Method for processing inapplicable tobacco leaves by musca domestica larva to prepare biological protein feed

A technology of biological protein feed and housefly larvae, applied in animal feed, animal feed, application, etc., to achieve the effect of occupying less space, less emission, and increasing profits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

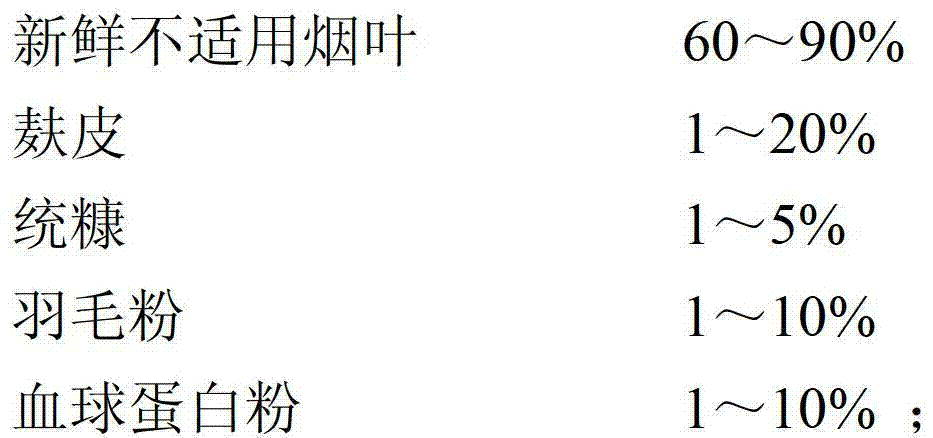

[0044] After clearing the fresh unsuitable tobacco leaves from the tobacco field, crush the unsuitable tobacco leaves with a crusher to make the particle size reach 2mm, then add appropriate amount of nutritional auxiliary materials (see Table 1), stir evenly, and prepare compost. Pour the culture material into a plastic pot (length×width×height=80×60×20cm), the height of the culture material is 6cm, and insert an appropriate amount of housefly eggs on the surface of the culture material, and the egg density is: 0.5g housefly eggs / kg compost. At room temperature, the housefly eggs hatched into larvae on the 2nd day and began to decompose and transform the compost. After 5 days, the housefly larvae treated the compost to brown, the material was loose, and had no irritating smoke smell. After drying with hot air at 80°C, it could be made into biological protein feed.

[0045] The prepared biological protein feed has a crude protein content of 20.8%, a nicotine content of 0.1%,...

Embodiment 2

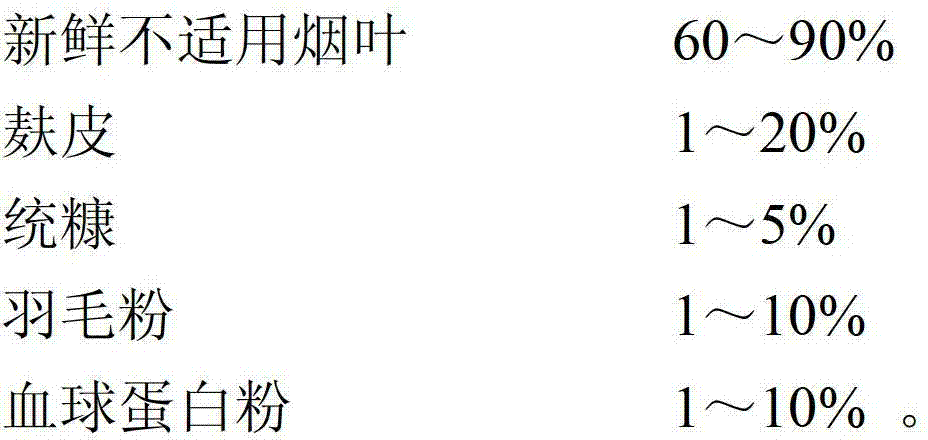

[0050] After the fresh unsuitable tobacco leaves are cleared from the tobacco field, the unsuitable tobacco leaves are crushed with a crusher to make the particle size reach 3mm, and then an appropriate amount of nutritional auxiliary materials (see Table 2) are added, stirred evenly, and prepared into a compost. Pour the culture material into a plastic pot (length×width×height=80×60×20cm), the height of the culture material is 7cm, and insert an appropriate amount of housefly eggs on the surface of the culture material, and the egg density is: 1.0g housefly eggs / kg compost. At room temperature, the housefly eggs hatched into larvae on the 2nd day and began to decompose and transform the compost. After 5 days, the housefly larvae treated the compost to brown, the material was loose, and had no irritating smoke smell. After drying with hot air at 100°C, it could be made into biological protein feed.

[0051] The prepared biological protein feed has a crude protein content of ...

Embodiment 3

[0057] After the fresh unsuitable tobacco leaves are cleared from the tobacco field, the unsuitable tobacco leaves are crushed with a crusher to make the particle size reach 4mm, and then an appropriate amount of nutritional auxiliary materials (see Table 3) are added, stirred evenly, and prepared into a compost. Pour the culture material into a plastic pot (length×width×height=80×60×20cm), the height of the culture material is 8cm, and insert an appropriate amount of housefly eggs on the surface of the culture material. The egg density is: 1.2g housefly eggs / kg compost. At room temperature, the housefly eggs hatched into larvae on the 2nd day and began to decompose and transform the compost. After 5 days, the housefly larvae treated the compost to brown, the material was loose, and had no irritating smoke smell. After drying with hot air at 80°C, it could be made into biological protein feed.

[0058] The prepared biological protein feed has a crude protein content of 20.0%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com