A heat collecting tube for dish solar reflector to gather heat

A solar reflector and heat collecting tube technology, which is applied to solar heat collectors, solar heat collectors using working fluids, and solar heat storage, etc. Due to the large initial investment and other problems, the effect of a wide range of heating medium, a simple structure and a short construction period can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

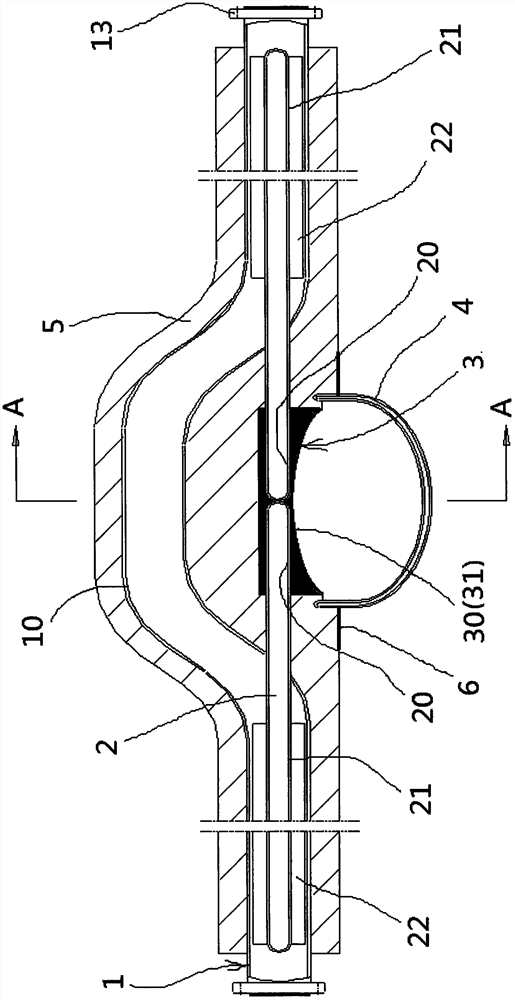

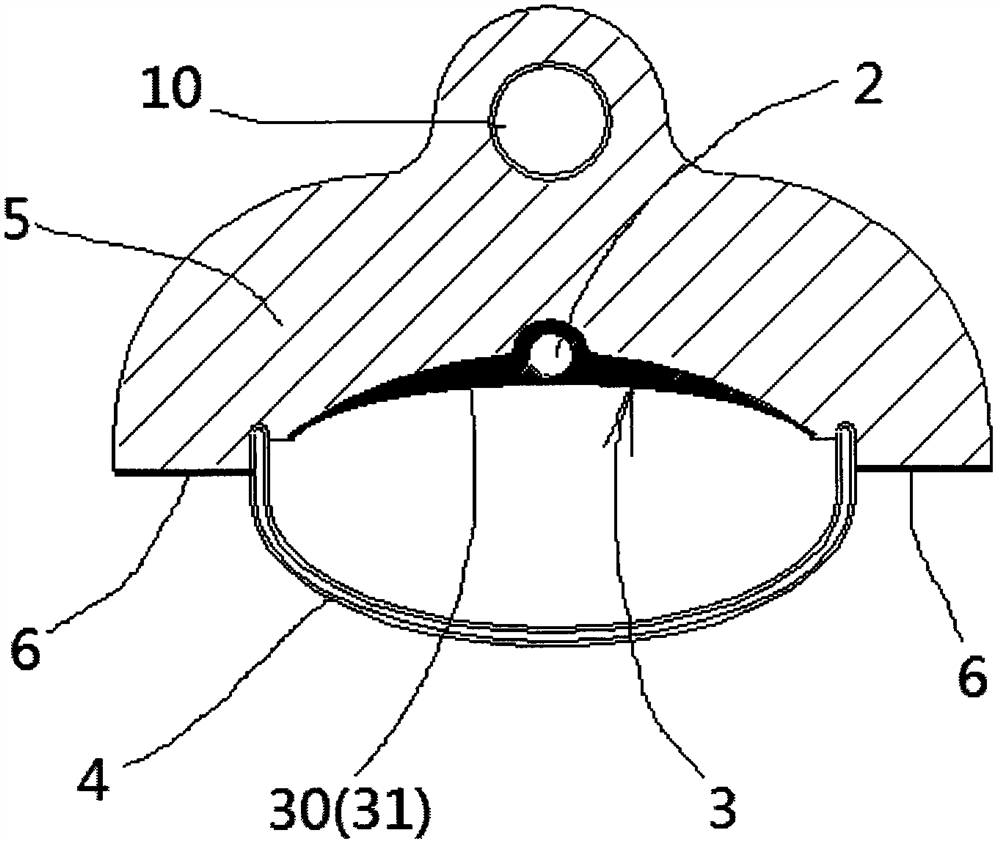

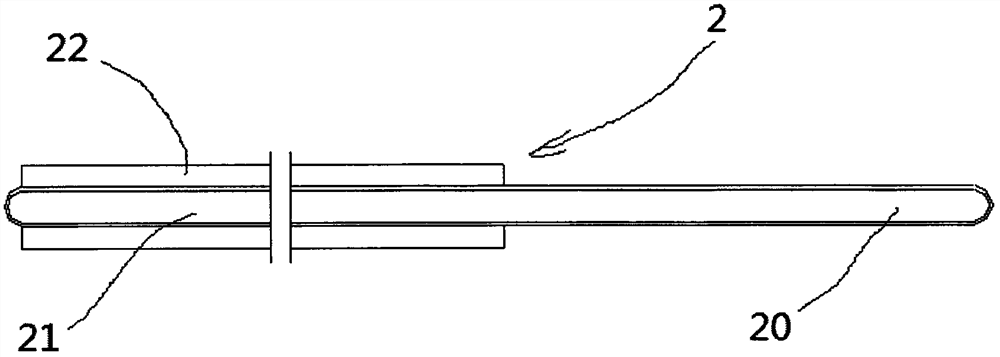

[0044] like figure 1 , figure 2 , image 3 and Figure 4 As shown in the figure, a heat collecting tube for dish solar reflectors includes a fluid pipe 1 , a heat pipe 2 and a light collecting head 3 .

[0045] The lower side of the fluid pipeline 1 near the middle section is provided with the described focusing head 3, and the heat pipe 2 includes a heat absorbing section 20 (or claiming an evaporating section) and a heat dissipation section 21 (or claiming a condensing section), with the focusing head 3 being a boundary point, One heat pipe 2 is arranged on each of the left and right sides, and the heat absorbing sections 20 of two adjacent heat pipes 2 are wrapped inside by the focusing head 3 , and the heat dissipation section 21 is located in the fluid pipe 1 .

