Patents

Literature

85 results about "Vitreous state" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

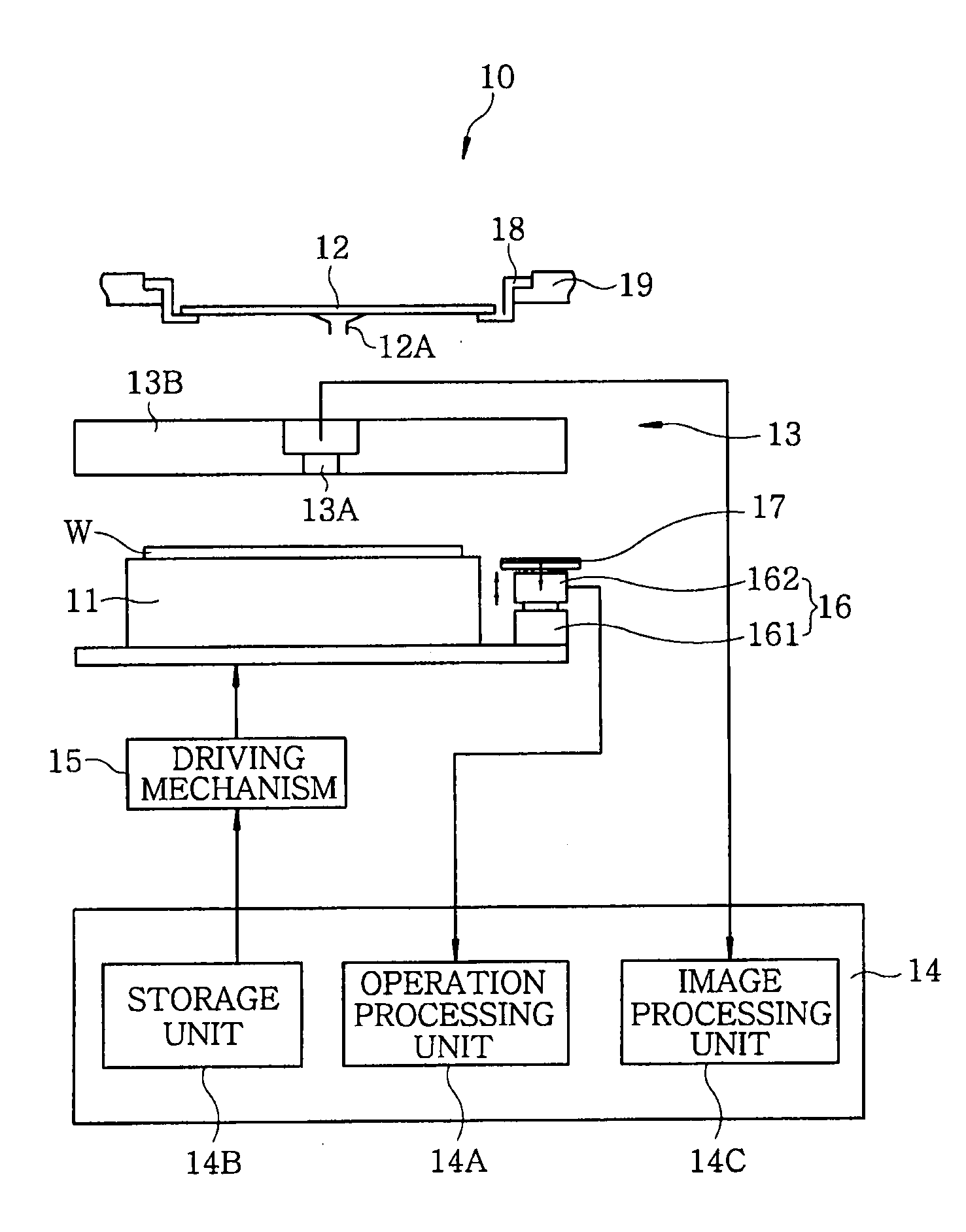

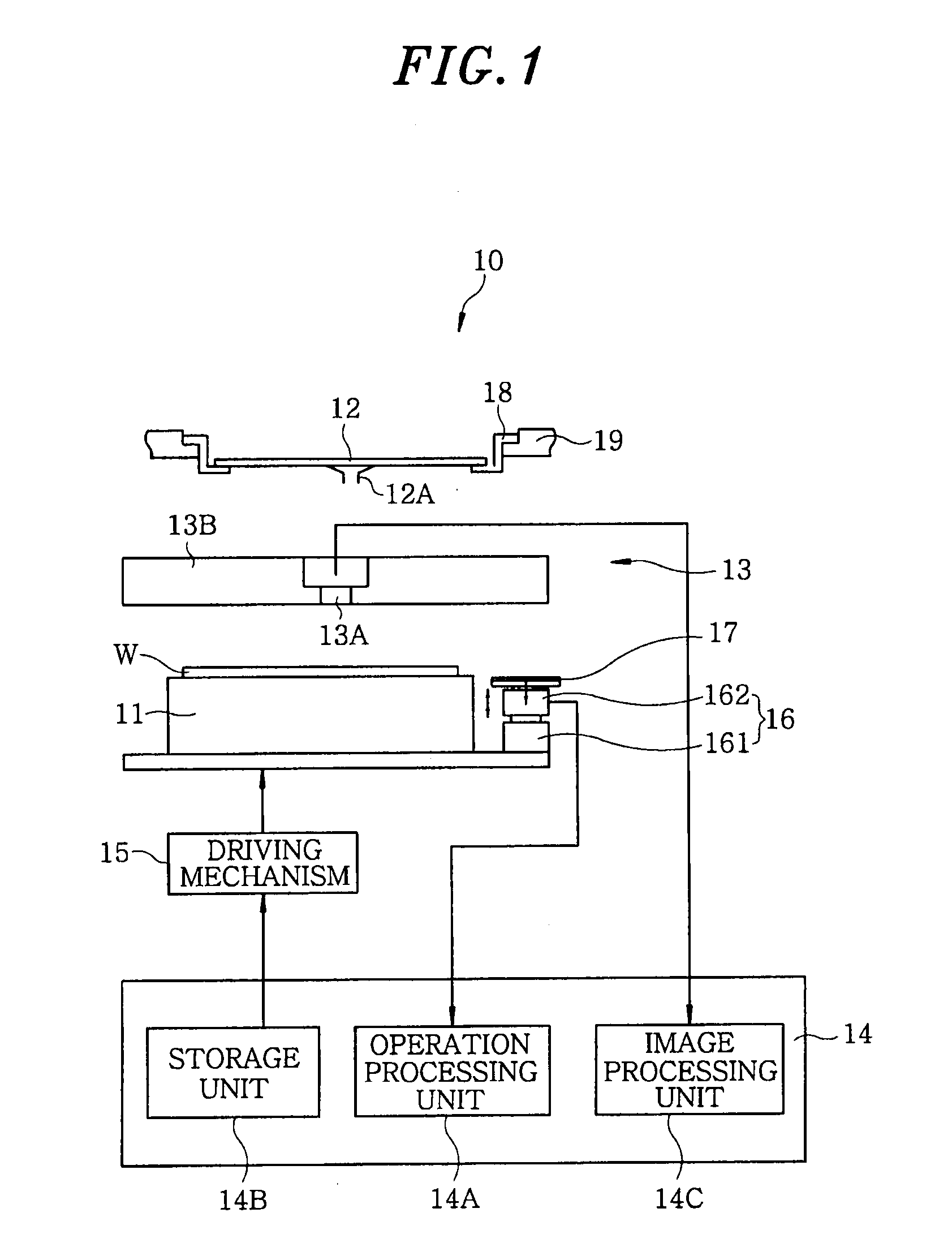

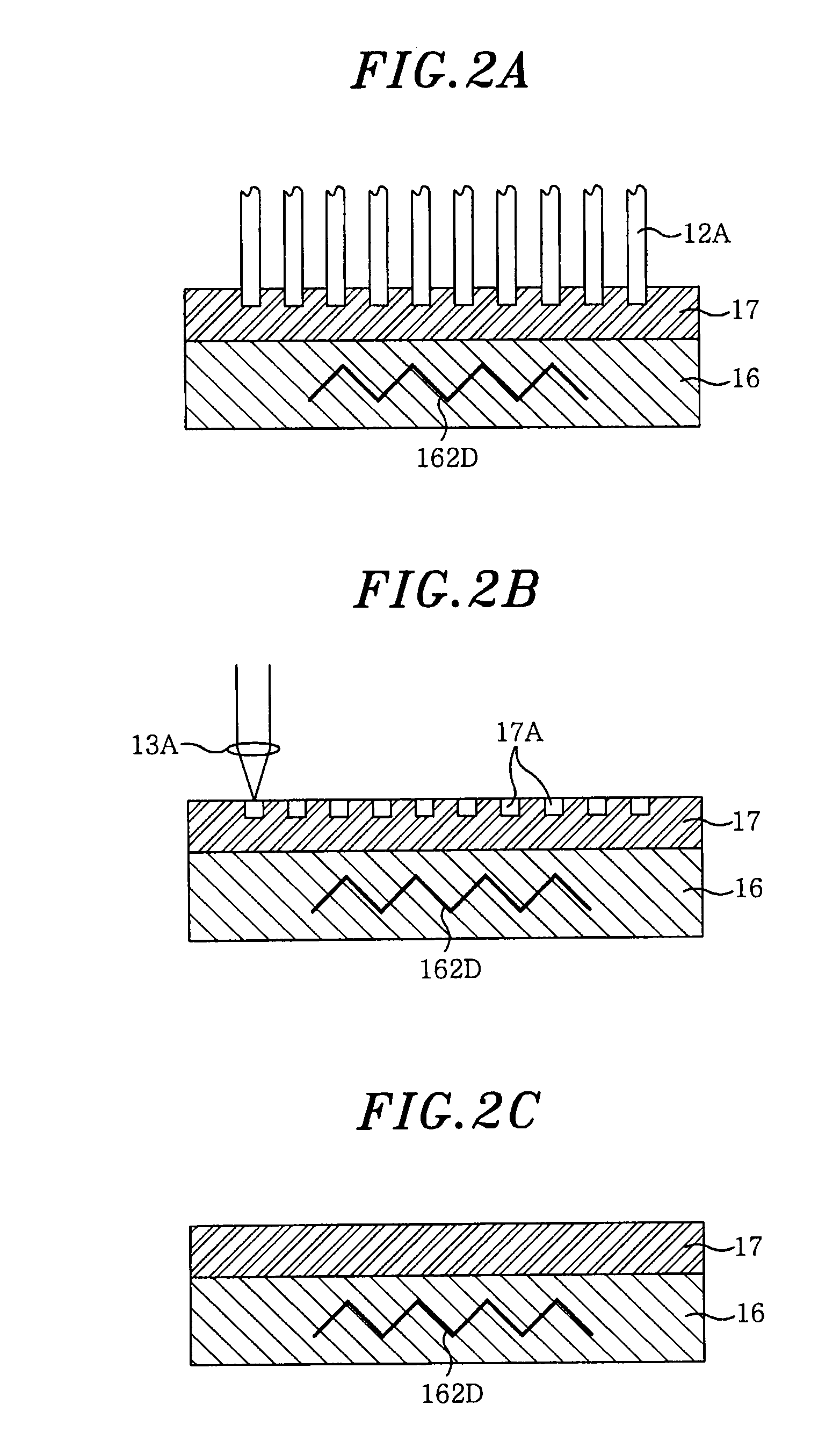

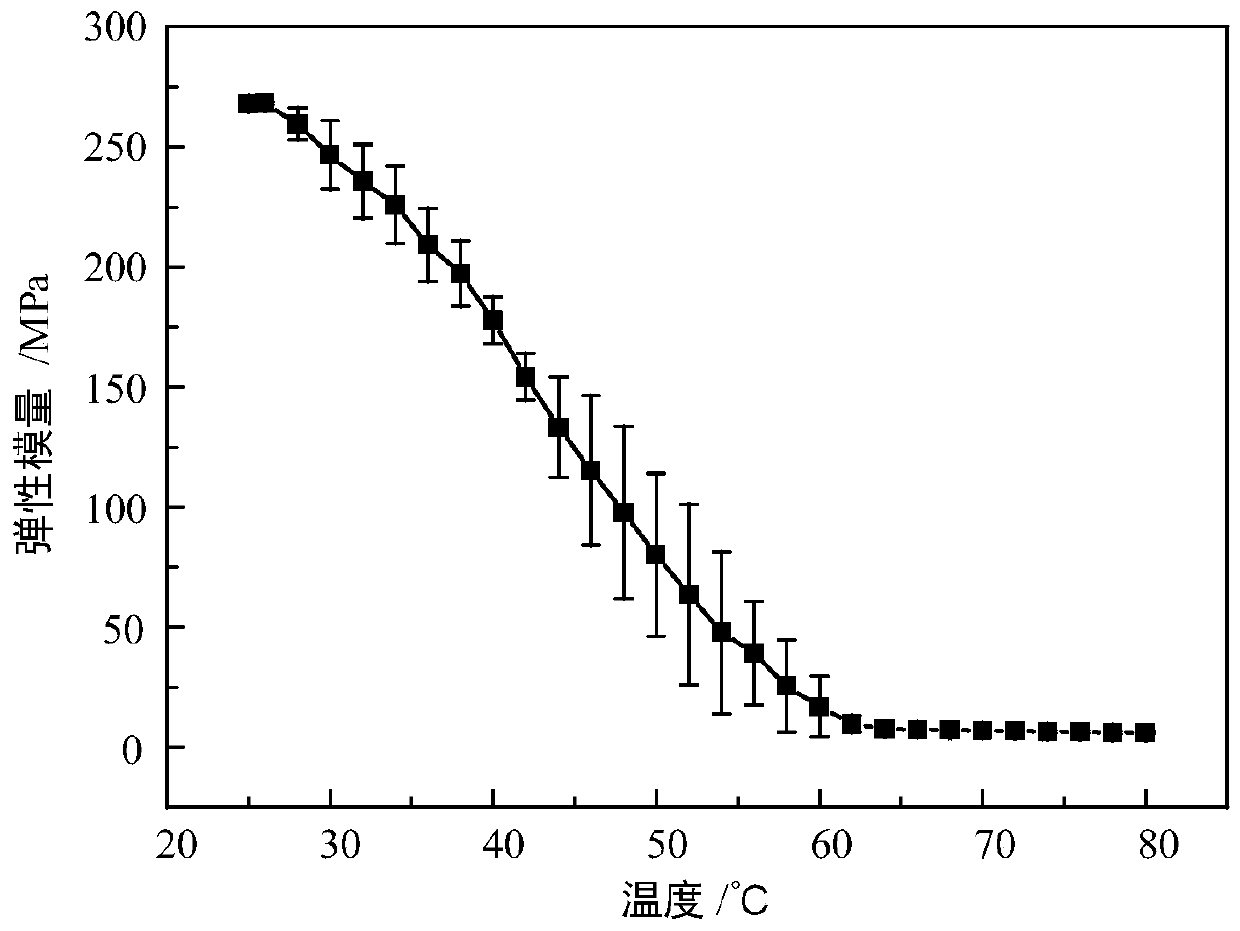

Needle trace transfer member and probe apparatus

ActiveUS20090212804A1Enhance inspection throughputReduce the effect of temperatureSemiconductor/solid-state device testing/measurementElectrical measurement instrument detailsVitrificationGlass transition

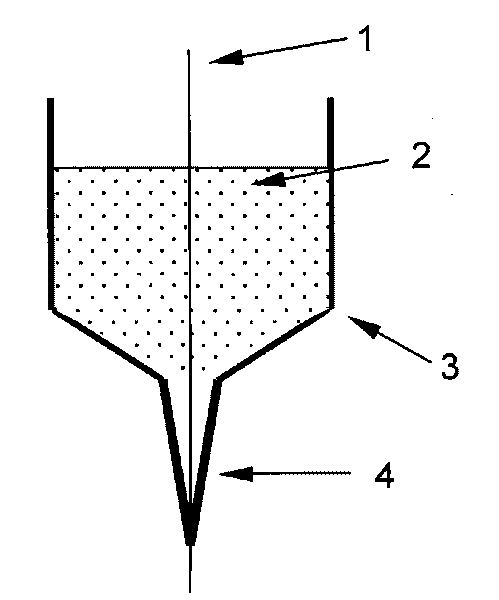

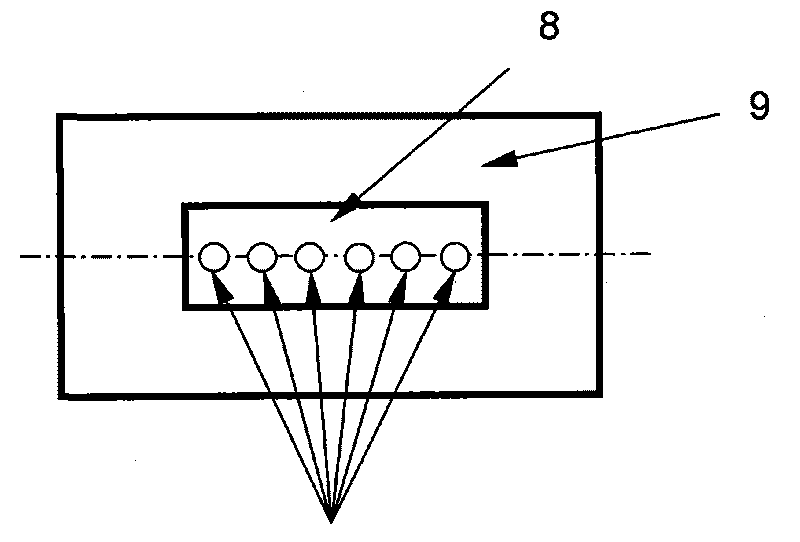

A needle trace transfer member to which needle traces of probes are transferred is installed at a movable mounting table to align the probes before electrical characteristics of a target object on the mounting table are inspected by bringing the probes into electrical contact with the target object. The needle trace transfer member is made of a shape memory polymer transformed reversibly and rapidly between a glass state with a high modulus elasticity and a rubber state with a low modulus of elasticity near its glass transition temperature. The glass transition temperature is set to a temperature close to a set temperature of the mounting table. The shape memory polymer is mainly made of polyurethane-based resin.

Owner:TOKYO ELECTRON LTD

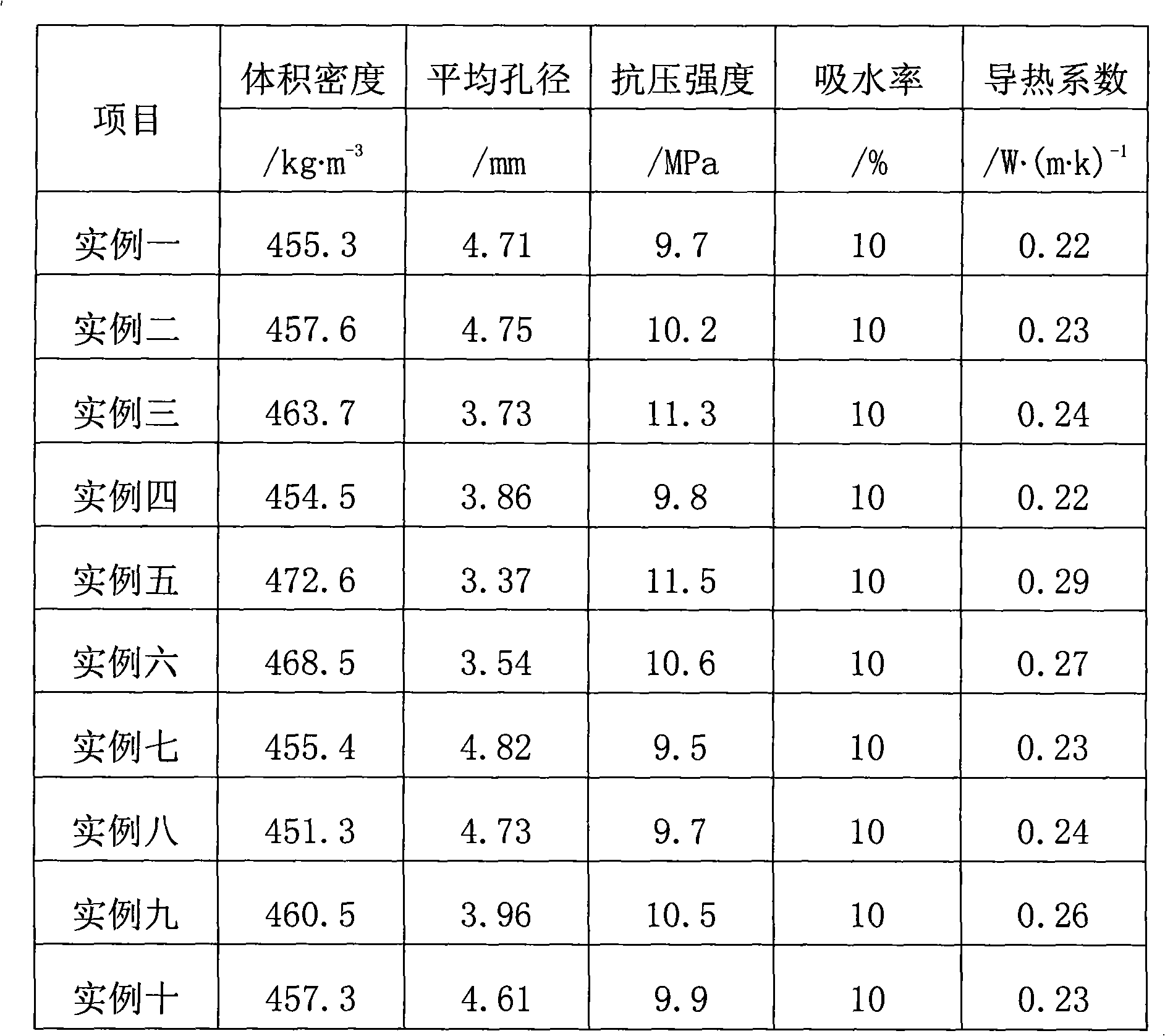

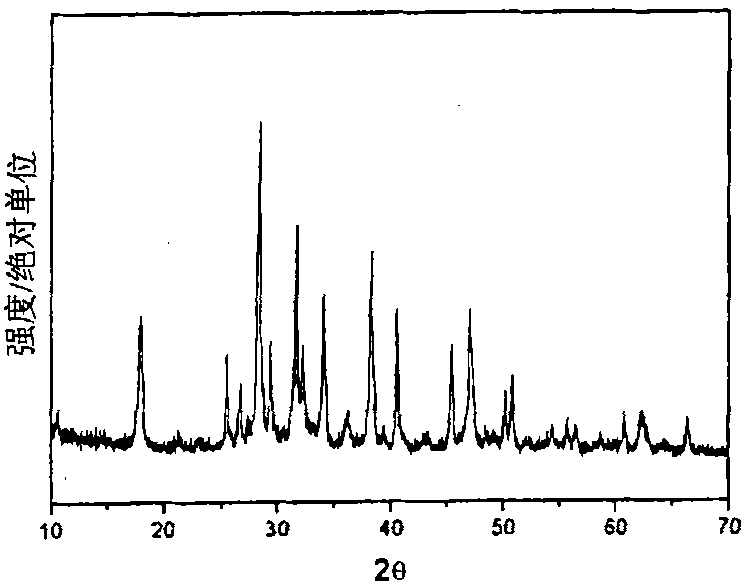

Method for preparing microcrystalline foamed glass by titanium-containing blast furnace slag

ActiveCN101323503ASolve the problem of difficult utilization of titanium-containing blast furnace slagReduce manufacturing costSlagFoam glass

The invention provides a method adopting the blast-furnace slag containing titanium to prepare foam glass, belonging to the metallurgy source comprehensive utilization and material preparation filed. The invention mainly adopts the blast-furnace slag containing 14 to 29 percent of TiO2 as the basic material, and properly adopts silicon materials to generate glass substances, and then adds foaming agent, foam stabilizer and fusing assistant to prepare foam glass-ceramic according to a special heat disposal system. The invention has the advantages that the manufacturing cost is low; the product quality is better; the manufacturing operation is simple; the second-time contamination can be avoided and the product volume density is low, etc.

