Patents

Literature

35results about How to "Meet diverse market needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel hot molten slag mineral cotton and its making method

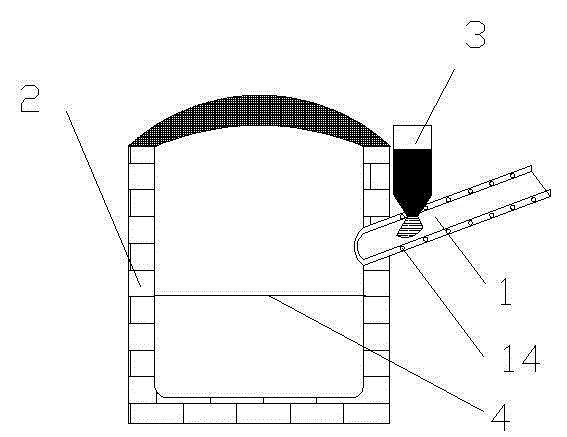

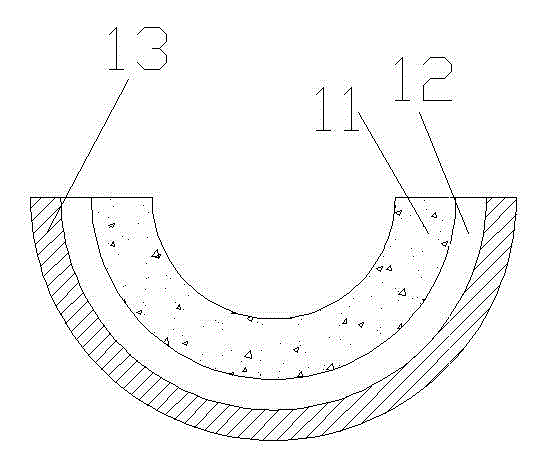

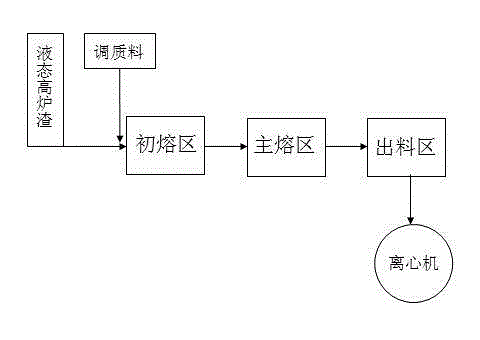

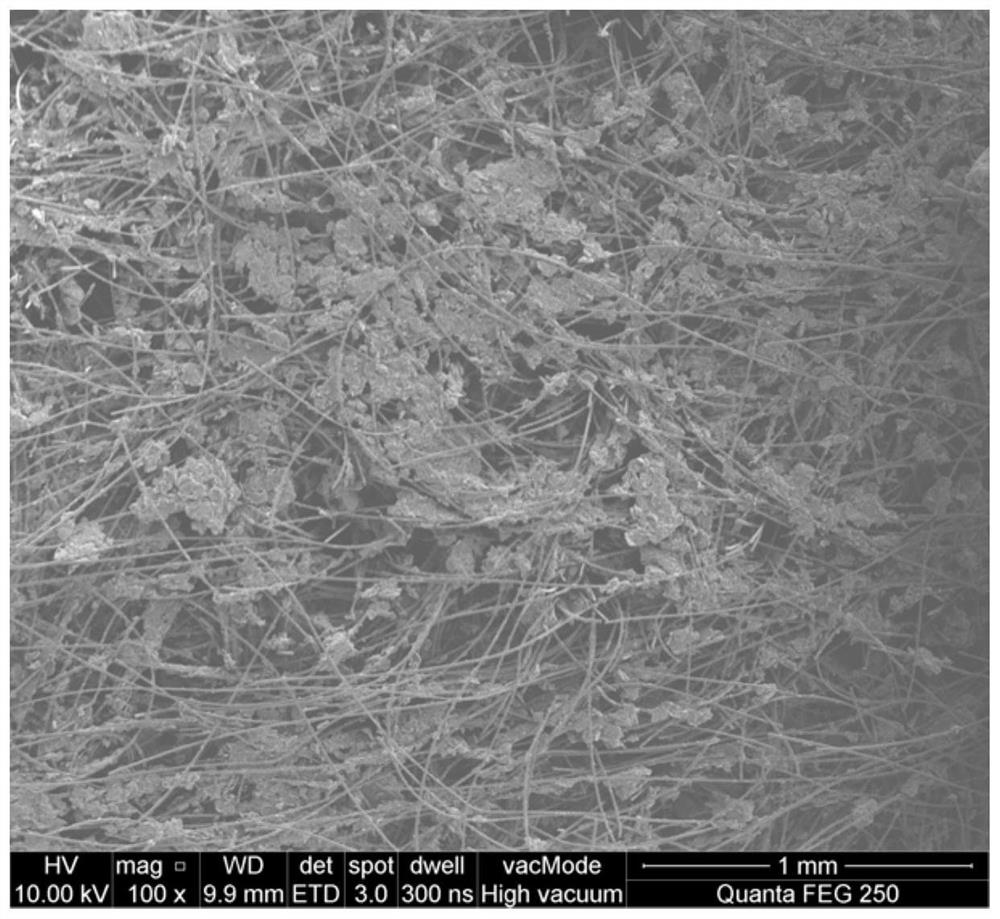

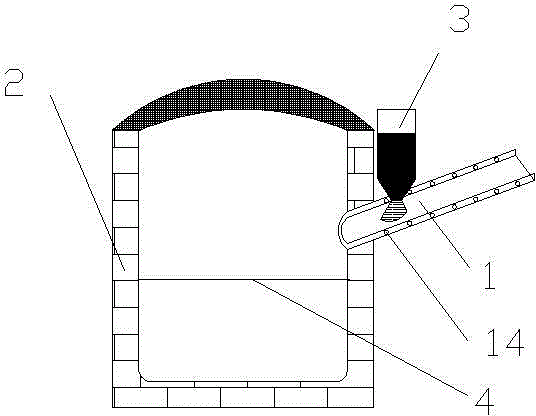

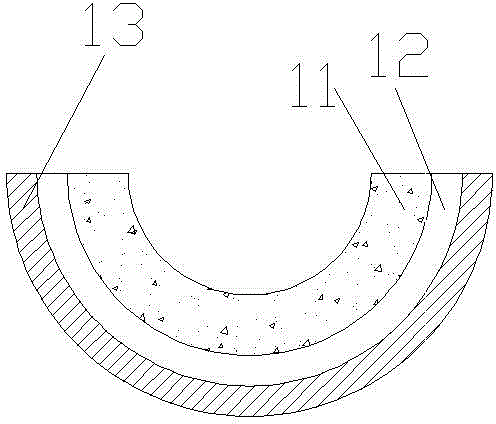

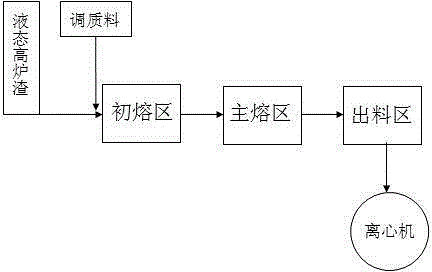

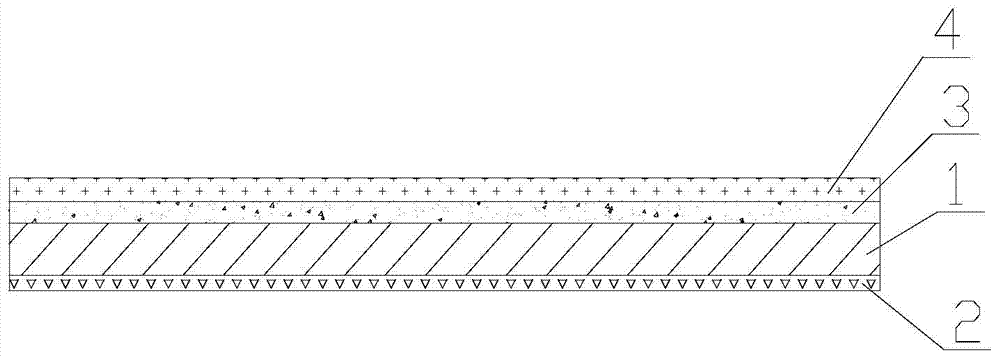

The invention relates to the technical field of mineral wool production and discloses a steel hot molten slag mineral cotton and its making method. The raw materials of the steel hot molten slag mineral cotton comprise 70-90% by mass of molten blast furnace slag and 10-30% by mass of a tempering material. The making method mainly comprises the following steps: directly introducing the hot molten slag to the initial melting zone of a slag melting furnace through a slag tank, and allowing the tempering material and the hot molten blast furnace slag to enter the initial melting zone of the slag melting furnace together; and maintaining the temperature of a melt in the initial melting zone in a range of 1400-1500DEG C for 4-6h, then allowing the melt to enter a primary melting zone, maintaining the temperature of the melt in the primary melting zone in a range of 1420-1450DEG C for 6-9h, then allowing the melt to enter a material discharge zone, and allowing the melt to flow to the roller of a centrifuge to form raw cotton. The preparation method has the advantages of energy saving, consumption reduction and simple process flow, and the prepared mineral cotton has the characteristics of good vitreous state, high fiber formation rate, wide adjustment range of the acidity coefficient and the like, and can satisfy the diversification demands of the market.

Owner:宝钢矿棉科技(宁波)有限公司

Method for producing mineral wool by using early-stage molten-state steel slag of converter

ActiveCN106045301AReduce manufacturing costImprove comprehensive benefitsGlass making apparatusBrown iron oxideFerrosilicon

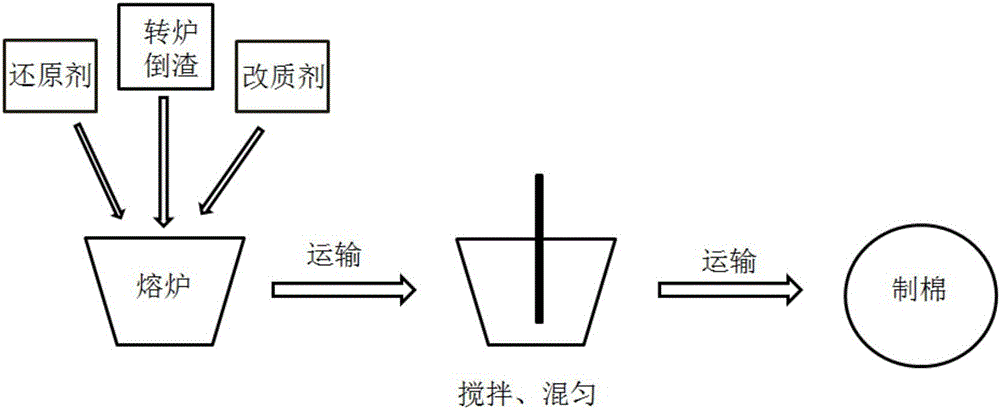

The invention discloses a method for producing mineral wool by using early-stage molten-state steel slag of a converter, and belongs to the technical field of production of mineral wool. The method comprises the following steps: pouring the early-stage molten-stage steel slag of the converter in a smelting furnace, adding a reducing agent and a modifier in a pouring process, and carrying out reducing and modifying; and after stirring, mixing evenly and standing for 0.5-1.5 hours, feeding slag at the temperature between 1,380 DEG C and 1,430 DEG C to wool producing equipment and processing into the mineral wool. Double advantages of 'residues' and 'heat' of the molten-state steel slag are played fully, ferrosilicon and aluminum granules are used as reducing agents, reaction of silicon, aluminum and iron oxide is silicothermal reaction and aluminothermal reaction, a large amount of thermal can be produced along with the reaction, and heat supply in a whole reducing and modifying process can be satisfied. After valuable elements are recycled, residues are directly prepared into the mineral wool with high additional value, the molten-state steel slag is comprehensively recycled, the problem of emission of the steel slag is solved, furthermore, the production cost of the mineral wool can be reduced, and the economic benefit and the environment benefit are good.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY +1

