Online dyeing equipment and process for asynchronous dyeing of two colors

A dyeing equipment and color technology, applied in the field of online dyeing equipment and technology, can solve the problem that dyeing equipment and process methods have no papers or patent records, and achieve the effect of wide application scope, wide coverage and shortening production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

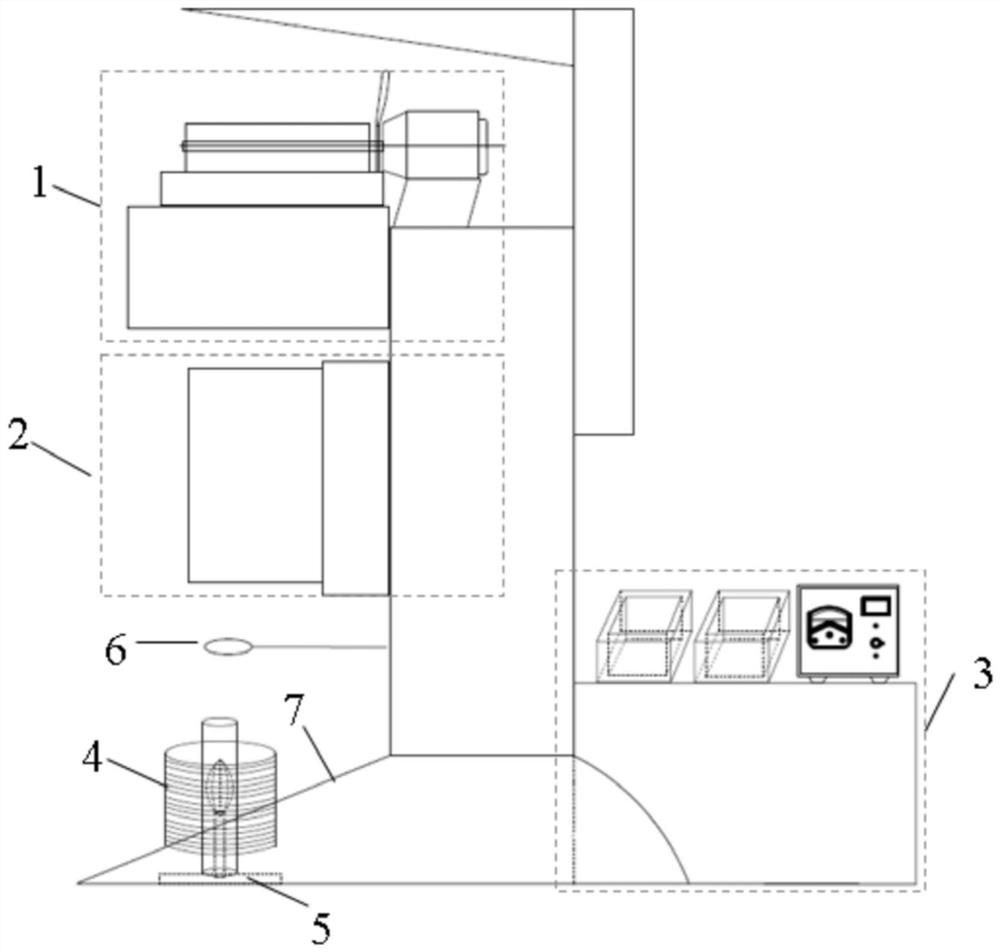

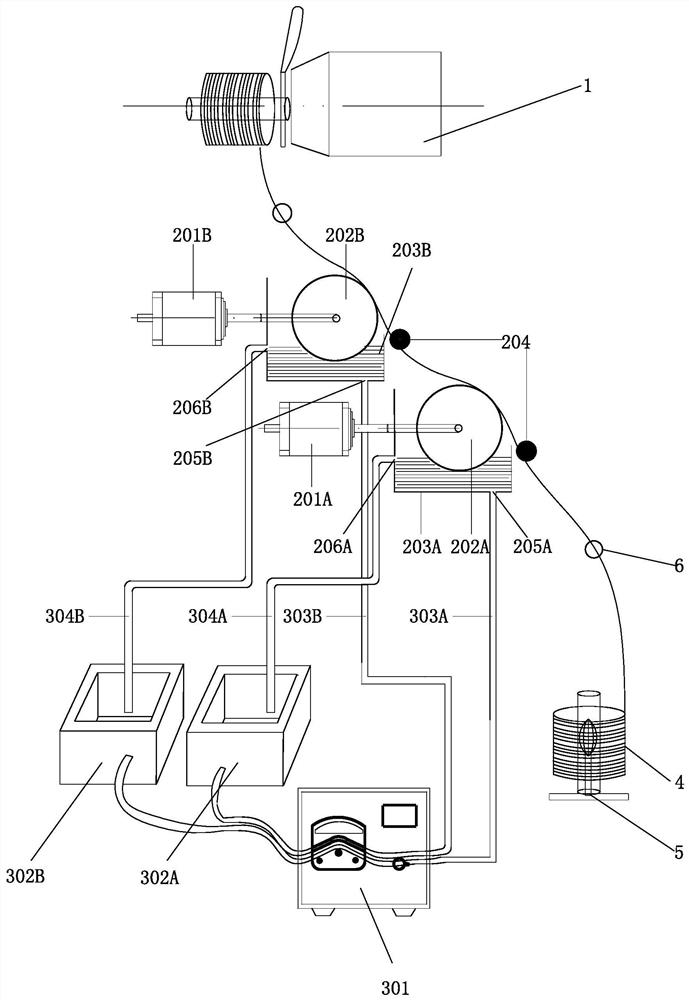

[0032] Such as Figure 1-2 As shown, the online dyeing equipment of the two colors not synchronously dyed, the online dyeing equipment is a winder with a dyeing unit 2 and a dye solution supply unit 3, and the online dyeing equipment consists of a bobbin winding device 1. Dyeing unit 2, dye solution supply unit 3, package yarn 4, yarn carrier base 5, balloon breaker 6 and equipment base 7, the balloon breaker 6 is fixed on the equipment base 7, the balloon breaker 6 Uniform high-speed axial unwinding tension of the yarn, reduce and prevent loop breakage, and achieve the purpose of improving productivity. The dyeing unit 2 is arranged between the package yarn 4 and the package yarn winding device 1, and the dyeing unit 2 includes 1# dyeing tank 203A and 2# dyeing tank 203B, described 1# dyeing tank 203A is provided with 1# dyeing runner 202A, and described 2# dyeing tank 203B is provided with 2# dyeing runner 202B, and described dye liquor Supply unit 3 comprises 1# dye soluti...

Embodiment 2

[0039] The on-line dyeing process that the two colors are dyed asynchronously comprises the following steps:

