Composite fiber as well as preparation method and application thereof

A composite fiber and fiber technology, applied in the field of material science, can solve problems such as solvent evaporation, poor dimensional stability, and easy short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The embodiment of the present invention also provides the preparation method of described composite fiber, and described preparation method comprises:

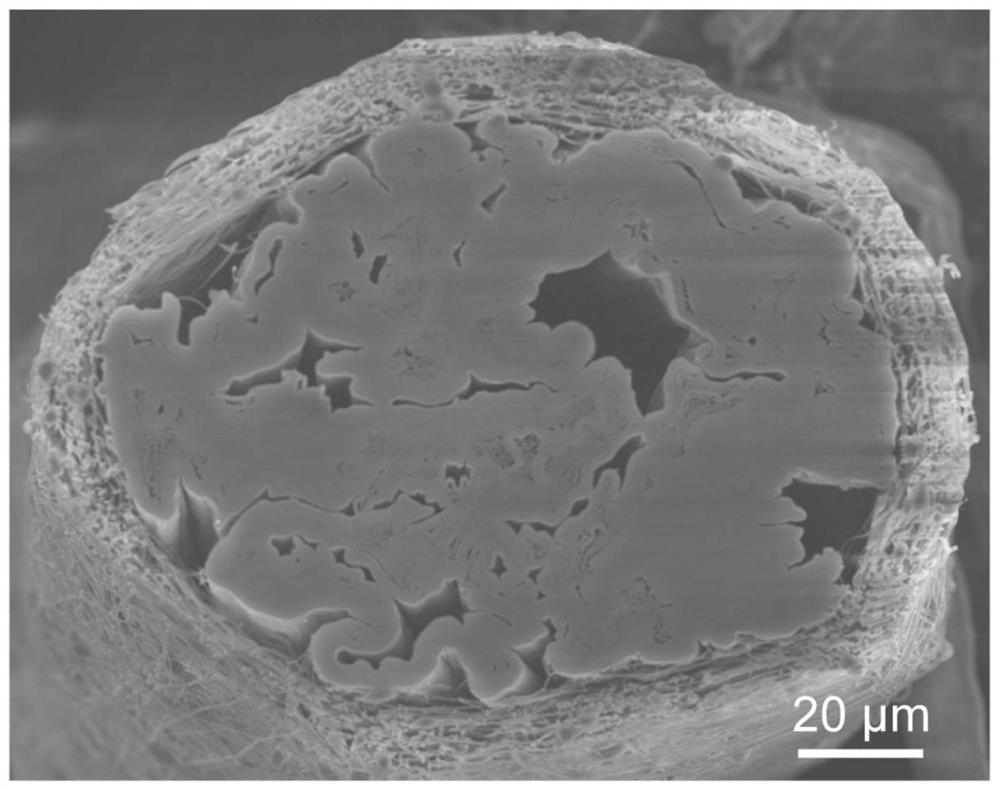

[0048] The nanofiber sheath covering the conductive fiber is formed in situ on the surface of the conductive fiber by electrospinning, and the nanofiber sheath includes a three-dimensional porous structure formed by interweaving polymer nanofibers; and, in the nanofiber The three-dimensional porous structure of the fiber sheath is filled with ionic liquids.