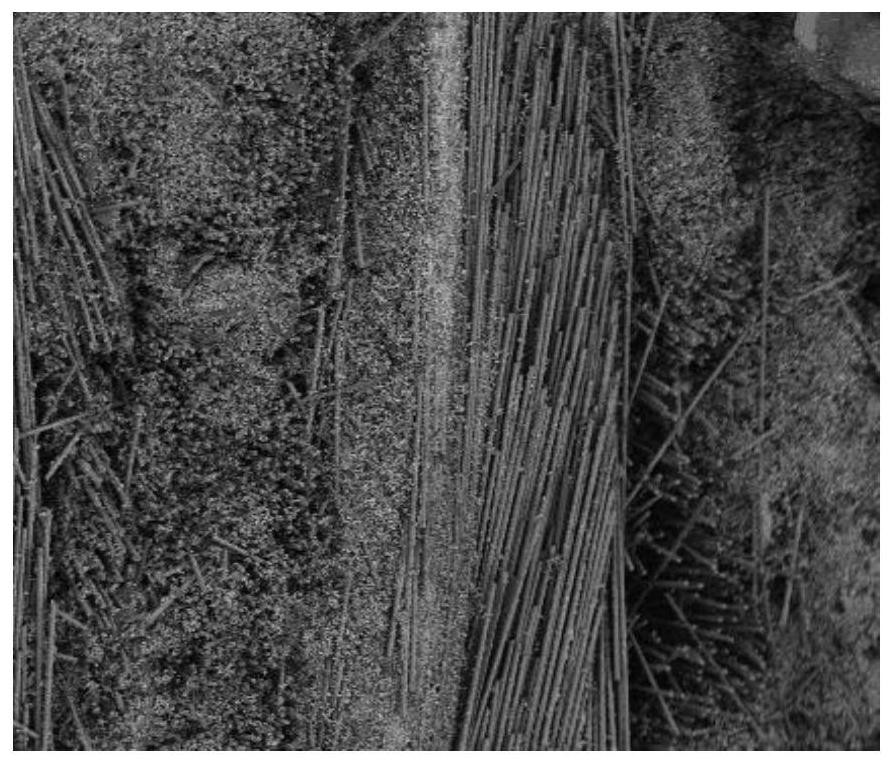

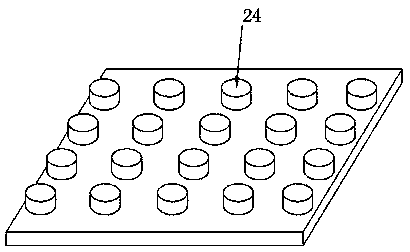

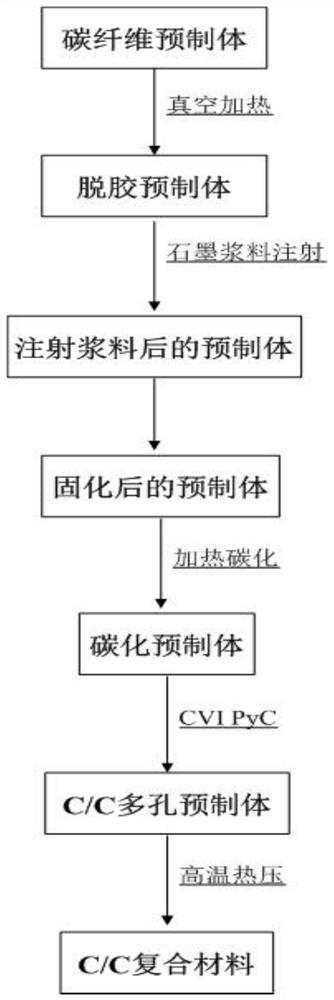

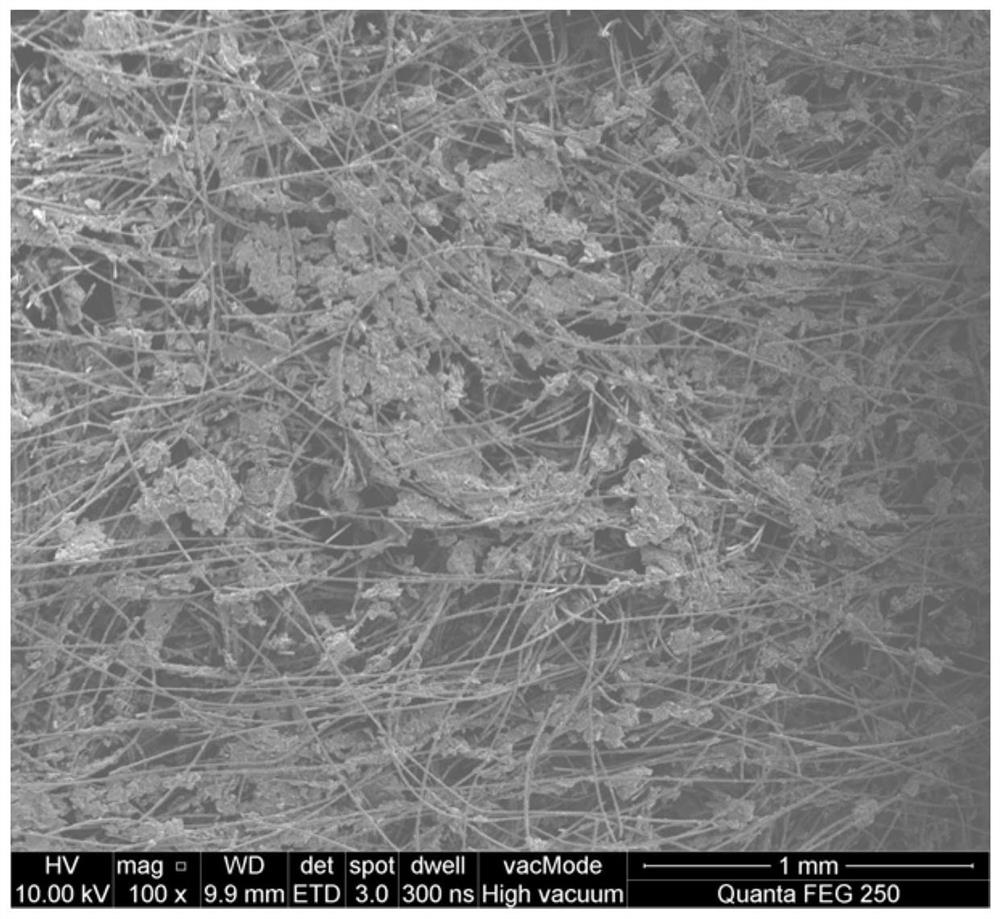

Rapid preparation method of C/C composite material

ActiveCN109384470ABreak the application limitationsImprove universal applicabilityWater basedCarbon fibers

The invention discloses a rapid preparation method of a C / C composite material and belongs to the technical field of material preparation. The rapid preparation method of the C / C composite material comprises the following steps: 1) preparation of a preform; 2) heat treatment of the preform; 3) preparation of water-based graphite slurry; 4) injection of graphite slurry; 5) recharging of the graphite slurry; 6) preparation of a green body; 7) carbonization treatment; and 8) densification treatment: the C / C porous preform is densified by using one or a combination of more of a chemical gas phasepermeation process, an impregnation-carbonization process and a high temperature hot pressing process. The rapid preparation method of the C / C composite material, disclosed by the invention, has the advantages that graphite powder is uniformly introduced by using a slurry injection method without destroying the bonding strength of the carbon fiber preform; the strength and microstructure uniformity of the material green body is guaranteed on the one hand, the densification time in the later period is greatly shortened on the other hand, the cost is reduced, and the rapid preparation method issuitable for industrial production; by using the water-based graphite slurry, the cost is low and pollution is avoided; and the C / C composite material prepared by using the method has the advantages of high strength, good wear resistance and reliable high temperature performance.

Owner:CENT SOUTH UNIV

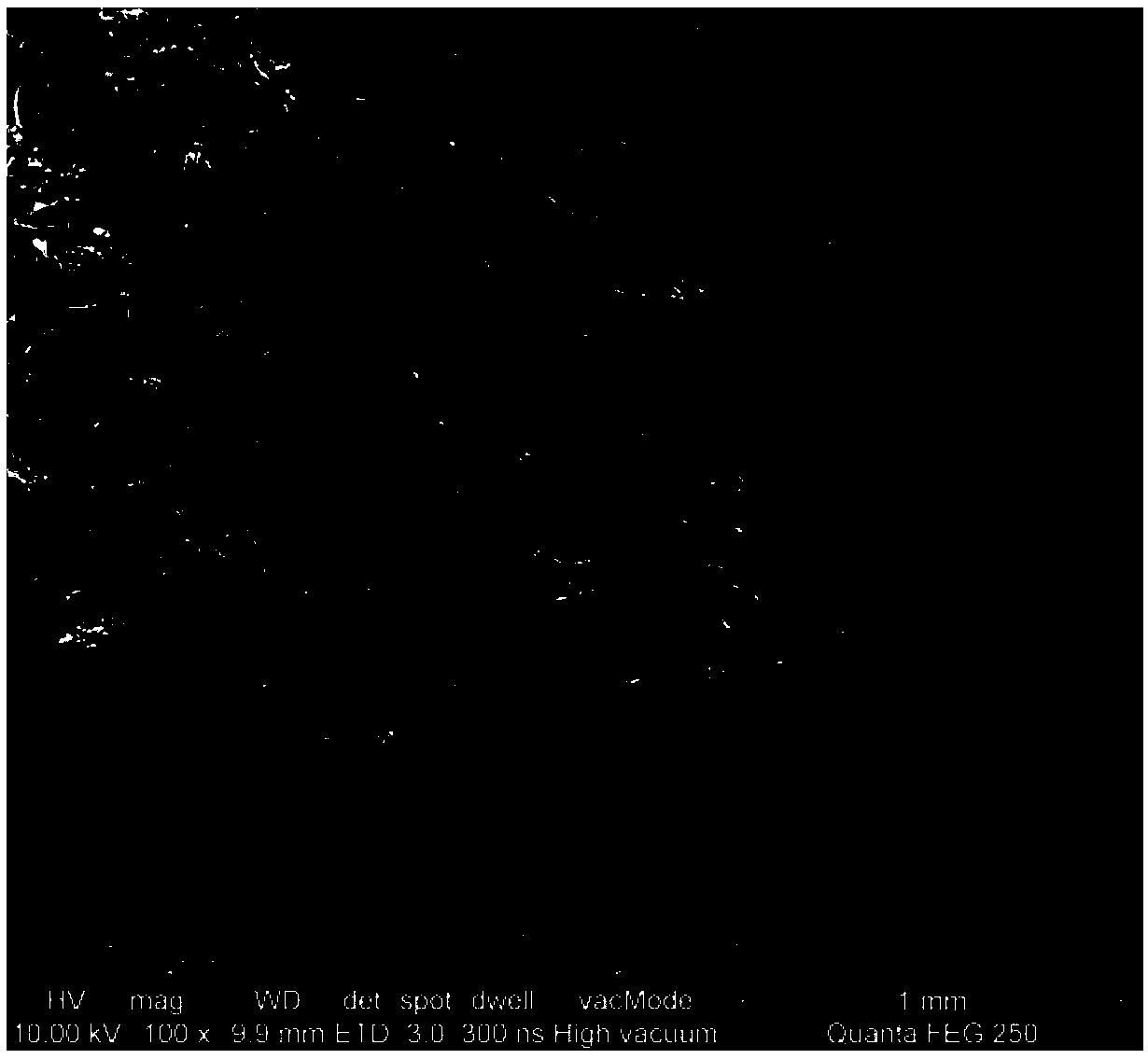

High-toughness ultrahigh-temperature ceramic-based composite material and preparation method thereof

The invention belongs to the technical field of composite material preparation, and particularly relates to a high-strength and high-toughness ultrahigh-temperature ceramic matrix composite material and a preparation method thereof. The preparation method comprises the following steps: alternately depositing two coatings on the surface of the carbon fiber material by adopting a chemical vapor deposition method to obtain the carbon fiber material with the multilayer CVD composite coating, wherein the two coatings are one of a pyrolytic carbon layer or a layered ceramic coating and an ultrahigh-temperature ceramic coating; adopting a phenolic resin / epoxy resin solution and ceramic powder to form ceramic slurry, coating the CVD composite coating carbon fiber material with the ceramic slurry, performing alternately staggered stacking and needling to obtain a stacked fiber felt, and after vacuum drying, performing warm-pressing curing and carbonization treatment, and obtaining a porous prefabricated body; and finally, carrying out densification treatment to obtain the ceramic-based composite material. The material has high strength, high fracture toughness, oxidation resistance, ablation resistance and corrosion resistance, and can be applied to high-temperature and ultrahigh-temperature structural materials, oxidation-resistant and corrosion-resistant materials and aerospace ablation-resistant materials.