[0046] In practical application, the focusing head 3 is always on the focusing point of the dish-type parabolic reflector, and the focusing head 3 quickly transfers the accumulated heat to the heat transfer m...

Embodiment 2

[0055] like Figure 5 , Image 6 , Figure 7 and Figure 8 As shown in the figure, a heat collecting tube for dish solar reflectors includes a fluid pipe 1 , a heat pipe 2 and a light collecting head 3 .

[0056] The lower side of the fluid pipe 1 near the middle section is provided with a condenser head 3, and the heat pipe 2 includes a heat absorption section 20 (or an evaporation section) and a heat dissipation section 21 (or a condensation section). One heat pipe 2 is provided, and the heat-absorbing sections 20 of two adjacent heat pipes 2 are wrapped in it by the condensing head 3, and the heat-dissipating section 21 is integrated with the fluid pipe 1. In practical applications, the condensing head 3 is always in the At the converging point of the type parabolic reflector, the concentrating head 3 quickly transfers the accumulated heat to the heat transfer medium in the fluid pipe 1 through the heat dissipation section 21 of the heat pipe 2, so as to achieve the purp...

Embodiment 3

[0063] like Figure 9 As shown, an application in which no heat conduction fins are provided in the fluid pipeline 1 is presented, and the others are the same as those in Embodiment 2, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com