Owner:QINGDAO HAIZHIXING BIOLOGICAL SCI & TECH

Novel process for performing pine pollen fermentation by probiotics

The invention discloses a novel process of performing pine pollen fermentation by probiotics. The process comprises the following steps of: (1) collecting pine pollen, timely drying the pine pollen in the sun, sieving the pine pollen for removing impurities, and carrying out drying treatment on the sieved pine pollen; (2) carrying out sterilization treatment on the pine pollen by a 60Co gamma radiation sterilization process; (3) carrying out fermentation by lactobacillus plantarum Lp-115 and lactobacillus paracasei Lpc-37 which are taken as pine pollen zymogens; and (4) after the fermentation is ended, drying a fermentation product in a drying box at 40-50 DEG C or performing reduced pressure evaporation on the fermentation product until the water content of the product is 5%-7%. The novel process for performing pine pollen fermentation by plantarum Lp-115 and lactobacillus paracasei Lpc-37 has the beneficial effects that the solubility, mouthfeel and special flavor of the pine pollen can be significantly improved, the nutritional value of the pine pollen is improved, and the crude protein content of the fermented pine pollen is enhanced by more than 16.89%. Moreover, the amount of active probiotics in the fermented pine pollen can reach 9.21*109cfu / g, so that the pine pollen has the efficacies of pollen and probiotics, and can be taken as an ideal ingredient of a health care product.

Owner:浙江亚林生物科技股份有限公司

Production technology of aspergillus oryzae fermented soybean meal

InactiveCN103859150AIncrease crude protein contentReasonable compositionAnimal feeding stuffFiberPhytase

The invention discloses a production technology of aspergillus oryzae fermented soybean meal. The production technology comprises the following steps: (1) aspergillus oryzae strain activation; (2) aspergillus oryzae strain liquid culture; (3) aspergillus oryzae strain culture in a triangular flask; and (4) soybean meal fermentation. The production technology is simple and easy to understand, the produced soybean meal is a main protein raw material of animal feeds, and has the advantages of high crude protein content, reasonable amino acid composition, high animal digestion utilization rate and the like. Aspergillus oryzae also can produce amylase, saccharifying enzyme, cellulase, phytase and the like, and under the action of protease, nondigestible macromolecular proteins are degraded into peptone, peptides and various amino acids, and so that crude fiber, phytic acid and other matters, which are difficult to absorb, in accessories can be degraded, and the nutritional value, health function and digestive rate can be improved.

Owner:QINGDAO ZHONGREN PHARMA

Fermented feed for fish

InactiveCN105104847AWide variety of sourcesLow costFood processingAnimal feeding stuffRed mulletCorn flour

The invention relates to an aquatic product culture feed and particularly relates to a fermented feed for fish, which is low in cost, wide in source and capable of increasing the growth rate. The fermented feed is prepared from the following raw materials in parts by weight: 20-25 parts of corn flour, 15-20 parts of wheat bran, 5-8 parts of peanut bran, 5-10 parts of fish meal, 5-10 parts of bagasse pith, 3-5 parts of leaven, 2-3 parts of molasses and 1-2 parts of microelements. The fermented feed for fish, provided by the invention, is rich in nutrient and simple in preparation method, and the fish like to eat the fermented feed.