Owner:湖南兴晟新材料科技有限公司

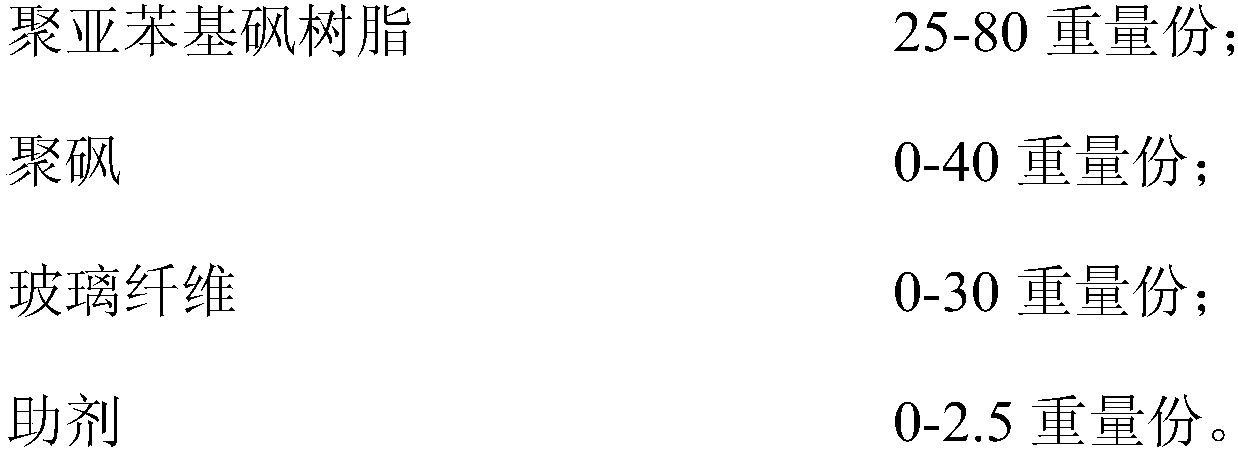

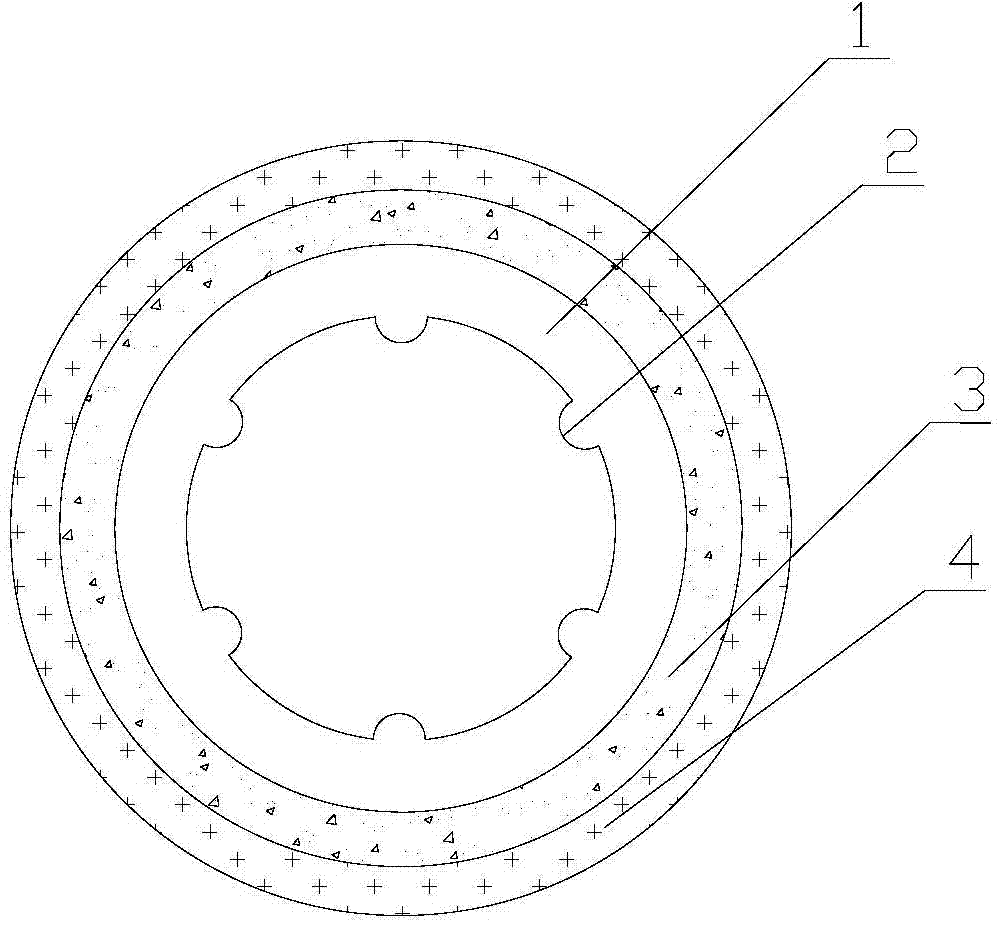

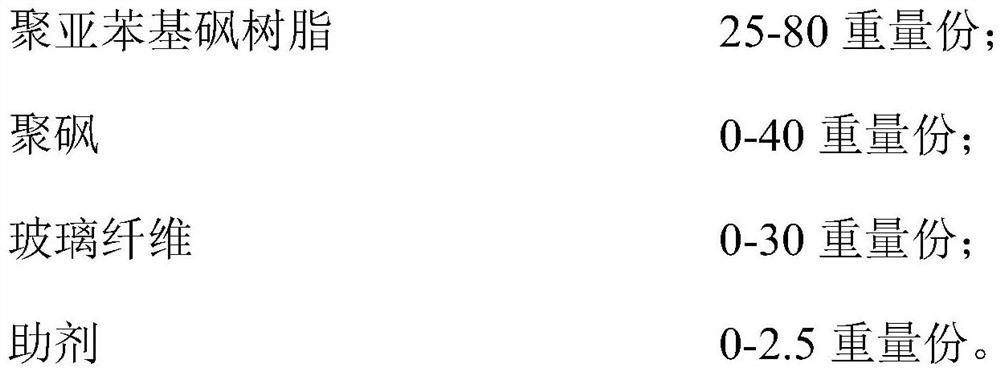

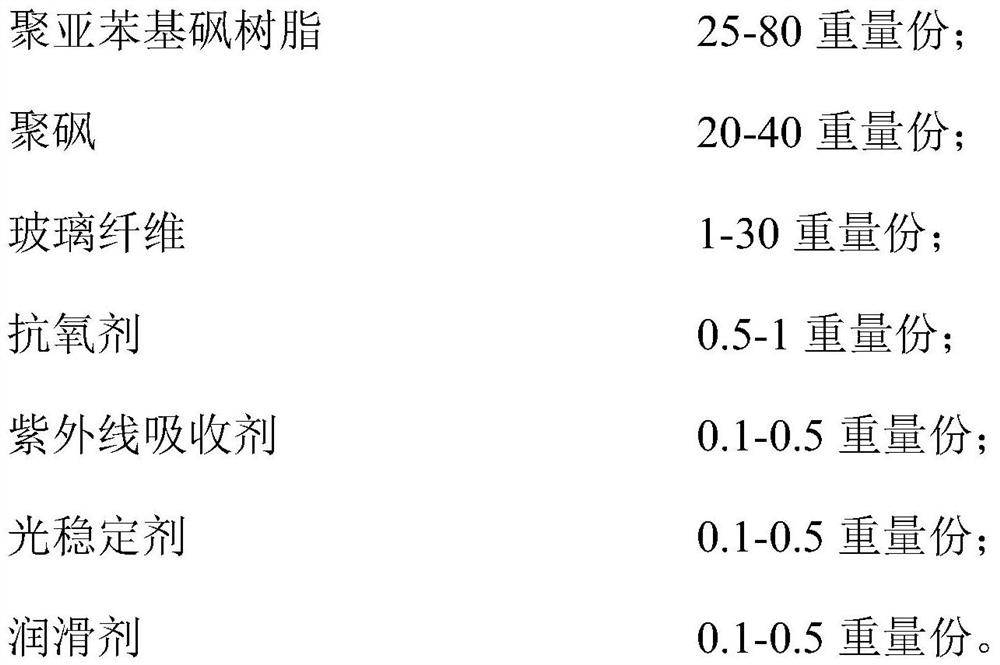

Method of bonding and fixing metal parts, polysulfone composite material for bonding and fixing metals, and preparation method and applications thereof

ActiveCN108676543AHigh bonding strengthLow dielectric propertiesNon-macromolecular adhesive additivesUltimate tensile strengthSulfone

The invention provides a method of bonding and fixing metal parts, a polysulfone composite material for bonding and fixing metals, and a preparation method and applications thereof. A novel application of polyphenylene sulfone resin as a metal bonding material is provided. Polyphenylene sulfone resin is usually used in fields such as food safety, medical instruments, and the like. The excellent metal bonding performance of polyphenylene sulfone resin is found for the first time. Polyphenylene sulfone resin is used to bond and fix metal parts, the bonding strength is high, and the peeling or breaking is difficult.

Owner:GUANGDONG SILVER AGE SCI & TECH CO LTD

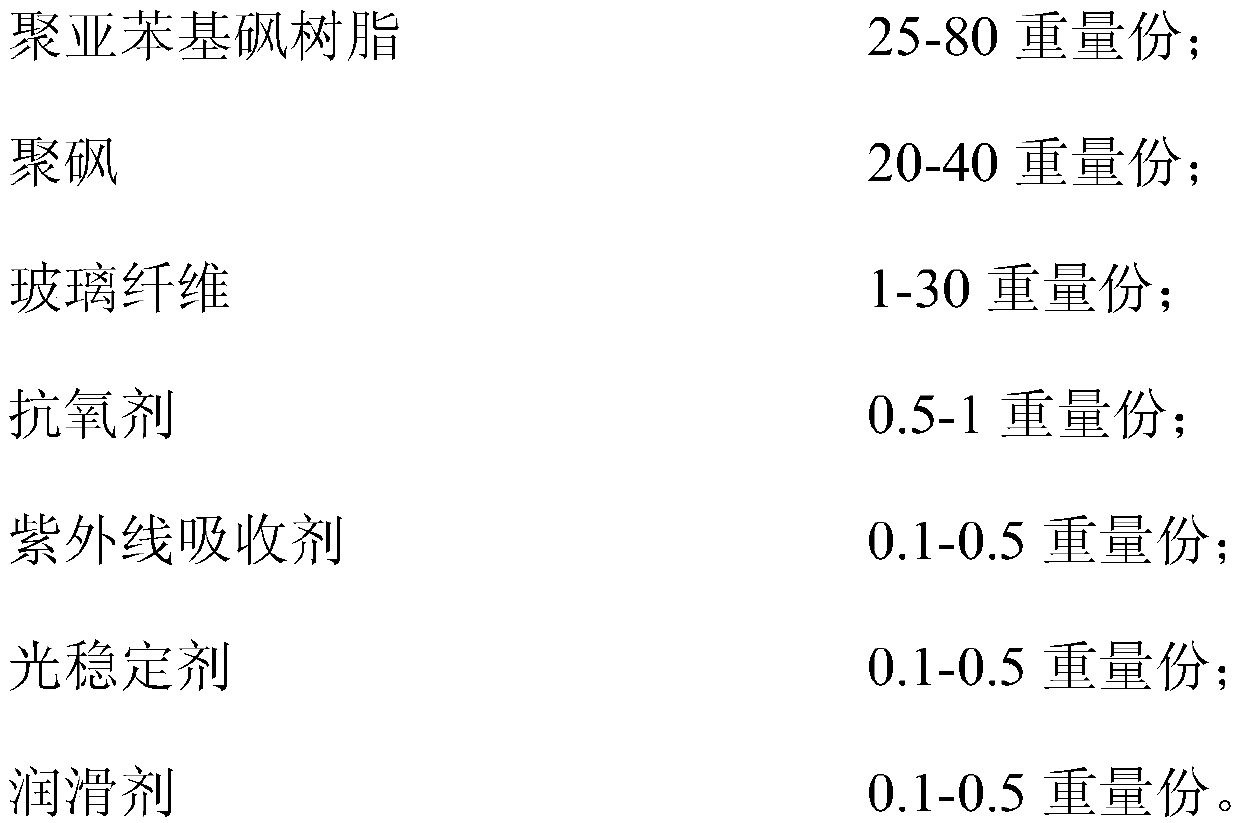

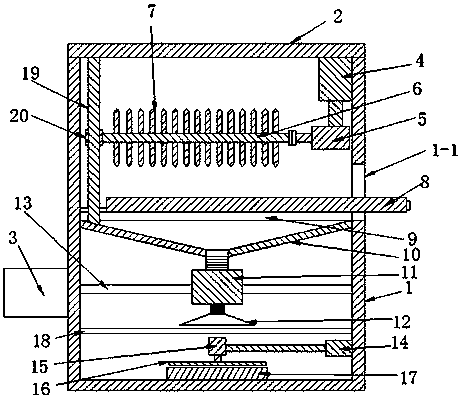

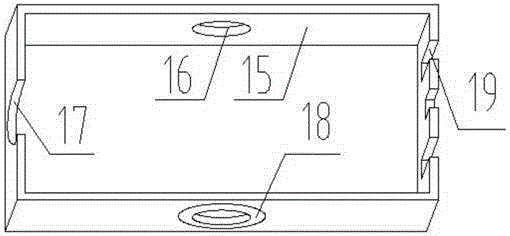

Traditional Chinese medicinal material slicing equipment capable of achieving multi-directional cutting

InactiveCN107756484AMeet diverse market needsPracticalDirt cleaningMetal working apparatusCouplingEngineering

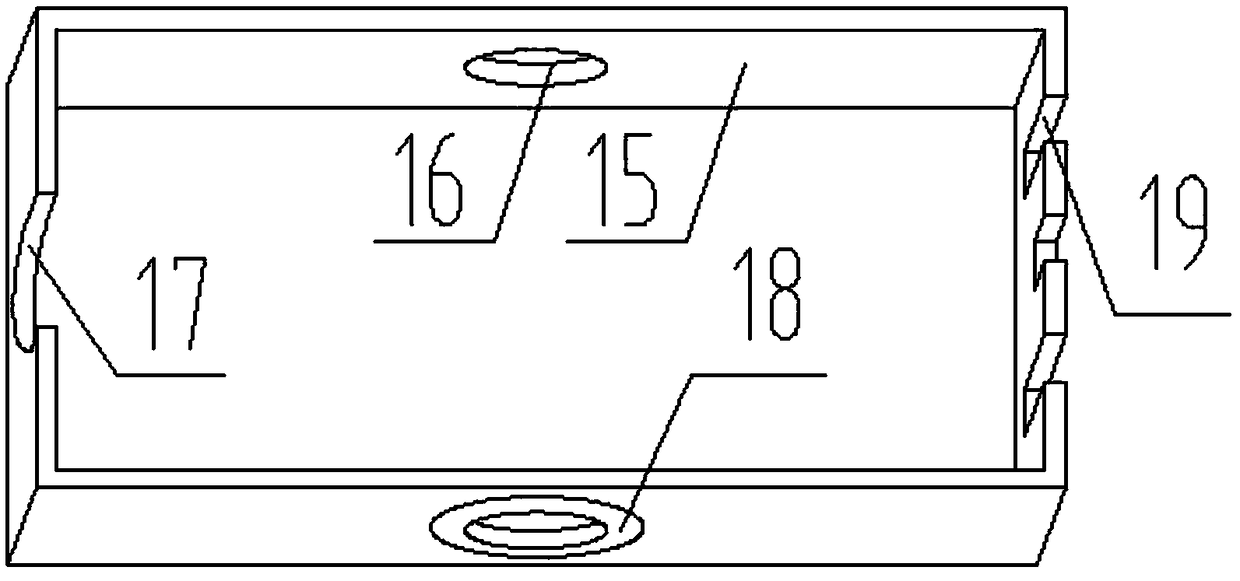

The invention relates to the technical field of medicinal material cutting equipment, in particular to multifunctional traditional Chinese medicinal material slicing equipment. An electric control boxis arranged on the outer wall of a machine shell. A top cover is arranged at the top of the machine shell. A first lifting motor is fixed to one side of the lower portion of the top cover. A rotary motor is fixed to an output shaft of the first lifting motor. An output shaft of the rotary motor is connected with a rotary shaft through a coupling. Multiple cutting discs are fixed to the rotary shaft. Rails are symmetrically arranged on the inner wall of the machine shell. A medicinal material placement disc is movably arranged on the rails and is arranged in an inserting opening in the side wall of the machine shell in an inserted manner. A guide hopper is arranged below the rails. A lower end opening of the guide hopper is connected with an air inlet pipe of a dust collector. An air outlet of the dust collector is connected with a powder discharging opening. Traditional Chinese medicinal materials can be subjected to slicing treatment according to needs, in addition, medicine powder generated by slicing can be subjected to tabletting treatment, the current diversified market requirements can be greatly met, and the multifunctional traditional Chinese medicinal material slicing equipment is wide in application range and higher in practicality.

Owner:泰兴市汇辰过滤器制造有限公司

Slag ball content control method for preparation of mineral wool from silicon-manganese slag

The invention provides a slag ball content control method for preparation of mineral wool from silicon-manganese slag and relates to improvement of a technological method for preparing mineral wool from metallurgical slag, particularly from the silicon-manganese slag. The method is characterized in that a flux is added to hot melt slag of a silicon-manganese alloy in the preparation process, wherein the flux contains calcium fluoride and magnesium oxide, adding amount of calcium fluoride is 5%-8% by weight of the hot melt slag of the silicon-manganese alloy, and the adding amount of magnesiumoxide is 3%-5% by weight of the hot melt slag of the silicon-manganese alloy. According to the method, the slag is diluted by adding the flux to the hot melt slag of the silicon-manganese alloy, flowability of the hot melt slag is enhanced, fibers can become thinner due to wool forming in a high-speed centrifugation state, content of slag balls in the mineral wool is reduced, tensile strength of the mineral wool is improved, cost is lower, and operation is facilitated; glass state of high-temperature melt of the prepared mineral wool is good, fiber forming rate is high, fiber forming quality is excellent, slag ball content is lower than 8%, heat conductivity coefficient is low, tensile strength is high, and diversified market demands can be met.