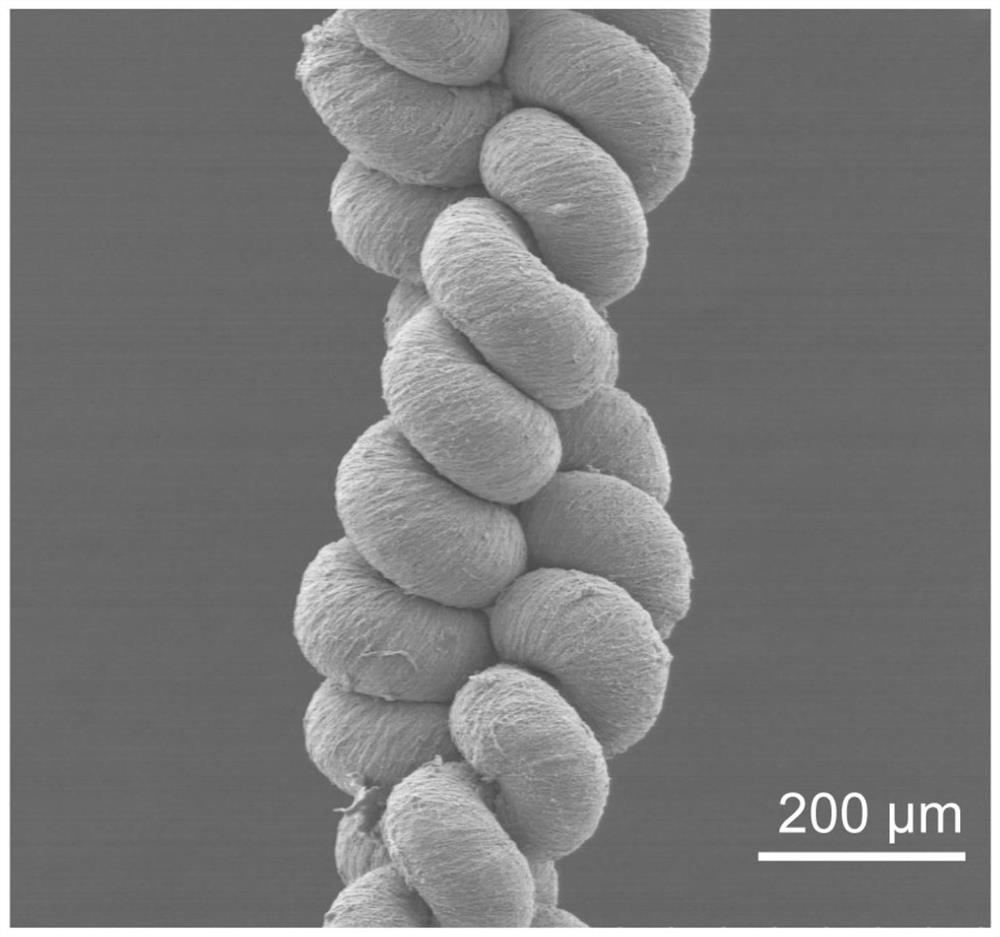

[0049] Further, the preparation method specifically includes: twisting a plurality of conductive fibers in sequence until a uniform helical structure is formed, or twisting a single conductive fiber until a uniform helical structure is formed, and then The surface of the conductive fiber is fabricated to form the nanofiber sheath.

[0050] Further, the preparation method specifically includes: immersing the nanofiber sheath in an ionic liquid, so that the ionic li...

Embodiment 1

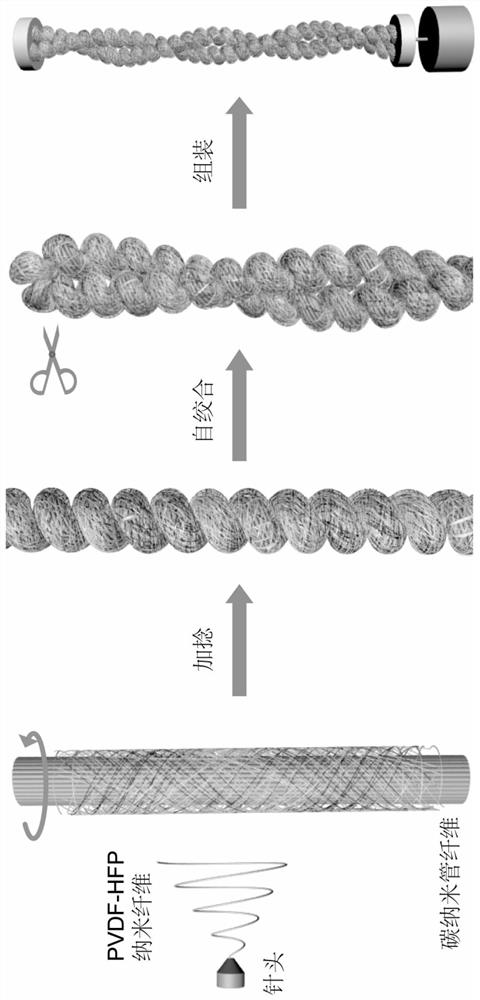

[0064] see figure 1 , a method for preparing artificial muscle fibers with high stability provided by the embodiment of the present invention, comprising depositing a layer of polyvinylidene fluoride-cohexafluoropropylene nanofiber network film on the surface of carbon nanotube fibers by electrospinning technology. Form a composite fiber, twist the composite fiber to obtain a helical fiber, fold the helical fiber in half in the middle, release the half-fold point to form a self-twisted fiber, then cut the fiber at the half-fold point, soak the twisted stranded fiber In [EMIm] BF 4 ) for 2 hours to obtain artificial muscle fibers.

[0065] Specifically, a method for preparing artificial muscle fibers with high stability specifically includes the following steps:

[0066] 1.1) After adding 4g of polyvinylidene fluoride-hexafluoropropylene (PVDF-HFP) particles to 20ml of N-N dimethylformamide solution and stirring for 12 hours, a uniform PVDF-HFP spinning solution was obtained;...

Embodiment 2

[0077] A method for preparing artificial muscle fibers with high stability, comprising the steps of:

[0078] The preparation method of the artificial muscle fiber in this embodiment is basically the same as that in Example 1, the difference is that the preparation method of the artificial muscle fiber in this embodiment specifically includes:

[0079] Add 4g of polyvinylidene fluoride (PVDF) particles to 20ml of N-N dimethylformamide solution and stir to obtain a uniform PVDF spinning solution. Electrospinning technology is used to form a layer of PVDF nanofibers on the surface of carbon nanotube fibers in situ. Fiber; after the electrospinning is completed, the obtained composite fiber is dried at 60° C. for 24 hours;

[0080] The dried composite fibers are twisted and self-twisted in sequence, and the composite fibers are cut at the folding point to form two twisted composite fibers, and then the two composite fibers are respectively used as two electrodes for wiring , and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com