Supercritical carbon dioxide power circulating system and method for fusion reactor

A carbon dioxide, circulating system technology, applied in steam application, greenhouse gas reduction, machine/engine, etc., to achieve the effect of efficient use of heat sources, simple structure, and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solutions of the present invention in detail.

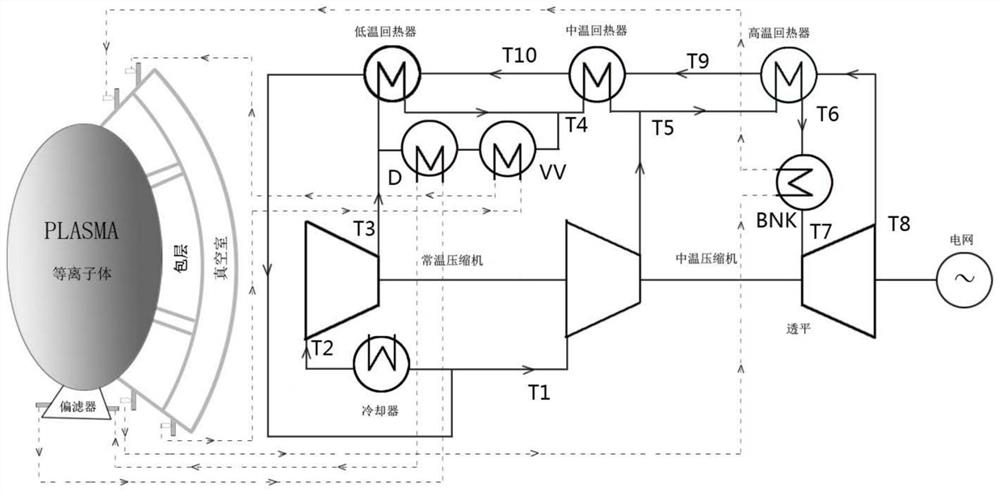

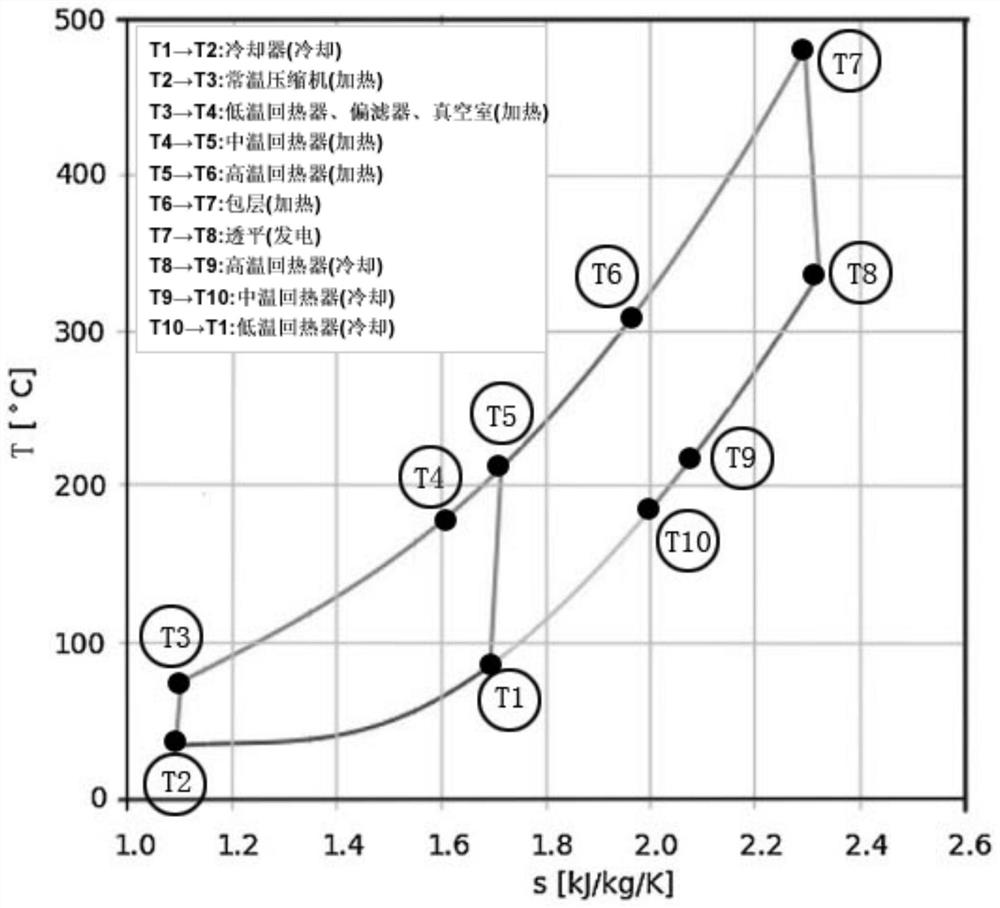

[0026] The specific implementation of the present invention is to adopt figure 1 The schematic diagram of a supercritical carbon dioxide power cycle system and method for comprehensive utilization of multiple heat sources and multiple working fluids for fusion reactors is shown, figure 2 It is the T-S diagram of the supercritical carbon dioxide power cycle system using multiple heat and multiple working fluids in the fusion reactor used in the present invention.

[0027] Such as figure 1 As shown, a supercritical carbon dioxide power cycle system and method for comprehensive utilization of multiple heat sources and multiple working fluids for fusion reactors used in the present invention is developed by S-CO 2 Circuit 1, low temperature regenerator 2, control valve 3, flow meter 4, cooler 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com