Heat collecting device for collecting heat of disc type or tower type solar reflector

A technology of tower-type solar energy and reflectors, which is applied to the components of solar collectors, solar thermal energy, and solar thermal power generation. And other problems, to achieve the effect of wide range of heating medium, simple structure, and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

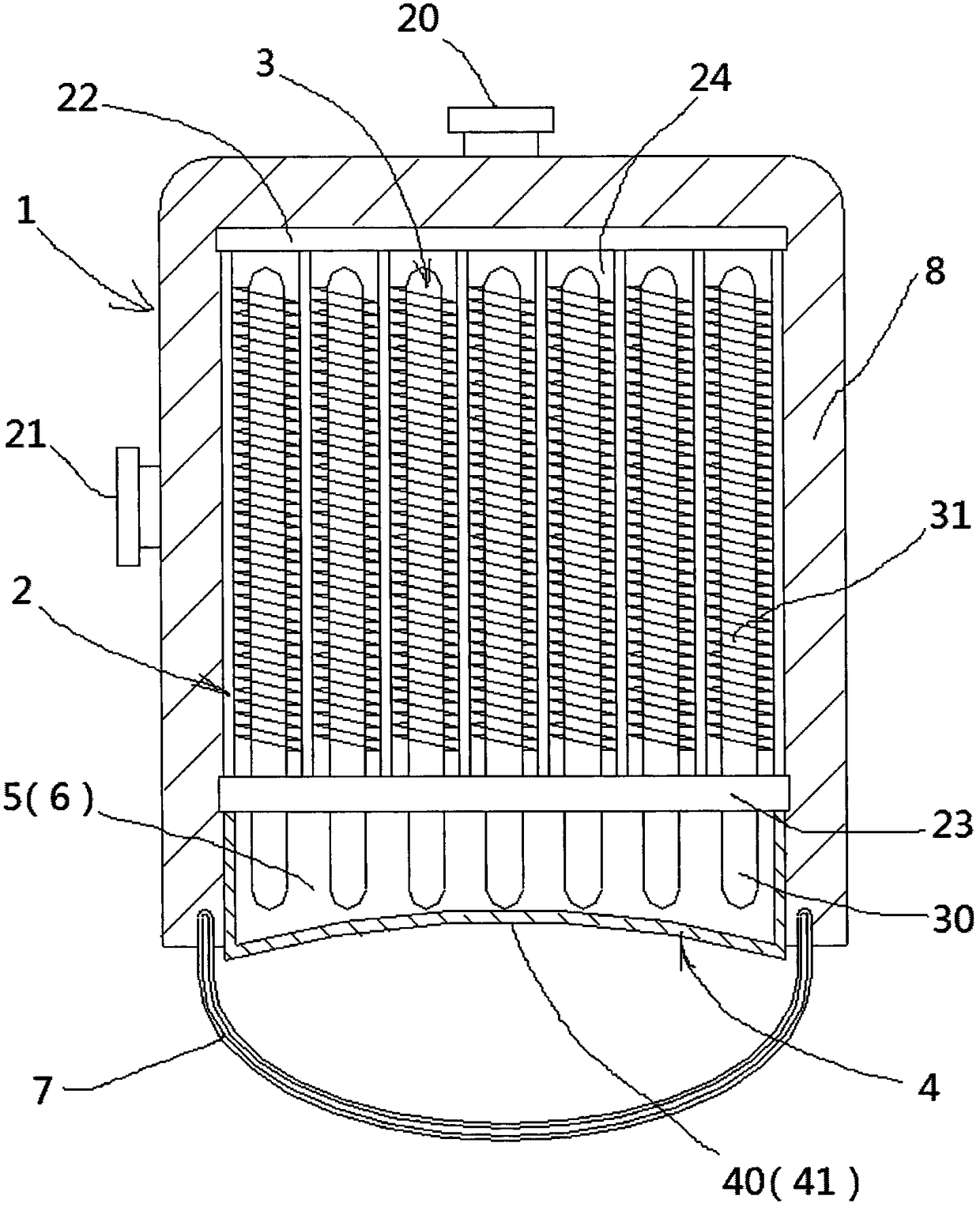

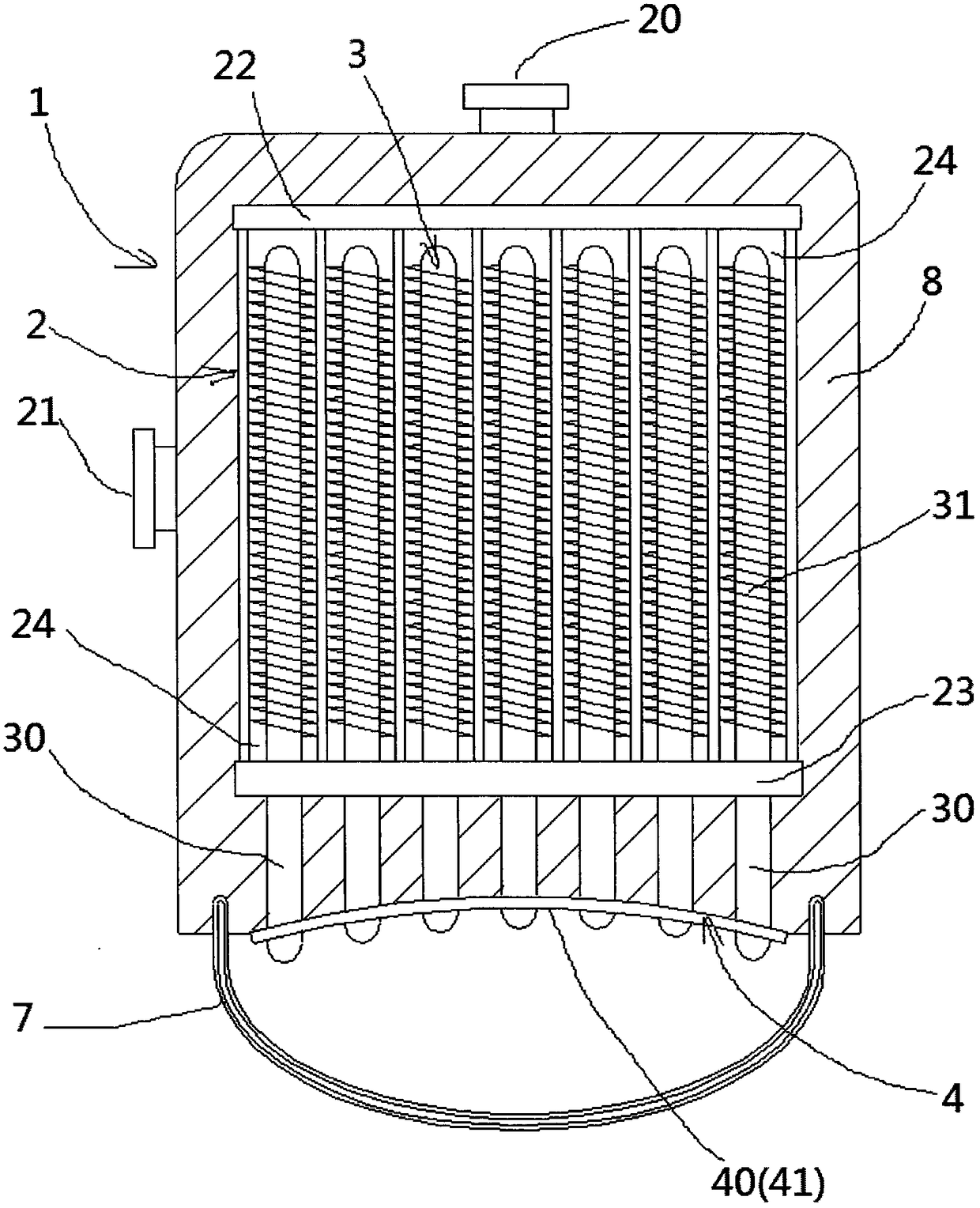

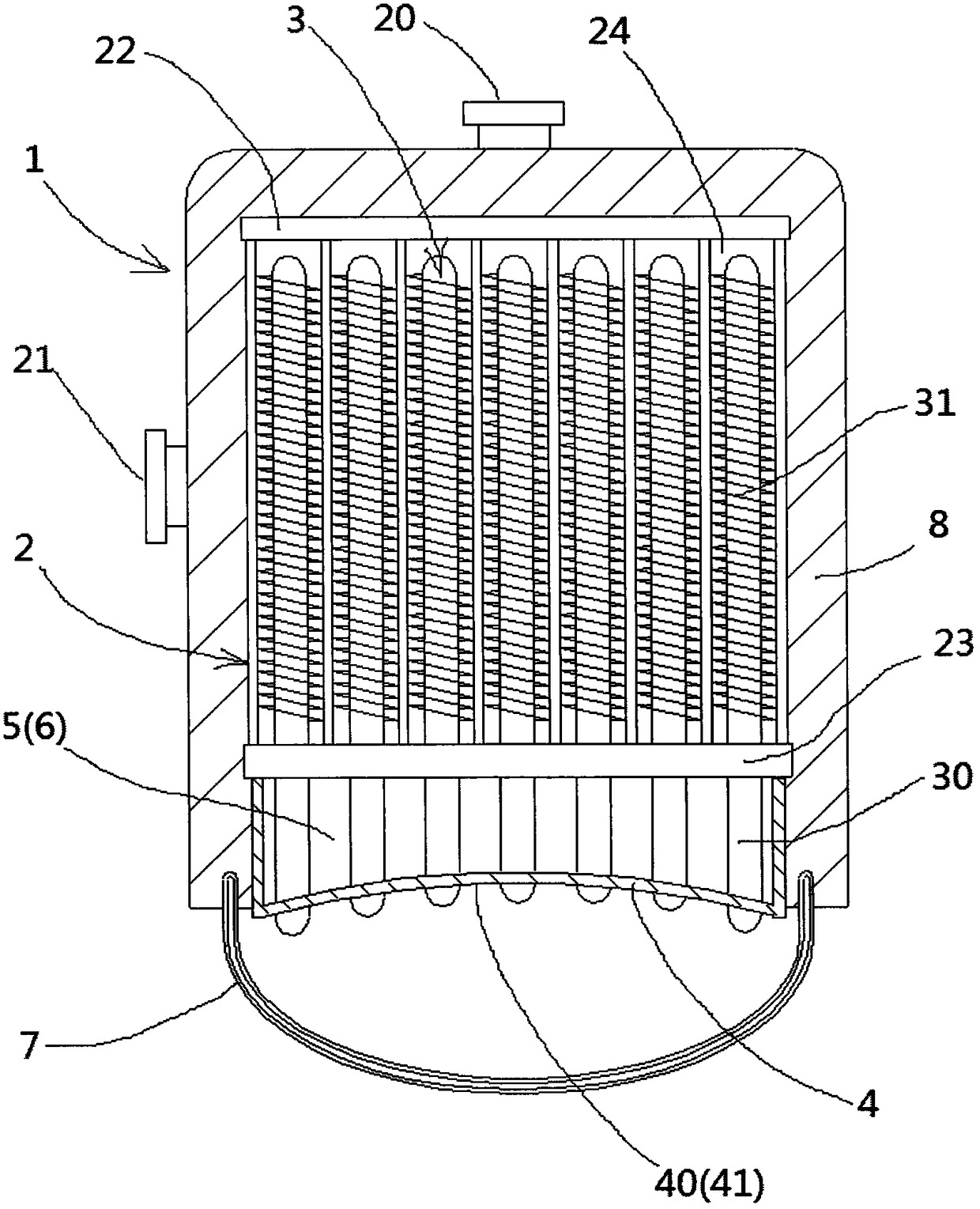

[0039] Such as figure 1 with Figure 4 As shown, a heat collecting device for dish or tower solar reflectors includes a heat collecting device 1, which is composed of a pressure-resistant heat exchange cavity 2, a heat pipe 3, and a light collecting head 4.

[0040] The pressure heat exchange cavity 2 is provided with a fluid outlet 20 and a fluid inlet 21. The pressure heat exchange cavity 2 is rolled into a single spiral flow channel by a steel plate, and welded at both ends of the single spiral flow channel. After the upper cover plate 22 and the lower cover plate 23, a single helical channel 24 is formed through which fluid can pass. One end of the single helical channel 24 is connected to the fluid outlet 20, and the other end is connected to the fluid inlet 21. .

[0041] The heat pipe 3 includes a heat absorption section 30 (or an evaporation section) and a heat dissipation section 31 (or a condensation section). Then, through the lower cover plate 23 , heat conducti...

Embodiment 2

[0045] Such as Figure 4 As shown, the heat transfer medium 6 filled in the housing cavity 5 is fine copper powder or nano silicon carbide or nano high temperature resistant alloy powder. For others, refer to Embodiment 1, which will not be repeated here.

Embodiment 3

[0047] Such as Figure 4 As shown, the accommodating cavity 5 is cast with copper or high temperature resistant alloy, so that the heat absorbing section 30 and the focusing head 4 are connected as a whole. For others, refer to Embodiment 1, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com