Heat Treatment Processes for Obtaining Tri-state and Bi-state Structures in Tial Alloys

A heat treatment furnace and organization technology, applied in the field of heat treatment technology, can solve the problems of high room temperature brittleness and difficult thermal processing of titanium aluminum alloy, and achieve the effects of large-scale industrialization, easy operation and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

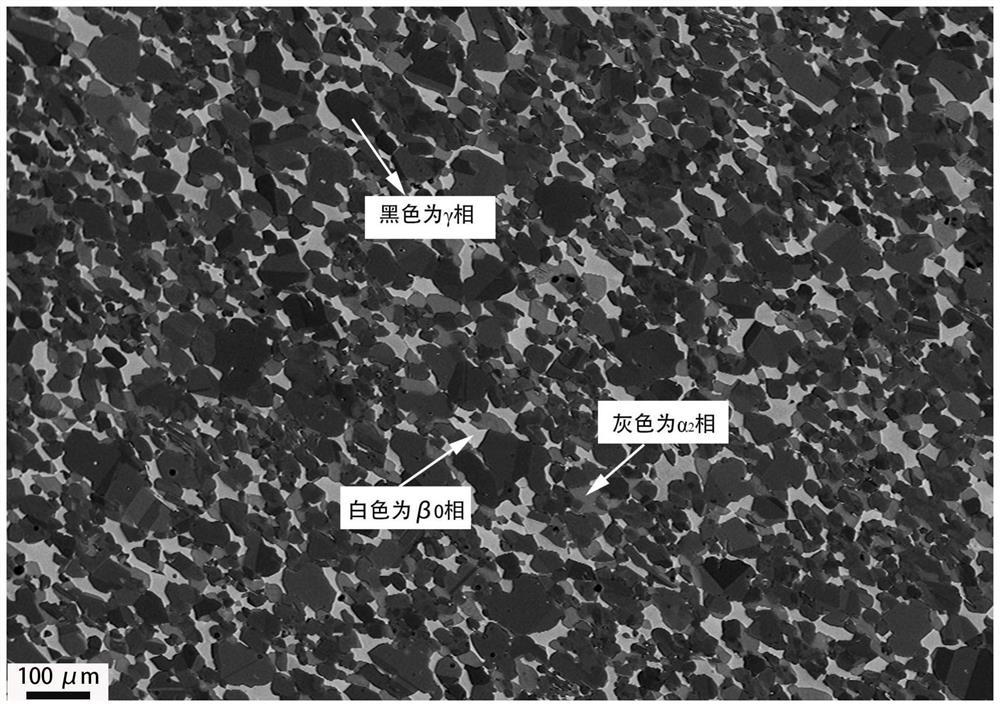

[0031] Step 1: First, cut a cylindrical heat treatment sample of Φ10*70mm from the forged TNM forging cake (forging temperature is 1170°C, engineering strain is 74%, isothermal forging is performed three times). After characterization by backscattered electrons on a scanning electron microscope, it was found that its microstructure is mainly composed of equiaxed γ, α 2 and a small amount of β 0 Phase grains and a very small amount of residual lamellar composition, such as figure 1 shown.

