Air conditioner system

A technology for air conditioning systems and evaporators, which can be used in high-efficiency regulation technology, lighting and heating equipment, and irreversible-cycle compressors, etc. It can solve the problems of lower evaporation temperature, increase in input force, and increase in pressure ratio, and improve comfort. , the effect of moderate air temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

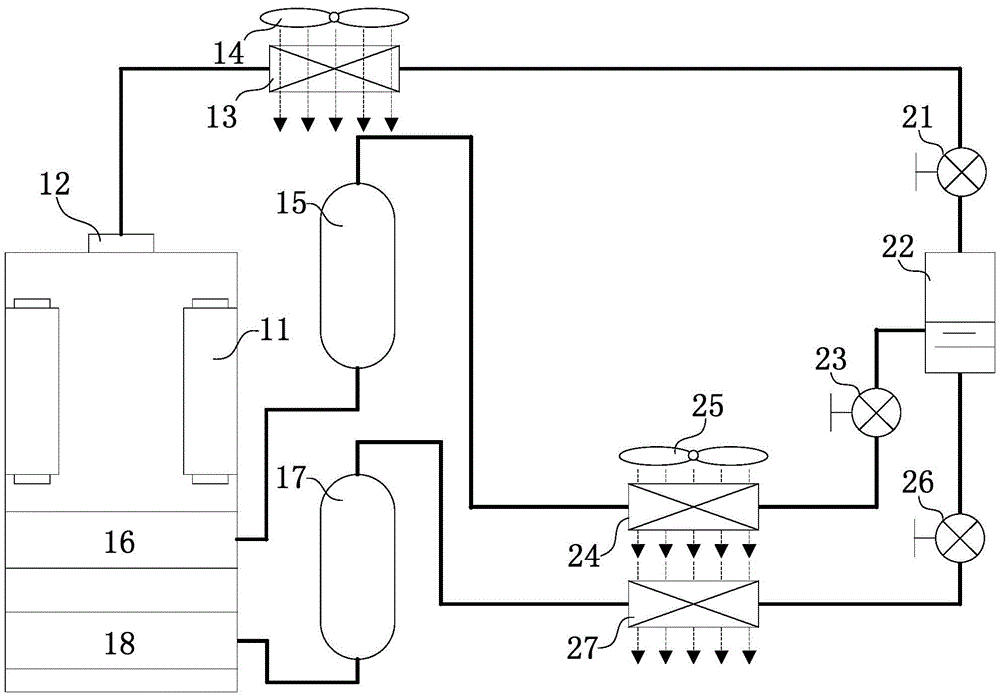

[0042] figure 1 It is a connection schematic diagram of the air conditioning system according to the first embodiment of the present invention. Such as figure 1 Shown, a kind of air conditioning system of the present invention, a compressor 11, a condenser 13, a first fan 14, a first electronic expansion valve 21, a flasher 22, the first pipeline and the second pipeline . The compressor 11 has a first compression chamber 16 and a second compression chamber 18. The exhaust port 12 of the compressor 11 is connected in series with a condenser 13, a first electronic expansion valve 21 and a flasher 22. The first electronic The expansion valve 21 throttles the refrigerant for the first time, and the flasher 22 has an exhaust port and a liquid discharge port. The air duct of the first fan 14 passes through the condenser 13 .

[0043] The first end of the first pipeline is connected to the exhaust port of the flasher 22, and the second end is connected to the first compression ch...

specific Embodiment approach

[0048] The exhaust gas of the compressor 11 of the present invention enters the condenser 13 , enters the first electronic expansion valve 21 for throttling once, and then enters the flasher 22 . The refrigerant liquid in the flasher 22 is stored at the bottom, and the flashed gas is placed at the top. The main function is to ensure that the liquid refrigerant is stable before throttling, has sufficient subcooling, and improves heat exchange efficiency. The outlet of the flasher 22 is divided into two paths. The gaseous refrigerant returns to the first compression chamber 16 from the top exhaust port through a first pipeline; the liquid refrigerant passes through a second pipeline from the bottom liquid discharge port. Back to the second compression chamber 18. The main refrigerant in the gaseous state of the flasher enters the first evaporator 24 (sensible heat evaporator) after being throttled twice; the main refrigerant in the liquid state of the flasher enters the second e...

no. 2 example

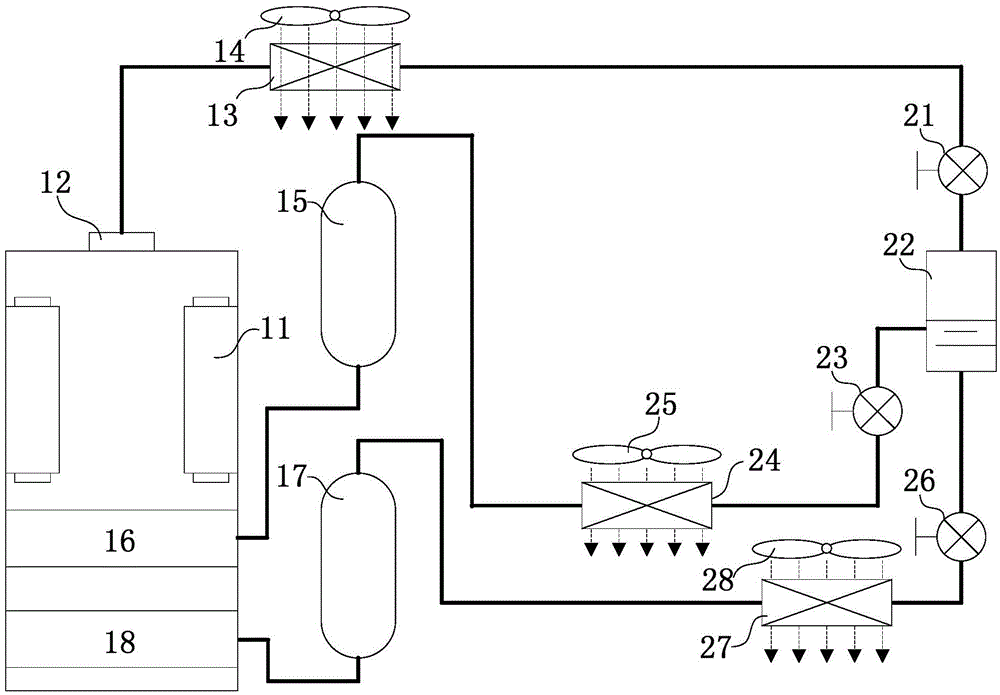

[0051] figure 2 It is a connection schematic diagram of the air conditioning system according to the second embodiment of the present invention. Such as figure 2Shown, another kind of air-conditioning system of the present invention is the same as the first embodiment, a kind of air-conditioning system of the present invention, a compressor 11, a condenser 13, a first fan 14, a first electronic expansion Valve 21, a flasher 22, first pipeline and second pipeline. The compressor 11 has a first compression chamber 16 and a second compression chamber 18. The exhaust port 12 of the compressor 11 is connected in series with a condenser 13, a first electronic expansion valve 21 and a flasher 22. The first electronic The expansion valve 21 throttles the refrigerant for the first time, and the flasher 22 has an exhaust port and a liquid discharge port. The air duct of the first fan 14 passes through the condenser 13 .

[0052] The first end of the first pipeline is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com