Method of Inducing Quantum Well Mixing Using Laser Micro-region Plasma

A laser plasma and plasma technology, applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problems of increasing light absorption rate and changing the width of the band gap, saving time, easy area selection operation, and realizing The effect of large-scale industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

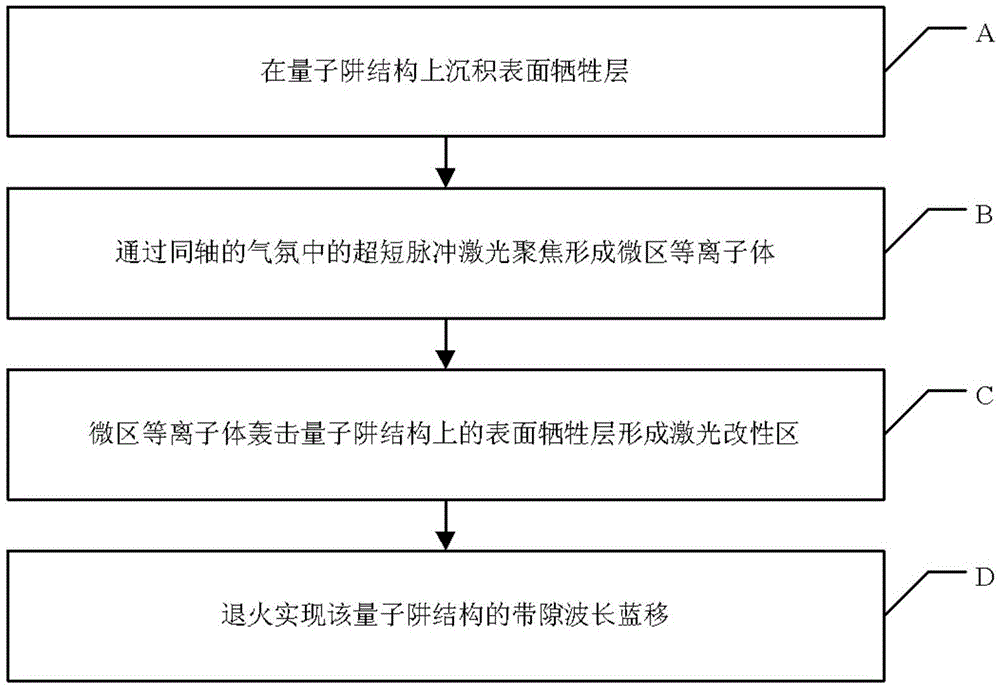

[0015] see figure 1 As shown, the present invention provides a kind of method utilizing laser micro-region plasma to induce quantum well mixing, comprising the following steps:

[0016] Step A: Deposit a surface sacrificial layer on the quantum well layer on the quantum well structure sheet, the thickness of the surface sacrificial layer is 50nm-500nm, and its material is indium phosphide, indium gallium arsenic, indium gallium arsenic phosphide, aluminum gallium arsenic, dioxide Silicon or silicon nitride, the quantum well layer is a single quantum well structure or multiple quantum well structure, the quantum well layer is InGaAs / InGaAsP, AlGaAs / GaAs, AlGaAs / InGaAs or AlGaInP / GaAs;

[0017] Step B: The laser beam is focused on the sacrificial layer on the surface through a laser head with a gas supply function to form a laser plasma of a reaction gas. The gas supply function is usually a coaxial gas supply with a nozzle, which can control the gas flow, pressure and speed; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com