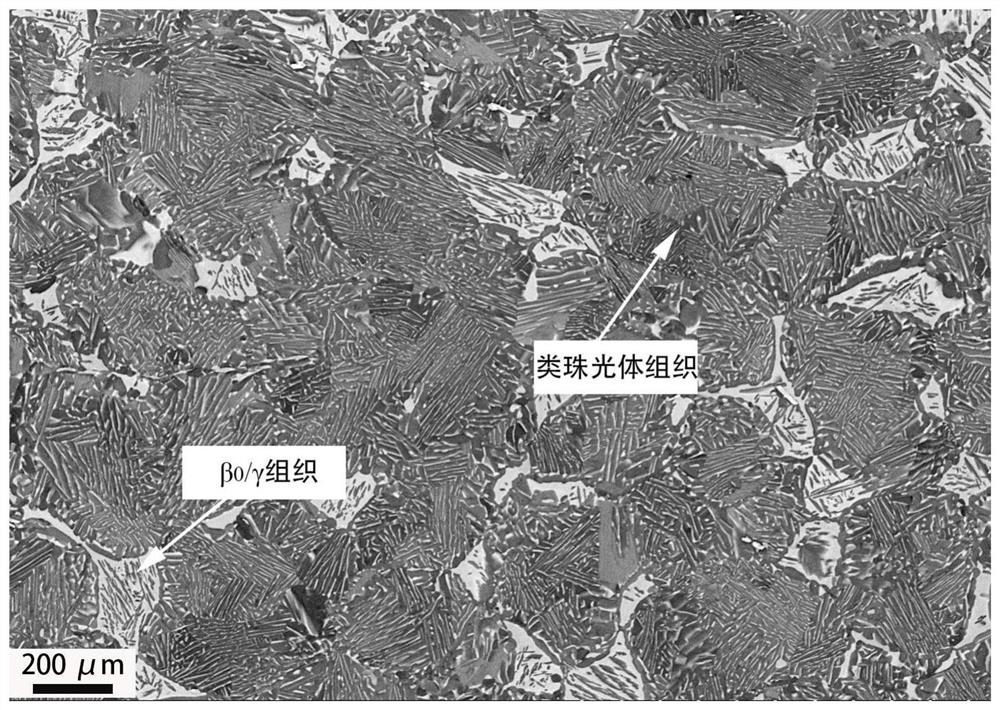

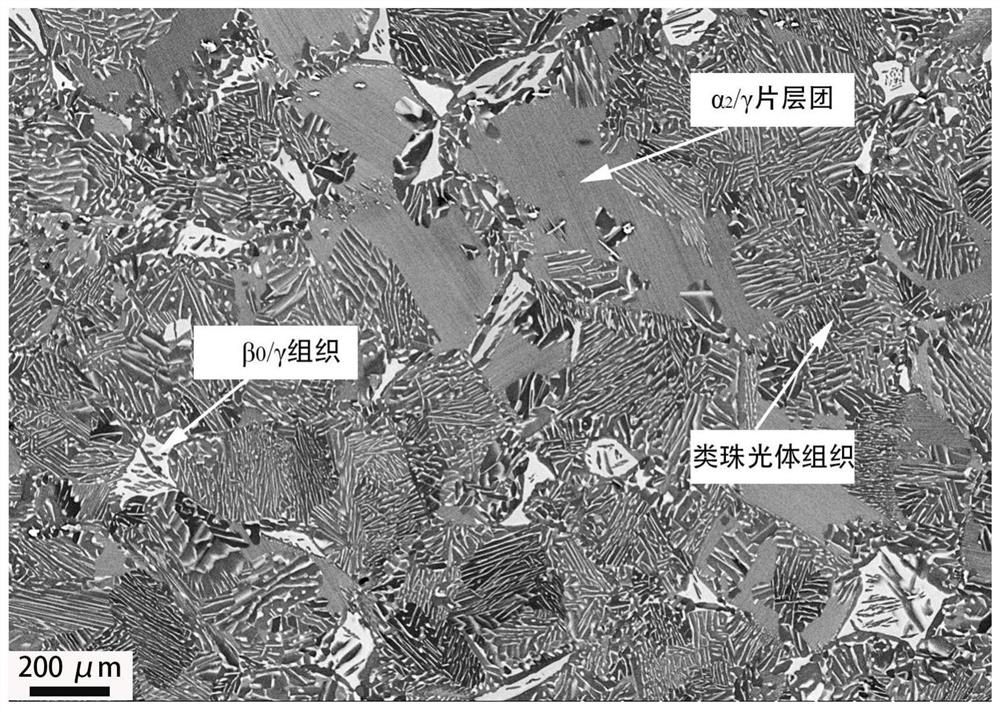

[0032] Step 2: Place the cylindrical heat treatment sample obtained in Step 1 in a heat treatment furnace with precise temperature control and good sealing (for example, a 1600°C tube furnace); heat up to 1280°C with the furnace, keep it warm for 1 hour, and then air cool. When the furnace temperature drops to 1050°C, put the sample into the heat treatment furnace, keep it warm for 3 hours, and then cool down to room temperature with the furnace. This step obtains a two-state tissue, such...

Embodiment 2

[0035] Step one, its operation method is the same as step one in embodiment one.

[0036] Step 2: Place the cylindrical heat-treated sample obtained in Step 1 in a heat-treatment furnace (such as a 1600° C. tube furnace) with precise temperature control and good sealing. Heat up to 1300°C with the furnace, keep warm for 1 hour and then air cool. When the furnace temperature drops to 1050°C, put the sample into the heat treatment furnace, keep it warm for 2 hours, and then cool down to room temperature with the furnace. This step yields bimorphic tissue.

[0037] Step 3: Place the cylindrical heat-treated sample obtained in Step 1 in a heat-treatment furnace (such as a 1600° C. tube furnace) with precise temperature control and good sealing. Heat up to 1300°C with the furnace, keep warm for 1 hour and then air cool. When the furnace temperature drops to 1000°C, put the sample into the heat treatment furnace, keep it warm for 2 hours, and then cool down to room temperature wi...

Embodiment 3

[0039] Step one, its operation method is the same as step one in embodiment one.

[0040] Step 2: Place the cylindrical heat-treated sample obtained in Step 1 in a heat-treatment furnace (such as a 1600° C. tube furnace) with precise temperature control and good sealing. As the furnace heats up to 1250 ° C, oil quenching after 1 hour of heat preservation. When the furnace temperature drops to 1050°C, put the sample into the heat treatment furnace, keep it warm for 6 hours, and then cool down to room temperature with the furnace. This step yields bimorphic tissue.

[0041] Step 3: Place the cylindrical heat-treated sample obtained in Step 1 in a heat-treatment furnace (such as a 1600° C. tube furnace) with precise temperature control and good sealing. As the furnace heats up to 1250 ° C, oil quenching after 1 hour of heat preservation. When the furnace temperature drops to 1000°C, put the sample into the heat treatment furnace, keep it warm for 6 hours, and then cool down to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com