[0040] (1) Dye solution configuration: 1% (mass percentage) of reactive red dye and 2% (mass percentage) of reactive blue dye were dissolved in ethanol 30% (mass percentage), water 69.5% (mass percentage), and penetrant 0.5% (mass percentage) system, add 30g / L soda ash, and keep stirring until the dye is completely dissolved.

[0041] (2) Use the peristaltic pump to supply the prepared dye solution to the dyeing tank of the improved loose winder. The 2# dyeing tank is reactive red dye, and the 1# dyeing tank is reactive blue dye. The peristaltic pump slowly adds liquid at a speed of 10 rpm. Carry out loose winding to yarn, the speed of winding machine is 800m / min, the rotating speed of 2# dyeing runner is 30r / min, and the rotating speed of 1# dyeing runner is 15r / min. The dyeing liquid is brought up by the high-speed rotating dyeing wheel, and quickly adheres and pe...

Embodiment 3

[0045] The on-line dyeing process that the two colors are dyed asynchronously comprises the following steps:

[0046] (1) Dye solution configuration: 2% (mass percentage) of reactive blue dye and 2% (mass percentage) of reactive red dye were dissolved in ethanol 20% (mass percentage), water 79% (mass percentage), and penetrant 1% (mass percentage) system, add 40g / L soda ash and stir continuously until the dye is completely dissolved.

[0047] (2) Use the peristaltic pump to supply the prepared dyeing solution to the dyeing tank of the improved loose winder, the 2# dyeing tank is reactive blue dye, and the 1# dyeing tank is reactive red solution. The peristaltic pump slowly adds liquid at a speed of 8 rpm. The flax yarn is loosely wound, the speed of the winding machine is 600m / min, the rotating speed of the 2# dyeing wheel is 40r / min, and the rotating speed of the 1# dyeing wheel is 20r / min. The dyeing liquid is brought up by the high-speed rotating dyeing wheel, and quickly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com