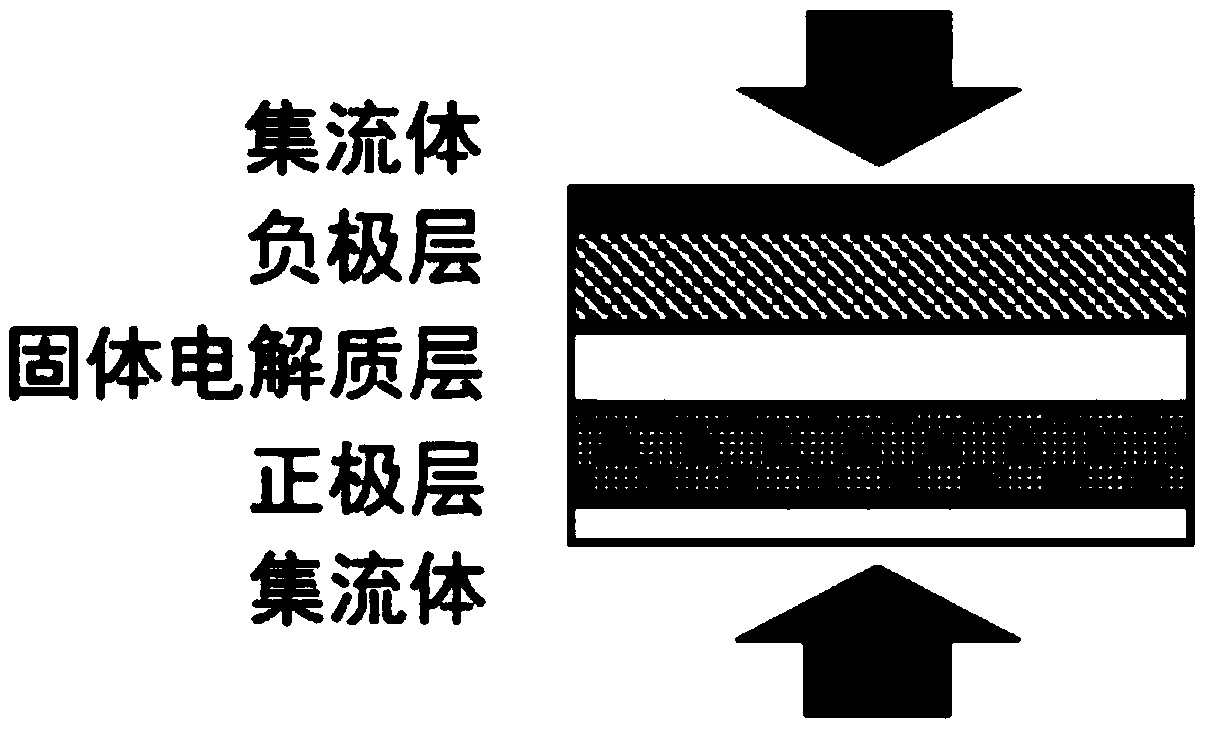

Full solid-state lithium-sulfur battery and manufacturing method thereof

A lithium-sulfur battery, all-solid-state technology, which is used in the manufacture of electrolyte batteries, battery electrodes, secondary batteries, etc., can solve the problems of poor rate performance of all-solid-state lithium-sulfur batteries, difficult to exert the sulfur capacity of active materials, and low ion transmission characteristics. , to improve the cycle life and Coulomb efficiency, improve the solid-solid interface problem, and solve the effect of dissolution and diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

