Biomass pyrolysis liquid hydrodeoxygenation oil hydrocracking catalyst as well as preparation method and application thereof

A hydrodeoxygenated oil, hydrocracking technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. Hydrogen treatment and other issues, to achieve the effects of large-scale industrialization, good hydrothermal resistance, and low comprehensive operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1.1 Preparation of alumina precursor: Prepare 5L of a mixed solution of aluminum sulfate and aluminum nitrate with a total concentration of 0.01mol / L, wherein the ratio of aluminum sulfate to aluminum nitrate is 1 / 5, which is recorded as solution A; add urea at room temperature, Stir continuously until the urea concentration is 0.05mol / L, and record it as solution B. Heat solution B to 90°C with a temperature gradient of 5°C / min, react at constant temperature for 1 hour, slowly cool down to room temperature, and replace it with 50L deionized water for 5 times to obtain sol C, which is spray-dried at 160°C and sprayed The pressure of the atomizing nozzle is 0.2-0.6MPa, and the diameter of the atomizing nozzle is 15±0.2μm. The obtained alumina precursor was calcined at 600°C for 12 hours to obtain a spherical alumina carrier;

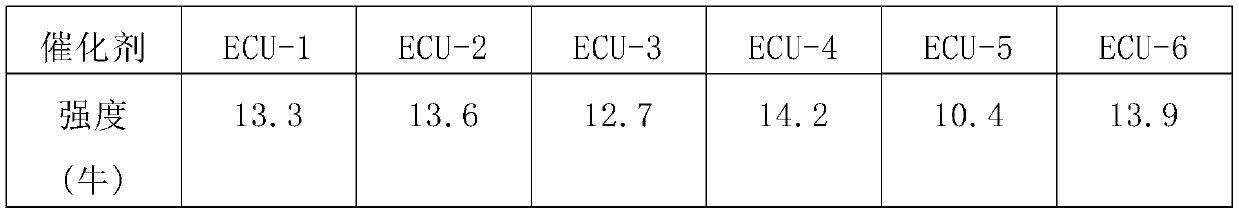

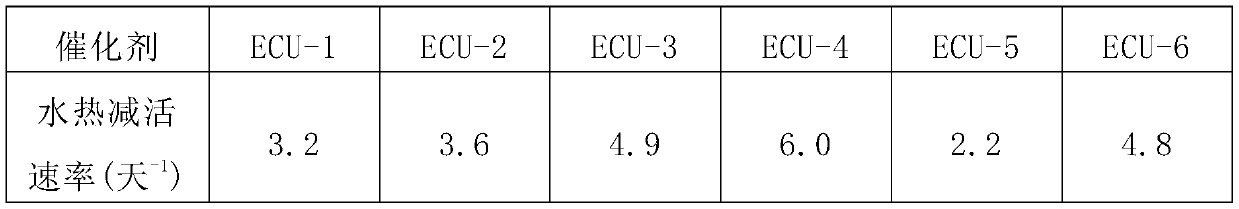

[0030] 1.2 Loading of active metals: 50 g of the alumina carrier obtained above was impregnated with Ni-Mo-containing impregnation solution for 8...

Embodiment 2

[0034] The preparation of alumina precursor was as described in 1.1. 50g of the above-obtained alumina carrier was impregnated with Ni-Mo-P-containing impregnation solution for 8 hours, dried at 120°C for 6 hours, and circulated three times. The final catalyst precursor was raised to 500°C at a rate of 10°C / min, and Calcined at constant temperature for 4 hours, the catalyst obtained was ECU-2. The methods described in 1.3 and 1.4 were used for catalyst strength test and hydrothermal deactivation rate determination respectively, and the results are listed in Table 1 and Table 2 respectively.

Embodiment 3

[0036] The preparation of alumina precursor was as described in 1.1. 50g of the above-obtained alumina carrier was impregnated with Ni-Mo-Cr-containing impregnation solution for 8 hours, dried at 120°C for 6 hours, and circulated three times, and the final catalyst precursor was raised to 500°C at a rate of 10°C / min, and Calcined at constant temperature for 4 hours, the catalyst obtained was ECU-3. The methods described in 1.3 and 1.4 were used for catalyst strength test and hydrothermal deactivation rate determination respectively, and the results are listed in Table 1 and Table 2 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com