Owner:NORTHEASTERN UNIV

Stainless steel high temperature oxidation resistance paint and application thereof

InactiveCN101265372ANo lossPrevent oxidationLiquid surface applicatorsAnti-corrosive paintsNichromeRoom temperature

The invention relates to the technology field of an antioxidation coating, in particular to a stainless steel high-temperature oxidation-resistant coating and the application thereof, and solves the problems in the prior stainless steel oxidation-resistant coating such as complex production process, high cost, low protection temperature, narrow painting temperature range and so on. The stainless steel high temperature oxidation-resistant coating is prepared with organic powdered ore in an amount of 30 to 50 parts; an inorganic binder in an amount of 50 to 70 parts; a suspending agent in an amount of 0.1 to 1 part; and water in an amount of 200 parts. The stainless steel high temperature oxidation-resistant coating is applicable to oxidation protection / decarburization when semi-finished nickel chromium stainless steel products are heated for 0.5 to 30 hours at the temperature of 800 DEG C to 1500 DEG C, and is sprayed or coated on stainless steel surfaces within the range from room temperature to 500 DEG C. The coating thickness ranges from 50 Mu m to 300 Mu m. The coating formed at the high temperature forms a vitreous dense coating during high-temperature processing of a stainless steel basal body, and prevents oxygen from spreading on the surface of the stainless steel basal body, thus resisting oxidation, alleviating depletion and decarburization of microelements on stainless steel surfaces, and improving the rolling quality of the surface of the base body. The raw materials used for preparing the coating are cheap, and the coating is friendly to the environment. The preparation process is simple. The high-temperature oxidation and melting loss of various semi-finished nickel chromium stainless steel products is reduced by more than 90 percent, and the output and the yield of good plate blanks can be improved.

Owner:SHANXI XIHUI TECH

High-temperature resistant optical fiber and method for manufacturing same

ActiveCN101726792AOvercome the inadequacies of being unable to withstand harsh working environmentsStable use characteristicsGlass making apparatusCladded optical fibreFiberHigh power lasers

The invention relates to high-temperature resistant optical fiber and a method for manufacturing the same and belongs to the technical field of special optical fiber communication and high-power laser communication and sensing. The high-temperature resistant optical fiber comprises optical fiber and a coating coated on the outer surface of the optical fiber, wherein the coating is the polyimide coating of which the single-sided thickness is 5 to 25mum, the Young modulus of the cured polyimide coating is equal to or more than 2GPa, the glassy state transition temperature is equal to or more than 300 DEG C, and the range of refractive index is 1.38 to 1.78; and the polyimide coating if formed by dipping the solution of polyimide on the outer surface of the optical fiber, and then heating the fiber to cure the solution of the polyimide, and the whole process comprises pre-coating, pre-curing and secondary coating. The high-temperature resistant optical fiber can be used at a high temperature and under severe working conditions; and when the high-temperature resistant optical fiber is used for a long time, the temperature reaches 300 DEG C, the operational performance is stable, and good persistence is kept. The high-temperature resistant optical fiber product, manufactured by the method, possesses a screening strength of 100kpsi and a segment length of 4km, even 6km.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

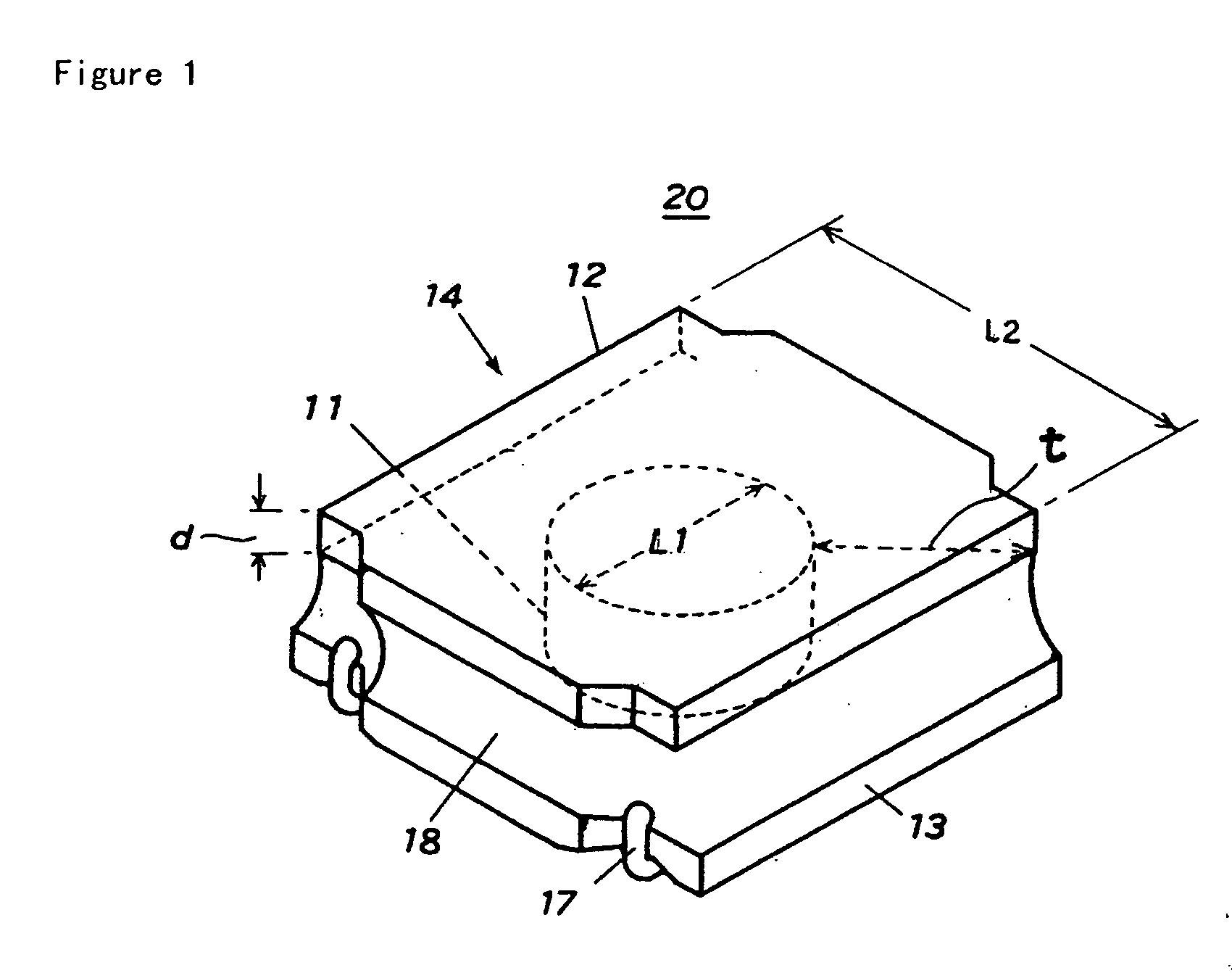

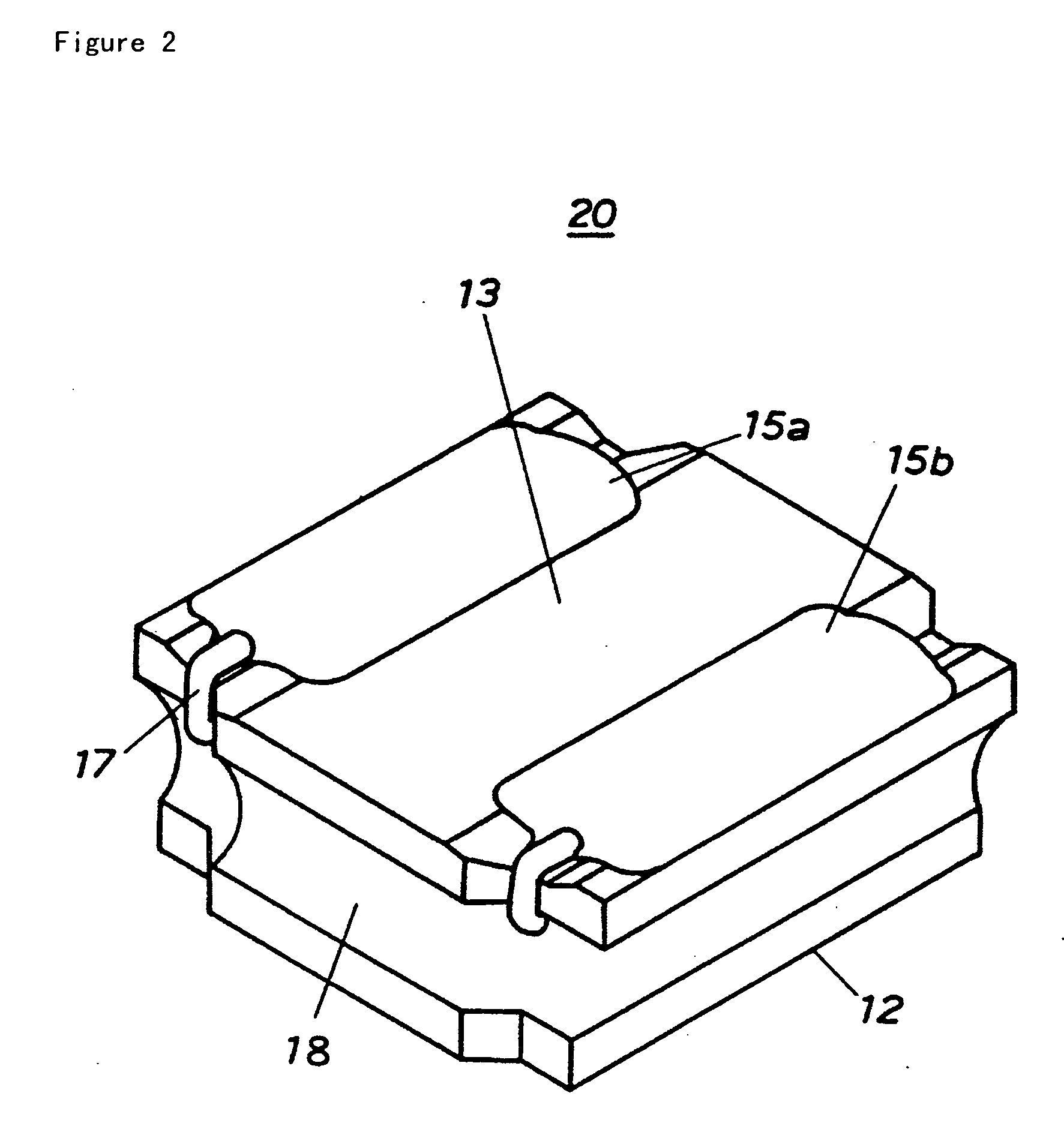

Surface-mounting coil component and method of producing the same

ActiveUS20050212643A1Low costReduced durabilityTransformers/inductances casingsTransformers/inductances coils/windings/connectionsShear modulusVitrification

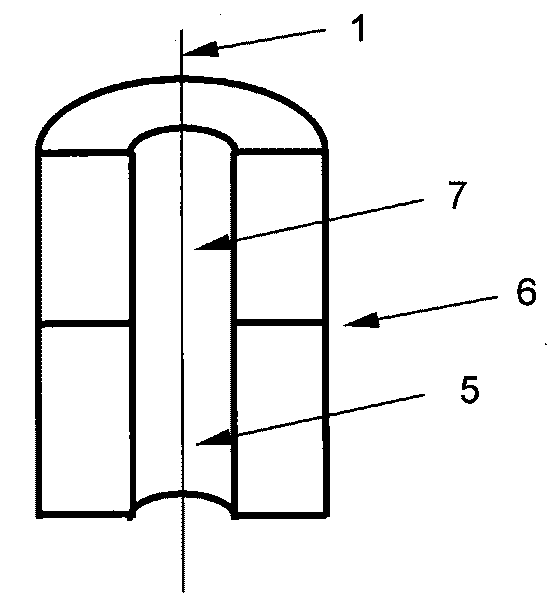

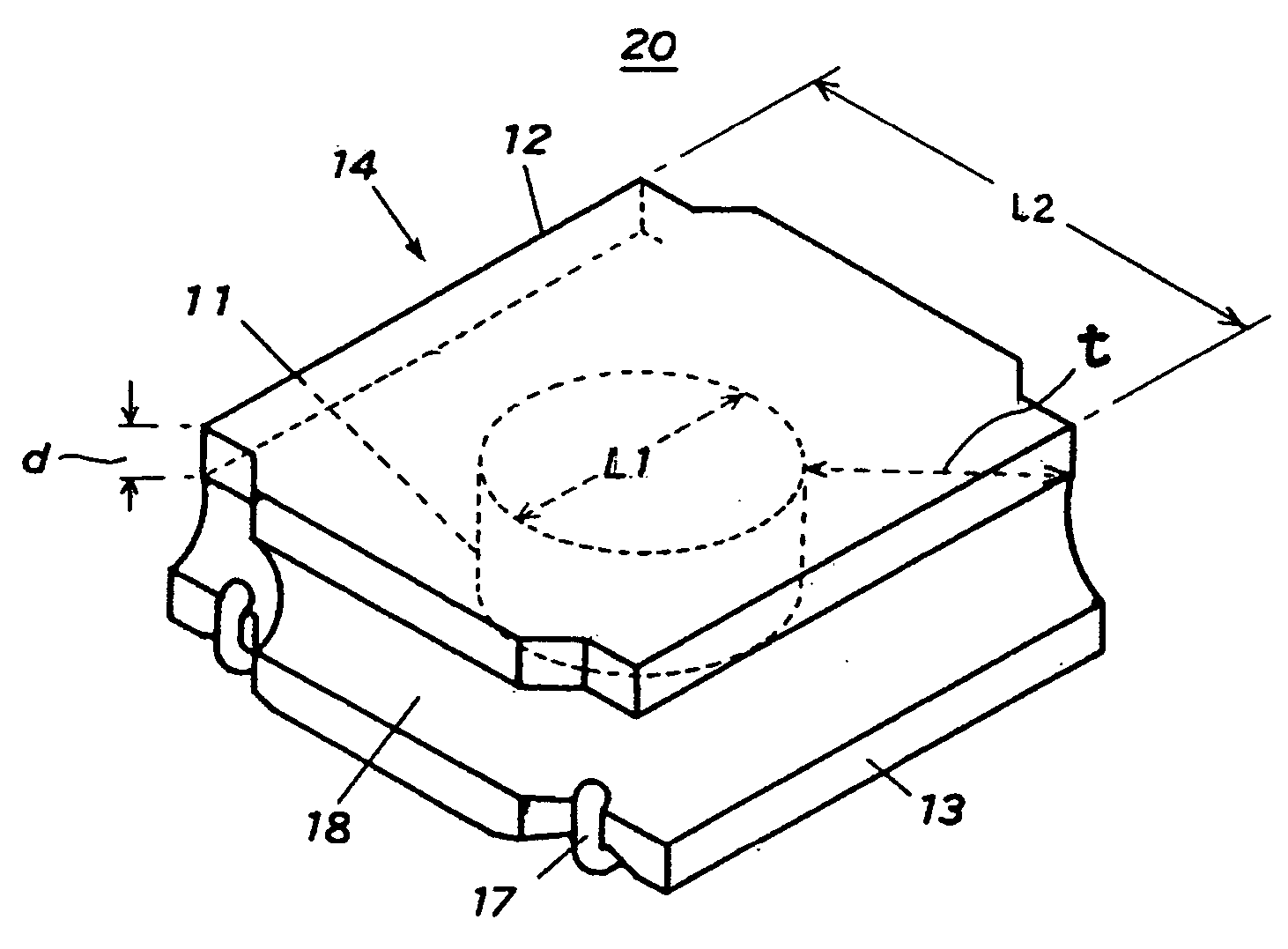

A surface-mounting choke coil has a resin coating material with magnetic powder which is filled a space between the upper flange and the lower flange of a drum-type ferrite core, while covering the circumferential of the winding. The resin coating material with magnetic powder has a glass transition temperature Tg of about −20° C. or lower, more preferably about −50° C. or lower in a course of transferring from a glass state to a rubber state during changing of shear modulus with respect to temperature as a physical property when hardening, and the thickness of the upper flange of the drum-type ferrite core is about 0.35 mm or less, and a value of a ratio L2 / L1 of an outer diameter L2 of the upper flange to a diameter L1 of the winding core of the drum-type ferrite core is about 1.9 or more.

Owner:TAIYO YUDEN KK

Process for preparing foamed glass form titan-containing blast furnace slag

The invention provides a method for preparing foam glass by utilization of titaniferous blast furnace slag, belonging to the metallurgical resource comprehensive utilization and material preparation field. The method mainly is to take the blast furnace slag containing 14 to 29 percent of TiO2 as base material, to adequately introduce silicious raw materials to generate vitreous substances, to add foaming agent, foam stabilizer and fluxing agent, and to prepare the foam glass with a specified heat treatment system. The method solves the problems that the prior titaniferous blast furnace slag is difficult to utilize and process and the utilization rate of the titaniferous blast furnace slag in the material preparation field is low, not only creates a novel path for utilization of the titaniferous blast furnace slag but also finds very cheap raw materials for production, and has the advantages of low production cost, good product quality, simple production operation, no secondary pollution and so on.

