A kind of recycling method of waste lithium ion battery negative electrode material

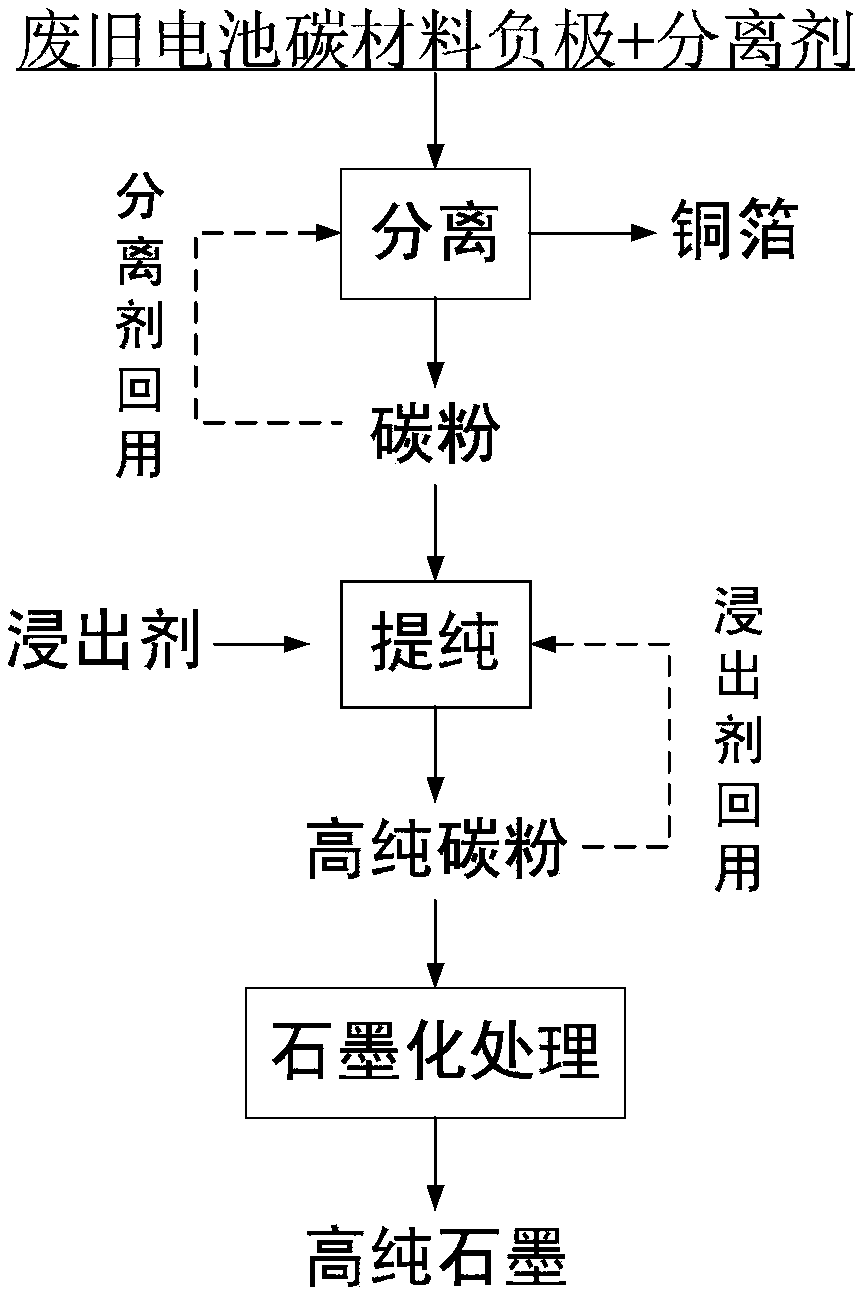

A technology for lithium-ion batteries and recycling methods, which is applied in the field of recycling waste lithium-ion battery negative electrode materials, can solve the problems of low recovery purity, secondary pollution, and non-recyclable solvents, and achieve high purity and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] (1) Take 10 g of the waste carbon material negative electrode and 100 mL of the separating agent (3mol / L formic acid), mix them, and stir at 120 r / min for 60 min at 35±2°C to obtain a mixture containing carbon powder and copper foil;

[0060] (2) Sieve with a vibrating sieve, rinse the vibrating sieve with deionized water, obtain a suspension containing carbon powder and copper foil, clean the copper foil with deionized water for 3 times, obtain 3.70 g of copper foil with a purity of 99.9%, and wash the liquid mixed with a suspension containing toner;

[0061] (3) Use 0.45 micron filter paper to filter the mixed solution of the flushing liquid and the suspension containing carbon powder to obtain 5.24g of carbon powder and 97mL of separating agent. acid+0.3mol / L sodium thiosulfate) 60mL mixed, stirred to obtain a suspension containing carbon powder, then filtered to obtain carbon powder and leaching agent; carbon powder was washed 3 times with 300mL deionized water, dri...

Embodiment 2

[0067] (1) Take 1 kg of waste carbon material negative electrode and 5 L of separating agent (2mol / L acetic acid) and mix them, and ultrasonicate for 20 minutes at 30±2°C to obtain a mixture containing carbon powder and copper foil;

[0068] (2) Sieve with a vibrating sieve, rinse the vibrating sieve with deionized water, obtain suspension and copper foil containing carbon powder, clean the copper foil with deionized water 3 times, obtain 320g of copper foil with a purity of 99.9%, rinse liquid and Mixing of suspensions containing carbon powder;

[0069] (3) Filter with a 300-mesh sieve to obtain 662 g of carbon powder and 4.82 L of separating agent, mix 662 g of carbon powder with 1 L of leaching agent (50% 4mol / L isobutyric acid + 10% hydrogen peroxide), and stir to obtain a suspension containing carbon powder liquid, then filtered to obtain carbon powder and leaching agent; the carbon powder was washed 3 times with deionized water, and dried to obtain 641g, 99.999% high-pur...

Embodiment 3

[0074] (1) Take 100g of waste carbon material negative electrode, mix 0.5L of separating agent (2mol / L propionic acid), and stir at 200r / min for 50min at 25±2°C to obtain a mixture containing carbon powder and copper foil;

[0075] (2) Sieve with a vibrating sieve, rinse the vibrating sieve with deionized water, obtain a suspension containing carbon powder and copper foil, clean the copper foil with deionized water for 3 times, obtain 37.9 g of copper foil with a purity of 99.9%, and wash the liquid mixed with a suspension containing toner;

[0076] (3) Filtrate with 0.45 micron filter paper to obtain 61.0g of carbon powder and 470mL of separating agent, mix 61.0g of carbon powder with 1.2L of leaching agent (3mol / L acetic acid+0.5mol / L sodium sulfite), and stir at 150r / min to obtain The suspension of carbon powder is then filtered to obtain carbon powder and leaching agent; the carbon powder is cleaned 3 times with deionized water and dried to obtain 55.8g, 99.998% high-purit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com