Owner:颜成存

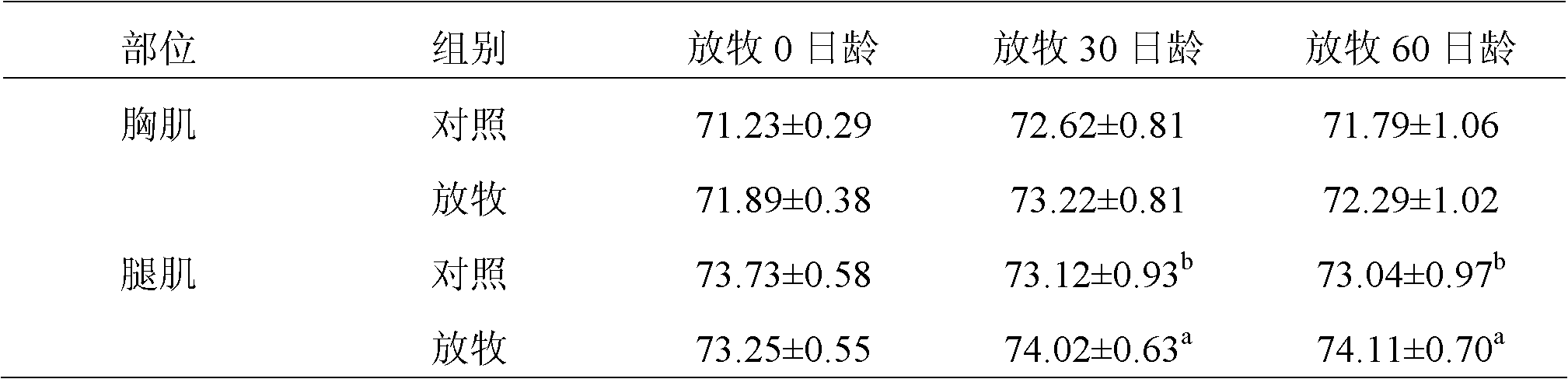

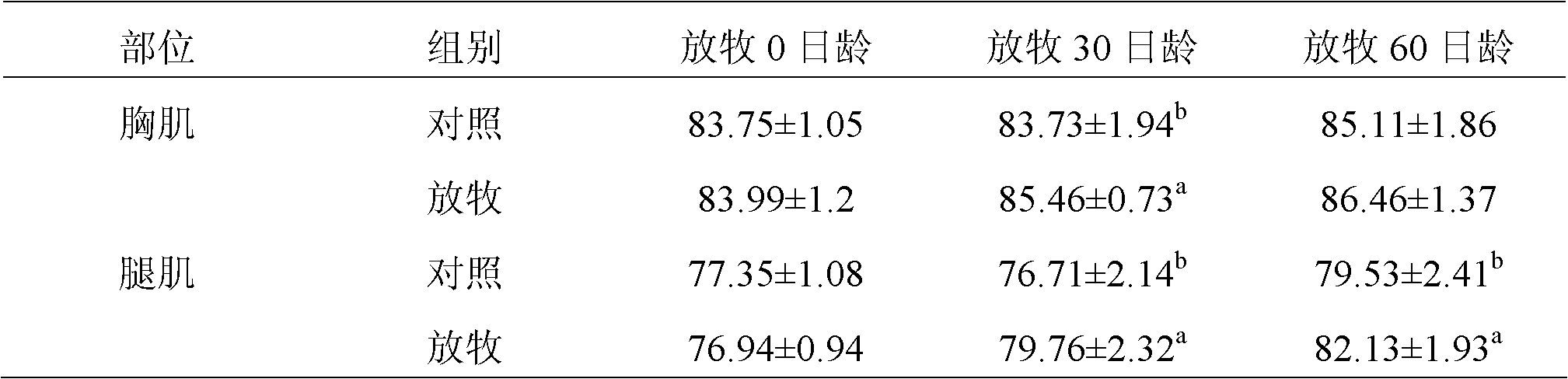

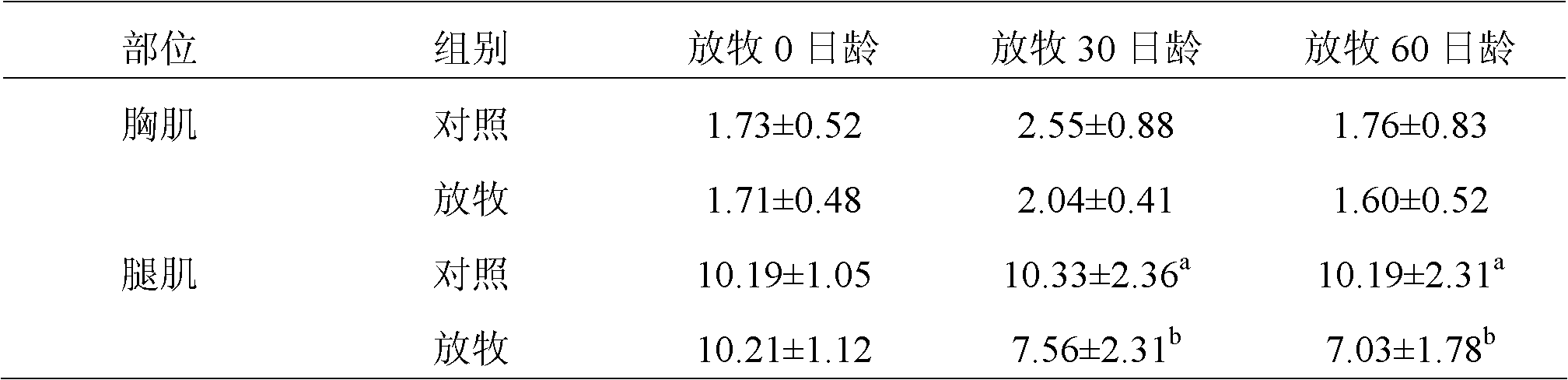

Cultivation method capable of improving flavor and quality of chicken meat

InactiveCN101971789AImprove survival rateImprove farming efficiencyAnimal feeding stuffGrazingFlavor

The invention discloses a cultivation method capable of improving the flavor and the quality of chicken meat and belongs to the field of animal husbandry in agriculture. In the method, a feeding process is divided into two stages: in the first stage, a high-density intensification cultivation mode is adopted, wherein chicken are fed in a plastic tent hen house during a period from the first day of age to the day when the weight of the chicken reaches market weight, the feeding density is 10-30 / m<2>, free choice feeding is adopted and the chicken drink freely throughout the day; and in the second stage, a low-density grazing cultivation mode is adopted, wherein when the weight of the chicken reaches the market weight, a grazing and supplementary feeding method is adopted, and the chicken are fed for 30-60 days, with the feeding density of 30-50 / mu. The two-stage broiler feeding method provided by the invention is favorable to the solving of the problems that chicken meat quality is decreased due to intensification cultivation at present, the survival rate is low, the cultivation cost is higher under a free broiler raising state, and the like, the improvement of the quality and flavor of the chicken meat and the increase of cultivation benefits.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Sunflower seed meal microbial protein feed and preparation method thereof

ActiveCN103598415AReduce manufacturing costImprove immunityFood processingAnimal feeding stuffBiotechnologyCandida tropicalis

The invention relates to a sunflower seed meal microbial protein feed. The sunflower seed meal microbial protein feed is prepared by the following steps: mixing sunflower seed meal and wheat bran in a weight part ratio of 80 to 20 and adding water to prepare a solid-state fermentation culture medium; inoculating 5 parts by weight of a mixed