Owner:NORTHEASTERN UNIV

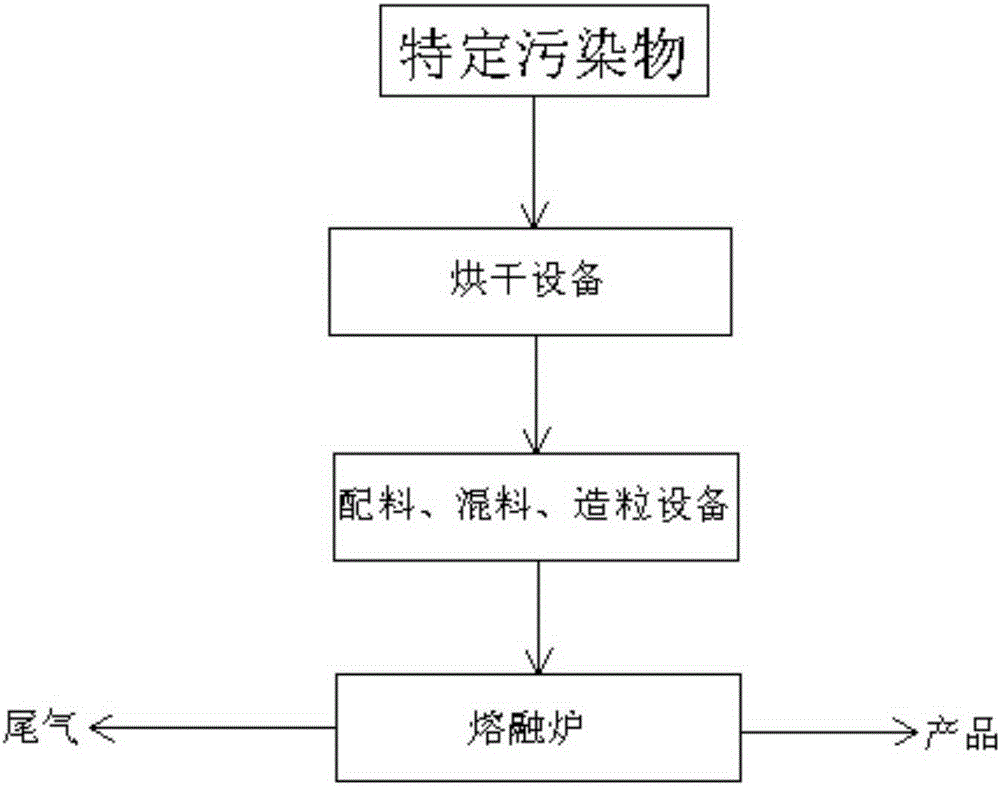

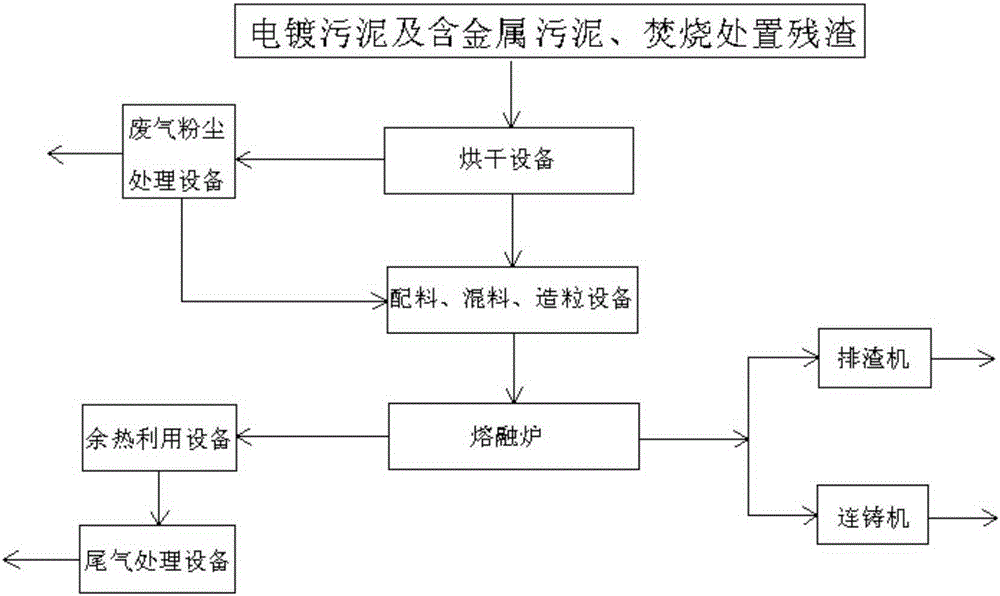

Method for treating specific pollutants through high-temperature melting technology

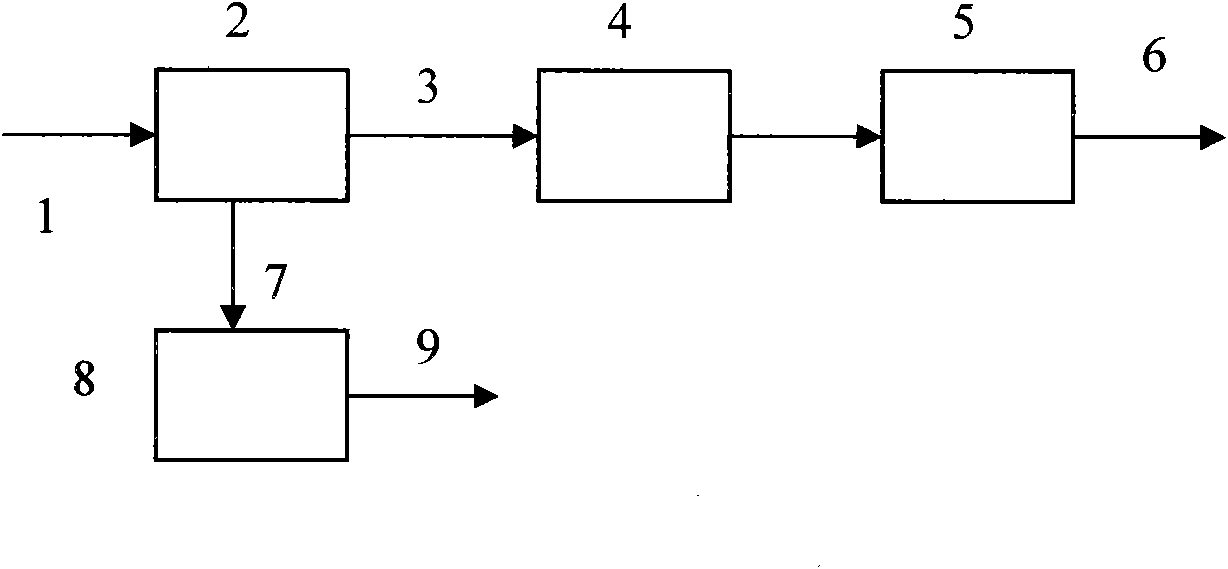

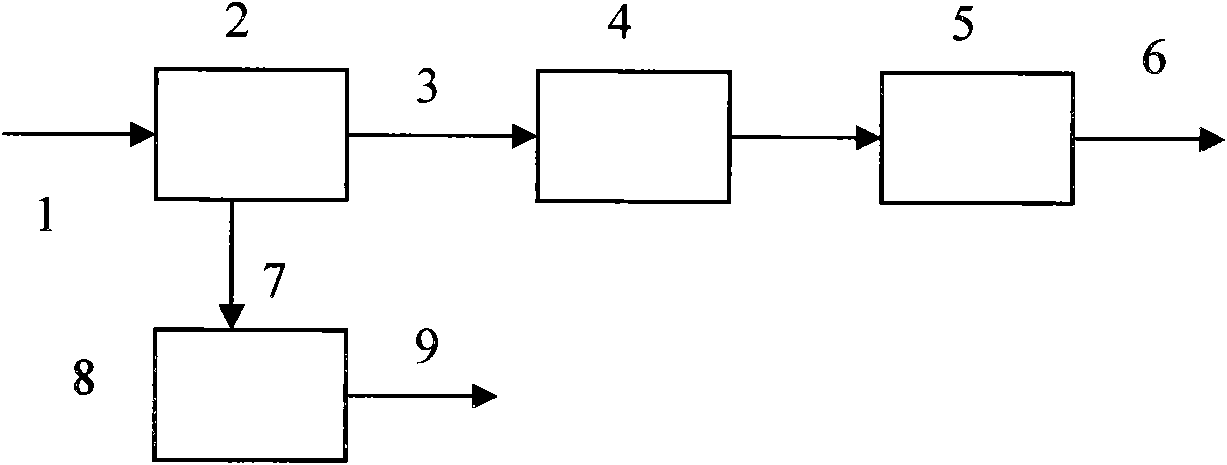

InactiveCN105344698AReduce operating costsResourcefulSolid waste disposalTransportation and packagingSludgeSlag

The invention provides a method for treating specific pollutants through a high-temperature melting technology. The specific pollutants comprise electroplating sludge, sludge containing metal and / or incineration disposal residues. The method comprises the steps that pretreatment is carried out, wherein the specific pollutants are pretreated, the water content of the specific pollutants is reduced to be 10 wt% or lower, and dry specific pollutant materials are obtained; burdening, blending and granulating are carried out, wherein regulating components are added as needed, mixed and granulated, and a granulated mixture is obtained; melting is carried out, wherein the granulated mixture is melted at the melting temperature ranging from 1,200 DEG C to 1,800 DEG C; and products are obtained, wherein the melted metal is settled on the lower layer and is discharged to obtain a metal alloy, and slag and a small part of metal float above the melted metal and are discharged to obtain glassy-state slag. After the specific pollutants are treated through the method, harmless and pollution-free resource materials can be obtained, and the method can be used for resource recycling, and is good in economic benefit and beneficial to commercial popularization.

Owner:SHANGHAI LVCHENG ENVIRONMENTAL PROTECTION TECH

Method for treating waste incineration fly ash by electric melting

The invention discloses a method for treating waste incineration fly ash by electric melting. The method comprises the following steps of: uniformly mixing the fly ash, quartz sand and an alkaline agent according to a weight ratio of fly ash: quartz sand: alkaline agent of (90-99):(1-10):(1-10), wherein the quartz sand and the alkaline agent are used as a melt preparation; then adding a mixture into a glass electric melting furnace; fully melting the mixture to form a glass metal at a high temperature of between 1,250 and 1,500 DEG C; and after performing water quenching by using cold water, cooling the glass metal at the room temperature to form glass dregs. In the method, the quartz sane and the alkaline agent (such as lime or sodium carbonate) are added to vitrify the flay ash, dioxin and other organic pollutants in the fly ash are decomposed at a high temperature, heavy metals such as copper, zinc, lead and the like are cured and stabilized after entering a glass crystal lattice, and the extraction concentration of the heavy metals is far lower than a standard limit value of 'Identification Standard for Hazardous Wastes-Identification for Extraction Toxicity (GB 5085.3-2007). The fly ash is transformed into inert solid waste in a glassy state.

Owner:刘阳生 +1

High strength sealing glass

InactiveUS6245699B1Improve stabilityAcceptable resultVessels or leading-in conductors manufactureCold cathode manufactureHigh intensityUltimate tensile strength

A sealing glass composition in powdered form comprising a crystallizable base glass in the vitreous state and vanadium zirconium silicate in an amount from about 0.1 to 1 weight percent of the base glass. The sealing glass also may contain aluminum oxide having a particle size of about 90 to 99 percent minus 325 mesh in an amount from about 0.1 to 1.0 weight percent of the base glass and bismuth nitrate in an amount from about 0.02 to 0.08 weight percent of the base glass. The glass composition can be used to seal cathode ray tube face plates and funnels with excellent results when heated to a hold range of about 4300 C to 4500 C. The crystallized sealing glass exhibits improved adhesion to seal edges of the face plates and funnels, increased strength, and improved resistance to organic contamination.

Owner:TECHNEGLAS

Dielectric ceramic materials for chip capacitor and method for preparing same

InactiveCN1654420AReduce manufacturing costOvercome weldingFixed capacitor dielectricCapacitanceDielectric

The present invention provides the preparation process of dielectric ceramic material for low voltage non-linear chip capacitor. The preparation process includes the following steps: 1) preparing glass state material as the third auxiliary component with SrO, CaO, BaO, B2O3 and SiO2 in the molar ratio of 0.5 to 0.5 to 0.2-0.5 to 1.0-2.0 to 0.5-1.0; 2) preparing the main component in the chemical expression of (Ca1-x-ySrxBay)(Ti1-zZrz)O3, where, x is 0.15-0.19, y is 0.14-0.18 and z is 0-0.04; 3) mixing homogeneously the main component, the first auxiliary component (MgO in 0.8-1.5 mol% and MnO2 in 0.1-0.2 mol%), the second auxiliary component (RE oxide Re2O3 in 0.4-1.5 mol%) and the third auxiliary component to obtain the dielectric ceramic material of the present invention. The dielectric ceramic material may be used in producing inner nickel electrode type ceramic capacitor with very low voltage non-linearity of capacitance.

Owner:SOUTH CHINA UNIV OF TECH

Vitrified composition which preserves biological materials

The present invention relates to a biological composition which is storable above cryogenic temperature which is comprised of a vitrification solution in a glassy state. The vitrification solution is comprised of a biological material and a vitrification agent.

