Biodegradable water-permeable mulching film ridge back microgroove multi-row mechanical film-mulching and sowing method

A biodegradable and micro-ditch technology, applied in planting methods, botanical equipment and methods, agricultural machinery and implements, etc., can solve problems such as the rupture and disintegration of fully biodegradable mulch, reduce the degradation rate, prevent soil compaction, improve The effect of comprehensive utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] In 2018, 20 mu of permeable mulch film was set up on the flat land of Xiejiagou Village, Jia County, Shaanxi Province to cover the experiment of double-row corn (Dafeng 30 variety) with micro-furrows on the back of the ridge.

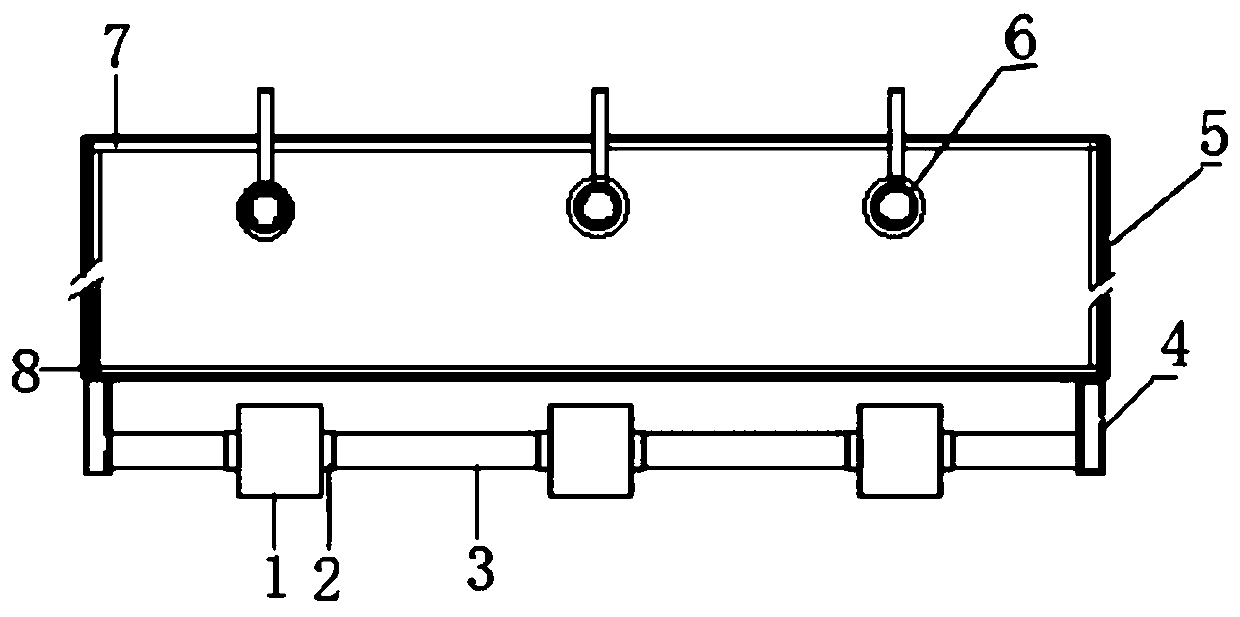

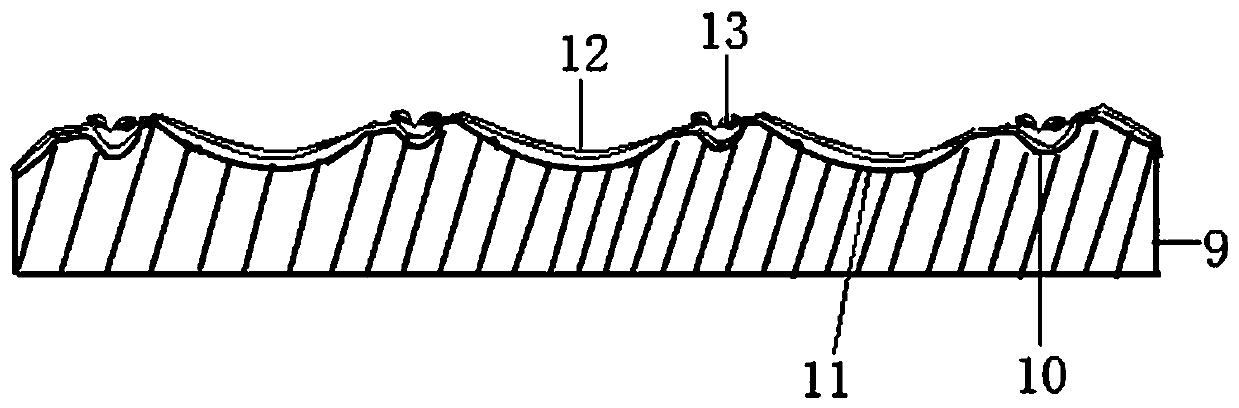

[0018] According to the method of the present invention, the test selects the fully biodegradable water-permeable mulch film with a width of 600 mm×thickness 0.007 mm, and adopts the 2MB-1 / 2 type film-laying drill machine produced by Changzhi Shenhe Yongcheng Agricultural Machinery Technology Development Co., Ltd. The machine is refitted, and a ditching disc (6) with a diameter of 230 mm is installed on the front beam (7) of the frame of the film seeding machine corresponding to the central position of the micro-groove (11) on the back of the ridge. (5) The place 160mm away from the rear end is the place where the steel shaft is connected (8), and the matching steel roller is connected to the plastic shaping module, and a steel roller (1) is arran...

Embodiment 2

[0021] In 2018, 30 mu of sorghum (Jinza No. 12) permeable plastic film was laid on the flat land of Yuancha Village, Jinmingsi Town, Jia County, Shaanxi Province, and the sowing test was covered with one film and three rows of micro-grooves on the back of the ridge.

[0022] According to the method of the present invention, the 2MB-1 / 3 type film laying hole seeder produced by Changzhi Shenhe Yongcheng Agricultural Machinery Technology Development Co., Ltd. is selected to use a fully biodegradable water seepage film with a width of 1300 mm×a thickness of 0.007 mm, and refit the film laying hole seeder , install a ditching disc (6) with a diameter of 230mm at about 250mm on both sides of the center of the front beam (7) of the frame and at the corresponding positions of the two ridge back micro-grooves (11); (5) The place 150mm away from the rear end is the place where the steel shaft is articulated (8), and the matching steel roller is articulated to suppress the plastic module,...

Embodiment 3

[0025] In 2017, 25 mu of permeable plastic film covering micro-grooves on the back of the ridge was carried out on the dry plains of Yangta Village, Fangta Town, Jiaxian County, Shaanxi Province, and a millet sowing test was carried out in one film and four rows. The variety was Jingu 21.

[0026] According to the method of the present invention, select width 1650 mm * thickness 0.007mm fully biodegradable water seepage mulch film, Changzhi City Shenhe Yongcheng Agricultural Machinery Technology Development Co., Ltd. produces 2MB-1 / 4 type film laying hole seeder, through refitting, in front of the frame A ditching disc (6) with a diameter of 230mm is installed at the corresponding positions of the crossbeam (7) and the micro-groove (11) on the back of the ridge, and the frame is articulated at a distance of 150mm from the rear end of the longitudinal beam (5) on both sides of the frame. The shaft (8) is connected with the matching steel roller pressing and shaping module, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com