Owner:NINGXIA JIYUAN JUNTAI NEW MATERIAL TECH CO LTD

Organic light-emitting diode assembly and lamp

ActiveCN106384787AMeet diverse market needsSolid-state devicesSemiconductor/solid-state device manufacturingFlexible organic light-emitting diodeElectronic transmission

The invention provides an organic light-emitting diode assembly. The organic light-emitting diode assembly comprises an organic light emitting diode; the organic light-emitting diode comprises an electronic transmission layer, an organic light emitting material layer and a cavity transmission layer; the organic light emitting diode assembly also comprises a magnetic field supply unit; the magnetic field supply unit is used for providing a magnetic field; when the magnetic field supply unit provides the magnetic field, at least part of the organic light-emitting diode is positioned inside the magnetic field; an electronic transmission layer of the organic light emitting diode is made of a material, wherein an electronic migration rate of the material is changed along the change of the magnetic field; and / or the cavity transmission layer of the organic light-emitting diode is made of a material, wherein a cavity migration rate is changed along the change of the magnetic field. The invention also provides a lamp. In the light emitting diode assembly, the intensity of the magnetic field which is provided by setting the magnetic field supply unit can determine a light-emitting color of the light-emitting diode. The invention provides a novel organic light-emitting diode assembly which enriches the market and provides variety of choices to the user.

Owner:CHENGDU BOE OPTOELECTRONICS TECH CO LTD +1

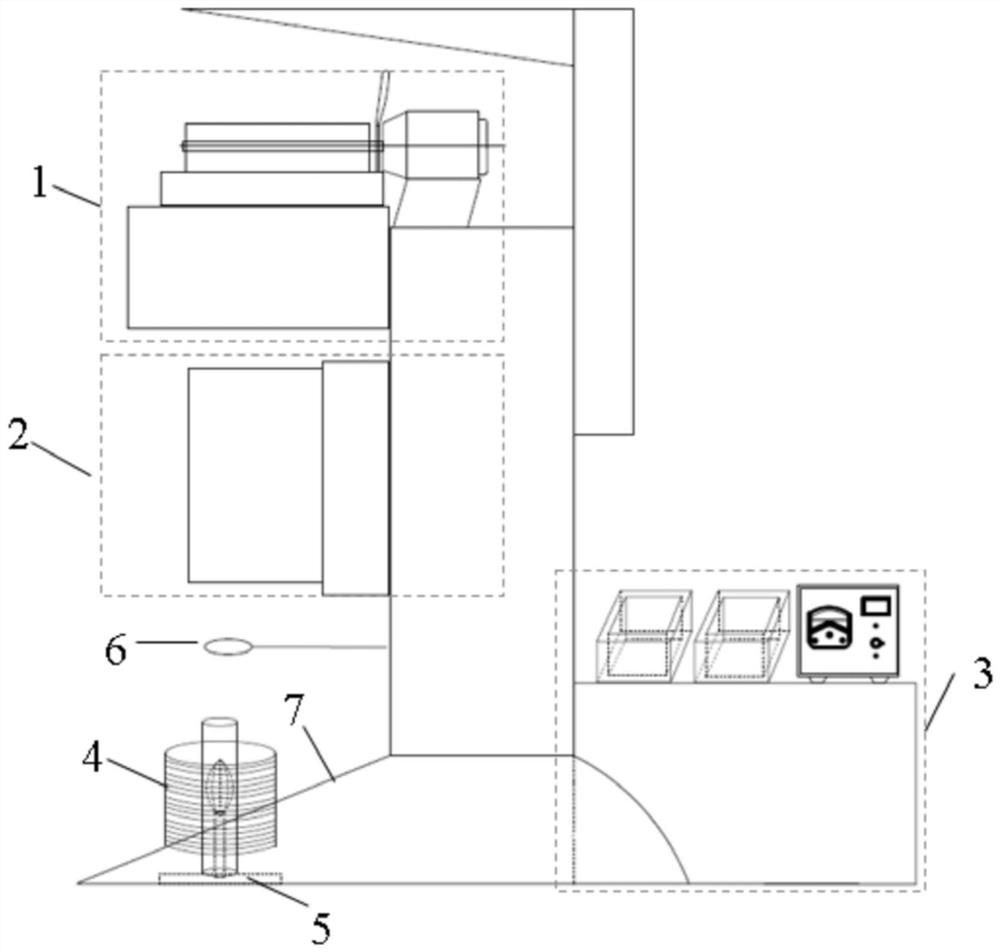

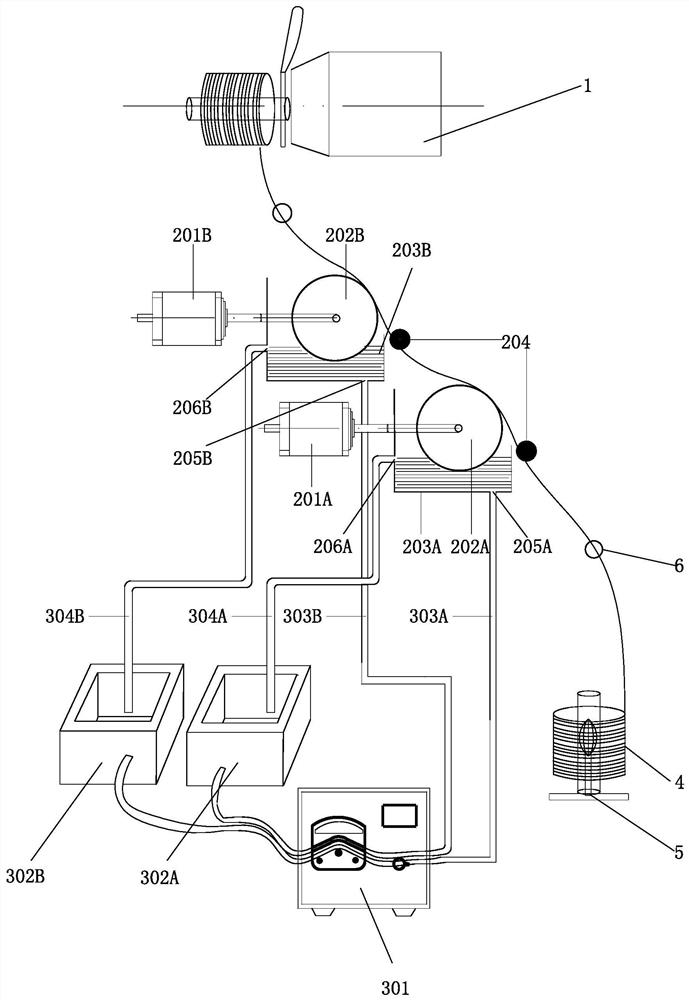

Online dyeing equipment and process for asynchronous dyeing of two colors

PendingCN113151998AColored yarn with unique styleReduce dosageSucessive textile treatmentsTextile treatment machine arrangementsYarnWinding machine

The invention belongs to the technical field of textile dyeing, and particularly relates to online dyeing equipment and process for asynchronous dyeing of two colors. The on-line dyeing equipment is a winding machine provided with a dyeing unit and a dye liquor supply unit, and is composed of a cone yarn winding device, the dyeing unit, the dye liquor supply unit, cone yarn, a yarn carrying base, an air ring breaker and an equipment base, wherein the dyeing unit comprises a first dye vat and a second dye vat, the dye liquor supply unit controls supply and circulation of dye liquor, the dye liquor is conveyed into the dye vats, during dyeing, the rotating speed and the running speed of a dyeing wheel are adjusted, the dye liquor on the surface of the dyeing wheel is rapidly adhered and permeates into fibers, dye is fixed through steaming treatment and aftertreatment, and finally the dyed yarn distributed with different colors is obtained. According to the process, the production process can be remarkably shortened, the production operation can be simplified, the using amount of dyeing auxiliaries can be reduced, the use coverage of dye types and yarn types is wide, diverse fabric styles and leisure production can be achieved, and the market requirements for small batch and diversification are met.

Owner:LUTAI TEXTILE

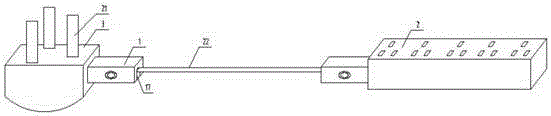

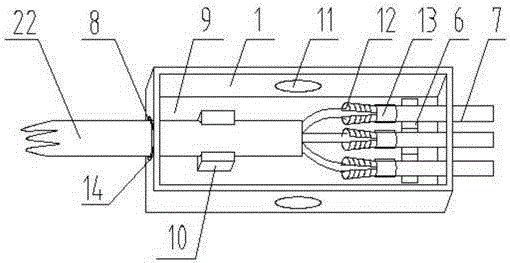

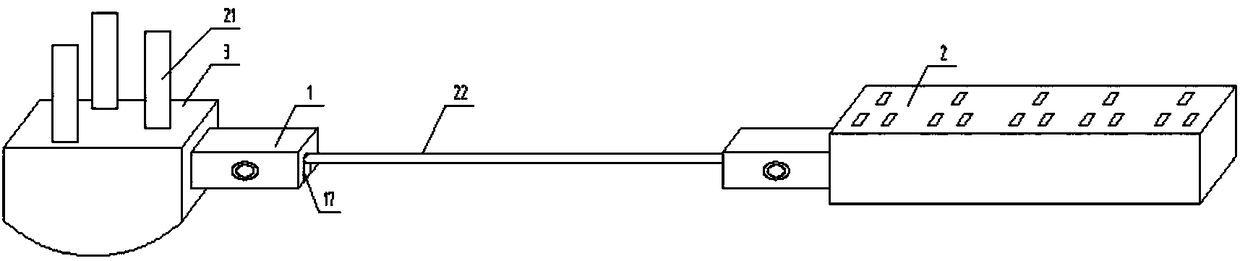

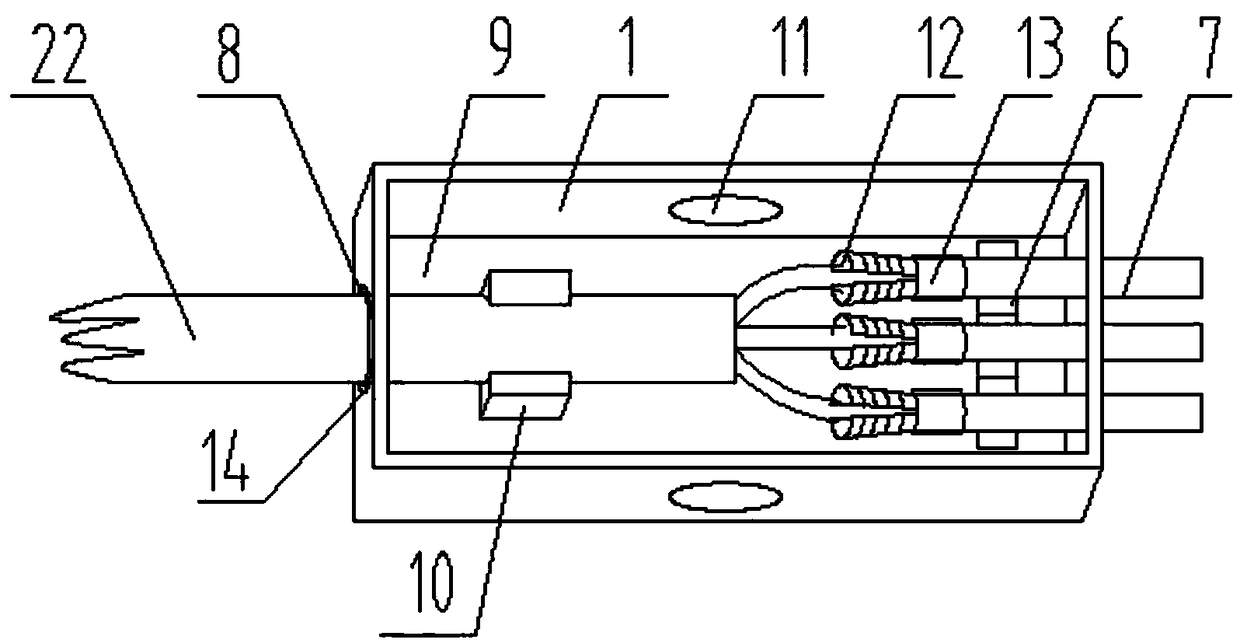

Connecting wire device of wire-changing power strip

InactiveCN106229779ASafe replacementEasy to operateCoupling device detailsClamped/spring connectionsSealantPower strip

The present invention belongs to the electric appliance equipment technology field, and relates to a connecting wire device of a wire-changing power strip. The main body structure of the connecting wire device comprises connecting plugs, a wireless power strip, a wireless socket, a first connecting jack, a second connecting jack and a connecting wire, and the main body structure of each connecting plug comprises a plug supporting base, a plug, a box body, a fixing bolt, a T-shaped sealant sleeve, a box cover, a bump fixing hole, a U-shaped groove, a sealant sleeve, a plug groove, a pull buckle, etc. The connecting plugs are arranged at the two ends of the connecting wire, the first connecting jack on the side surface of the wireless power strip is in inserted connection with the connecting plug at one end of the connecting wire, and the connecting plug at the other end of the connecting wire is in inserted connection with the second connecting jack on the front side surface of the wireless socket. By just plugging the connecting plugs out of the wireless power strip and the wireless socket, and opening the box cover, the connecting wire of any length is disassembled and replaced. The connecting wire device is simple in main body structure, good in safety and friendly in application environment, is convenient to install and use, and possesses a good market application prospect.