Owner:JUNIVERSITI OF NORT KAROLINA EHT SHARLOTT

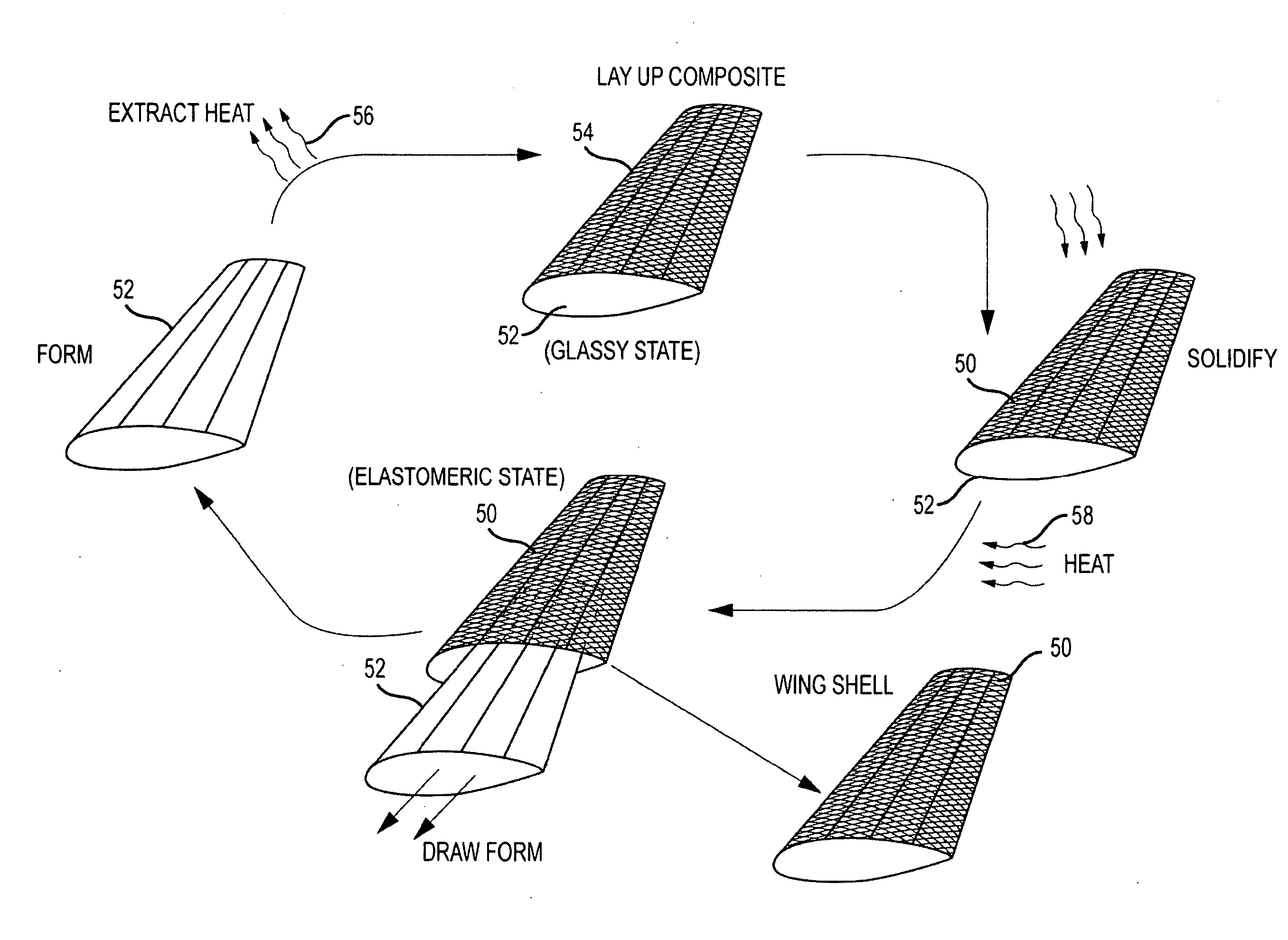

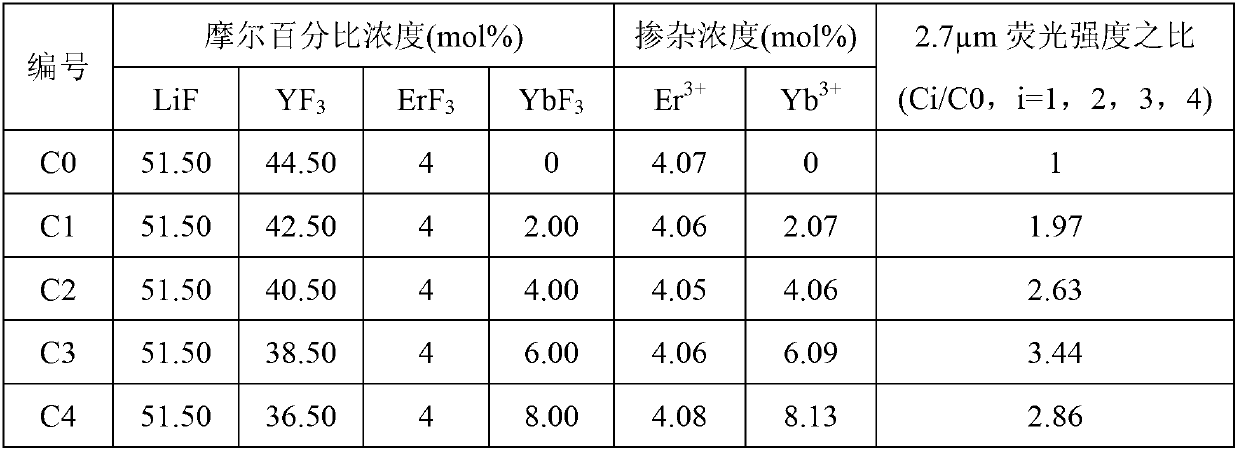

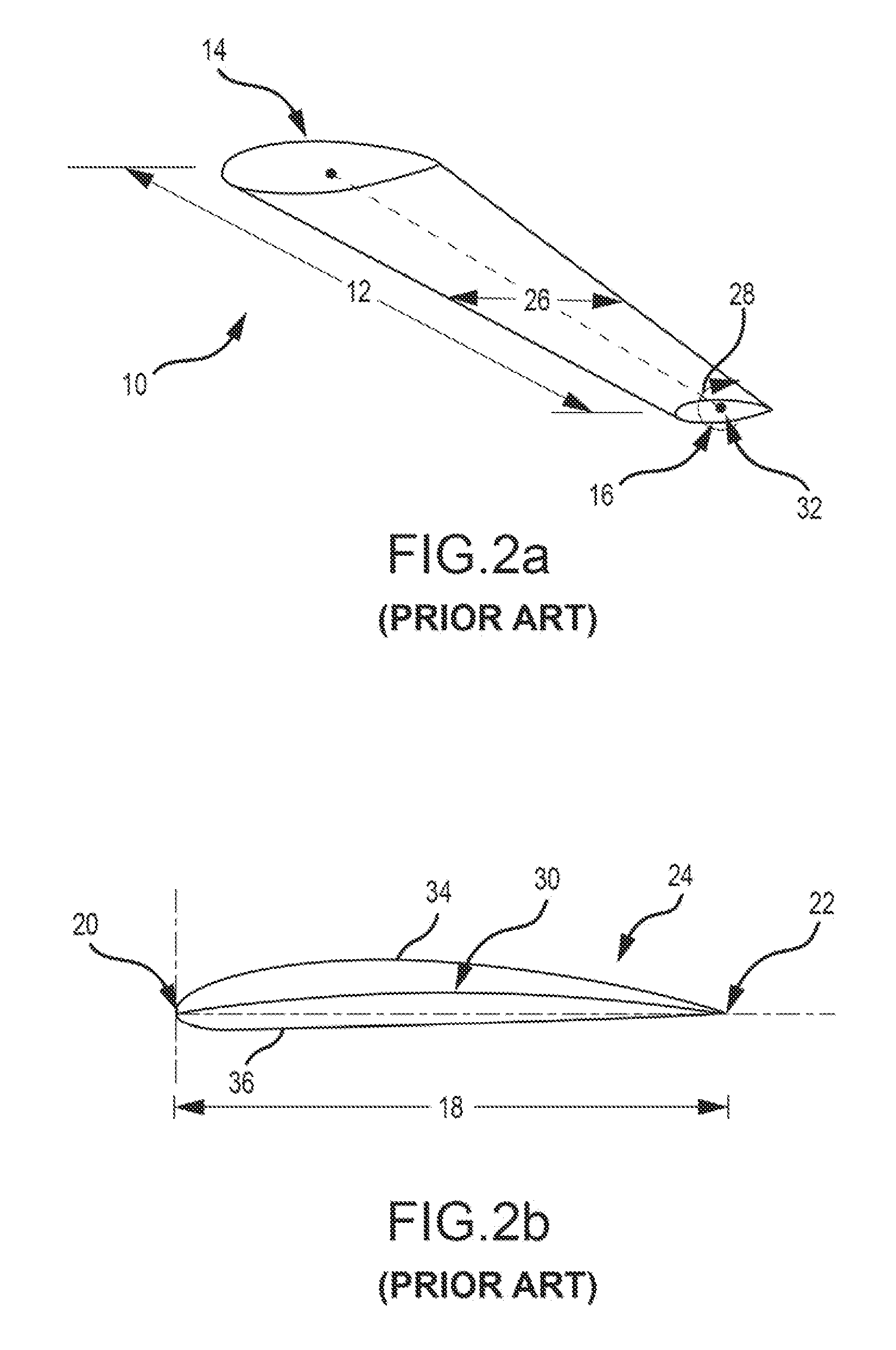

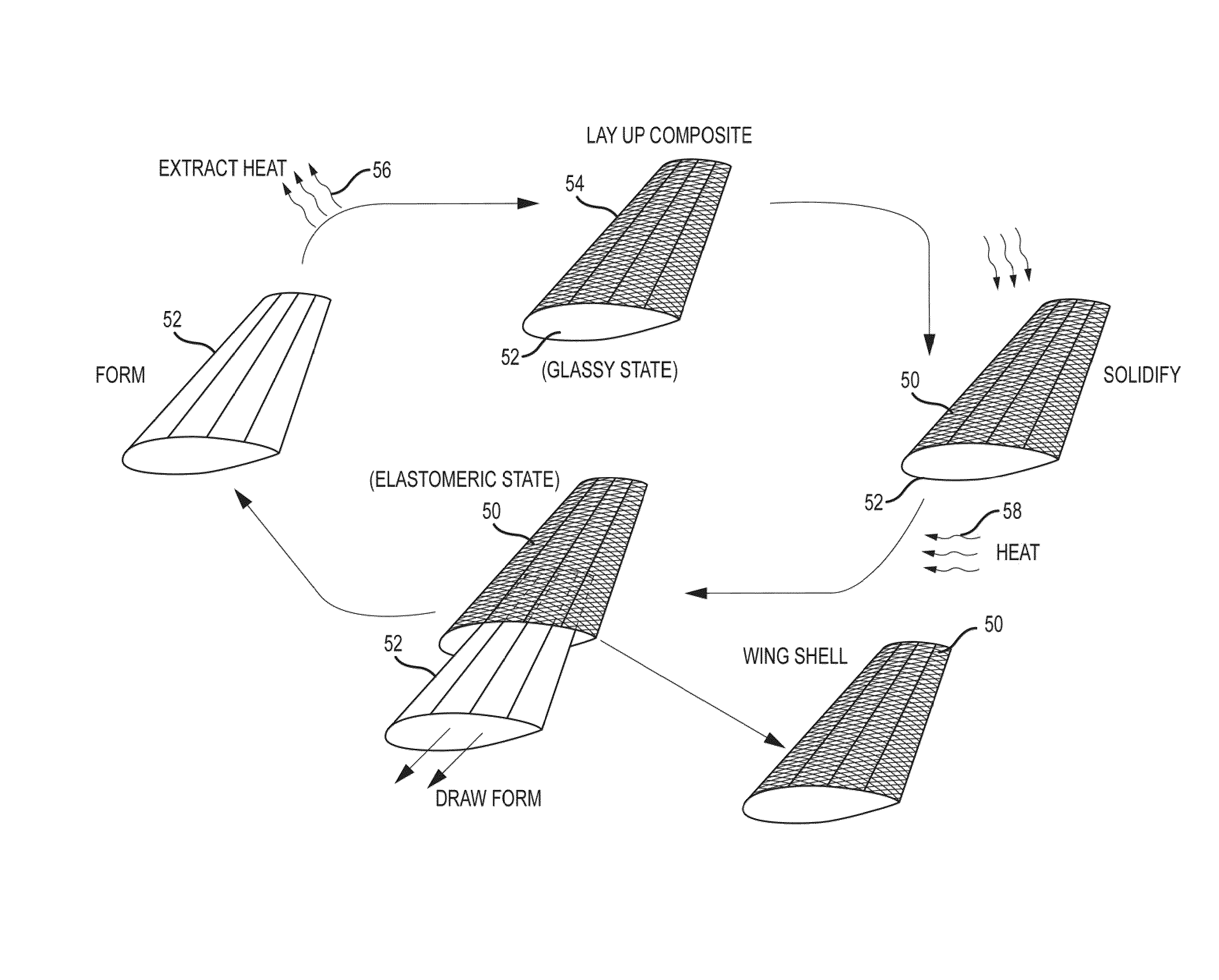

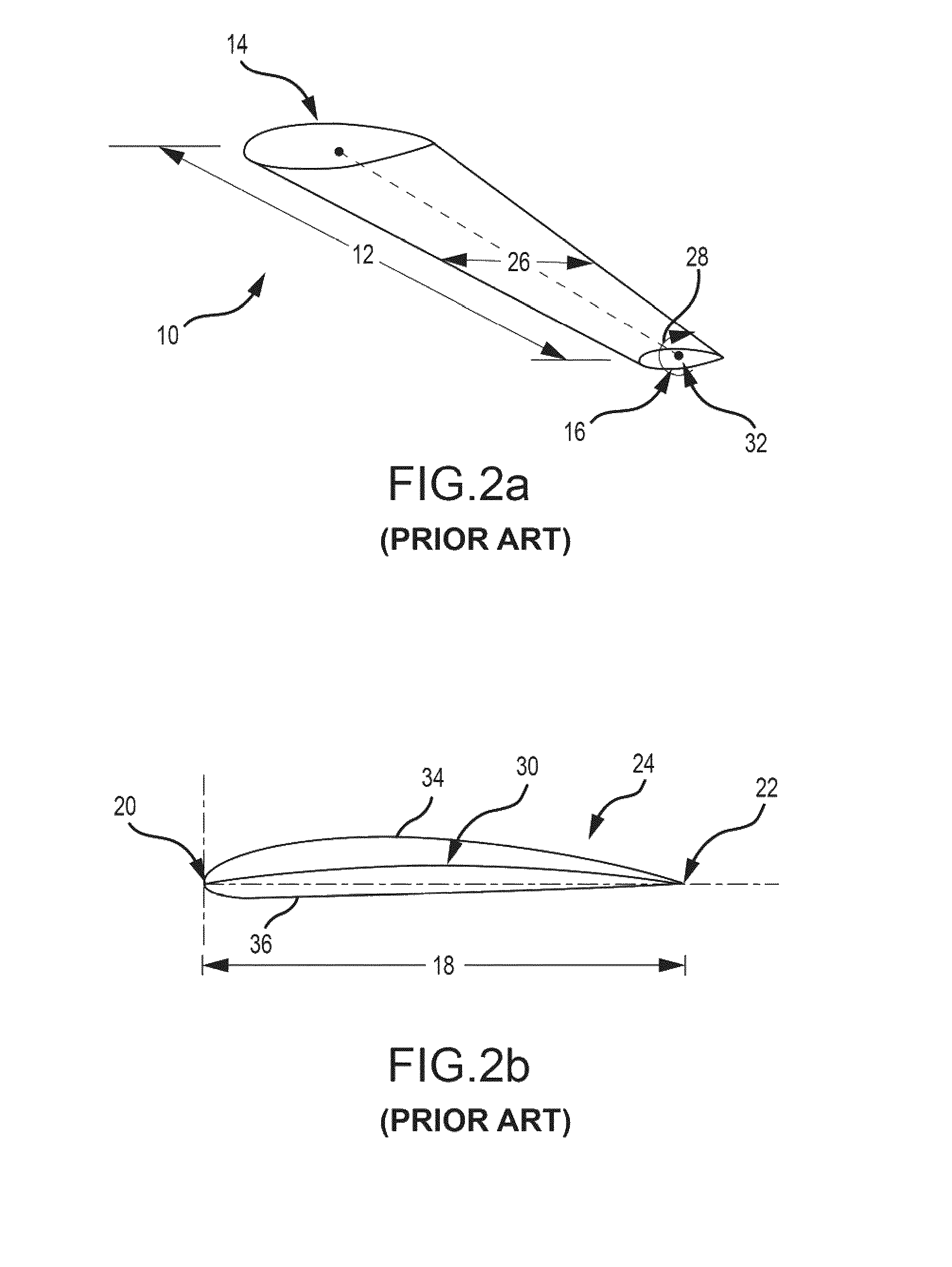

Method of manufacture of one-piece composite parts with a polymer form that transitions between its glassy and elastomeric states

ActiveUS20100230859A1Low cost manufacturingProcess economyAdditive manufacturing apparatusShaping conveyorsElastomerVitreous state

A polymer is formed into the shape of a one-piece composite part and then solidified by curing, setting, hardening or otherwise solidifying the polymer to form a shaped polymer form having a shape that does not draw. Composite material is laid lip on the form and solidified to from the composite part. The rigidity required of the form to lay up the composite part can be provided by operating in the polymer form's glassy state, forming the shaped polymer form with a hollow core and placing a rigid insert designed to draw inside the hollow core with the polymer form in its elastomeric state or through a combination of both. In its elastomeric state the form becomes pliable (without relaxing to a different memorized shape) and can be drawn out of the one-piece composite part. Because the shape of the form does not draw, the form deforms as it is drawn. If used, the rigid insert is drawn out prior to removing the shaped polymer form. Upon removal, the polymer form in its elastomeric state returns to its original shape. The form may be used once and thrown away or reused to form multiple composite parts of the same shape.

Owner:RAYTHEON CO

Novel chromium slag innocent treatment method

The invention discloses a novel chromium slag innocent treatment method. In the method, quartz sand and an alkaline medicament are taken as melting agents, and chromium slag, the quartz sand and the alkaline medicament are uniformly mixed in a weight ratio of 25-45:35-75:5-22; the mixture is added into an electric glass melting furnace and is fully melted at a high temperature of between 1,350 and 1,500 DEG C to form molten glass; and the molten glass is subjected to water quenching by cold water, and cooled at room temperature to form glass slag. Through high-temperature electric melting treatment, hexavalent chromium in the chromium slag is reduced into trivalent chromium and is cured and stabilized after entering glass lattices, and the chromium slag is converted into glass state inert waste, and the leaching concentration of heavy metals is far lower than a standard limit value in Identification Standard for Hazardous Wastes-Identification for Extraction Procedure Toxicity (GB5085.3-2007) of the nation.

