Small-size heat pump drying device realizing high-efficiency dehumidification

A drying device, dehumidification heat technology, applied in heating device, drying gas arrangement, drying and other directions, can solve the problems of improving the inlet air temperature, and achieve the effect of increasing the outlet air temperature and great flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

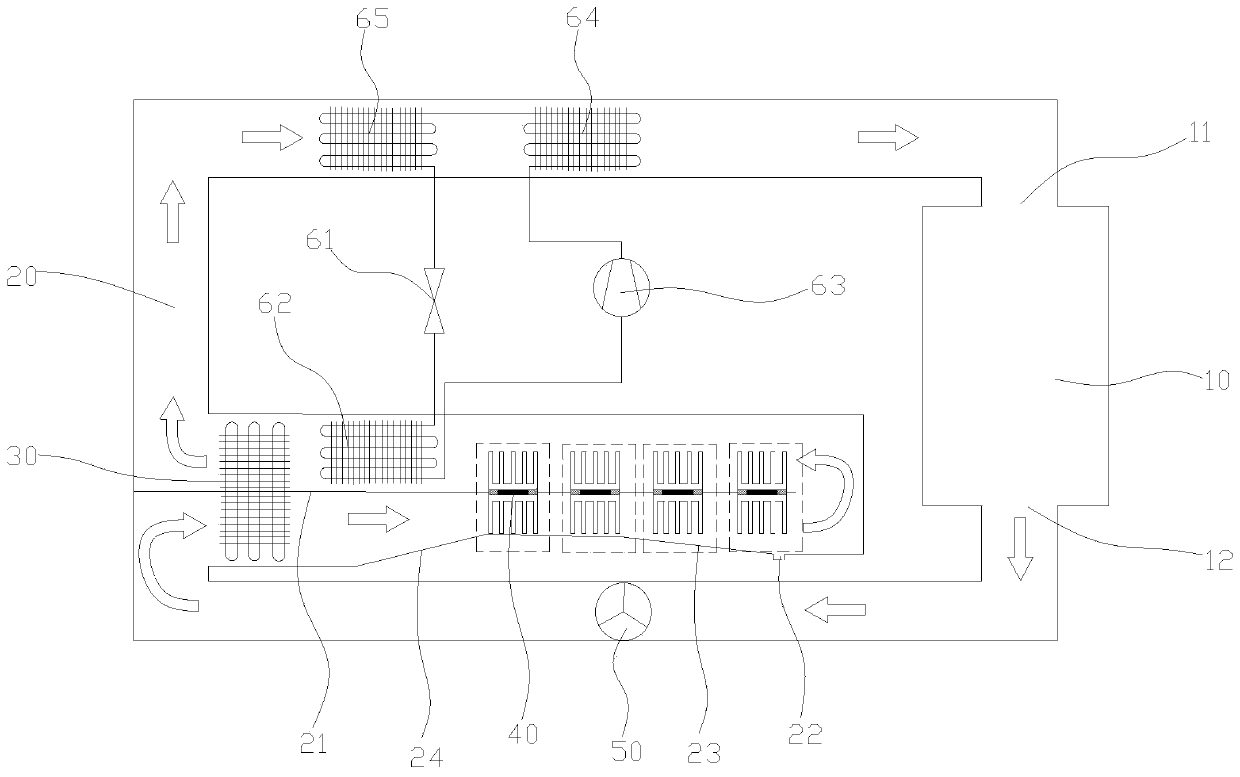

[0019] Please refer to figure 1 , A small and high-efficiency dehumidification heat pump drying device, including a sealed drying chamber 10, a heat pipe heat exchanger 30, a thermoelectric module 40 and a heat pump. The heat pump includes an expansion valve 61, an evaporator 62, and a compressor connected by pipes to form a loop. 63. The first condenser 64 and the second condenser 65, the evaporator 62, the first condenser 64 and the second condenser 65 are respectively finned heat exchangers;

[0020] The drying chamber 10 is provided with an air inlet 11 and an air outlet 12. The air inlet 11 and the air outlet 12 are connected by a drying channel 20, and the drying channel 20 is provided with a circulation that blows air from the air outlet side to the air inlet side. Fan 50;

[0021] The evaporator 62 is arranged on the side of the drying channel 20 close to the air outlet 12, and the first condenser 64 and the second condenser 65 are arranged on the side of the drying channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com