Owner:QINGDAO UNIV

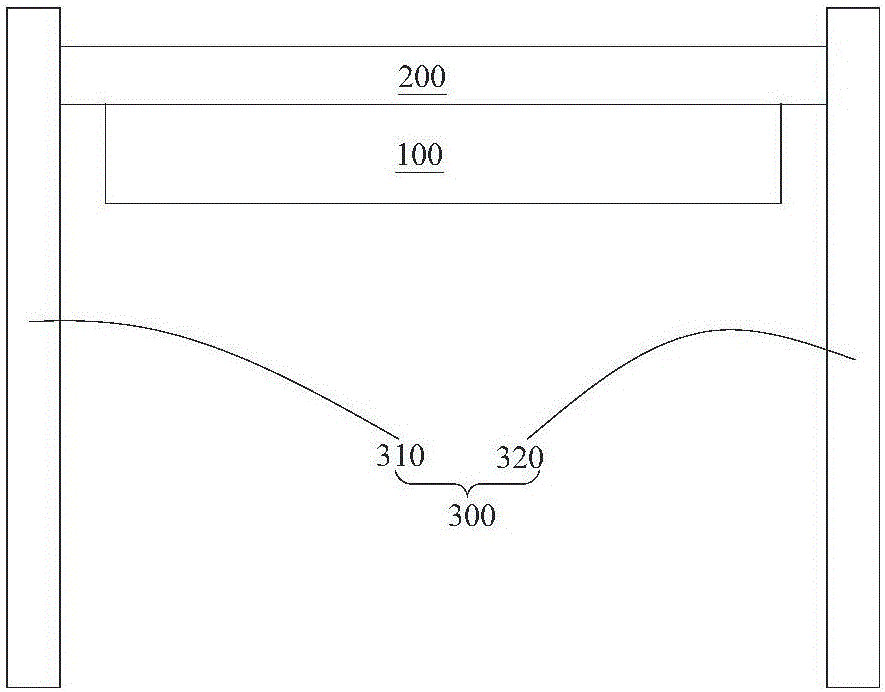

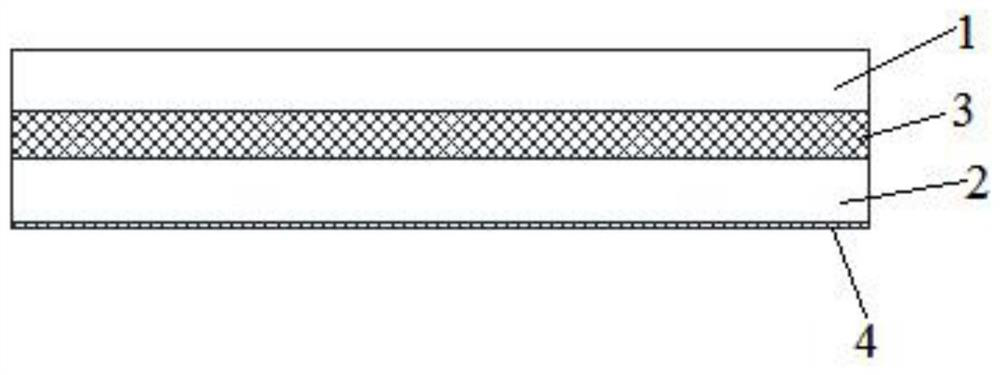

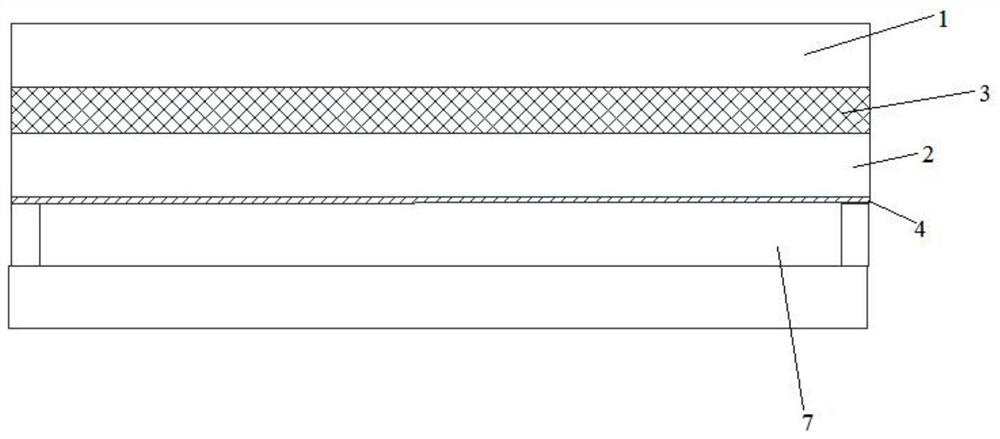

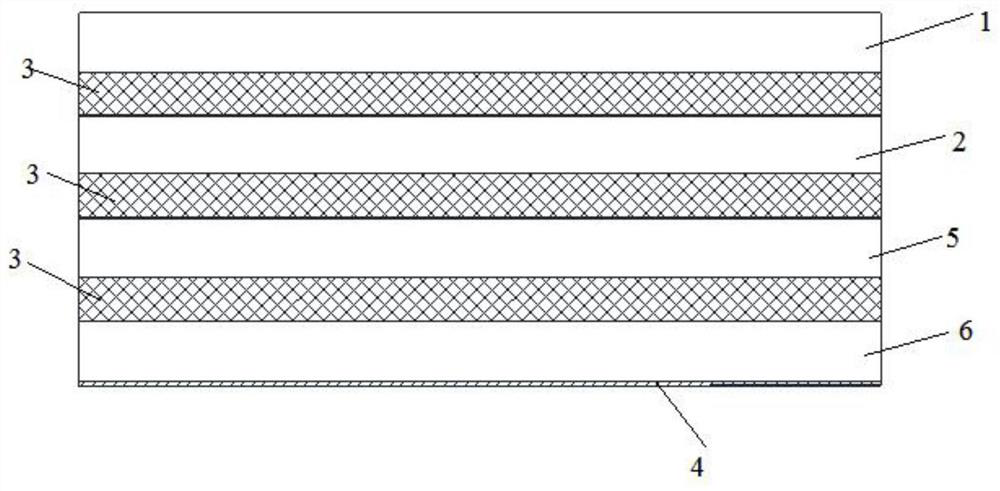

LOW-E coated laminated glass, hollow glass and preparation method of LOW-E coated laminated glass

ActiveCN112406222AReduced risk of air bubblesImprove flatnessClimate change adaptationSynthetic resin layered productsSputteringHeat treated

The invention relates to LOW-E coated laminated glass, hollow glass and a preparation method of the LOW-E coated laminated glass and the hollow glass. The preparation method comprises the following steps: step 1, preparing n glass substrates, namely the first glass substrate to the nth glass substrate, in sequence from top to bottom; performing vacuum magnetron sputtering LOWE coating processing treatment on the bottom of the nth glass substrate; 2, sequentially carrying out interlayer laminating processing treatment on from the n-1th glass substrate to the first glass substrate at the top ofthe nth glass substrate obtained in the step 1; 3, pasting a PVC protective film at the bottom of the nth glass substrate; then, heating and rolling the first glass crude product twice in sequence ina two-stage interlayer roller press; and 4, placing the crude glass product obtained in the step 3 in a reaction kettle, and carrying out pressurization and heating treatment to obtain the LOWE coatedlaminated glass. The preparation method provided by the invention is simple to operate, and can effectively improve the yield of LOW-E coated laminated glass products and the total production efficiency.