Owner:刘阳生 +1

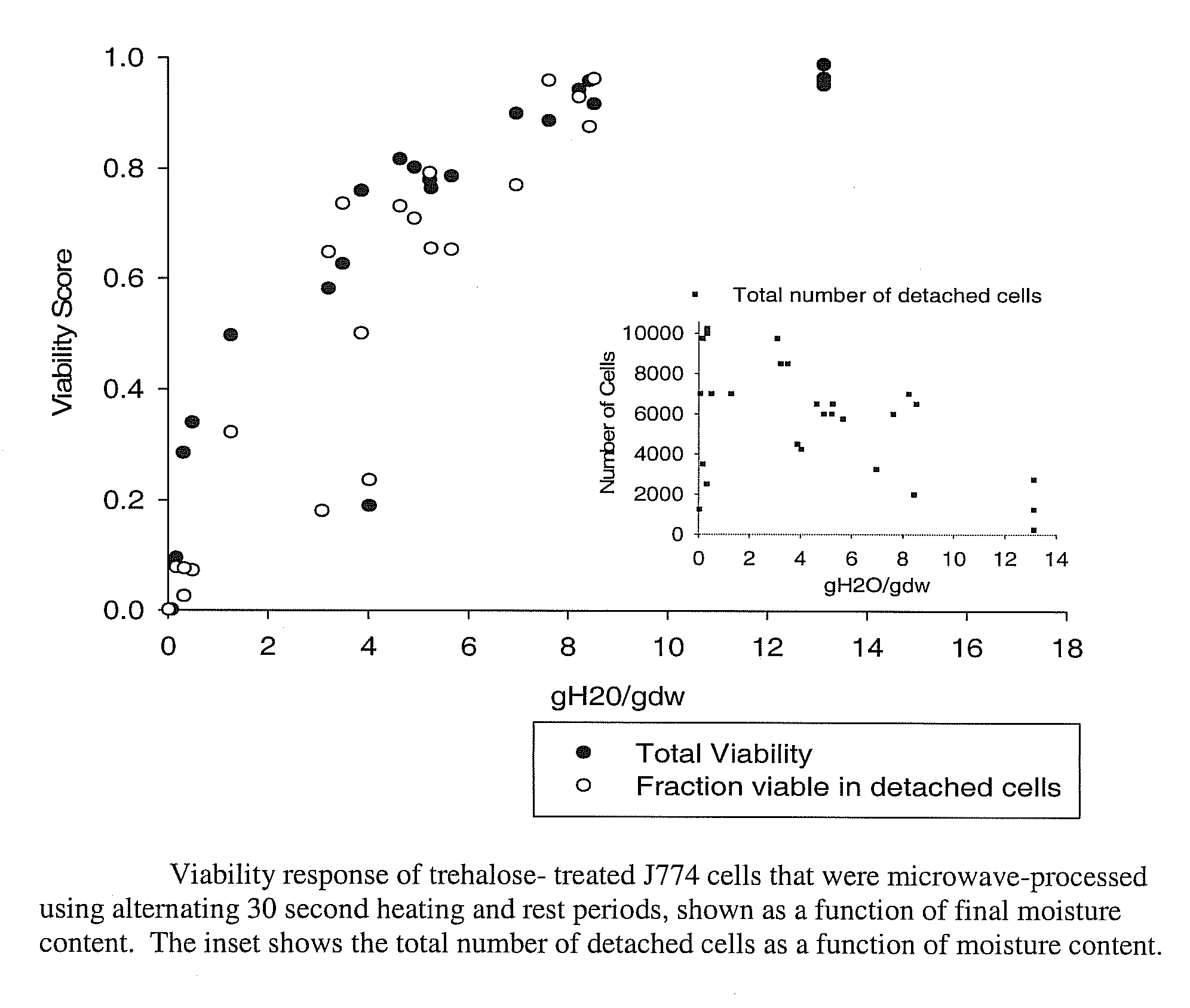

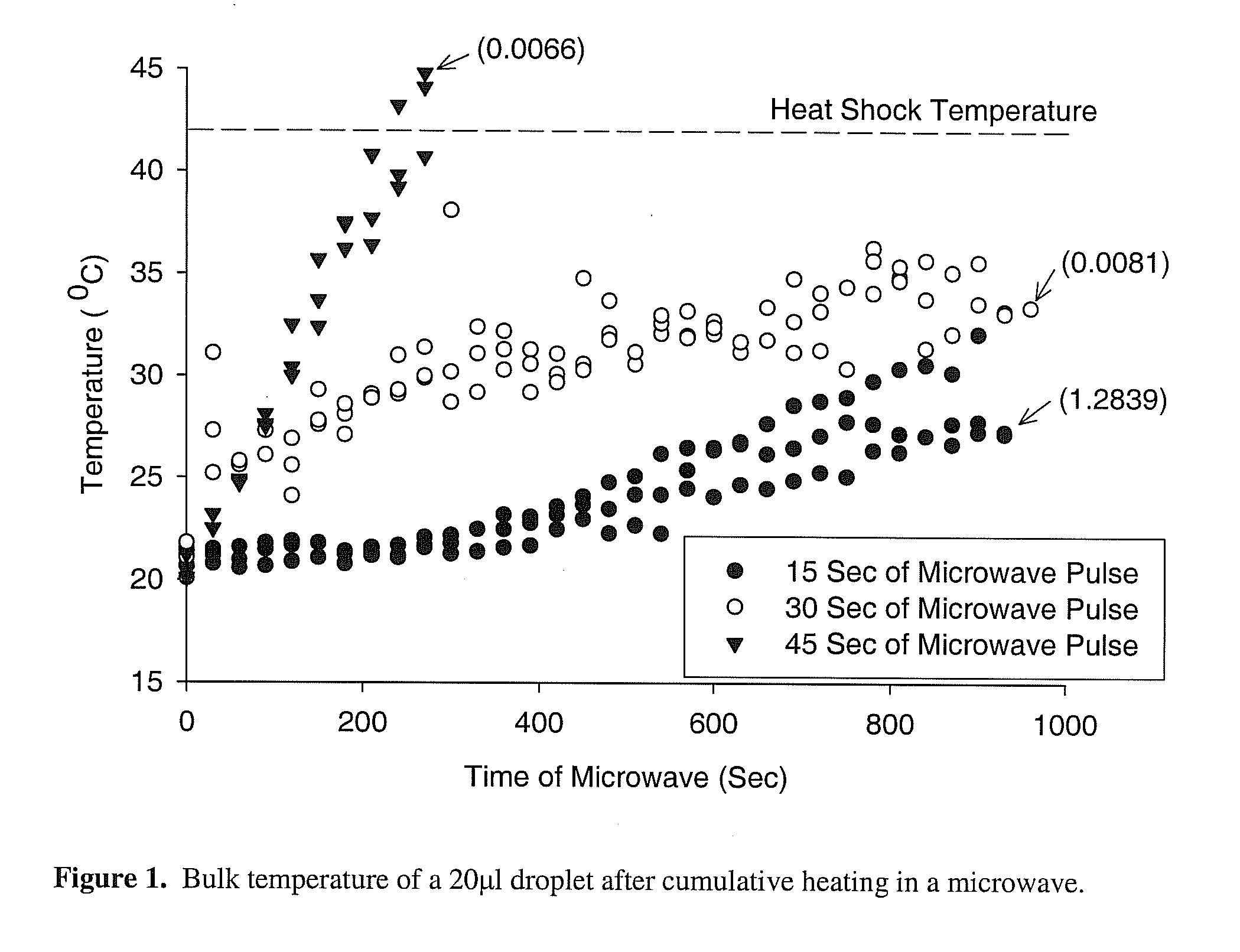

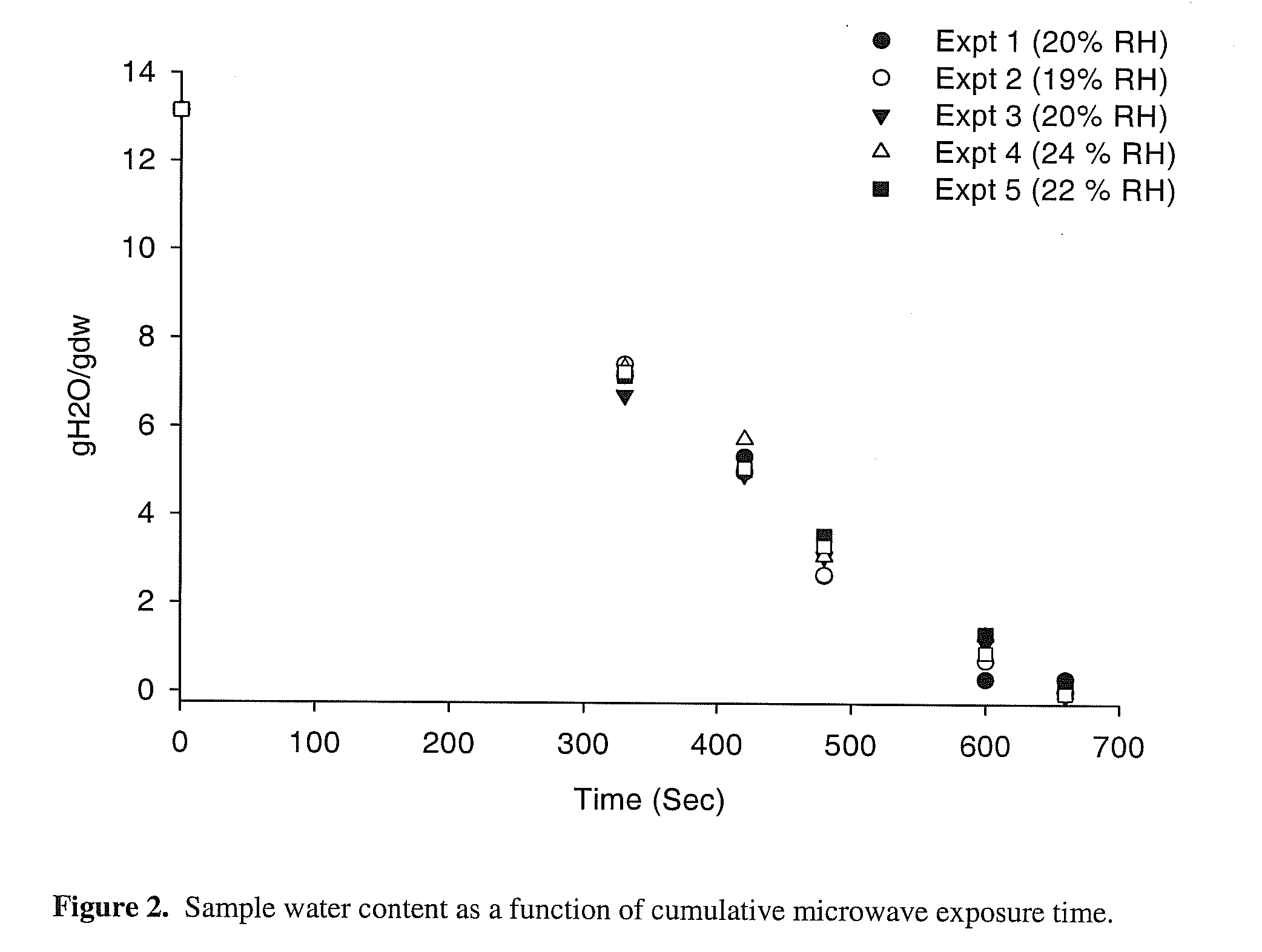

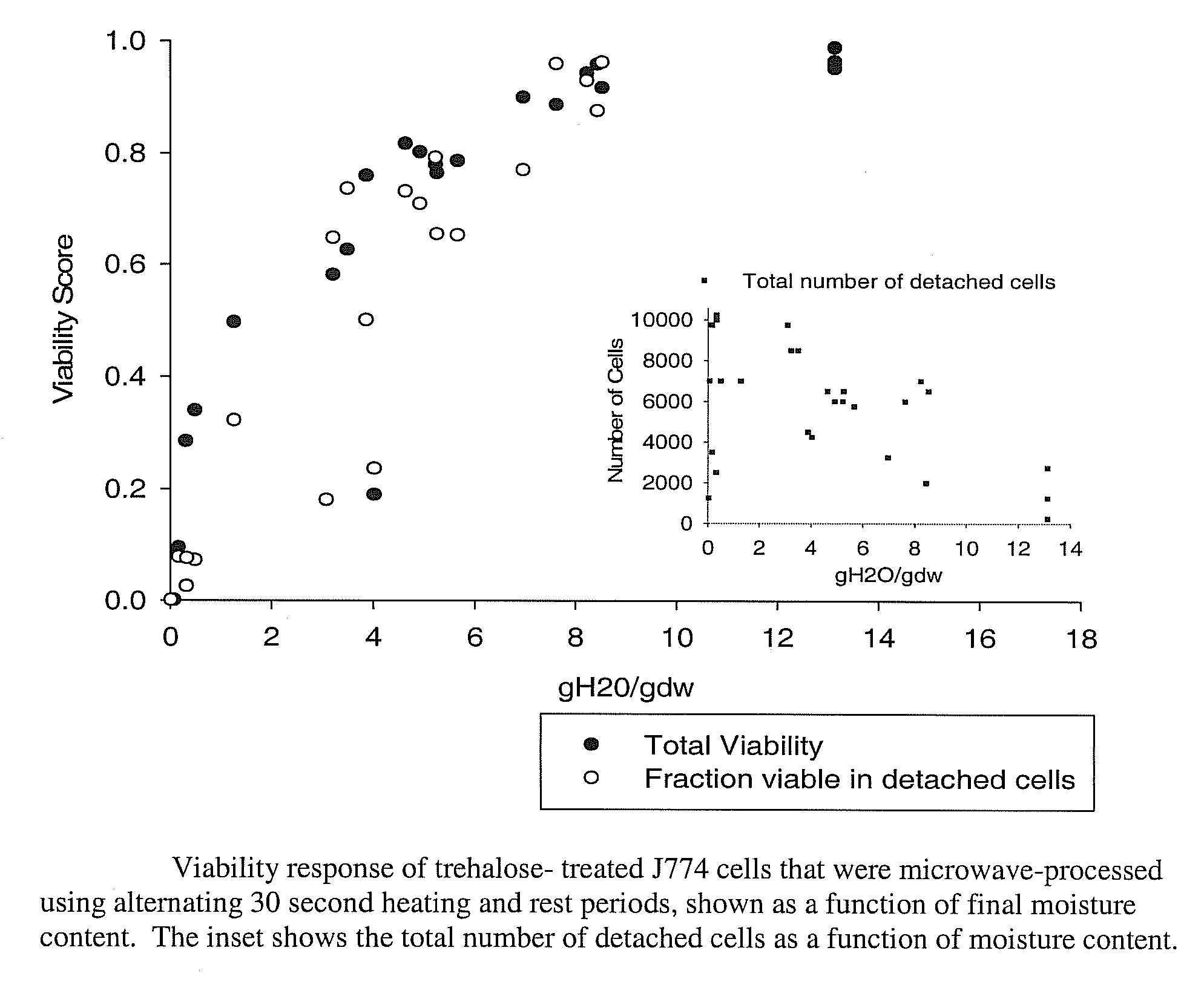

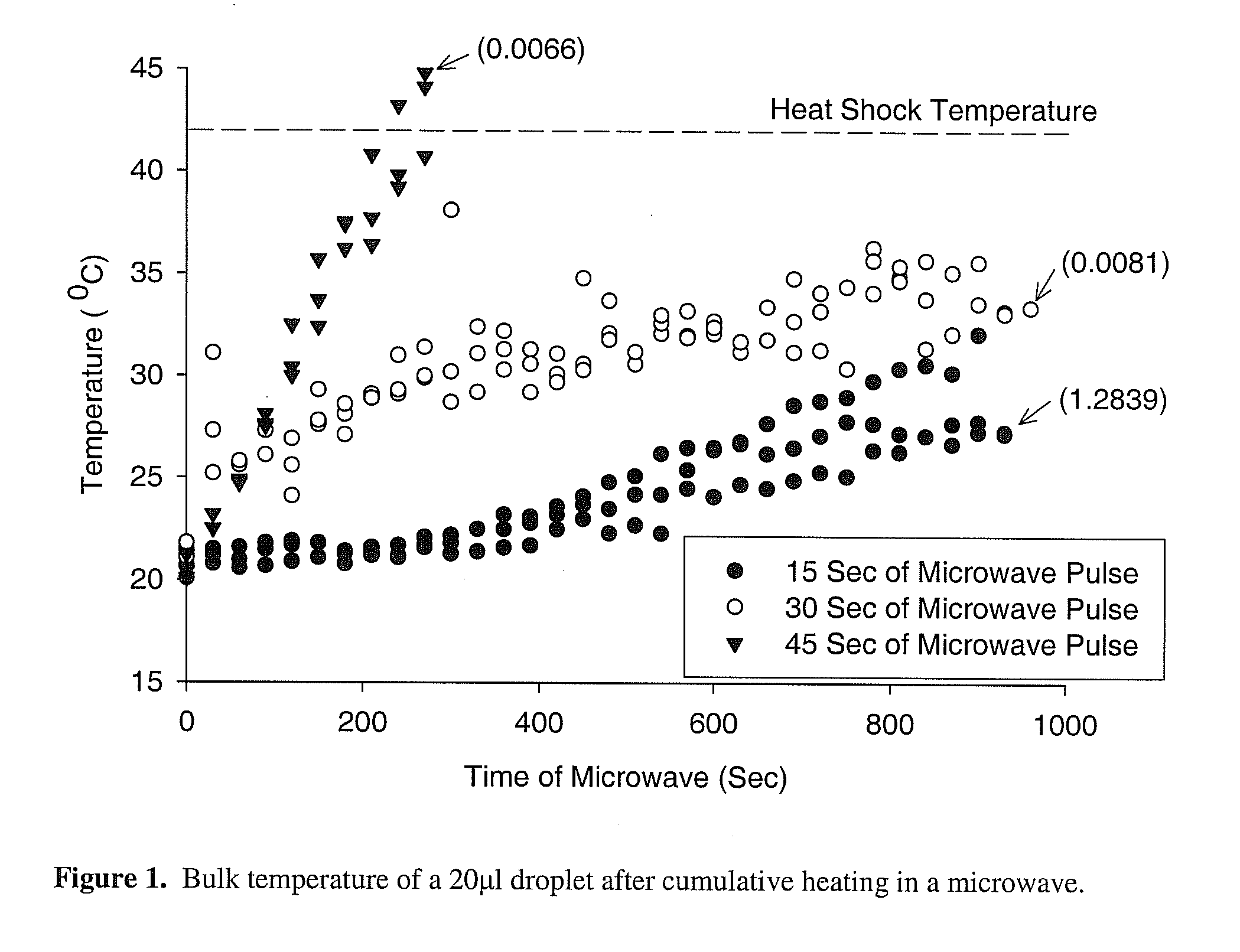

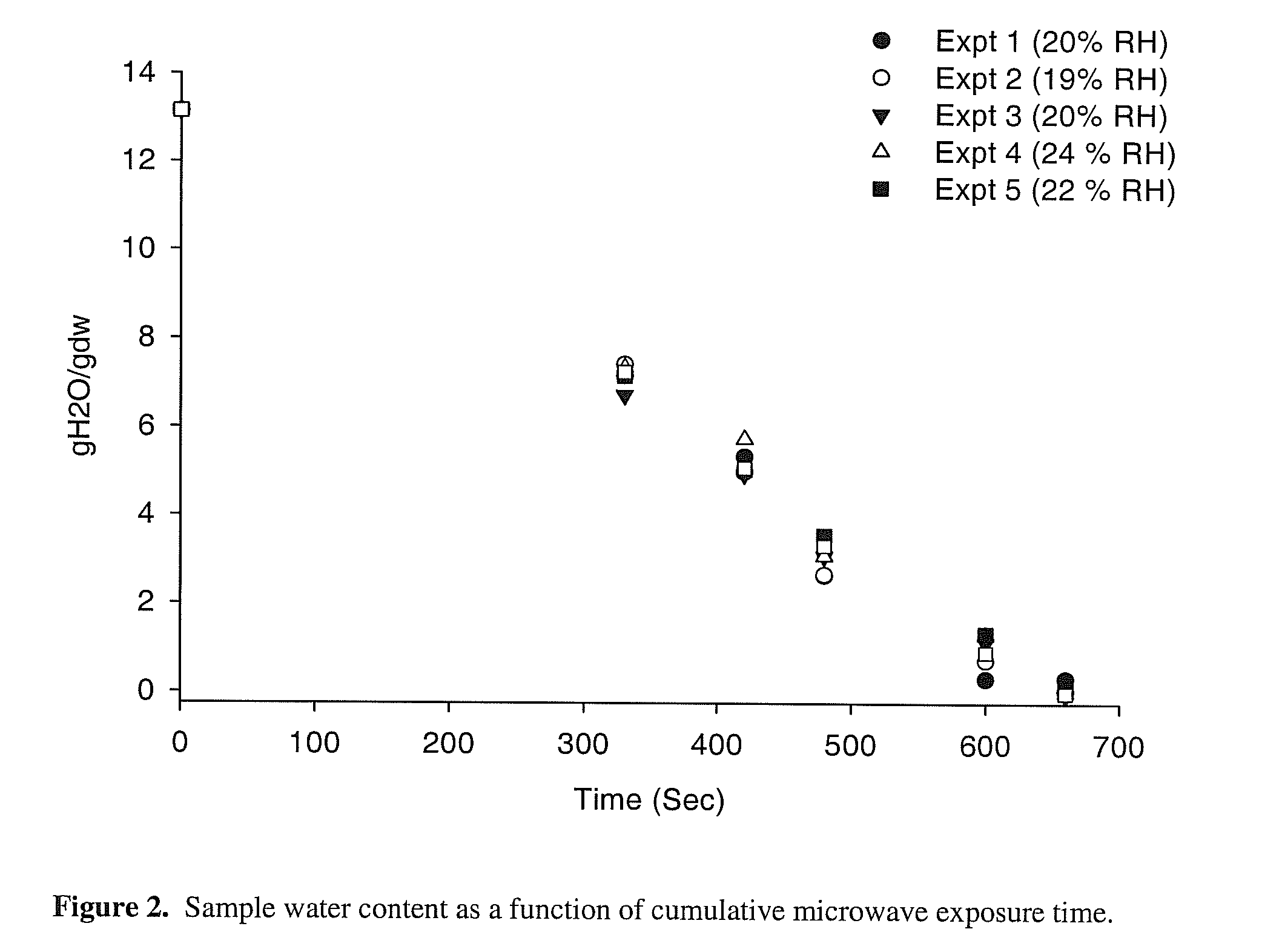

Microwave drying process for vitrification of biologics

Owner:JUNIVERSITI OF NORT KAROLINA EHT SHARLOTT

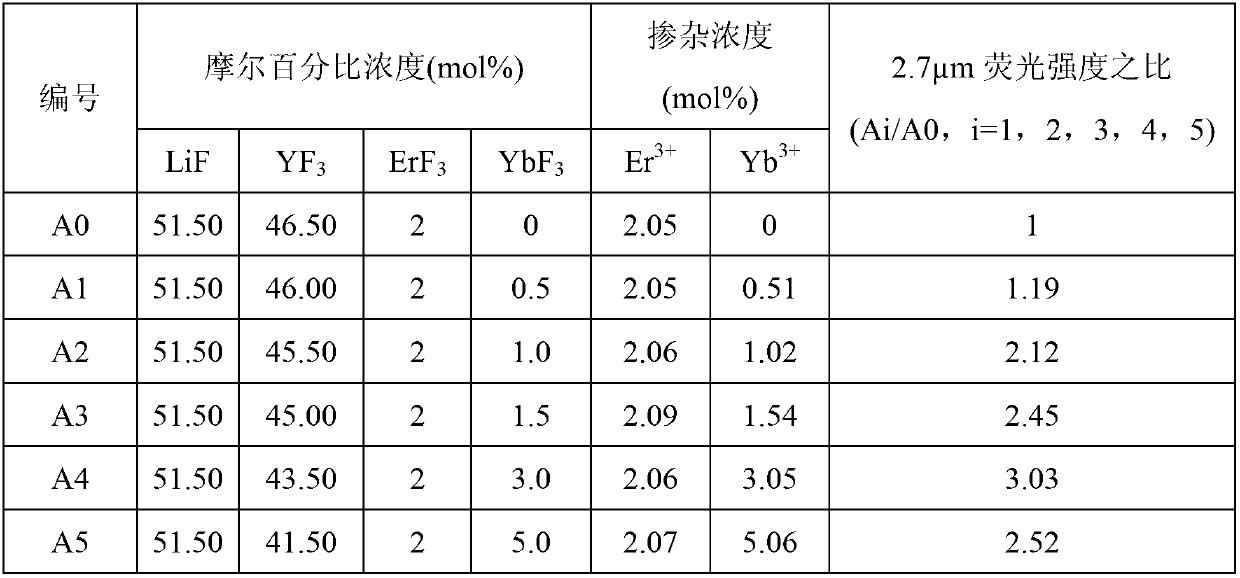

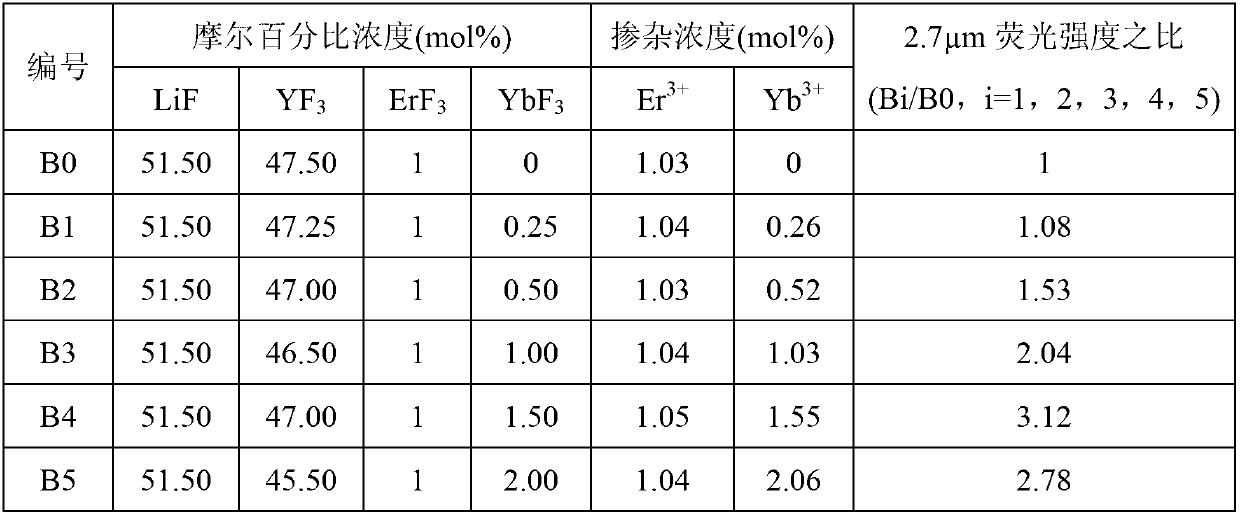

Er<3+>/Yb<3+> co-doped yttrium lithium fluoride monocrystal and preparation method thereof

InactiveCN102978701AHigh phonon energyPhonon energy low highPolycrystalline material growthFrom frozen solutionsWater vaporOxygen

The invention discloses an Er<3+> / Yb<3+> co-doped yttrium lithium fluoride monocrystal and a preparation method thereof. The yttrium lithium fluoride monocrystal is a rare earth ion Er<3+> / Yb<3+> co-doped monocrystal; the molecular formula is LiY(1-x-y)ErxYbyF4, wherein x is greater than or equal to 0.008 and less than or equal to 0.085, and y is greater than or equal to 0.002 and less than or equal to 0.170; the segregation coefficients of Yb<3+> and Er<3+> in the yttrium lithium fluoride are about 1, and efficient intermediate infrared laser of 2.7 microns can be output; and the yttrium lithium fluoride monocrystal has high transmittance of intermediate infrared laser, has better thermal, mechanical and chemical stabilities than those of glass state materials and has the characteristics of low phonon energy, high optical transmittance of wavebands with width of 300-5500nm, less color center forming amount, low thermal lens effect and the like, thereby being more easily processed and more suitably used in laser devices. In the preparation method disclosed by the invention, a sealing crucible falling technology is used, so that the operation is simple; the raw material is fluorated at high temperature in a sealed water-free and oxygen-free environment, so that the crystal is isolated from air and water vapor during the growth; and therefore, the high-quality Er<3+> / Yb<3+> co-doped LiYF4 monocrystal containing little OH<-> ion and oxide is obtained.

Owner:NINGBO UNIV

Method of manufacture of one-piece composite parts using a two-piece form including a shaped polymer that does not draw with a rigid insert designed to draw

ActiveUS20100230850A1Low cost manufacturingAdditive manufacturing apparatusDomestic articlesVitreous stateHollow core

A polymer is formed into the shape of a one-piece composite part and then solidified by curing, setting, hardening or otherwise solidifying the polymer to form a shaped polymer form having a shape that does not draw. Composite material is laid up on the form and solidified to from the composite part. The rigidity required of the form to lay up the composite part can he provided by operating in the polymer form's glassy state, forming the shaped polymer form with a hollow core and placing a rigid insert designed to draw inside the hollow core with the polymer form in its elastomeric state or through a combination of both. In its elastomeric state the form becomes pliable (without relaxing to a different memorized shape) and can he drawn out of the one-piece composite part. Because the shape of the form does not draw, the form deforms as it is drawn. If used, the rigid insert is drawn out prior to removing the shaped polymer form. Upon removal, the polymer form in its elastomeric state returns to its original shape. The form may be used once and thrown away or reused to form multiple composite parts of the same shape.

Owner:RAYTHEON CO

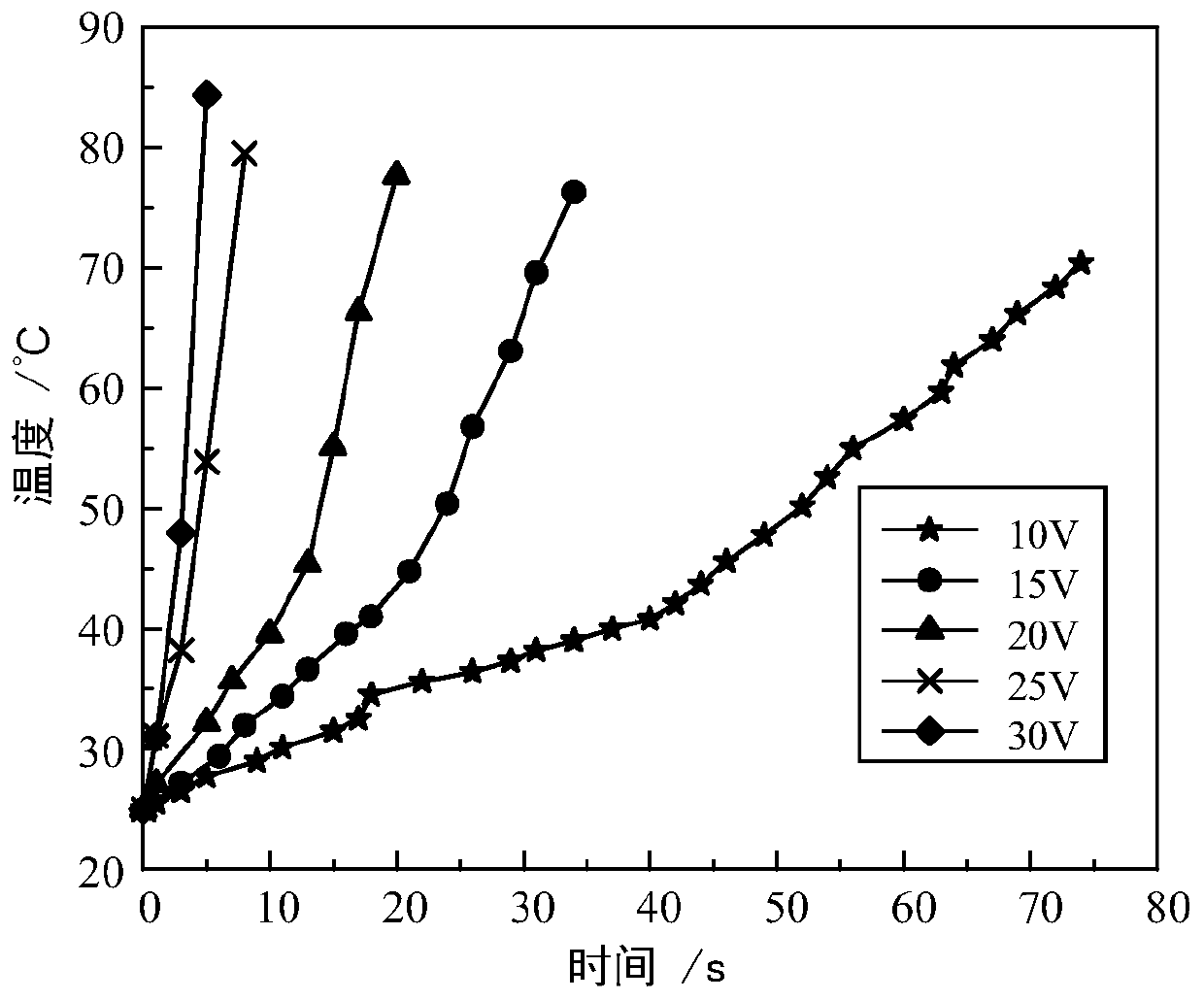

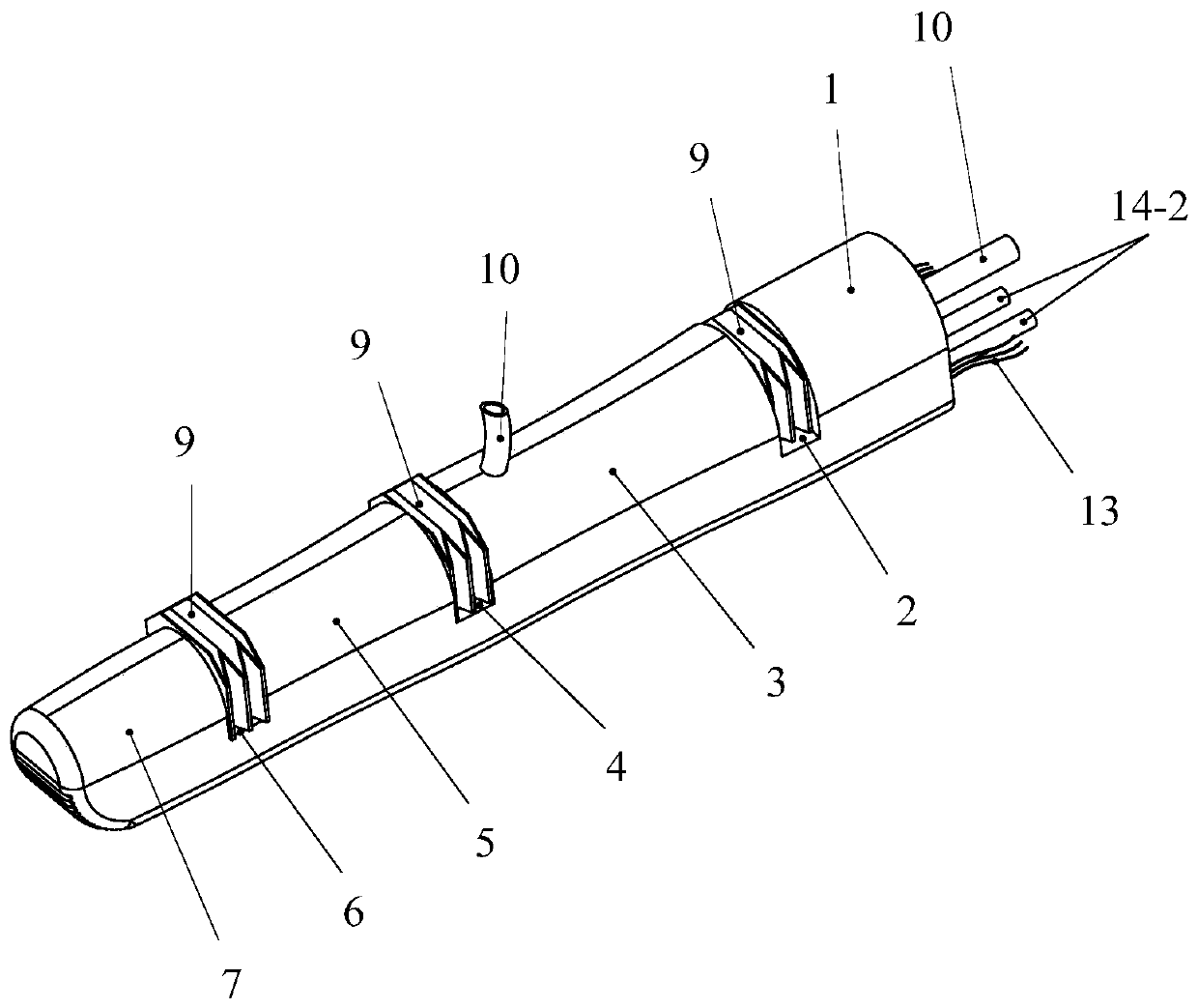

Preparation method of conductive thermoplastic starch polymer and polymer-based humanoid soft finger with folding paper structure

The invention relates to a preparation method of a conductive thermoplastic starch polymer and a polymer-based humanoid soft finger with a folding paper structure, belongs to the technical field of humanoid fingers, and aims to solve the problems that in an existing humanoid soft finger with the variable rigidity realized by utilizing a thermal phase change material, the variable rigidity responsespeed is low due to long response time of conversion from a glass state to a high-elasticity state, and the joint motion flexibility and the rigidity of the humanoid soft finger cannot be realized atthe same time. The polymer-based humanoid soft finger comprises a finger root, a metacarpophalangeal joint, a proximal phalanx, an interphalangeal joint, a middle phalanx, a finger tip joint, a distal phalanx, a strain restraint layer, a variable rigidity layer, a cooling layer and a contact layer, wherein each joint is provided with a U-shaped groove, and the outer side of each joint is wrappedwith Yoshimura line type folding paper; and three self-made conductive thermoplastic starch polymer plates are arranged at the bottom of the finger. The humanoid soft finger not only can realize rapidand active control of the rigidity of the phalanxes, but also can realize synchronous and passive adjustment of joint flexible motion and joint rigidity, and has the advantages of fast variable rigidity, high adaptability and flexibility in motion.