strain on the solid-state fermentation culture medium and mixing and fermenting at 20-32 DEG C; and after fermenting, drying and crushing a fermented product to obtain the feed. The sunflower seed meal microbial protein feed takes the sunflower seed meal with husks as a main raw material, so that the production cost is low. The sunflower seed meal microbial protein feed contains bacillus subtilis, kluyveromyces marxianus, lactobacillus plantarum and candida tropicalis, has no any chemical additive and has the mellow flavor of fermented natural plants; the crude protein content of the feed is 35.5% and a plurality of amino acids, vitamins and microelements are contained in the feed, so that the sunflower seed meal microbial protein feed is a high-quality and low-price nutritional microbial protein feed.

Owner:孙萍

Method for producing feed of high-yield dairy cow by using corn straws fermented by Rhodotorula glutinis

InactiveCN102178037AStrong reproductive abilityFull of nutritionFood processingAnimal feeding stuffChemistryMilk yield

The invention discloses a method for producing a feed of high-yield dairy cows by using corn straws fermented by Rhodotorula glutinis. The method comprises the following steps of: activating a yeast strain to obtain a corn straw material fermented by the Rhodotorula glutinis by adding aqueous solution, uniformly mixing 40 to 60 weight percent of corn material, 5 to 10 weight percent of cottonseedmeal, 5 to 12 weight percent of distillers dried grains with soluble, 10 to 20 weight percent of concentrated feed and 20 to 30 weight percent of corn straw material fermented by the Rhodotorula glutinis to obtain a mixture, feeding the mixture into a solid fermentation chamber and fermenting, drying a fermented solid feed, crushing, adding a silage into the solid feed, and mixing and stirring uniformly and packaging to obtain the feed of the high-yield dairy cows. In the method, the corn straws are fermented by a biological strain and then are taken as a feed raw material, so that the cost is reduced, the nutrition is rich and easy to absorb, and the method is favorable for improving the milk yield of dairy cows.

