Method for bonding and fixing metal parts, polysulfone composite material for bonding and fixing metal, preparation method and application

A technology for metal parts and composite materials, applied in the direction of non-polymer adhesive additives, adhesives, adhesive additives, etc., can solve the problems of poor metal bonding effect, difficult processing of PTFE, dielectric properties, weather resistance and other related properties No effective improvement has been achieved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

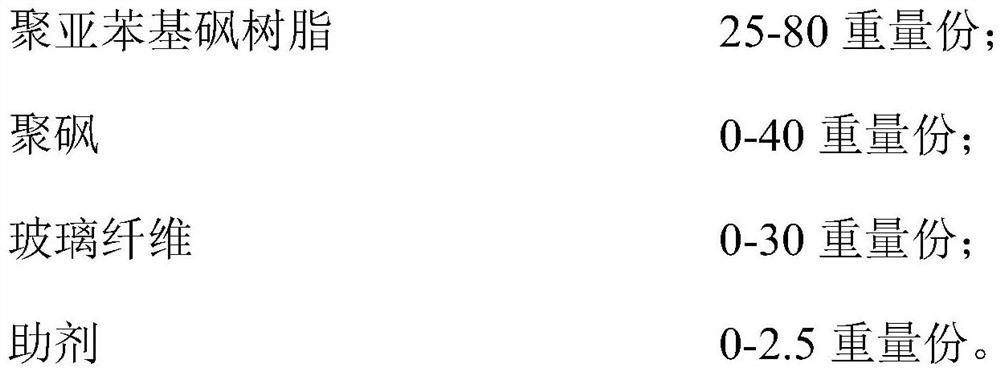

[0065] A composite material for bonding and fixing metals includes the following components:

[0066]

[0067] Among them, the polysulfone is bisphenol A polysulfone; the antioxidant is a composition composed of antioxidant 1010, antioxidant PEPQ and antioxidant 412S in a mass ratio of 1:1:1; the ultraviolet absorber is UV-234 ; The light stabilizer is 770D; the lubricant is pentaerythritol stearate.

[0068] The preparation method is as follows:

[0069] (1) Pre-mix the antioxidant and lubricant in the formulation amount, pre-mix the UV absorber and light stabilizer in the formulation amount, and then mix the pre-mixed mixture with the polyphenylene sulfone resin and polysulfone in the formulation amount Add to a high-speed mixer and mix well;

[0070] (2) The mixture finally obtained in step (1) is added to the screw extruder from the main feed port, and the glass fiber of the formula is added to the screw extruder from the side feed port of the five districts, melted, ...

Embodiment 2

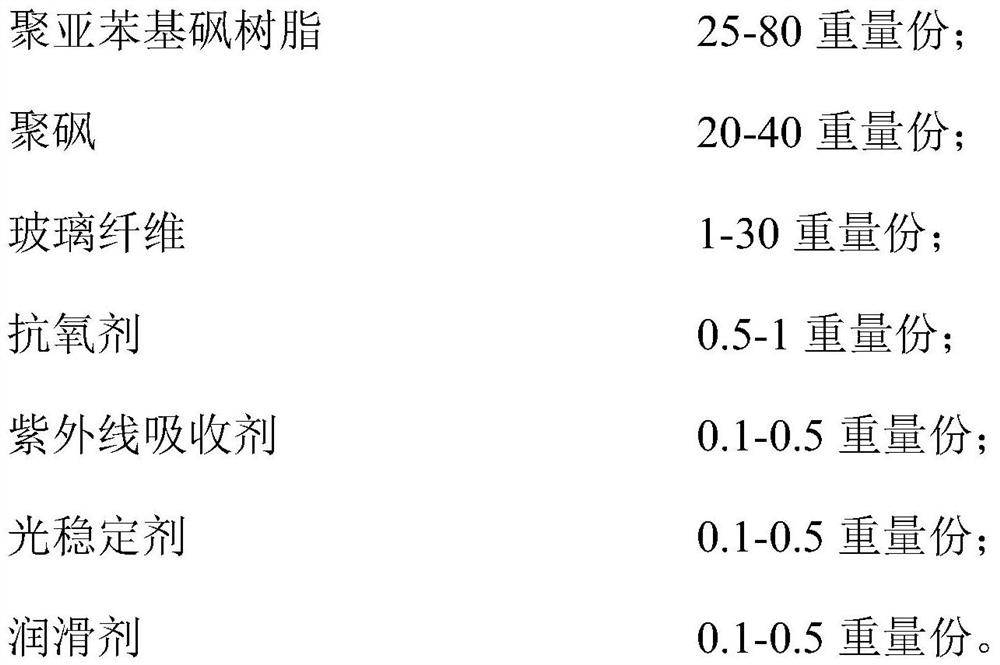

[0072] A composite material for bonding and fixing metals, comprising the following components:

[0073]

[0074] Among them, the polysulfone is bisphenol A polysulfone; the antioxidant is antioxidant 1010; the ultraviolet absorber is UV-234; the light stabilizer is 770D; the lubricant is pentaerythritol stearate.

[0075] The preparation method is as follows:

[0076] (1) Pre-mix the antioxidant and lubricant in the formulation amount, pre-mix the UV absorber and light stabilizer in the formulation amount, and then mix the pre-mixed mixture with the polyphenylene sulfone resin and polysulfone in the formulation amount Add to a high-speed mixer and mix well;

[0077] (2) The mixture finally obtained in step (1) is added to the screw extruder from the main feeding port, and the glass fiber of the formula is added to the screw extruder from the side feeding port of the five districts, melted, extruded, and produced pellets to obtain a composite material; wherein, the length...

Embodiment 3

[0079] A composite material for bonding and fixing metals, comprising the following components:

[0080]

[0081] Among them, the polysulfone is bisphenol A polysulfone; the antioxidant is antioxidant 1010; the ultraviolet absorber is UV-234; the light stabilizer is 770D; the lubricant is pentaerythritol stearate.

[0082] The preparation method is as follows:

[0083] (1) Pre-mix the antioxidant and lubricant in the formulation amount, pre-mix the UV absorber and light stabilizer in the formulation amount, and then mix the pre-mixed mixture with the polyphenylene sulfone resin and polysulfone in the formulation amount Add to a high-speed mixer and mix well;

[0084] (2) The mixture finally obtained in step (1) is added to the screw extruder from the main feeding port, and the glass fiber of the formula is added to the screw extruder from the side feeding port of the five districts, melted, extruded, and produced pellets to obtain a composite material; wherein, the length...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| bond strength | aaaaa | aaaaa |

| bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com