Owner:SICHUAN NANBO ENERGY SAVING GLASS CO LTD +1

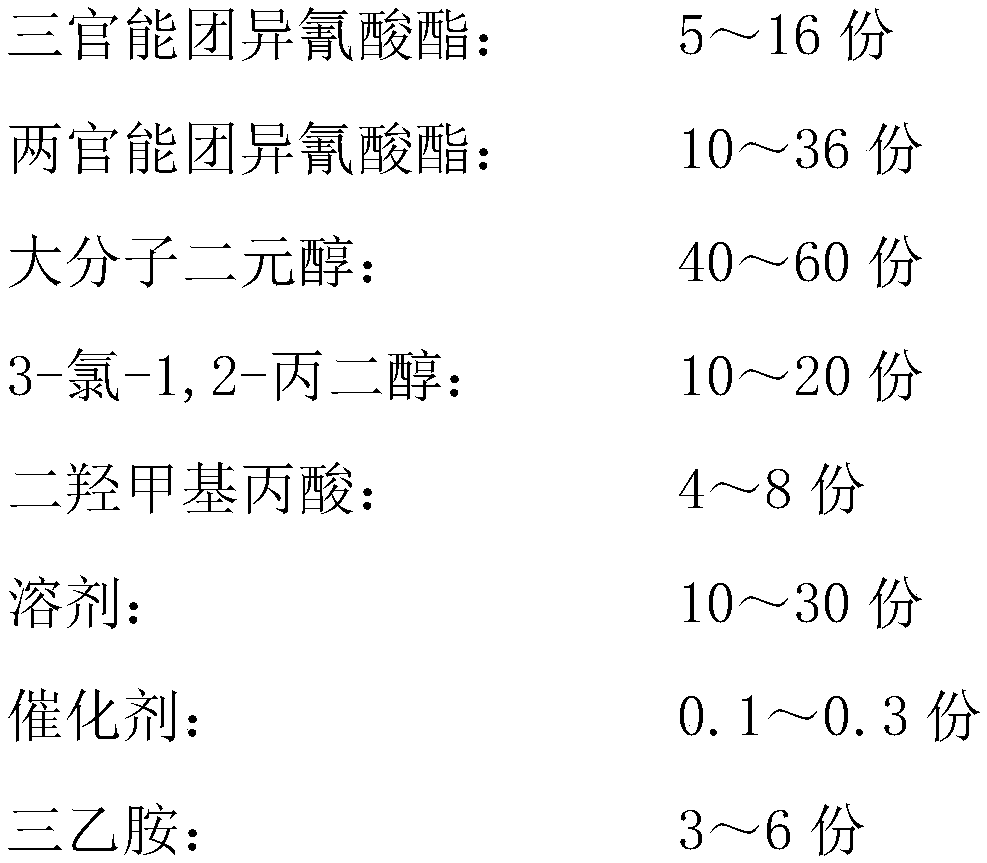

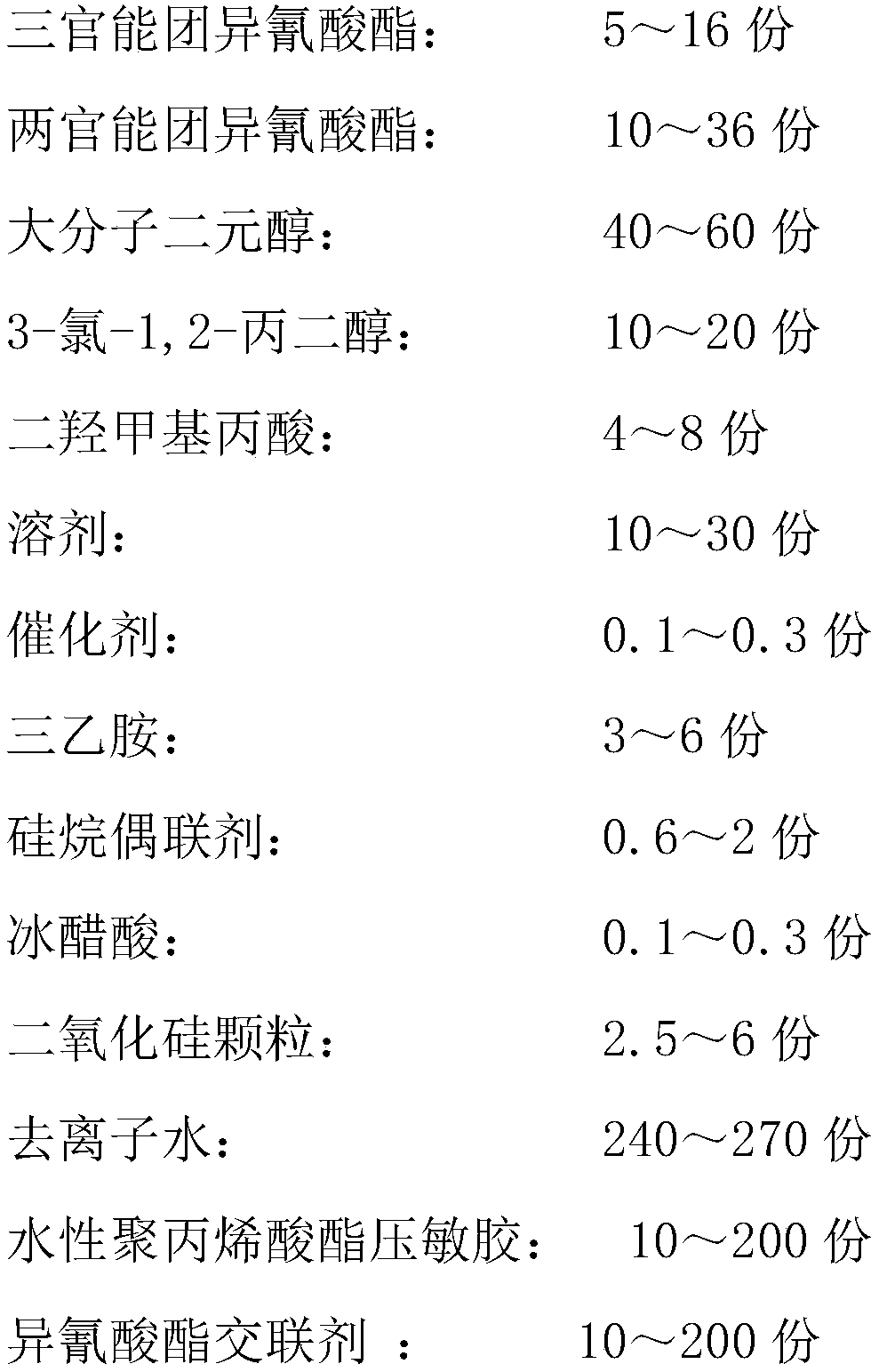

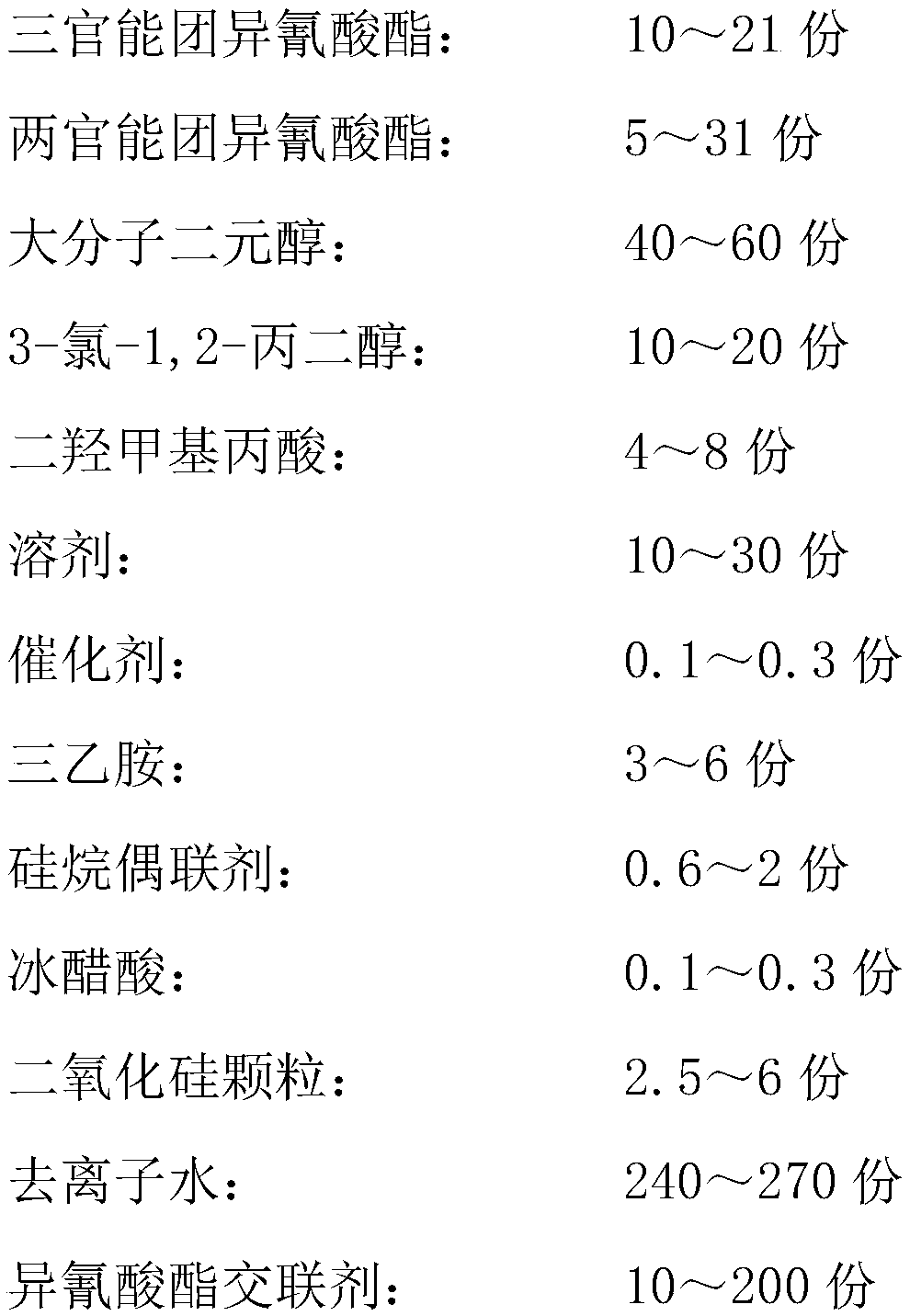

Durable film composite substrate for laminating card manufacturing and manufacturing process

InactiveCN109135607AMeet traditional printing requirements such as offset printingRealize digital printing functionNon-macromolecular adhesive additivesFilm/foil adhesivesAdhesiveComposite substrate

The invention discloses a durable film composite substrate for laminating card manufacturing and a manufacturing process. The composite substrate structurally comprises a printed layer, a connection layer, a film, a composite adhesive, a back adhesive A, a substrate sheet and a back adhesive B in sequence from top to bottom. The film can be one of a PET aluminum laminated film, a PET film, a PC film and a PETG film in thickness of 10-50micron; when the film is the PET aluminum laminated film, an aluminum laminated surface of the film is connected with the substrate sheet through the compositeadhesive and the back adhesive A; the substrate sheet can be one of PVC, PC, PETG and ABS in thickness of 80-800micron. The film composite substrate can be applied to the field of laminating card manufacturing; after laminating, initial 90-degree peel strength of the film and the substrate sheet reaches 12N / cm or above and still reach 9N / cm or above after aging for 14 days at 50 DEG C under the relative humidity of 93%, the substrate is superior to similar imported products in performance, and technical requirements on peel strength in international standards ISO7810, CQM and the like are completely met.

Owner:TIANJIN BOYUAN NEW MATERIALS

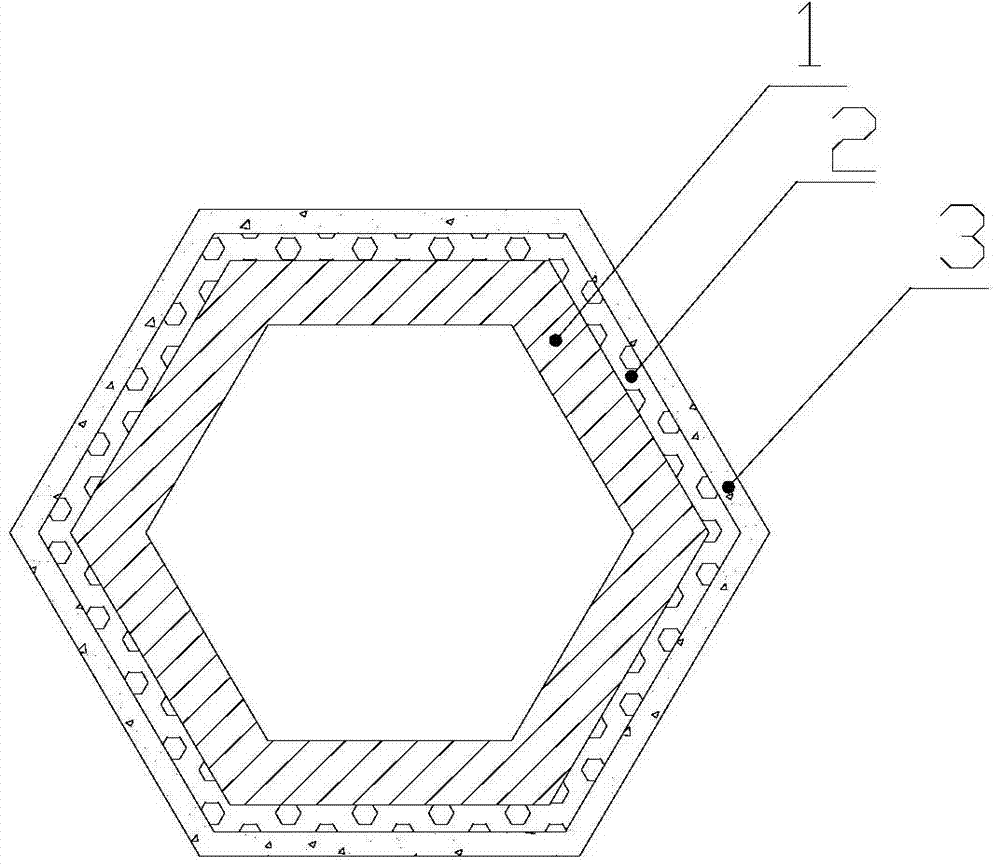

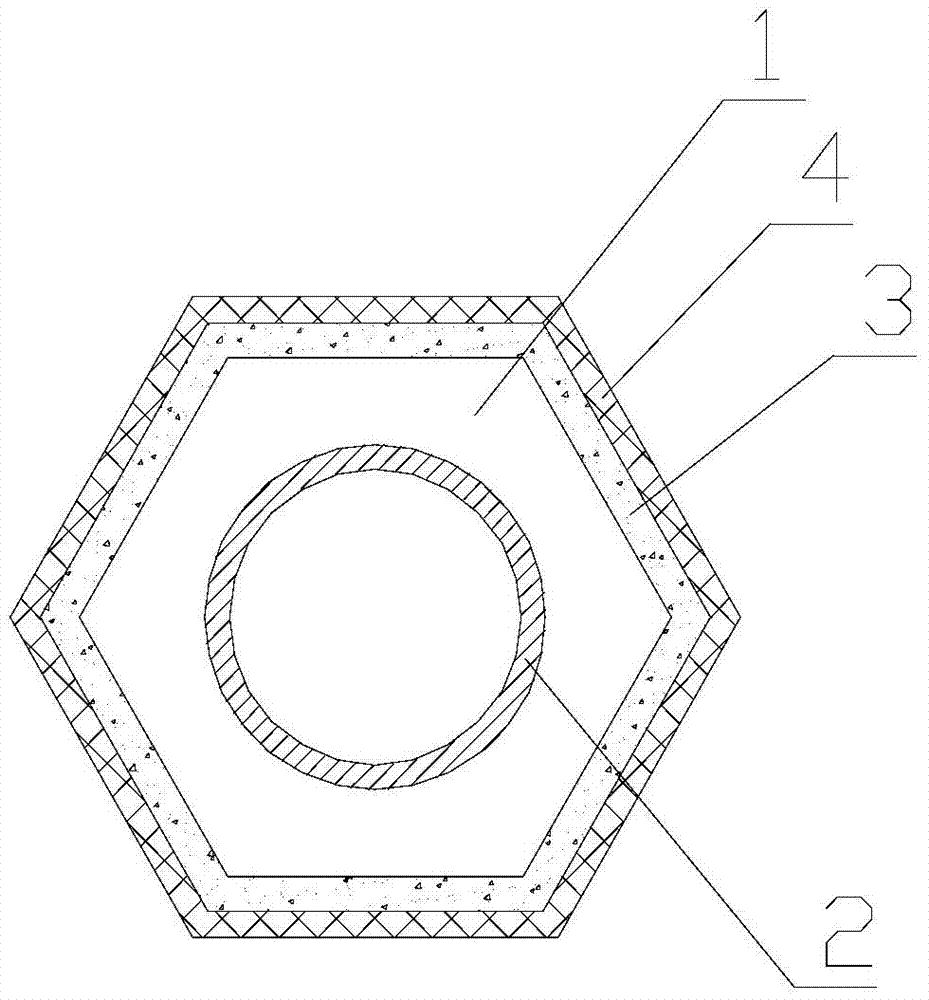

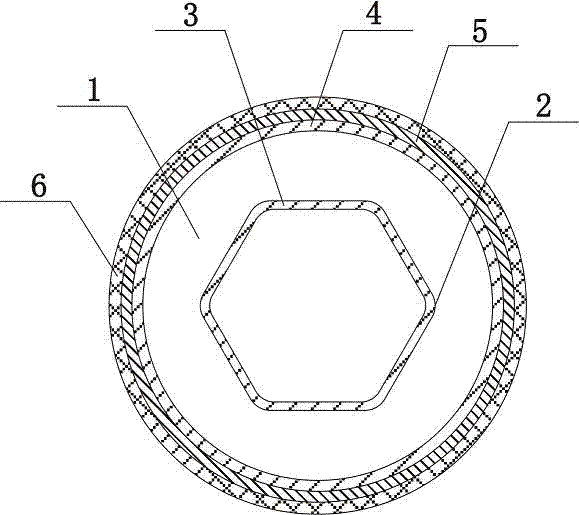

Hexagonal anti-corrosion insulation metal pipe

InactiveCN104747810ANovel structureTo satisfy the market's needsCorrosion preventionPipe protection against corrosion/incrustationFluorocarbonCorrosion

The invention relates to the technical field of metal pipes, in particular to a hexagonal anti-corrosion insulation metal pipe. The hexagonal anti-corrosion insulation metal pipe comprises a metal pipe body, the outer wall and the inner wall of the metal pipe body are hexagonal, the outer wall of the metal pipe body is coated with a fluorocarbon paint anti-corrosion layer, and an insulation layer is wound on the surface of the fluorocarbon paint anti-corrosion layer. The hexagonal anti-corrosion insulation metal pipe is novel in structure, diversified market requirements are met, the surface of the metal pipe is coated with the anti-corrosion layer, the corrosion resistance of the metal pipe is effectively enhanced, the insulation layer can achieve the insulation effect, and use is safe and reliable.