Owner:河南宏翔生物科技有限公司

Fermented feed containing rapeseed meal, and preparation method of fermented feed

ActiveCN104397347AImprove palatabilityPromote absorptionAnimal feeding stuffBacillus licheniformisRapeseed

The invention relates to the field of livestock feed, and discloses a fermented feed containing rapeseed meal, and a preparation method of the fermented feed. The preparation method comprises the steps of carrying out solid state fermentation on fermentation raw materials including the rapeseed meal, compound microbial strain, sodium hydroxide and water, and then drying to obtain the fermented feed containing the rapeseed meal. According to the preparation method, lactobacillus plantarum, bacillus subtilis, bacillus licheniformis and saccharomyces cerevisiae are taken as microbial strains for the solid state fermentation of the rapeseed meal, and the aim of remarkably improving the contents of protein and small peptide of the rapeseed meal can be realized in the environment of solid state fermentation in virtue of metabolic activity and interaction of all microorganisms, so that the application of the rapeseed meal in the feed can be further expanded.

Owner:COFCO GROUP +2

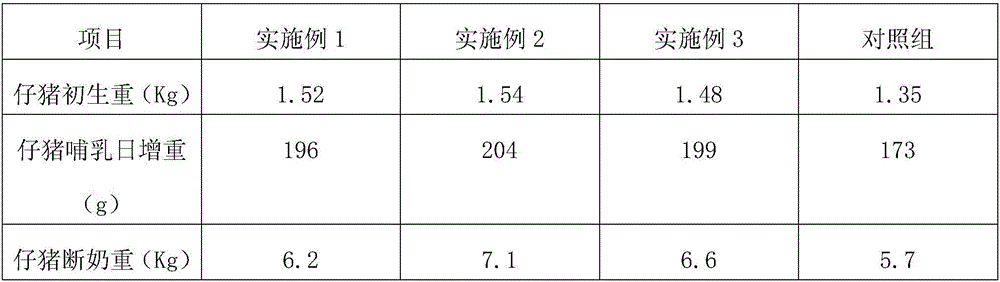

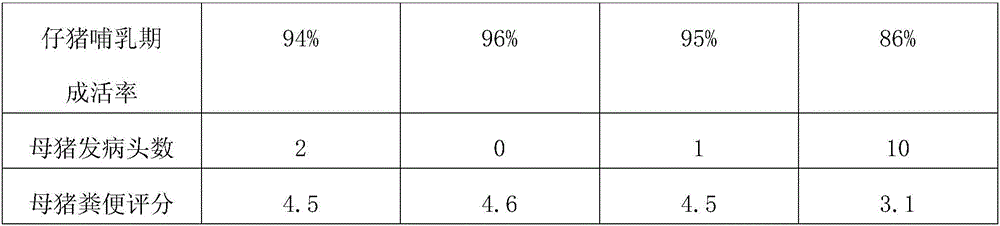

Lactating sow feed capable of increasing milk yield and preparation method thereof

InactiveCN106615798APromote milk productionIncrease with good tasteFood processingAnimal feeding stuffAnimal scienceEconomic benefits

The invention provides a lactating sow feed capable of increasing the milk yield and a preparation method thereof, and relates to the technical field of feeds. The feed is prepared from the following raw materials: corn, bean cake, peanut cake, wheat bran, fish meal, bone meal, shell powder, salt, a functional additive, and green feed; wherein the functional additive can promote the appetite and lactation of sows and enhance the immunity of sows, and the green feed is a feed composition, which contains multiple vitamins and is low in lignin. The provided lactating sow feed is green and safe and has comprehensive nutrients. Traditional Chinese herbals are added, the feed cost is reduced, moreover, the lactation of sows is promoted, and the feed utilization rate is improved. The taste is better accepted by sows, the appetite of sows is promoted; at the same time, the milk quality is improved, the incidence and death rate of piglets are largely reduced, and the economic benefits are increased.

Owner:广西浩昌敏再生资源利用有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com