Biological feed for sheep and preparation method thereof

A technology for biological feed and raw materials, applied in the field of livestock and poultry feed, can solve the problems of waste of feed, difficulty in operation, decay, etc., and achieve the effects of promoting lactic acid fermentation, improving absorption rate, and improving functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

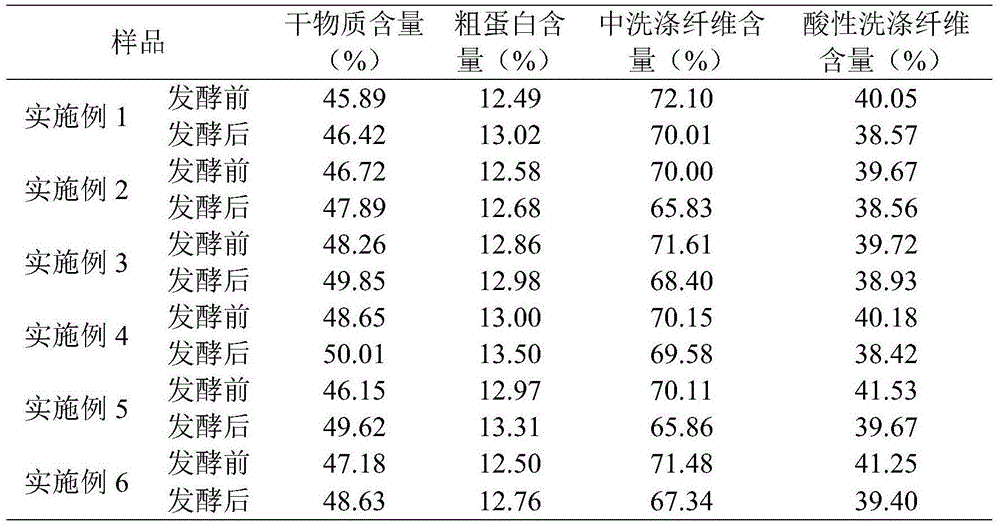

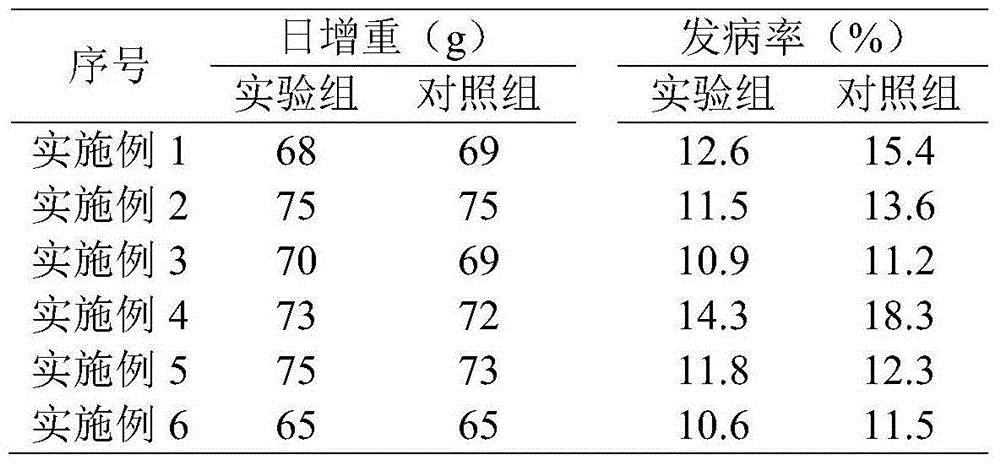

Examples

Embodiment 1

[0023] A biological feed for sheep, made from the following raw materials in parts by mass: bagasse 20kg, dry cassava bagasse 5kg, sugarcane tail leaves 5.0kg, calcium hydrogen phosphate 0.5kg, urea 2.0kg, waste molasses 2.0kg, cellulose Enzyme 0.05kg, lactic acid bacteria 0.05kg, yeast 0.05kg, bifidobacteria 0.05kg.

[0024] A method for preparing biological feed for sheep, comprising the following steps:

[0025] (1) Add the mixture of cellulase, lactic acid bacteria, saccharomyces and bifidobacteria in the formulated amount to make a suspension with 30°C water, add the formulated amount of calcium hydrogen phosphate, waste molasses and urea, and mix well;

[0026] (2) Add bagasse, dried cassava bagasse, and tail leaves of sugarcane in a formula amount, mix evenly, seal and ferment for 10 days, and obtain the biological feed for sheep of the present invention.

Embodiment 2

[0028] A biological feed for sheep, made of the following raw materials in parts by mass: bagasse 30kg, dry cassava bagasse 7.5kg, sugarcane tail leaves 7.5kg, calcium hydrogen phosphate 1.0kg, urea 3.0kg, waste molasses 3.0kg, fiber Sulfase 0.15kg, lactic acid bacteria 0.1kg, yeast 0.1kg, bifidobacteria 0.1kg.

[0029] A method for preparing biological feed for sheep, comprising the following steps:

[0030] (1) Add the mixture of cellulase, lactic acid bacteria, saccharomyces and bifidobacteria in the formulated amount to make a suspension with 40°C water, add the formulated amount of calcium hydrogen phosphate, waste molasses and urea, and mix well;

[0031] (2) Add bagasse, dried cassava bagasse, and tail leaves of sugarcane in a formula amount, mix evenly, seal and ferment for 15 days, and obtain the biological feed for sheep of the present invention.

Embodiment 3

[0033] A biological feed for sheep, made of the following raw materials in parts by mass: bagasse 25kg, dry cassava bagasse 6kg, sugarcane tail leaves 6kg, calcium hydrogen phosphate 0.7kg, urea 2.5kg, waste molasses 2.5kg, cellulase 0.1kg, lactic acid bacteria 0.07kg, yeast 0.07kg, bifidobacteria 0.07kg.

[0034] A method for preparing biological feed for sheep, comprising the following steps:

[0035] (1) Add the mixture of cellulase, lactic acid bacteria, saccharomyces, and bifidobacteria in the formulated amount to make a suspension with 35°C water, add the formulated amount of calcium hydrogen phosphate, waste molasses and urea, and mix well;

[0036] (2) Add bagasse, dried cassava bagasse, and tail leaves of sugarcane in a formula amount, mix evenly, and seal and ferment for 12 days to obtain the biological feed for sheep of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com