Owner:HARBIN INST OF TECH

Extracellular matrix freeze-drying protection liquid and application method thereof

ActiveCN102746372AStrong penetrating powerImprove permeabilityDead animal preservationPeptide preparation methodsTectorial membraneFreeze-drying

The invention relates to an extracellular matrix freeze-drying protection liquid. The extracellular matrix freeze-drying protection liquid takes normal saline as a solvent and comprises the following components: chondroitin sulfate, vitamin C, polyethylene glycol, trehalose, glucan, serine and threonine. The invention has the following advantages: the protection liquid has high penetrability, can be vitrified under a low-temperature condition, is rich in negative polar groups and hydroxyl groups, and can be efficiently bonded with collagen molecules; the stable and uniform extracellular matrix freeze-drying effect can be ensured; the protection liquid can be formed into the vitreous state at low temperature, thereby preventing ice crystals from damaging the protein structure; and a protection film is formed at the outer layer of the matrix in stead of hydrogen bonds formed by water molecules and collagen, thereby protecting the collagen function and the stability of the three-dimensional structure. The extracellular matrix freeze-drying protection liquid has low cytotoxicity, and can be used immediately after being rinsed with normal saline or sterilized water; the freeze-dried extracellular matrix can be preserved at normal temperature for more than three years when being packaged in vacuum; and the extracellular matrix freeze-drying protection liquid is suitable for the preservation of purified extracellular matrix such as collagen, elastin, glucoprotein and the like, and is also suitable for various biologic materials constructed by extracellular matrix materials.

Owner:西安博和医疗科技有限公司

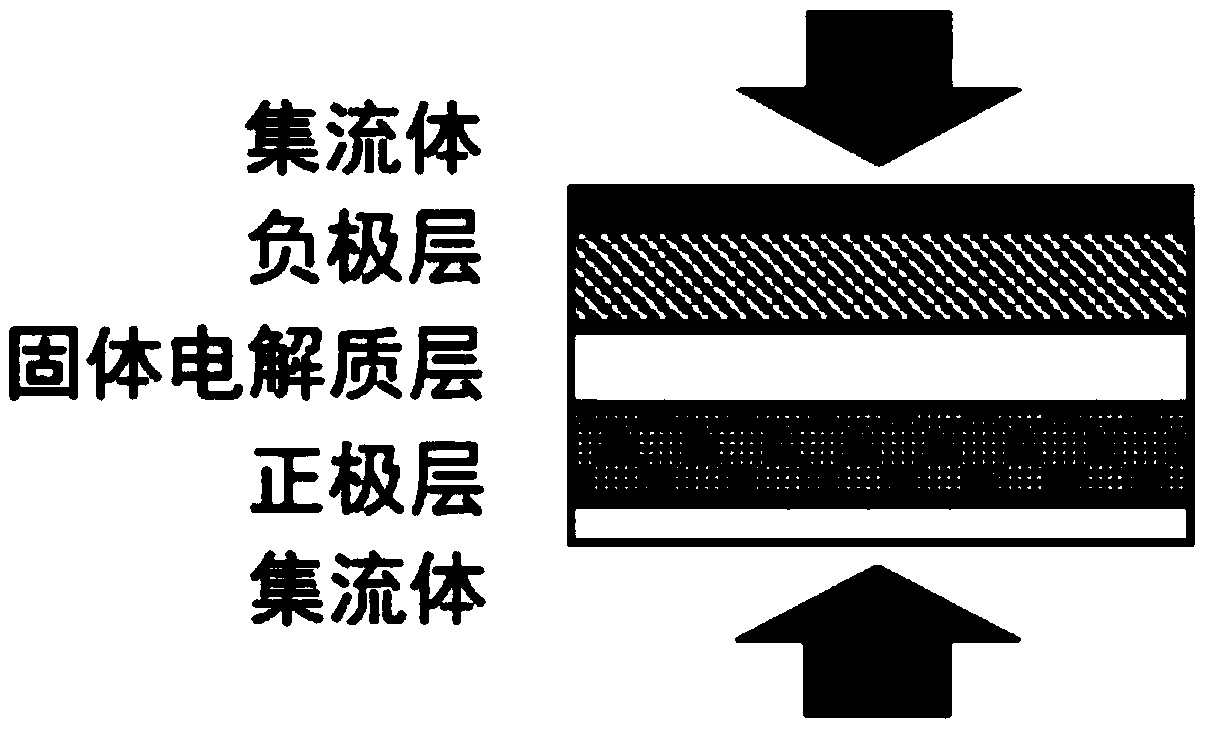

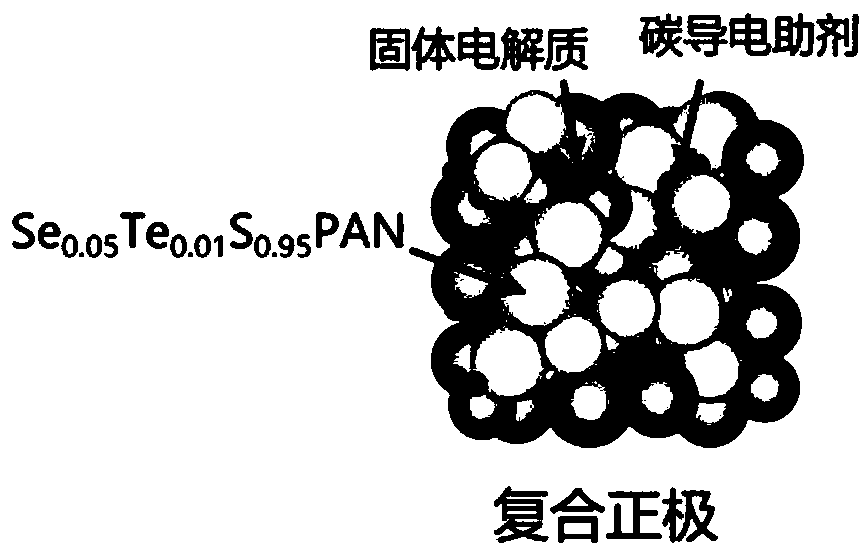

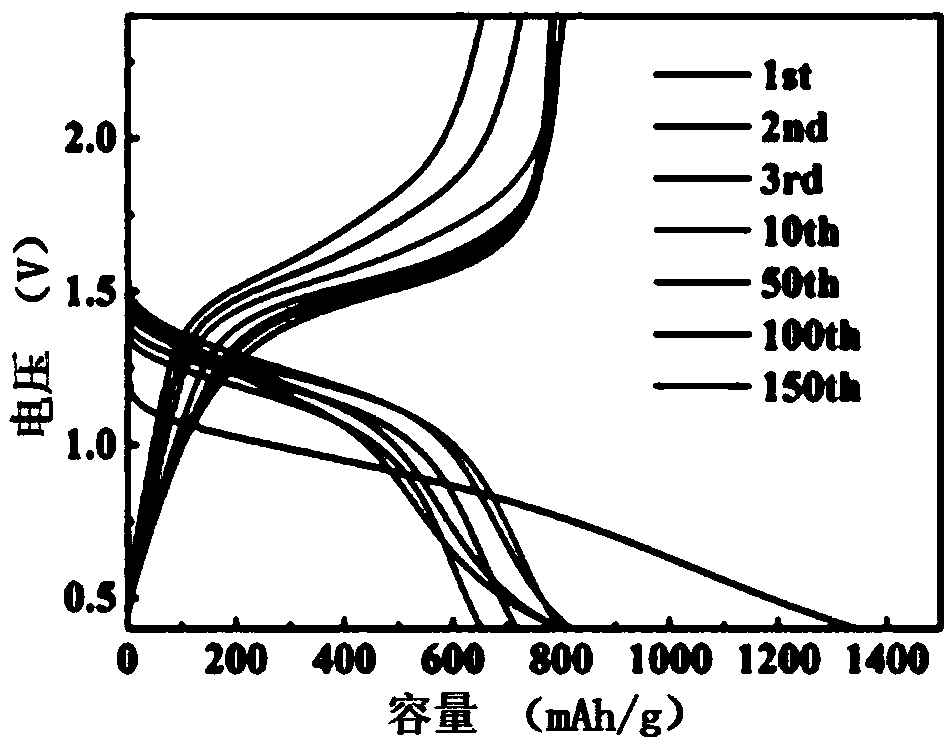

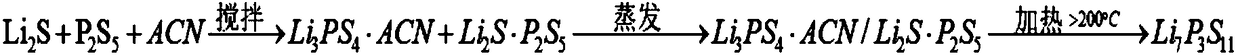

Full solid-state lithium-sulfur battery and manufacturing method thereof

InactiveCN109638240AImprove cycle lifeImprove Coulombic efficiencySolid electrolytesFinal product manufactureArgyroditeLithium sulfur

The invention belongs to the technical field related to the preparation of the lithium ion battery, and discloses a full solid-state lithium-sulfur battery. The full solid-state lithium-sulfur batterycomprises a metal negative electrode, a sulfide solid electrolyte and a composite positive electrode; the material of the metal negative electrode is selected from one of Li metal, Li-In alloy, Li-Alalloy, Li-Si alloy or Li-Sn alloy; the sulfide solid electrolyte is selected from one or combination of Li10GeP2S12 type solid electrolyte, Li2S-P2S5 glass-state electrolyte, and argyrodite type solid electrolyte; the composite positive electrode is commonly composed of selentellurium-doped sulfide polyacrylonitrile, a positive solid electrolyte with components same as that of the sulfide solid electrolyte, and a carbon-based conductive additive in a specific proportion. The invention further discloses a corresponding manufacturing method. Through the full solid-state lithium-sulfur battery disclosed by the invention, the defect that the conventional full solid-state lithium-sulfur battery is low in rate performance and low in active substance utilization efficiency can be well overcome,and a three-phase interface of the active substance, the solid electrolyte and the conductive auxiliary is optimized at the same time.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for improving reheated texture of frozen prepared tuberous vegetables

InactiveCN106857802AReduce contentHigh glass transition temperatureFruits/vegetable preservation by freezing/coolingFruits/vegetable preservation by blanchingAdditive ingredientGlass transition

The invention relates to a method for improving the reheated texture of frozen prepared tuberous vegetables, belonging to the technical field of agricultural product processing. The whole reheated texture improvement process of the frozen prepared tuberous vegetables is completed by combining raw material pretreatment and low-frequency ultrasonic-assisted osmotic dehydration with blanching, quick-freezing, glass state freezing storage and reheating. By adopting the low-frequency ultrasonic-assisted osmotic dehydration, the method increases the glass-transition temperature of the tuberous fruits and vegetables, reduces the damage of ice crystal formation to cell structures in a freezing process, can be used for freezing at the glass-transition temperature, and maintains the sensory quality and nutritional ingredients of the vegetables to a greater extent. Furthermore, multiple methods are adopted for cooperative reheating at the later period, so that the materials can be rapidly and stably reheated, and the change of the reheated texture and nutritional quality of the vegetables can be improved.

Owner:JIANGNAN UNIV +1

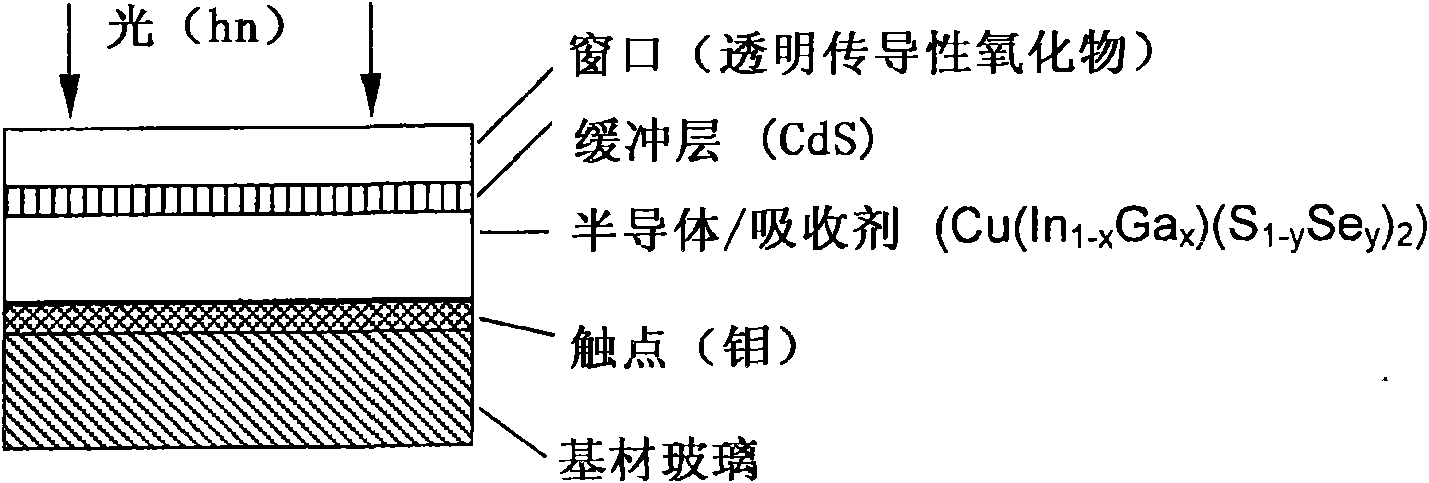

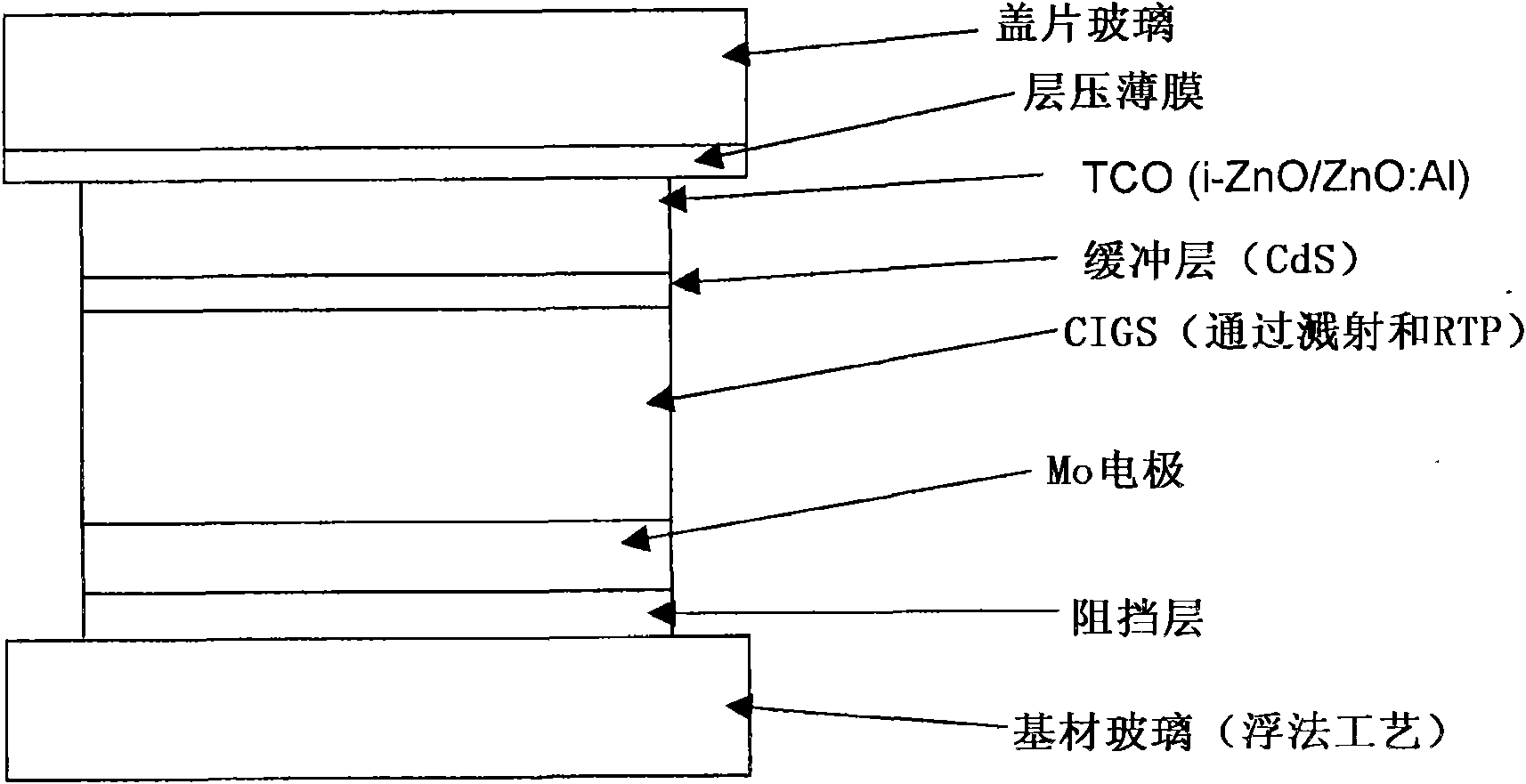

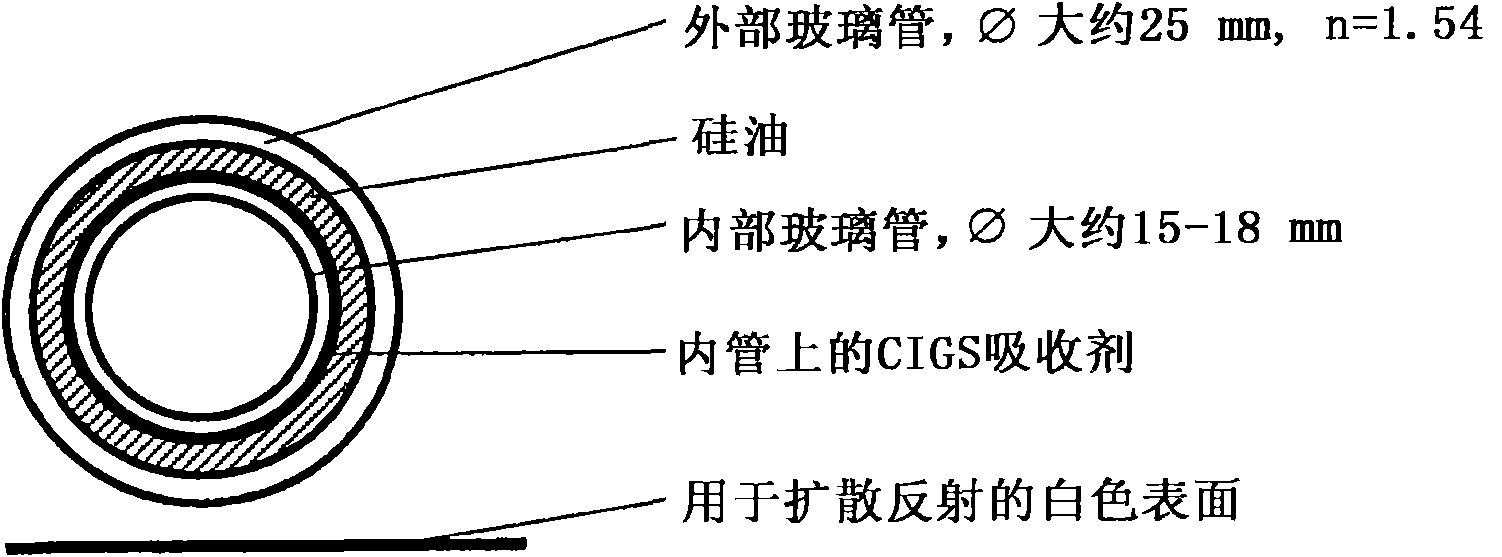

Thin-film solar cell

The claimed thin-film solar cell comprises at least one multicomponent substrate glass containing Na2O, said substrate glass containing less than 1 wt.% B2O3, less than 1 wt.% BaO and less than, in total, 3 wt.% CaO + SrO + ZnO. The molar ratio of the substrate glass components (Na2O+K2O) / (MgO+CaO+SrO+BaO) is greater than 0.95, the molar ratio of the substrate glass components SiO2 / AI2O3 is less than 7, and the substrate glass has a transformation temperature Tg which is higher than 550 DEG C, in particular higher than 600 DEG C.

