A kind of preparation method of flame retardant superhydrophobic fabric based on foam finishing method

A foam finishing, super-hydrophobic technology, applied in the direction of flame-retardant fibers, plant fibers, fiber processing, etc., can solve the problems of human injury, toxic and corrosive gases, environmental impact, etc., to prevent pollution, reduce fire, and reduce losses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Preparation of hydrophobic finishing solution: Add 0.6 g of polydimethylsiloxane and 0.06 g of supporting curing agent into deionized water, ultrasonically oscillate and stir vigorously, then add 0.1 g of sodium lauryl sulfate and 0.04 g of Dodecanol, continue to add 0.6 g of copper phytate particles and 1.5 g of ammonium polyphosphate, and stir vigorously for 15 minutes under the action of ultrasonic oscillation (frequency 40 KHz) to obtain a hydrophobic and flame-retardant finishing solution;

[0033] 2) Apply foam to finish the fabric: The hydrophobic and flame-retardant finishing solution prepared above is stirred and foamed under the action of a mechanical stirrer, where the stirring speed is 2000 r / min, and the stirring time is 180 s, and the hydrophobic and flame-retardant foam is applied to the fabric Then put the fabric in an oven at 150 °C for 120 min to obtain a superhydrophobic flame-retardant fabric.

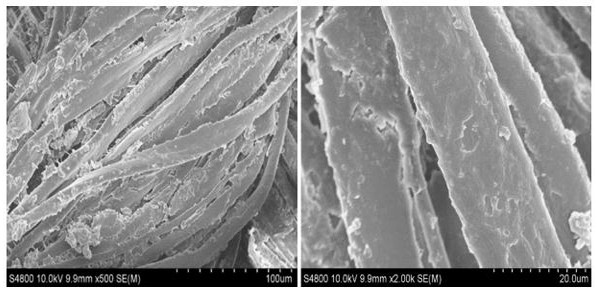

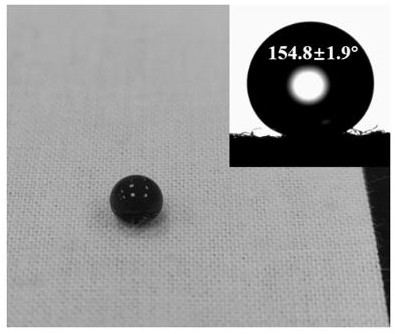

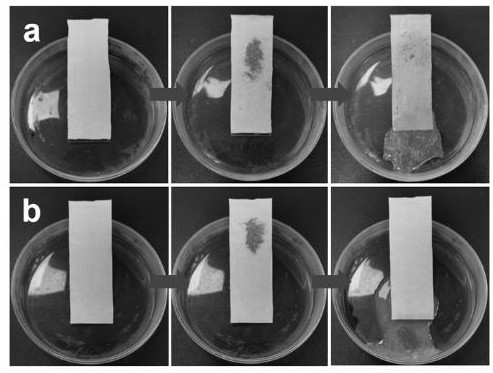

[0034] Such as figure 1 As shown, the surface morph...

Embodiment 2

[0036] 1) Preparation of hydrophobic finishing solution: Add 1.5 g of polydimethylsiloxane and 0.15 g of supporting curing agent into deionized water, ultrasonically oscillate and stir vigorously, then add 0.3 g of sodium lauryl sulfate and 0.1 g of Dodecanol, continue to add 1.5 g of copper phytate particles and 2 g of ammonium polyphosphate, and stir vigorously for 15 min under the action of ultrasonic oscillation (frequency 40 KHz) to obtain a hydrophobic and flame-retardant finishing solution;

[0037] 2) Applying foam to finish the fabric: The hydrophobic and flame-retardant finishing solution prepared above was stirred and foamed under the action of a mechanical stirrer, the stirring speed was 1500 r / min, and the stirring time was 240 s, and the hydrophobic and flame-retardant foam was applied to the fabric Then put the fabric in an oven at 160 °C for 100 min to obtain a superhydrophobic flame-retardant fabric.

Embodiment 3

[0039] 1) Preparation of hydrophobic finishing solution: Add 2 g of polydimethylsiloxane and 0.2 g of supporting curing agent into deionized water, ultrasonically oscillate and stir vigorously, then add 0.6 g of sodium lauryl sulfate and 0.2 g of Dodecanol, continue to add 2 g of copper phytate particles and 3 g of ammonium polyphosphate, and vigorously stir for 15 min under the action of ultrasonic oscillation (frequency 40 KHz) to obtain a hydrophobic and flame-retardant finishing solution;

[0040] 2) Apply foam to finish the fabric: The hydrophobic and flame-retardant finishing solution prepared above is stirred and foamed under the action of a mechanical stirrer, where the stirring speed is 2500 r / min, and the stirring time is 240 s, and the hydrophobic and flame-retardant foam is applied to the fabric Then the fabric was dried in an oven at 150 °C for 90 min to obtain a superhydrophobic flame-retardant fabric.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com