Owner:李莹

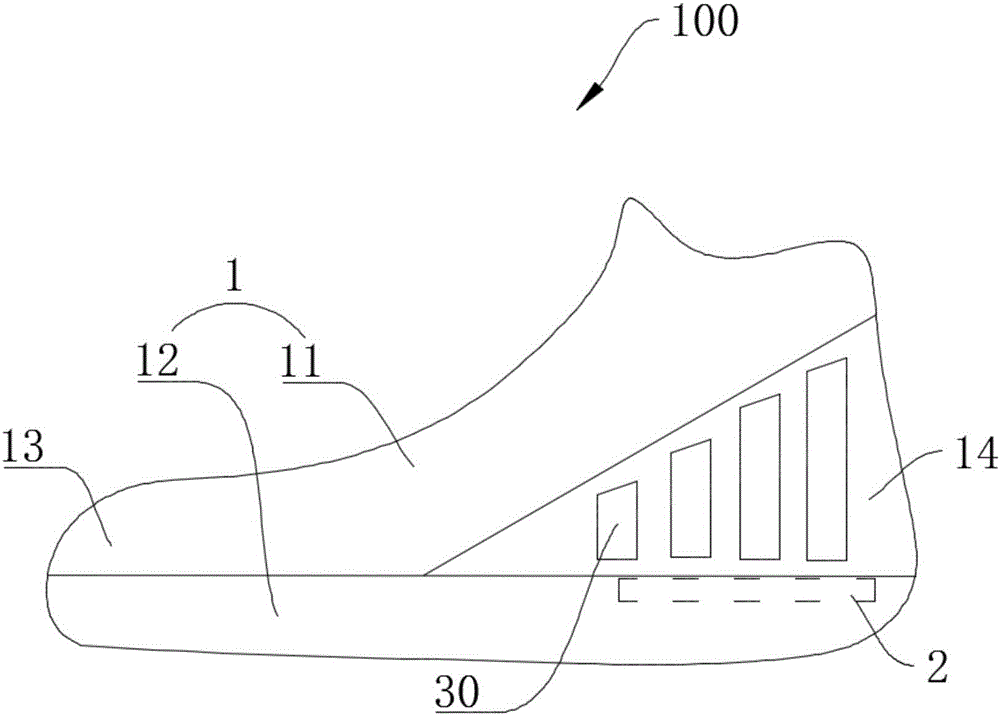

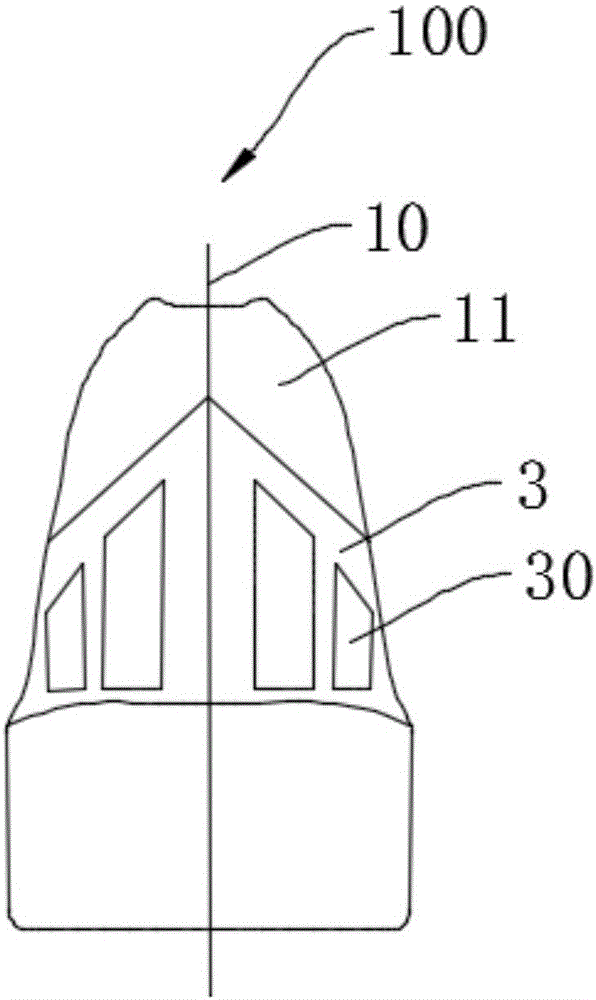

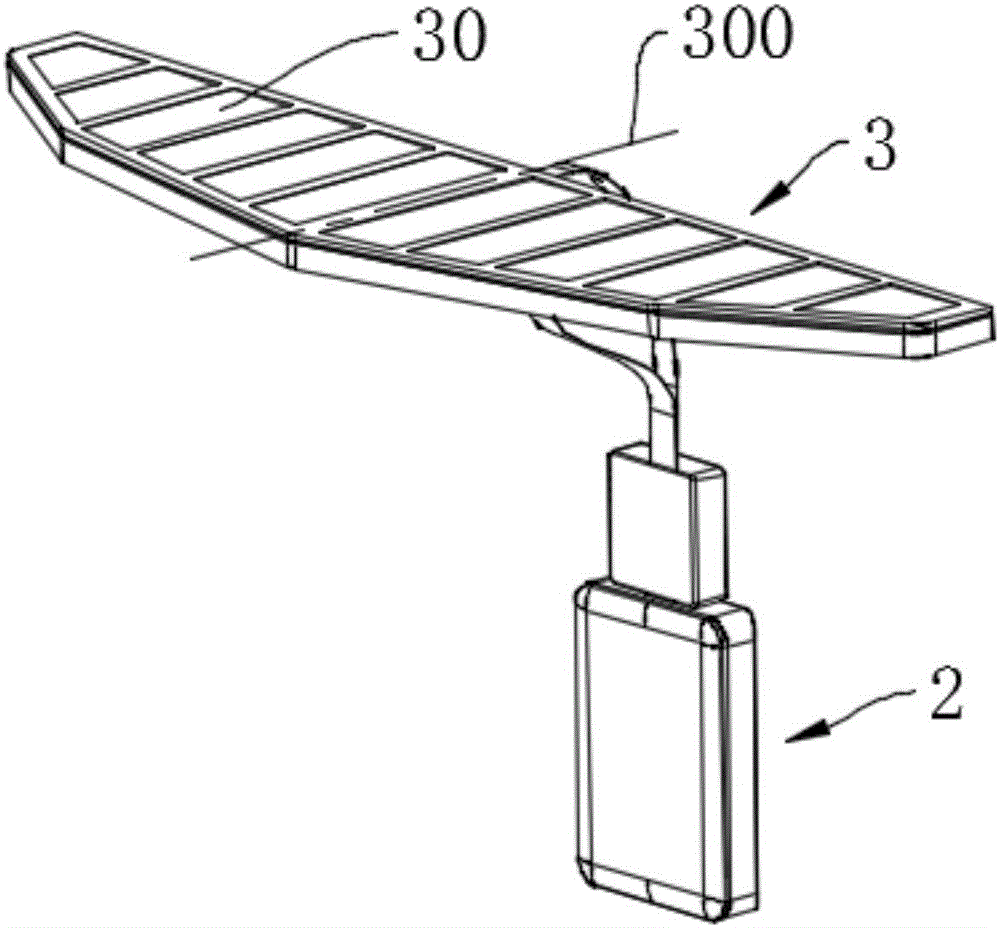

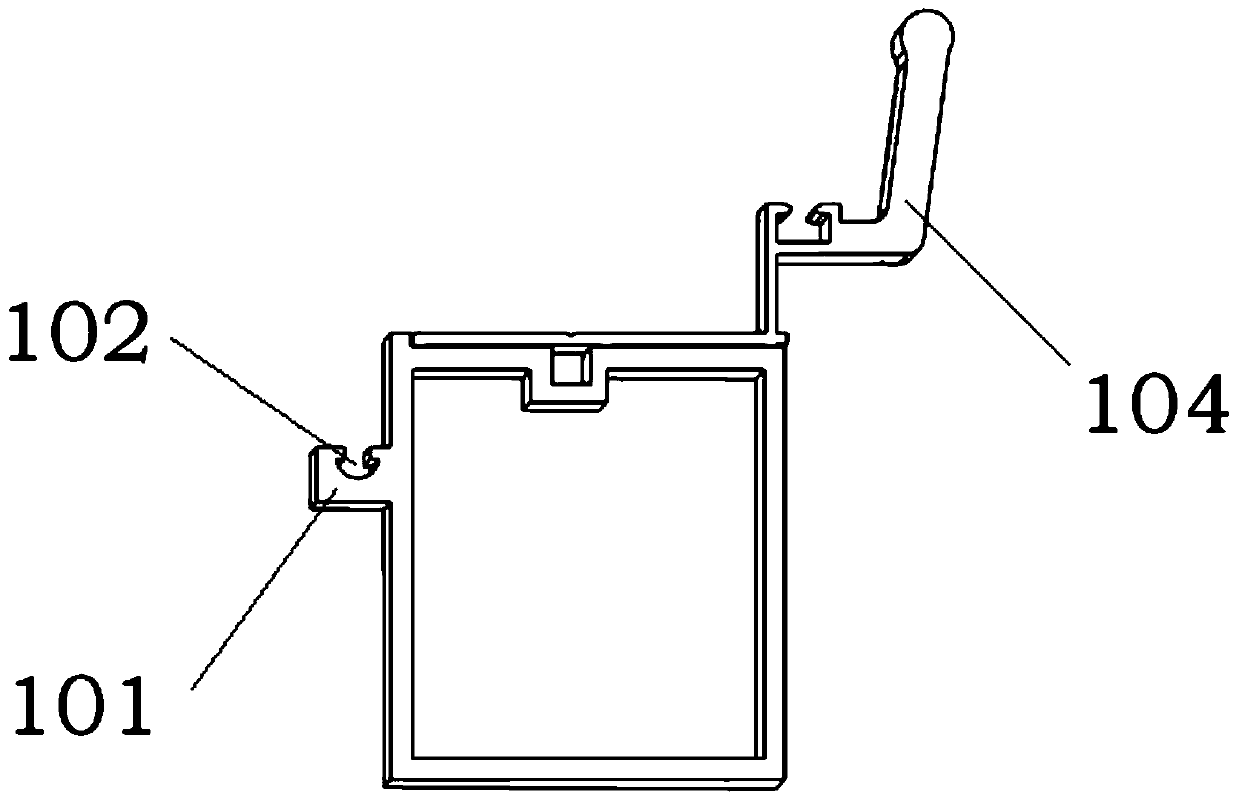

Smart shoes

Owner:SHENZHEN ROYOLE TECH CO LTD

Sunroom skylight system and manufacturing method thereof

ActiveCN105649280BAvoid enteringImprove insulation effectDoors/windowsSky-lights/domesThermal insulationAgricultural engineering

Owner:VIEWMAX DOORS & WINDOWS CO LTD

A connection line device for changing lines and inserting a row

InactiveCN106229779BSafe replacementEasy to operateCoupling device detailsClamped/spring connectionsEngineeringSealant

Owner:QINGDAO UNIV

Technology for producing tool part blank for cutting thin-wall steel plate by virtue of casting method

The invention discloses a technology for producing a tool part blank for cutting a thin-wall steel plate by virtue of a casting method. The technology for producing the tool part blank for cutting thethin-wall steel plate by virtue of the casting method comprises the following steps: alloy smelting, shell roasting, pouring, shell vibration, lifting-blasting, cutting, annealing, grinding, machining, and carbon restoration and hardening-tempering, wherein the used alloy comprises the following substance components in percentage: 0.35%-0.45% of C, 0.30%-0.45% of Si, 0.1%-0.4% of Mn, 1.0%-1.8% ofCr, 0.1%-0.4% of Mo, 1.0%-2.5% of W, not greater than 0.3% of V, less than 0.03% of impurity elements, and the balance Fe. According to the technology for producing the tool part blank for cutting the thin-wall steel plate by virtue of the casting method, the components of the adopted casting alloy are easy to control, and a casting die is simple to produce, and capable of producing special platecutting tools with complex shapes, and meeting small-batch and diversified market needs; and the part blank of a cutting tool is produced through the casting method, the part blank can be produced only by producing one die, and the production efficiency for the blank is greatly increased, so that the problem that the blank produced by a forging method is unsuitable for producing the special platecutting tools with complex structure, is solved.

Owner:阳信东泰精密金属有限公司

A kind of rapid preparation method of c/c composite material

ActiveCN109384470BBreak the application limitationsImprove universal applicabilityCarbon fibersCarbonization

The invention discloses a rapid preparation method of a C / C composite material, which belongs to the technical field of material preparation. The method comprises the following steps: 1) preparation of a preform; 2) heat treatment of the preform; 3) preparation of a water-based graphite slurry ; 4) Graphite slurry injection; 5) Graphite slurry refilling; 6) Preparation of biscuit; 7) Carbonization treatment; One or more combinations of C / C porous preforms are densified. The invention adopts the method of slurry injection, and uniformly introduces graphite powder without destroying the bonding strength of the carbon fiber prefabricated body. On the one hand, it ensures the strength and uniformity of the material body, and on the other hand, it greatly shortens the later densification time. , which reduces the cost and is suitable for industrial production; the use of water-based graphite slurry has low cost and no pollution; the C / C composite material prepared by this method has high strength, good wear resistance, and reliable high-temperature performance.

Owner:CENT SOUTH UNIV

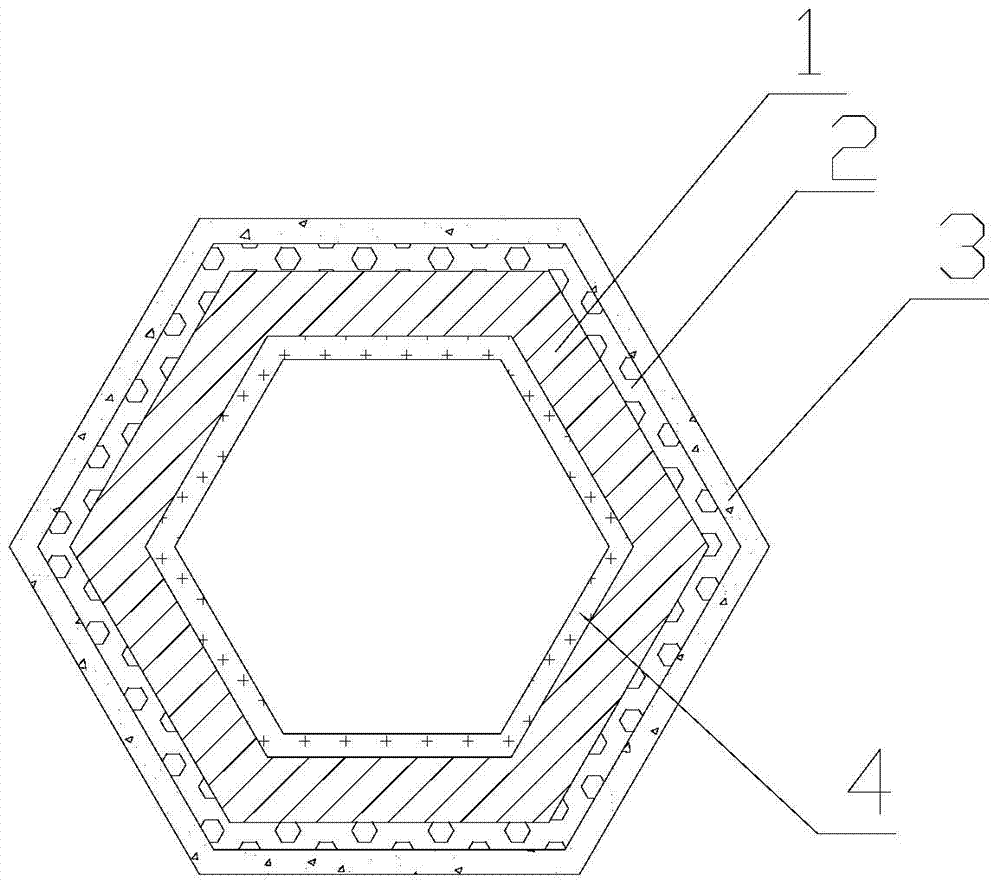

Anti-corrosion insulating steel pipe

InactiveCN104747816ANovel structureImprove corrosion resistanceThermal insulationPipe protection by thermal insulationEpoxyCorrosion resistant

The invention relates to the technical field of metal pipes, in particular to an anti-corrosion insulating steel pipe which comprises a steel pipe body. Multiple arc protruding bars are annularly and evenly distributed on the inner wall of the steel pipe body, the outer wall of the steel pipe body is coated with an epoxy oil-resistant corrosion-resistant layer, and an insulating layer is wound on the surface of the epoxy oil-resistant corrosion-resistant layer. The anti-corrosion insulating steel pipe is novel in structure and meets diversified market requirements, the surface of the steel pipe is coated with the corrosion-resistant layer, so that the corrosion resistance of the metal pipe is effectively enhanced, the insulating layer has an insulating effect, and the anti-corrosion insulating steel pipe is safe and reliable to use.