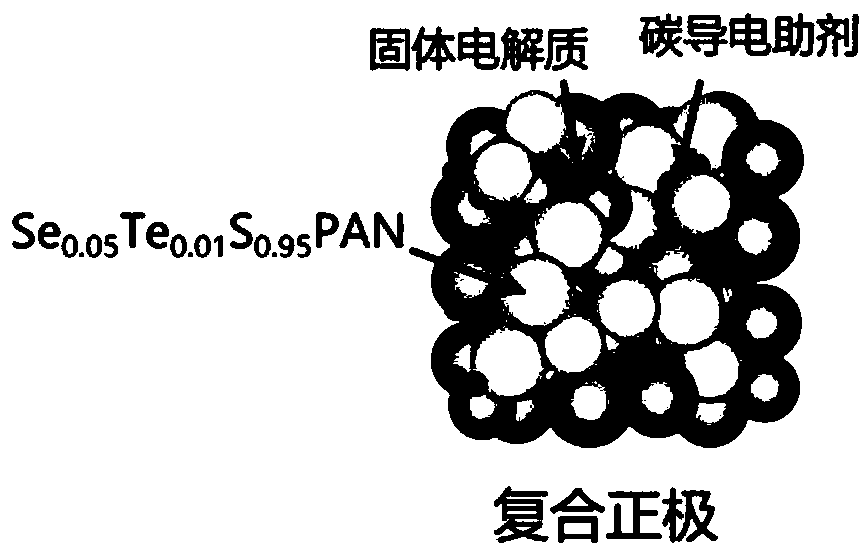

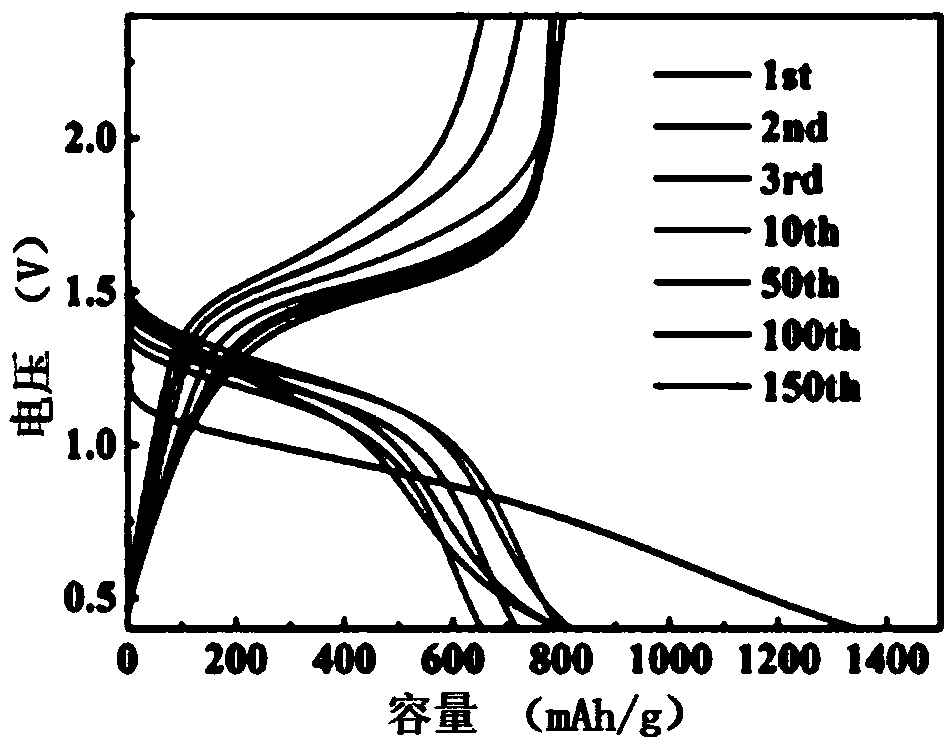

[0041] Sulfurized polyacrylonitrile doped with selenium and tellurium (Se 0.04 Te 0.01 S 0.95 @PAN), argentite-type Li 6 P.S. 5 The ratio of Br solid electrolyte and graphene is 6:2:2 to make composite positive electrode. The mixing method is one step: Se 0.04 Te 0.01 S 0.95 @PAN, graphene and argentite-type Li 6 P.S. 5 The Br solid electrolyte was mixed by wet ball milling at a speed of 100 rpm for 2 hours with heptane as the medium. Assembling a composite cathode by powder lamination│Sulphide-Argentite-type Li 6 P.S. 5 Br solid electrolyte│Li metal all-solid-state battery, and the battery was charged and discharged. Composite cathode load capacity 4~10mg / cm 2 .

Embodiment 2

[0043] Sulfurized polyacrylonitrile doped with selenium and tellurium (Se 0.04 Te 0.01 S 0.95 @PAN), Li 10 GeP 2 S 12 Type solid electrolyte and carbon nanotubes in a ratio of 4:3:3 to make a composite positive electrode. The mixing method is two steps (1) Se 0.04 Te 0.01 S 0.95 @PAN and carbon nanotubes were ball milled and mixed for 1 hour at a speed of 300rpm; (2) adding Li 10 GeP 2 S 12 Type solid electrolyte was ball milled and mixed for 20 minutes at a speed of 100 rpm. Assembling the composite cathode by powder lamination│Li 10 GeP 2 S 12 type solid electrolyte│Li-In alloy all-solid-state battery, and the battery was charged and discharged. Composite cathode load capacity 4~10mg / cm 2 .

Embodiment 3

[0045] Sulfurized polyacrylonitrile doped with selenium and tellurium (Se 0.04 Te 0.01 S 0.95 @PAN), argentite-type Li 7.25 Si 0.25 P 0.75 S 6 Solid electrolyte and Ketjen black are used in the ratio of 5:3:2 to make a composite positive electrode. The mixing method is two steps (1) Se 0.04 Te 0.01 S 0.95 @PAN and Ketjen black were ball milled and mixed for 1 hour at a speed of 300rpm; 7.25 Si 0.25 P 0.75 S 6 Type solid electrolyte into a vortex mixer and mix for 10 minutes. Assembling the composite cathode by powder lamination│Li 7.25 Si 0.25 P 0.75 S 6 Type solid electrolyte│Li-Si alloy all-solid-state battery, and charge and discharge tests were carried out on the battery. Composite cathode load capacity 4~10mg / cm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com