Owner:SCHOTT AG

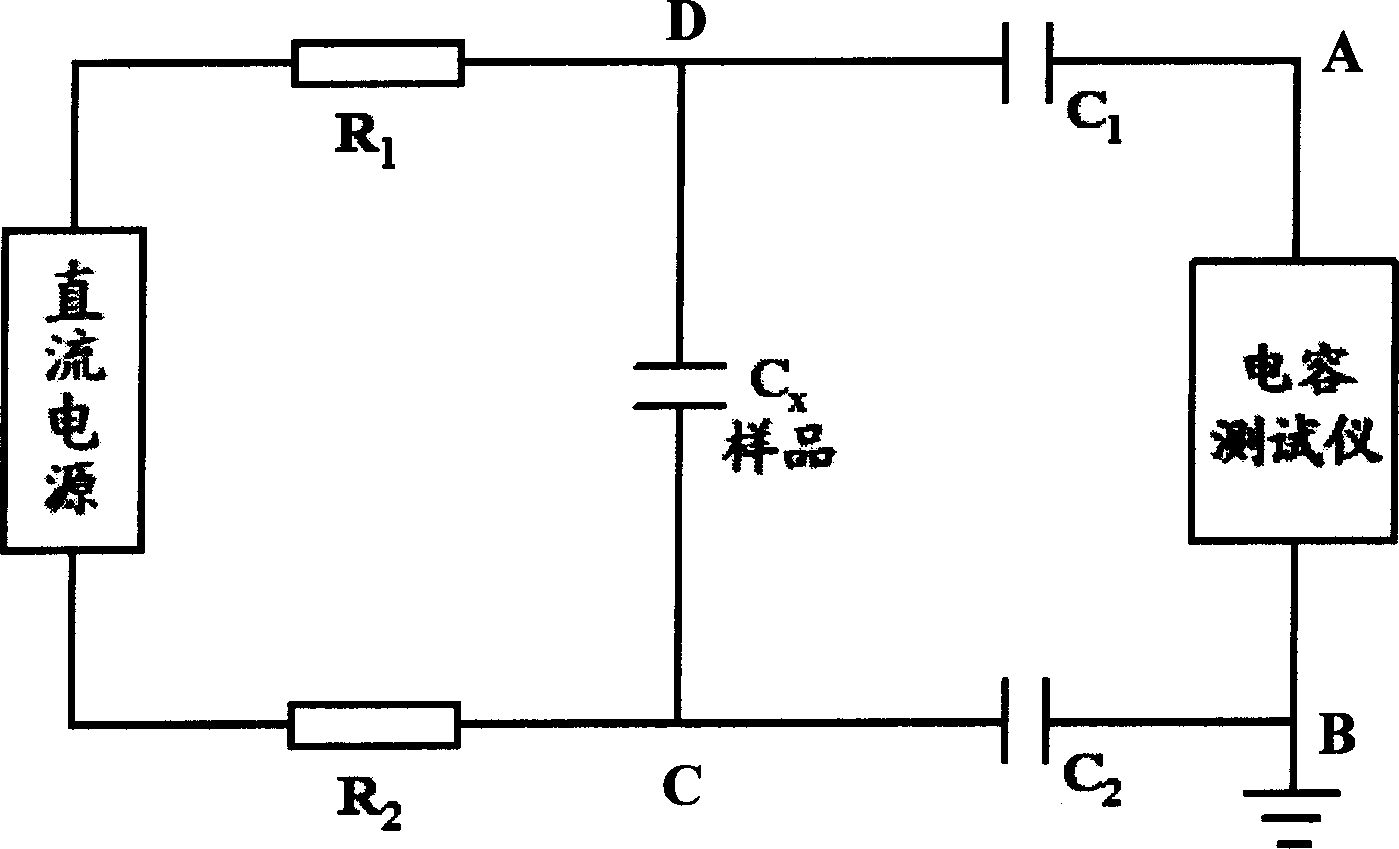

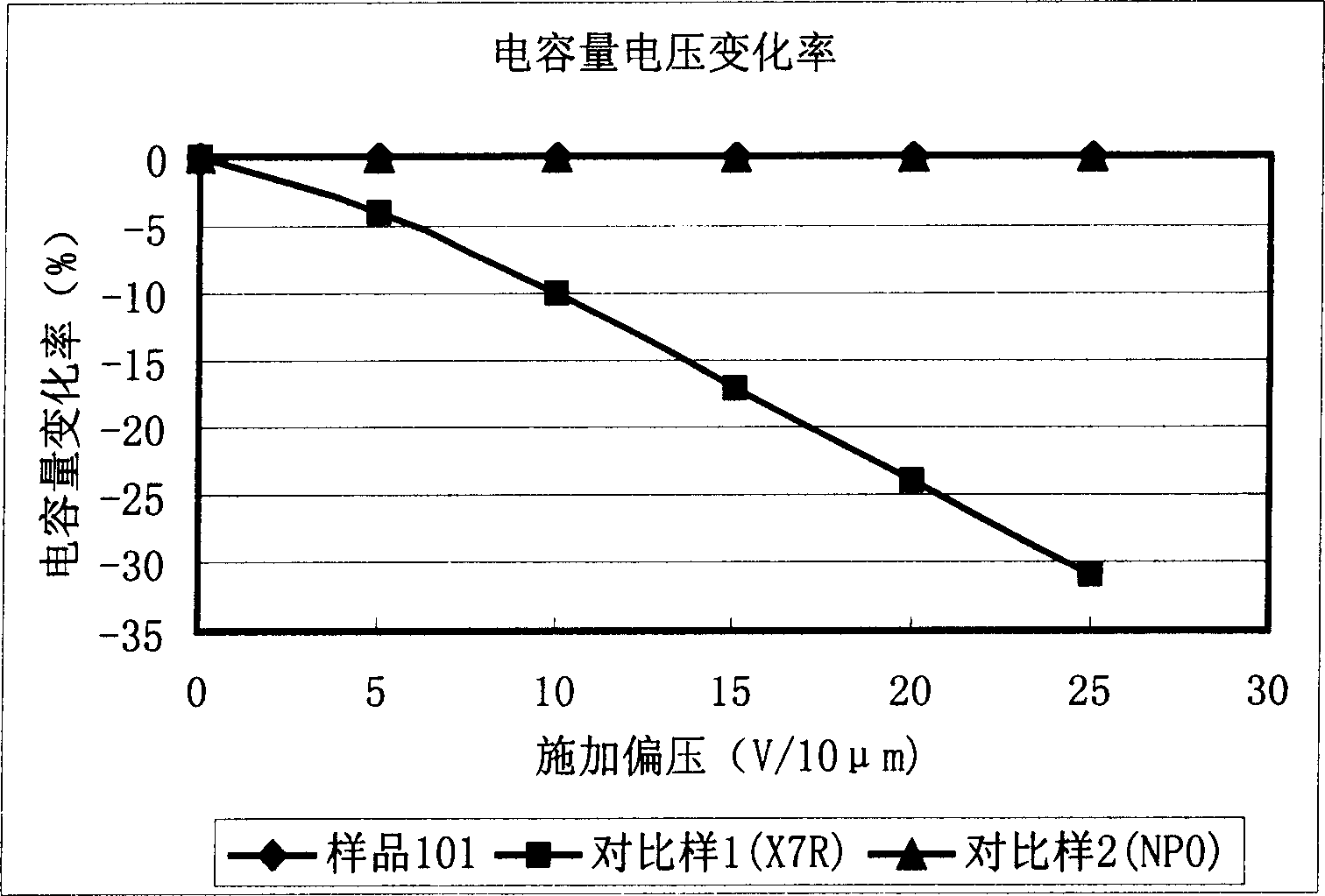

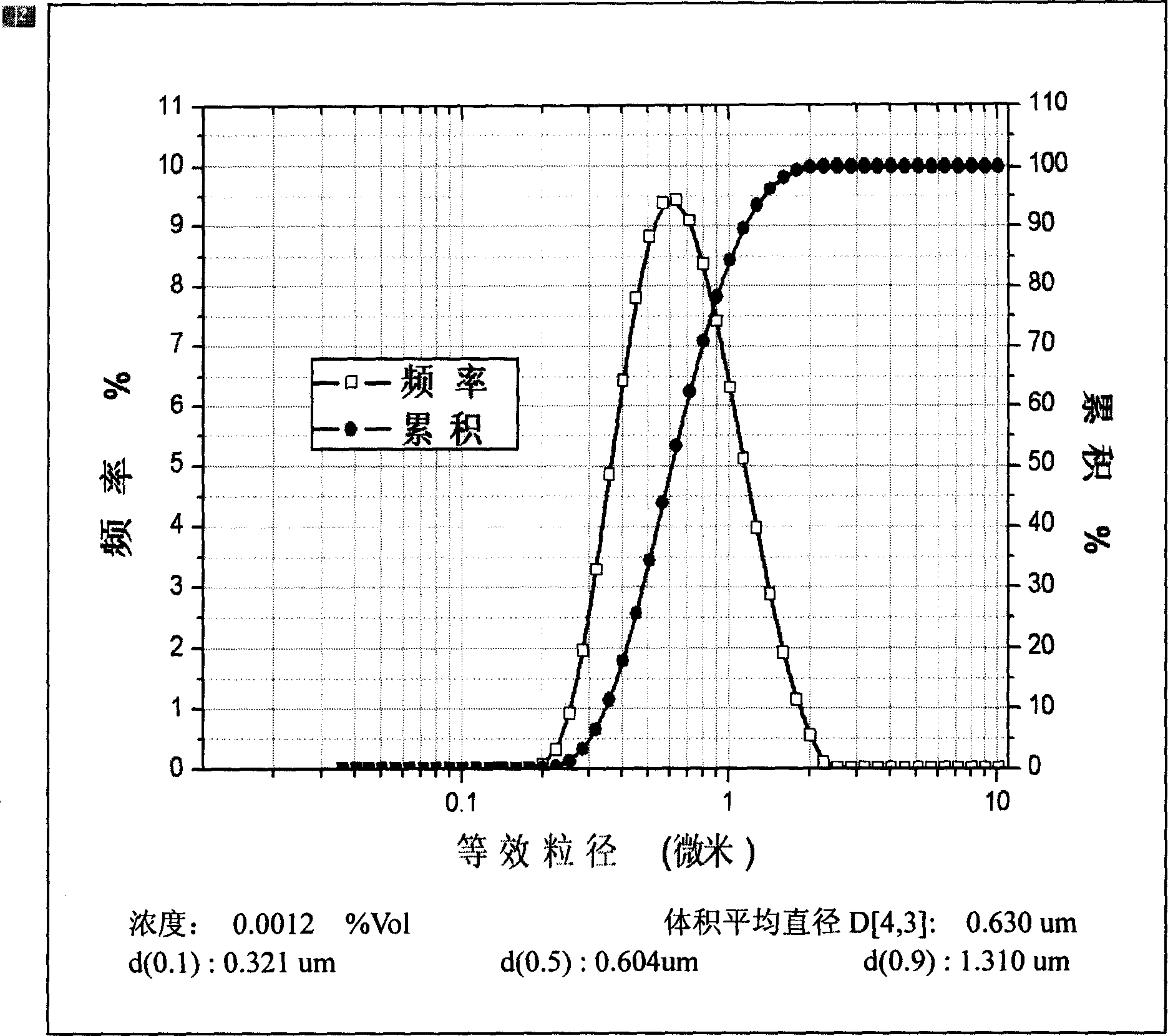

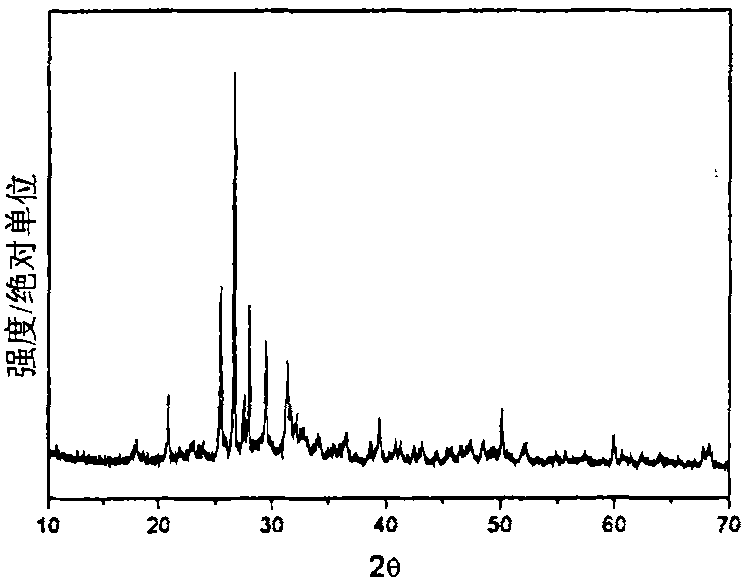

Dielectric ceramic material for piece type capacitor and preparing method thereof

InactiveCN1594217ADielectric properties are flatEasy to meet X7R characteristicsFixed capacitor dielectricCeramicsVitreous stateQuenching

The invention discloses a dielectric ceramic material for piece type capacitor and preparing method, which comprises the steps of, (1) mixing each of third accessory constituents, heating till molten, using water-cooled quenching method to obtain glass, disintegrating by ball grinding to obtain glass state material, (2) mixing the main constituent and the first accessory constituent, watering, ball grinding or mixing uniformly to obtain slip, drying the slip into powder material, (3) subjecting the powder material obtained through drying in step (2) to calcinations in the air at 1100-1250 deg. C, thermal insulating 0.5-5 hours, watering, ball grinding till the grain size in the particles D50<=0.7 um, drying to obtain the main ingredient, (4) mixing the main ingredient, the second accessory constituent and the glass state material obtained in step (1) uniformly.

Owner:SOUTH CHINA UNIV OF TECH

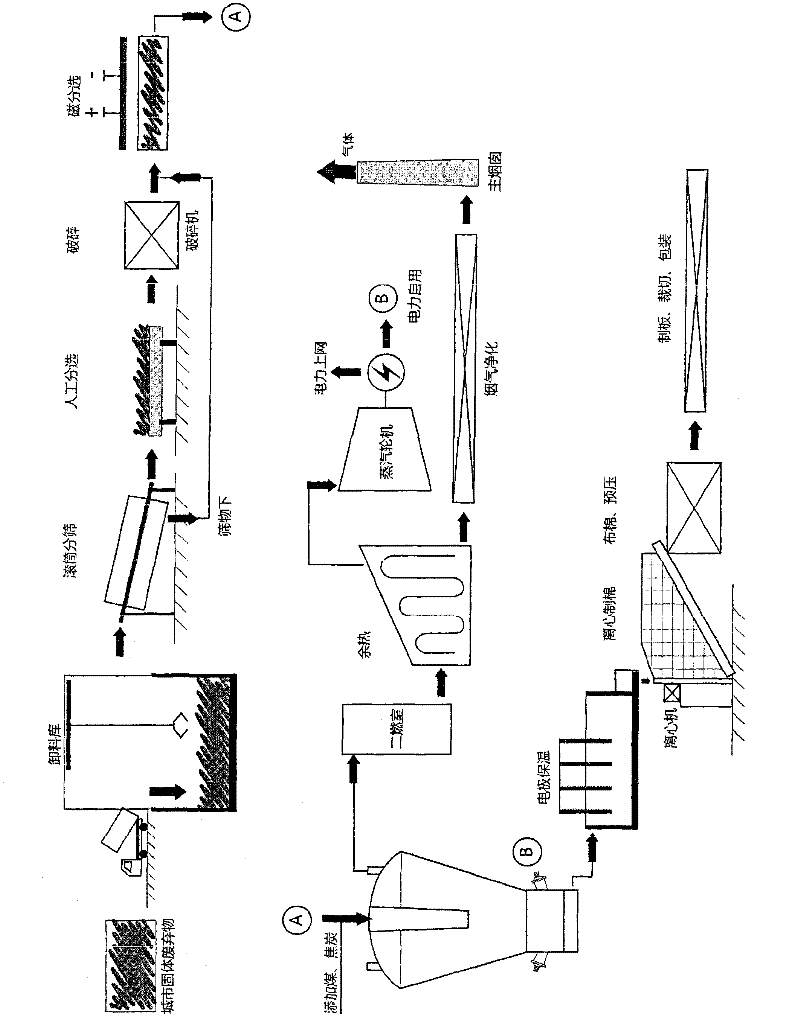

Method for producing mineral wool from solid waste by using plasma gasification furnace

The invention relates to the technical field of building material production, environmental protection, energy sources and the like, in particular to a method for directly producing a mineral wool product from hot slag produced by gasification of urban solid waste by using a plasma gasification furnace. The method comprises the following steps of: treating urban solid waste in the plasma gasification furnace to obtain glass-state hot slag; making the glass-state hot slag directly flow from the bottom of the plasma gasification furnace into a heat-preserving regulating reservoir through a heat-preserving discharging channel without cooling; adding mineral auxiliary materials into the heat-preserving regulating reservoir according to a hot slag parameter measured by an online detection device; and making regulated glass-state hot slag enter a mineral wool production system from the discharging hole of the heat-preserving regulating reservoir to obtain mineral wool. Compared with the mineral wool production method in the prior art, the method for producing mineral wool from urban solid waste by using the plasma gasification furnace has the advantages of environmental friendliness, energy saving, low economic cost and resource recycling.

Owner:AMERICAN GREEN ENERGY RESOURCE DEV

Granular savoury food concentrate

A granular savoury food concentrate comprising from 10 to 65 wt.% of salt, from 1 to 20 wt.% of yeast extract and from 10 to 50 wt.% of flour, starch or a mixture thereof, wherein the granular food concentrate is not in a glassy state.

Owner:UNILEVER NV

Polyurethane reinforced grouting material containing phase change additive and preparation method thereof

ActiveCN102643532ALower internal heat storage temperatureEnsure safetyBuilding insulationsPhase changePhase-change material

The invention belonging to the technical field of materials, and particularly relates to a polyurethane reinforced grouting material containing a phase change additive and a preparation method of the polyurethane reinforced grouting material. The polyurethane reinforced grouting material containing the phase change additive comprises the following components in percentage by weight: 50-7% of polyurethane, 15-30% of dimethyl methylphosphate, 3-30% of phase change additive, 0.3-1.2% of tin compound, 0.3-1.2% of amine compound, and 0-0.8% of organosilicon defoaming agent. The phase change additive is an inorganic phase-change material, an organic phase-change material or a mixture thereof, and is uniformly distributed in polyurethane base in a dispersion manner; and when polymerization reaction radiates heat, the phase-change material can change from solid state into liquid or vitreous state into rubber state, rubber-like state and the like, absorbs part of heat radiated by the reaction of isocyanate and polyether polyol, and effectively reduces the inside heat accumulation temperature of the polyurethane grouting material.

Owner:LIAONING TECHNICAL UNIVERSITY

Sulfide solid electrolyte and preparation method thereof and equipment

InactiveCN108878961AImprove microwave absorption performanceImprove solid electrolyteSecondary cellsLithiumPhysical chemistry

The invention relates to a preparation method of a sulfide solid electrolyte. The preparation method comprises the following steps of putting reaction raw materials into a water-free oxygen-free sealed container, and grinding the reaction raw materials, carrying out microwave radiation heating for a certain time, and then cooling to obtain the sulfide solid electrolyte. In the preparation process,the reaction raw materials are all contained in one sealed container, and replacement of the container is not needed in the middle of the process, so that industrial production can be realized easily; the probability of contact with water and air is lowered, and the occurrence of side reactions is reduced; the reaction is carried out in a microwave heating condition, so that rapid heating and cooling and realized; on one hand, the glassy state and the amorphous state in the synthesized product are relatively more, and the channels for rapid migration of the lithium ions are increased, so thatthe conductivity of the lithium ions is improved; and on the other hand, relatively more point defects and / or plane defects exist in the synthesized products, the channels for rapid migration of thelithium ions are increased, and the conductivity of the lithium ions is improved. Experiments prove that the lithium ion conductivity of the sulfide solid electrolyte prepared according to the methodcan reach 8*10<-4>s / cm to 6*10<-3>s / cm at the room temperature.

Owner:桑德新能源技术开发有限公司 +1

Method of manufacture of one-piece composite parts with a polymer form that transitions between its glassy and elastomeric states

ActiveUS7887734B2Low cost manufacturingStiffness desired to lay up the composite materialAdditive manufacturing apparatusShaping conveyorsElastomerVitreous state

A polymer is formed into the shape of a one-piece composite part and then solidified by curing, setting, hardening or otherwise solidifying the polymer to form a shaped polymer form having a shape that does not draw. Composite material is laid up on the form and solidified to from the composite part. The rigidity required of the form to lay up the composite part can be provided by operating in the polymer form's glassy state, forming the shaped polymer form with a hollow core and placing a rigid insert designed to draw inside the hollow core with the polymer form in its elastomeric state or through a combination of both. In its elastomeric state the form becomes pliable (without relaxing to a different memorized shape) and can be drawn out of the one-piece composite part. Because the shape of the form does not draw, the form deforms as it is drawn. If used, the rigid insert is drawn out prior to removing the shaped polymer form. Upon removal, the polymer form in its elastomeric state returns to its original shape. The form may be used once and thrown away or reused to form multiple composite parts of the same shape.