Owner:李莹

Method for bonding and fixing metal parts, polysulfone composite material for bonding and fixing metal, preparation method and application

ActiveCN108676543BImprove adhesionHigh bonding strengthNon-macromolecular adhesive additivesPolymer sciencePhenyl group

The invention provides a method for bonding and fixing metal parts, a polysulfone composite material for bonding and fixing metal, a preparation method and an application, and the bonding and fixing are carried out by using polyphenylene sulfone resin. The present invention provides a new use of polyphenylene sulfone resin as a metal bonding material. Polyphenylene sulfone resin is usually used in the fields of food safety or medical equipment, and the present invention finds that it has excellent metal bonding properties, It is used for bonding and fixing metal parts, with high bonding strength, and it is not easy to peel off or break.

Owner:GUANGDONG SILVER AGE SCI & TECH CO LTD

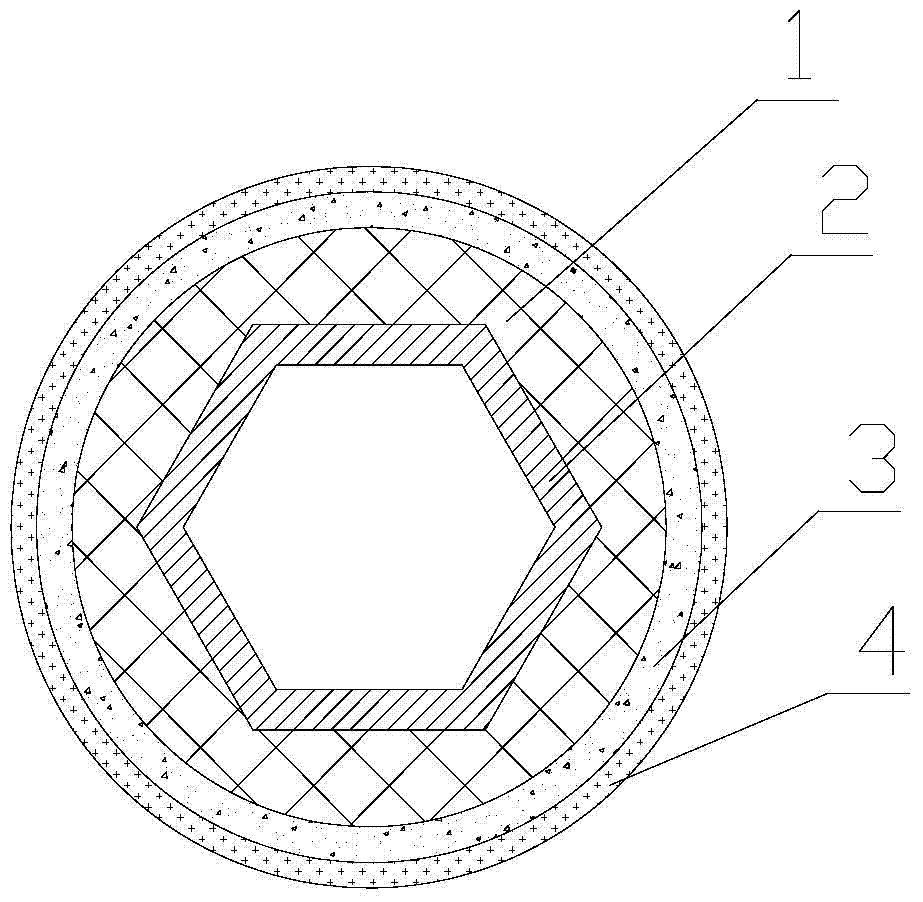

Outer-hexagonal anti-corrosion sterilization steel pipe

InactiveCN104747824ANovel structureImprove corrosion resistanceCorrosion preventionPipe protection against corrosion/incrustationTectorial membraneWater quality

The invention relates to the technical field of metal pipes, in particular to an outer-hexagonal anti-corrosion sterilization steel pipe. The outer-hexagonal anti-corrosion sterilization steel pipe comprises a steel pipe body, the outer wall of the steel pipe body is of a regular hexagon structure, the inner wall of the steel pipe body is coated with a nanometer sterilization layer, the outer wall of the steel pipe body is coated with a Fluorocarbon paint anti-corrosion layer, and a protection film is arranged on the surface of the Fluorocarbon paint anti-corrosion layer. The outer-hexagonal anti-corrosion sterilization steel pipe is novel in structure and meets diversified market demands, the surface of the steel pipe is coated with the anti-corrosion layer, the corrosion resistance of the metal pipe is reinforced effectively, the nanometer sterilization layer is arranged on the inner wall of the metal pipe, an effective sterilization function can be achieved, cleanness of water can be maintained, and human health is facilitated.

Owner:李莹

A kind of c/c composite material and preparation method thereof

The invention discloses a C / C composite material and a preparation method thereof, which belong to the technical field of material preparation and are suitable for preparing friction and wear materials and sealing materials, comprising the following steps: 1) preparation of a preform; 2) degumming treatment; 3) water 4) Graphite slurry injection; 5) Graphite slurry refilling; 6) Preparation of green body; 7) Carbonization treatment; 8) Densification treatment: sequentially adopt chemical vapor infiltration process and high temperature hot pressing The process densifies the C / C porous prefabricated body to obtain a C / C composite material with excellent friction and wear properties. Introducing graphite powder, the C / C composite material prepared by the present invention can be applied to friction and wear materials such as large aircraft brakes, high-speed trains, automobiles, and large trucks, and can also be applied to sealing materials for aerospace vehicles and precision instruments, especially for vacuum, inert, etc. High temperature sealing material in gaseous or reducing gas environment.

Owner:CENT SOUTH UNIV

Internal hexagonal cold-drawn steel pipe

The invention discloses an internal hexagonal cold-drawn steel pipe. The internal hexagonal cold-drawn steel pipe includes a steel pipe body on which cold-drawing seamless processing is performed; a cross section of an outer wall of the steel pipe body is round; a cross section of an inner wall of the steel pipe body is hexagonal; fillets are arranged on corners of the hexagonal structure; a polishing layer is arranged on the inner wall of the steel pipe body; a carburized layer is arranged on the outer wall of the steel pipe body; a zinc coating is arranged on a surface of the carburized layer; and an anticorrosive coating is arranged on a surface of the zinc coating. The internal hexagonal cold-drawn steel pipe is simple in structure, can meet the diversified market demands; the surface of the zinc coating is coated with an epoxy resin anticorrosive coating, the corrosion resistant characteristic of the epoxy resin coating is fully utilized, the zinc coating will not be released, a better anticorrosive effect is achieved, and the use life of the cold-drawn steel pipe is prolonged.

Owner:朱江

A kind of tempering material for making mineral wool from hot blast furnace slag and its preparation method

The invention discloses a conditioning material for preparation of mineral wool from thermal blast furnace slag and a preparation method thereof. The conditioning material for preparation of mineral wool from thermal blast furnace slag is composed of the following raw materials by mass: 30-80% of nepheline, 5-40% of fly ash, 2-10% of Cr2O3, and 5-20% of NaNO3. The preparation method of the conditioning material for preparation of mineral wool from thermal blast furnace slag sequentially includes the steps of: (1) weighing nepheline and fly ash according to mass percentage, and fully mixing them to obtain a mixture A; then weighing Cr2O3 and NaNO3 according to mass percentage, and fully mixing them to obtain a mixture B; and (2) weighing the mixture A and mixture B according to mass percentage, and fully mixing them to obtain the conditioning material for preparation of mineral wool from thermal blast furnace slag. The conditioning material provided by the invention has the advantages of low cost, easily available raw materials and easy processing, and significant conditioning effect. The prepared granulated wool has the characteristics of good high temperature melt glassy state, high fiber forming rate, good quality of formed fiber, and adjustable acidity coefficient.

Owner:宝钢矿棉科技(宁波)有限公司

Preparation process for producing mineral wool from solid waste silicon-manganese slag

InactiveCN110255914ASave energyReduce energy consumptionGlass making apparatusSurface/boundary effectSlagManganese

The invention discloses a preparation process for producing mineral wool from solid waste silicon-manganese slag. The preparation process comprises the following steps: S1, preparation of a hardening and tempering material: selecting a proper amount of nepheline and fly ash, and adding the nepheline and the fly ash into a high-speed stirrer for stirring treatment to obtain the hardening and tempering material; S2, mixing treatment: feeding the silicon-manganese slag into a feeding tank through a slag channel, adding the tempering material in the step S1 into the feeding tank, and fully and uniformly mixing all the components; and S3, feeding the mixture prepared in the step S2 into a slag furnace for treatment to obtain a high-temperature solution, and adding the high-temperature solution to a roller in a centrifugal machine to form raw wool. The preparation process is good in practicability, energy consumption is reduced, the technological process is simple, the qualification rate of the mineral wool can be increased, and meanwhile the attractiveness of the prepared mineral wool can be improved.

Owner:内蒙古普泽新材料科技有限公司

Hexagonal acid-resisting flame-retardant metal pipe

InactiveCN104747818ANovel structureImprove corrosion resistanceCorrosion preventionPipe protection against corrosion/incrustationWater qualityHuman health

The invention relates to the technical field of metal pipes, in particular to a hexagonal acid-resisting flame-retardant metal pipe. The hexagonal acid-resisting flame-retardant metal pipe comprises a metal pipe body, the inner wall of the metal pipe body is of a regular hexagon structure, the inner wall of the metal pipe body is coated with a nanometer sterilization layer, and the outer wall of the metal pipe body is coated with a fluorocarbon paint anti-corrosion layer. The hexagonal acid-resisting flame-retardant metal pipe is novel in structure, diversified market requirements are met, the surface of the metal pipe is coated with the anti-corrosion layer, the corrosion resistance of the metal pipe is effectively enhanced, the nanometer sterilization layer is arranged on the inner wall, the effective sterilization function can be achieved, water quality is kept clean, and human health is facilitated.

Owner:李莹

Hexagonal socket anti-corrosion insulation steel tube

InactiveCN104747823ANovel structureImprove corrosion resistanceCorrosion preventionPipe protection against corrosion/incrustationInsulation layerFluorocarbon

The invention relates to the technical field of metal tubes, in particular to a hexagonal socket anti-corrosion insulation steel tube. The hexagonal socket anti-corrosion insulation steel tube comprises a steel tube body, the inner wall of the steel tube body is of a hexagonal structure, a polished layer is arranged on the inner wall of the steel tube body, the outer wall of the steel tube body is coated with a fluorocarbon paint anti-corrosion layer, and an insulation layer is wound on the surface of the fluorocarbon paint anti-corrosion layer. The hexagonal socket anti-corrosion insulation steel tube is novel in structure, the diversified market demands are met, the surface of the hexagonal socket anti-corrosion insulation steel tube is coated with the anti-corrosion layer, the anti-corrosion performance of the steel tube is effectively enhanced, the insulation effect can be achieved through the insulation layer, and use is safe and reliable.

Owner:李莹

A kind of preparation method of centrifugal spinning nanofiber body type material

ActiveCN110863349BIncrease productivityImprove mechanical propertiesMonocomponent cellulose artificial filamentAlginate artificial filamentsPolymer scienceSpinning

The invention relates to the field of nanofiber material processing, and aims to provide a preparation method of a centrifugally spinning nanofiber body type material. The method includes: performing centrifugal spinning with a light-cured spinning solution to obtain fluffy nanofiber aggregates; placing the nanofiber aggregates obtained by centrifugal spinning into a transparent mold, and irradiating and forming with an ultraviolet lamp to obtain nanofiber blocks; The nanofiber bulk is soaked in a crosslinking agent solution, and then heated for crosslinking reaction to form a nanofiber bulk material. The invention directly cross-links and solidifies the fluffy three-dimensional block spun by the centrifugal spinning method, reduces the damage to the fiber structure, and ensures that the nanofiber block has better mechanical properties. The double cross-linking method, that is, the light-curing method, is used to cross-link the interior of the fibers, and the cross-linking agent solution cross-links the bonding points between the fibers, so that the material has excellent structural stability and higher mechanical strength; the process is simple, the operation is convenient, and the cross-linking process Rapidly, the process time is greatly shortened, and it is suitable for mass production.

Owner:ZHEJIANG SCI-TECH UNIV

Steel hot molten slag mineral cotton and its making method

The invention relates to the technical field of mineral wool production and discloses a steel hot molten slag mineral cotton and its making method. The raw materials of the steel hot molten slag mineral cotton comprise 70-90% by mass of molten blast furnace slag and 10-30% by mass of a tempering material. The making method mainly comprises the following steps: directly introducing the hot molten slag to the initial melting zone of a slag melting furnace through a slag tank, and allowing the tempering material and the hot molten blast furnace slag to enter the initial melting zone of the slag melting furnace together; and maintaining the temperature of a melt in the initial melting zone in a range of 1400-1500DEG C for 4-6h, then allowing the melt to enter a primary melting zone, maintaining the temperature of the melt in the primary melting zone in a range of 1420-1450DEG C for 6-9h, then allowing the melt to enter a material discharge zone, and allowing the melt to flow to the roller of a centrifuge to form raw cotton. The preparation method has the advantages of energy saving, consumption reduction and simple process flow, and the prepared mineral cotton has the characteristics of good vitreous state, high fiber formation rate, wide adjustment range of the acidity coefficient and the like, and can satisfy the diversification demands of the market.

Owner:宝钢矿棉科技(宁波)有限公司

Outer wall luminous heat preservation decorative sheet

The invention relates to the technical field of building materials, in particular to a heat insulated and waterproof outer wall luminous heat preservation decorative sheet. The outer wall luminous heat preservation decorative sheet comprises an aluminum-plastic panel, a thermal insulation waterproof layer is arranged on the inner wall of the aluminum-plastic panel, a heat preservation layer is arranged on the surface of the aluminum-plastic panel, and the surface of the heat preservation layer is coated with a luminous paint coating. The outer wall luminous heat preservation decorative sheet integrates heat preservation and decoration, is good in thermal insulation property, light in dead weight and high in intensity, and has good waterproof performance; in addition, the surface of the outer wall luminous heat preservation decorative sheet is coated with the luminous paint coating, the corrosion resistance of the sheet can be enhanced effectively, and the sheet has a luminous effect and meets diversified market requirements.

Owner:李莹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com