Thin-film solar cell

A technology of solar cells and thin films, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as backwardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

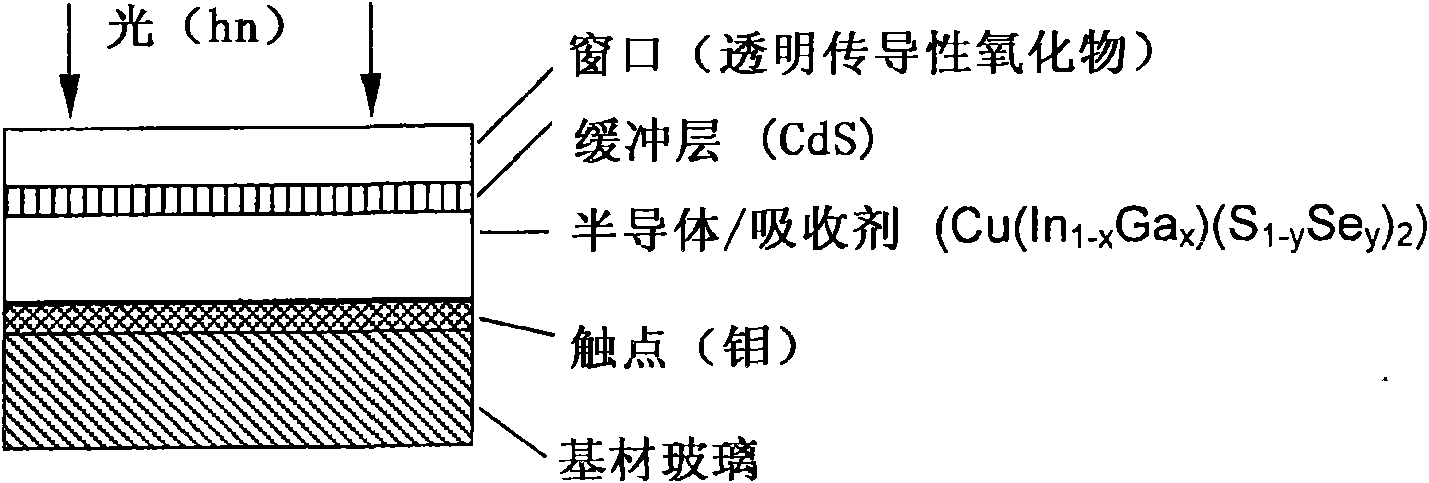

[0087] figure 1 Illustrates that the present invention has based on Cu (In 1-x Ga x )(S 1-y Se y ) 2 Schematic structure of a pn heterojunction planar thin-film solar cell.

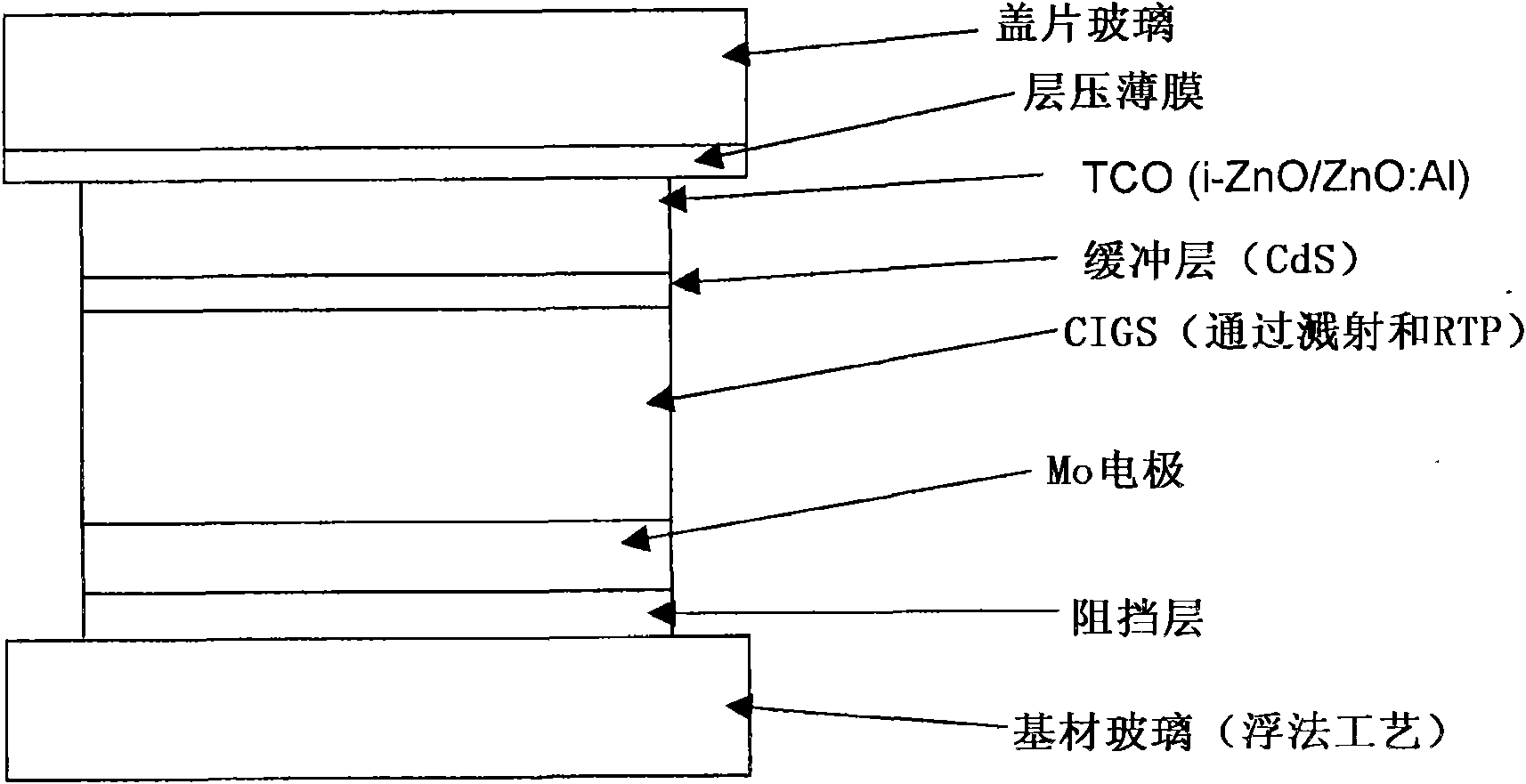

[0088] exist figure 1 In one embodiment shown in Table 2, a substrate glass having a glass composition of 2 and a Tg of 632°C was produced by a float process and cut into small pieces by a cemented carbide cutting tool. The substrate glass plate obtained in this way was cleaned according to standard industrial processes and coated with the following layer system: substrate glass / back contact (molybdenum, by sputtering technique) / absorber (CIGS, with Metal layer applied and subsequently reacted by "rapid thermal processing" in an environment containing chalcogens, RTP short, T 退火 >550°C) / buffer layer (CdS, by chemical bath deposition) / window layer (i-ZnO / ZnO:Al, by sputtering technique). Depending on the embodiment, module or solar cell, the integrated series connection is obtained by various inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com