Owner:RAYTHEON CO

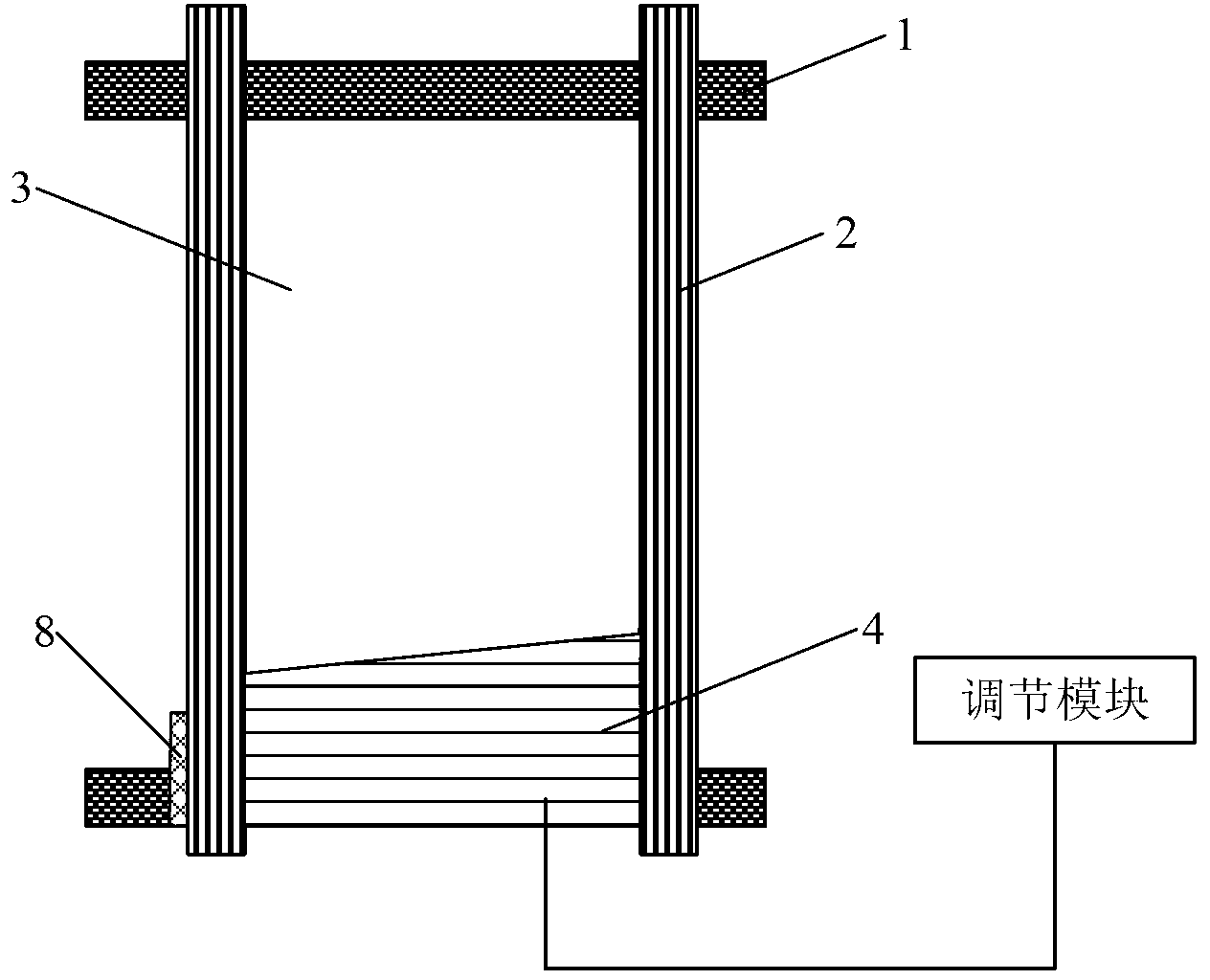

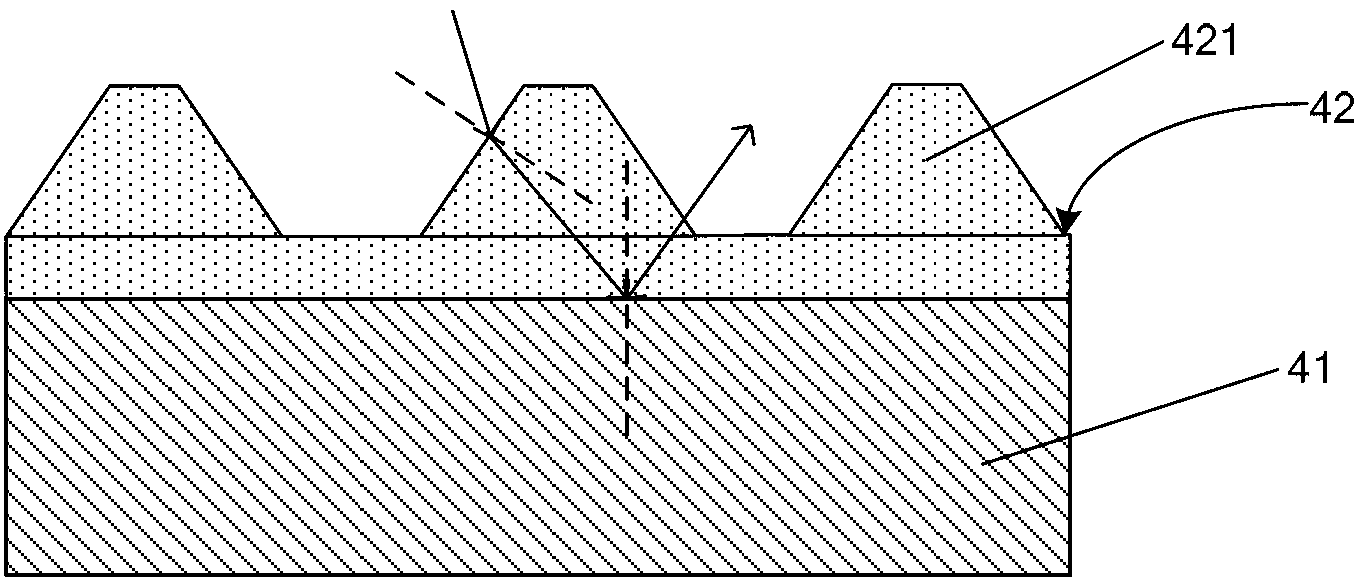

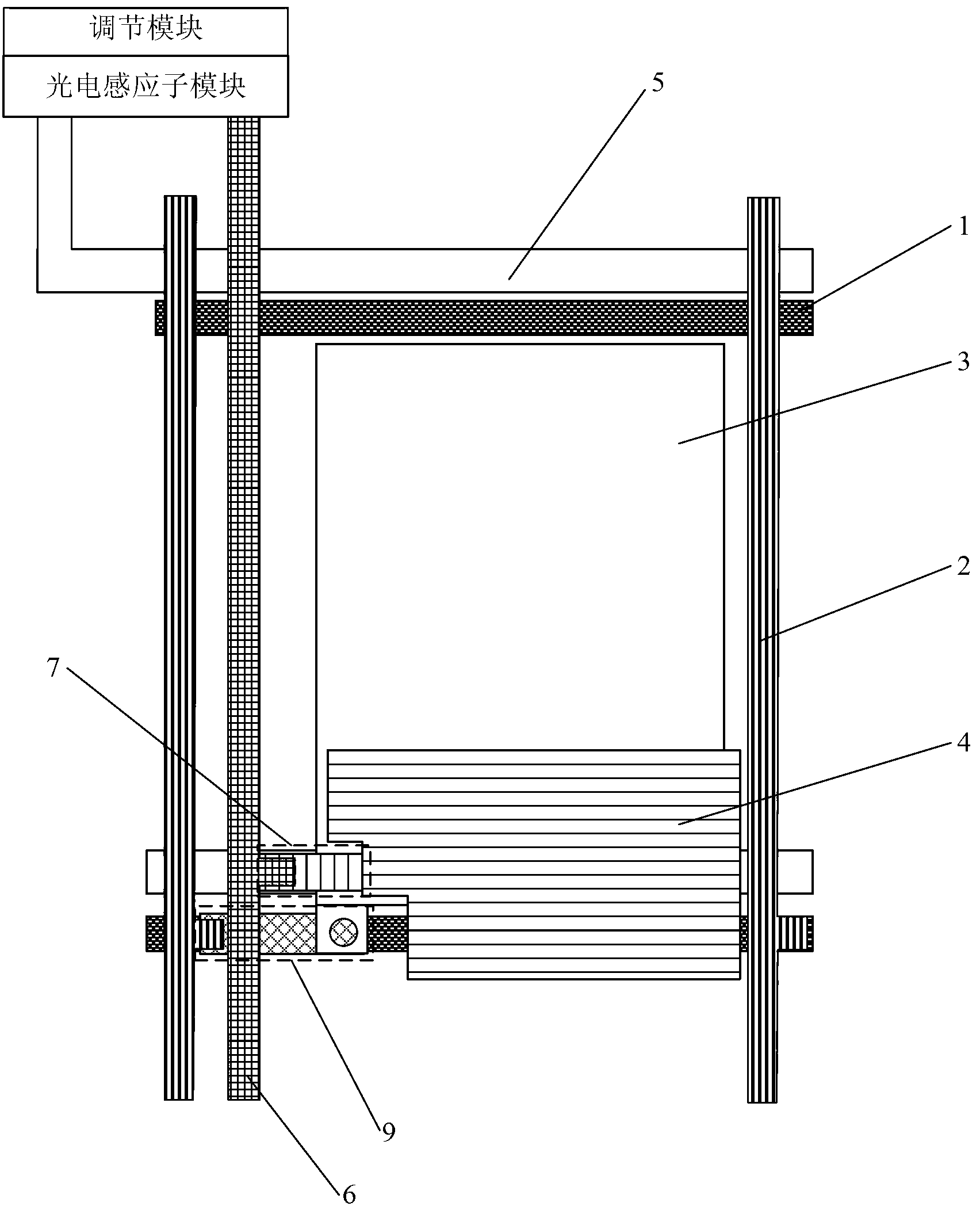

Array substrate and semi-permeable and half-reflecting LCD panel

The embodiment of the invention discloses an array substrate and a semi-permeability and half-reflecting LCD (Liquid Crystal Display) panel, and relates to the field of liquid crystal displays. The array substrate and the semi-permeability and half-reflecting LCD panel can improve the aperture opening ratio of the semi-permeability and half-reflecting LCD panel of the array substrate. The array substrate comprises grid lines and a plurality of sub pixel areas, wherein the grid lines are distributed in a crossed manner, the pixel areas are formed by the dividing of the data cables, each pixel area comprises a transmission region and a reflecting region, the array substrate further comprises an adjusting module, when external light intensity is smaller than pre-arranged light intensity, the adjusting module sends out conditioning signals, and the reflecting region is adjusted to be a vitreous state from a non-transparent state.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

Anti-sticking sand casting coating and preparation method thereof

InactiveCN108787996AHigh densityReduce voidsFoundry mouldsFoundry coresMulliteVolumetric Mass Density

The invention relates to an anti-sticking sand casting coating and a preparation method thereof, and belongs to the technical field of casting. According to the anti-sticking sand casting coating andthe preparation method thereof, a refractory aggregate is selected, an irreversible phase change is generated at a relatively low temperature and large expansion is generated, so that the surface of powder particles in a coating layer sintering shell is sintered more sufficiently, and the particles are in general adhesion due to surface fusion; the coating layer is in a glassy state, the gap of the coating layer is less, the density is higher, the shielding effects of element migration and diffusion are stronger, high-viscosity square quartz generated during high-temperature transformation canresist permeation of metal liquid, and the defect of mechanical sand sticking of castings can be prevented; and the line shrinkage coefficient differences between the glass state coating layer and the casting metal are also large after cooling, the cutting stress of the interface between the casting and the coating layer is increased, so that the coating layer and the casting are peeled off automatically, so that a casting with a smooth surface is obtained; and the thermal chemical stability of a generated mullite phase is high, the generated mullite phase is not easy to react with acid and alkaline oxides, and the prevention of the chemical sand sticking defects of castings is facilitated.

Owner:FOSHAN GAOMING DISTRICT ZHUAHE NEW MATERIAL TECH CO LTD

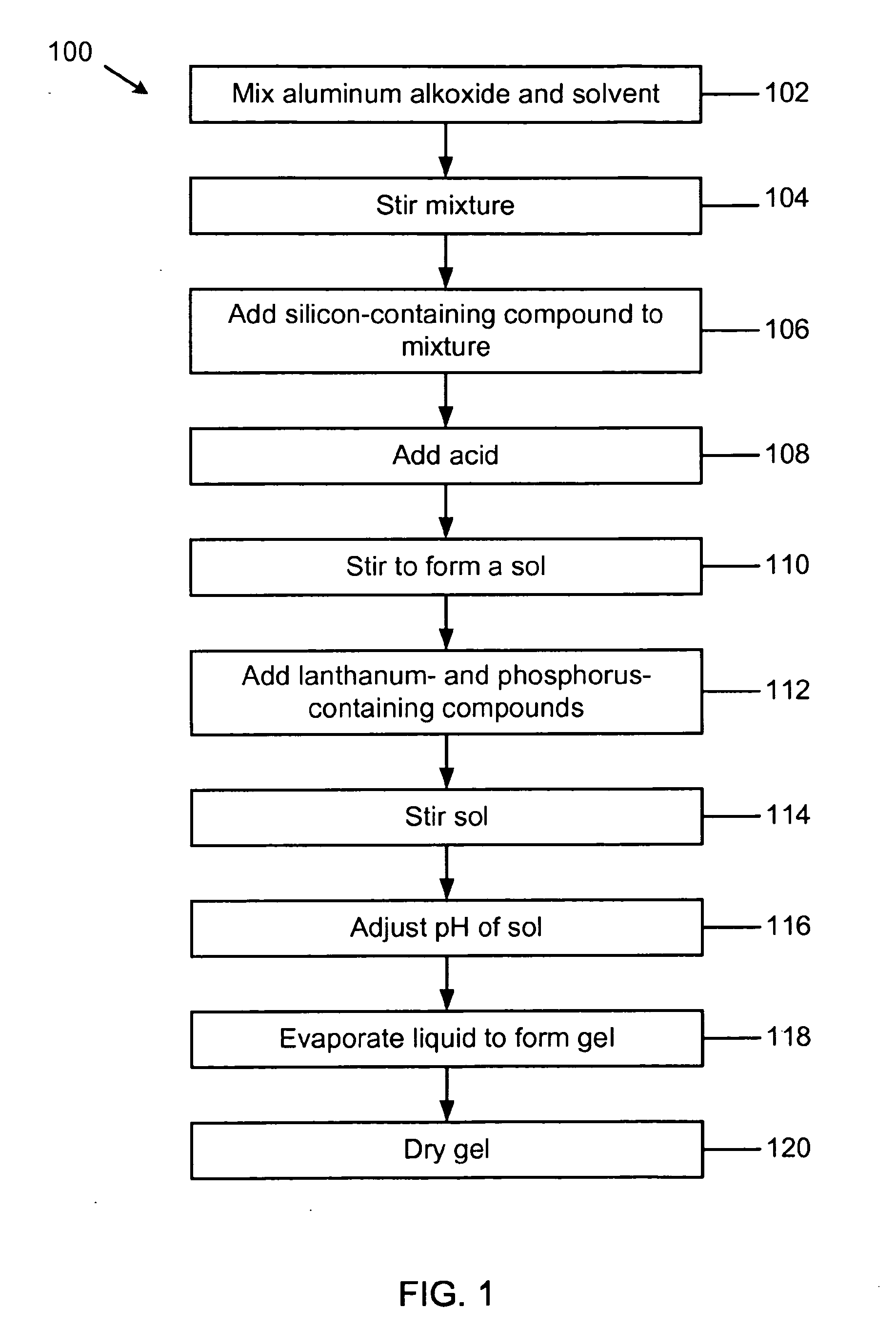

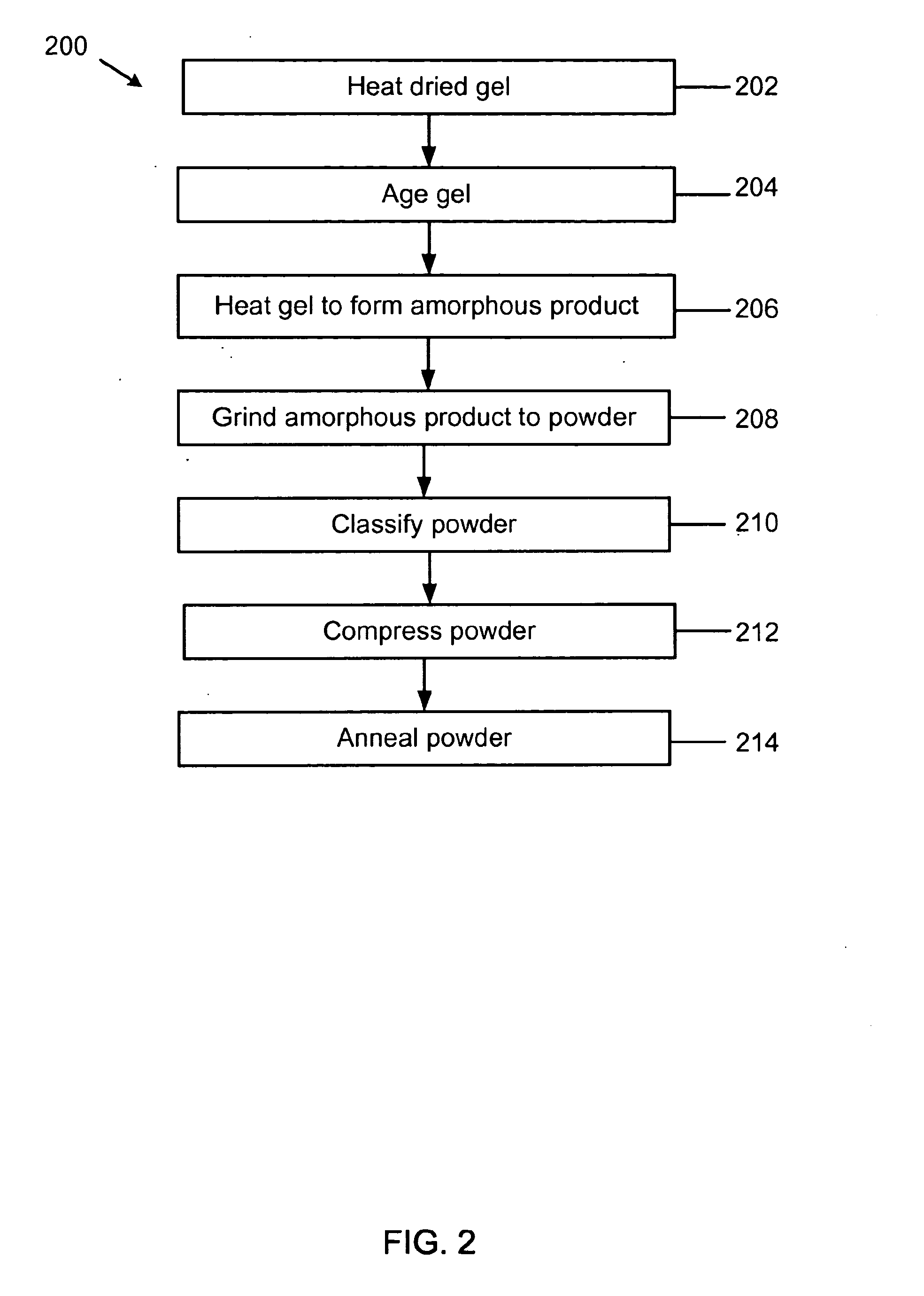

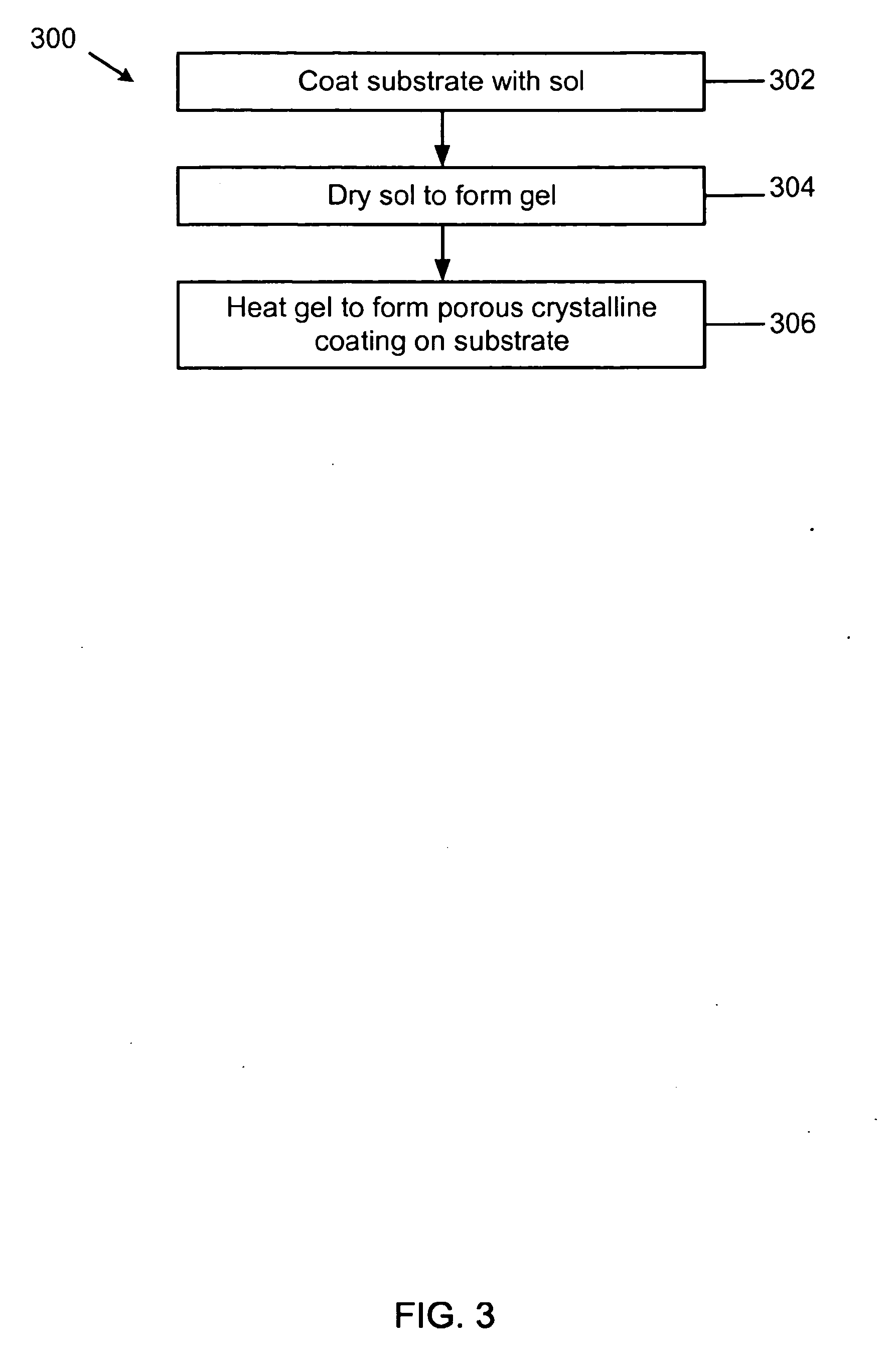

Refractory Porous Ceramics

A refractory, porous ceramic composite including crystalline mullite (3Al2O3+2SiO2 or 3Al6Si2O11) and a crystalline phase of LaPO4 is formed from a mullite-LaPO4 sol-gel by annealing the dried gel. During the annealing process, particle sintering and self-foaming occur in the glassy state, and pores are produced due at least in part to the release of entrapped gases that form during the pyrolysis of the gel. The resulting crystalline composite, or crystalline nanocomposite, has a high porosity and is dimensionally and chemically stable at high temperatures. The composite also has a high degree of structural (e.g., mechanical) stability, related at least in part to the fine texturing and mixing of the mullite and LaPO4 during preparation of the sol. The resulting ceramic composite shows little or no shrinkage or expansion between about 1000C and about 1200° C.

Owner:ARIZONA STATE UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com