Durable film composite substrate for laminating card manufacturing and manufacturing process

A composite substrate, durable technology, applied in the field of laminated cards, can solve the problem of not meeting the requirements of digital printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) Prepare the emulsion required for the connection layer, composite glue, back glue A and back glue B

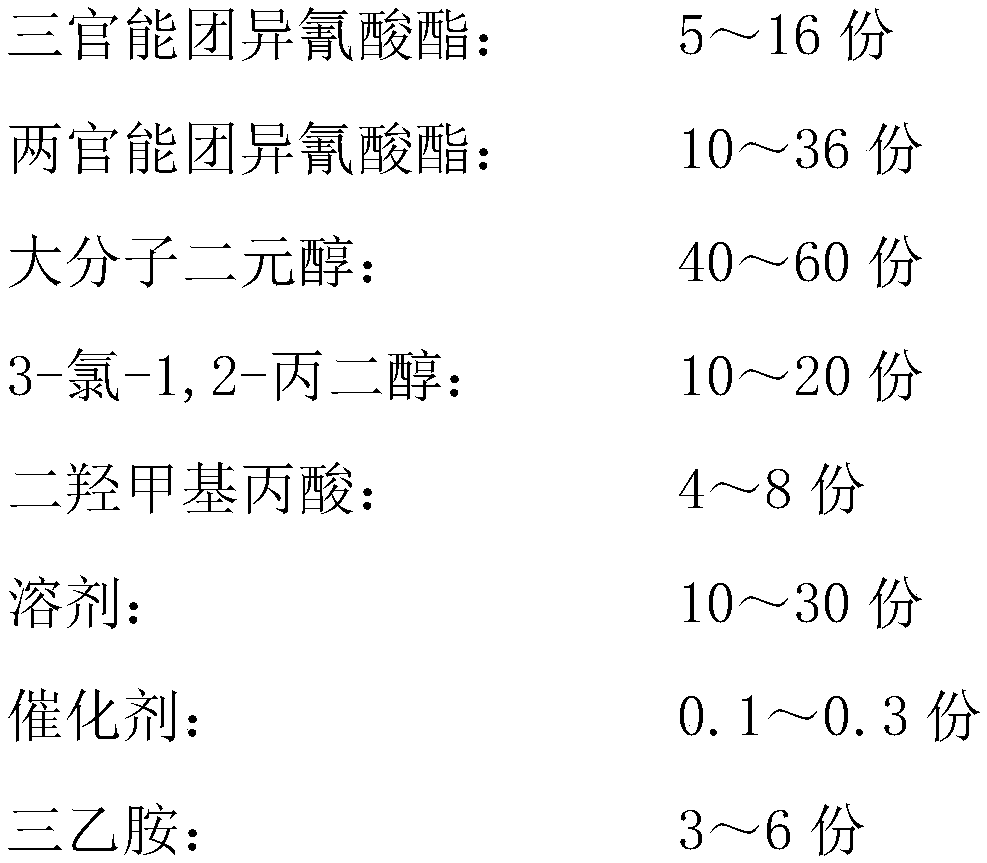

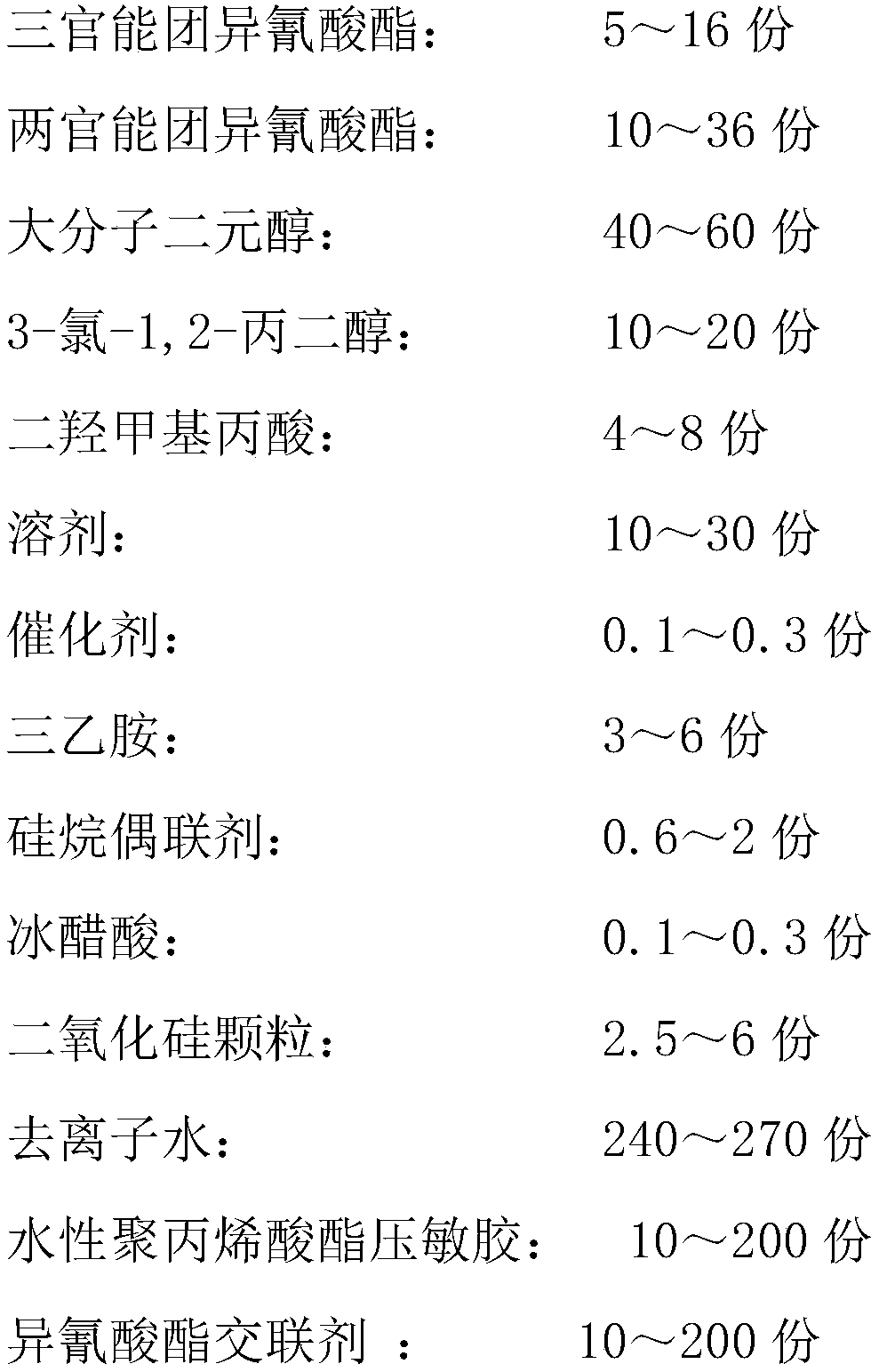

[0049] Under nitrogen atmosphere, in the reaction vessel that stirrer and reflux condenser are equipped with, add 5 parts of hexamethylene diisocyanate trimers, 16 parts of hexamethylene diisocyanates, 20 parts of isophorone diisocyanates, 25 parts of poly 2,4-dichloro-1,6-adipic acid-1,6-hexanediol ester diol with a number average molecular weight of 4000, 26 parts of poly 2,4-diol with a number average molecular weight of 6000 Chloro-1,6-adipic acid-1,3-propylene glycol ester diol, 8 parts of dimethylol butyric acid, 30 parts of dimethyl carbonate, 0.1 part of dibutyltin dilaurate are mixed evenly, and the control The temperature is 90°C, react for 3 hours, cool down to 40°C, add 6 parts of triethylamine and stir evenly to obtain polyurethane prepolymer; under nitrogen environment, add 270 parts of deionized water, 1 part of γ-aminopropyltriethoxysilane, 0.2 part...

Embodiment 2

[0058] (1) Prepare the emulsion required for the connection layer, composite glue, back glue A and back glue B

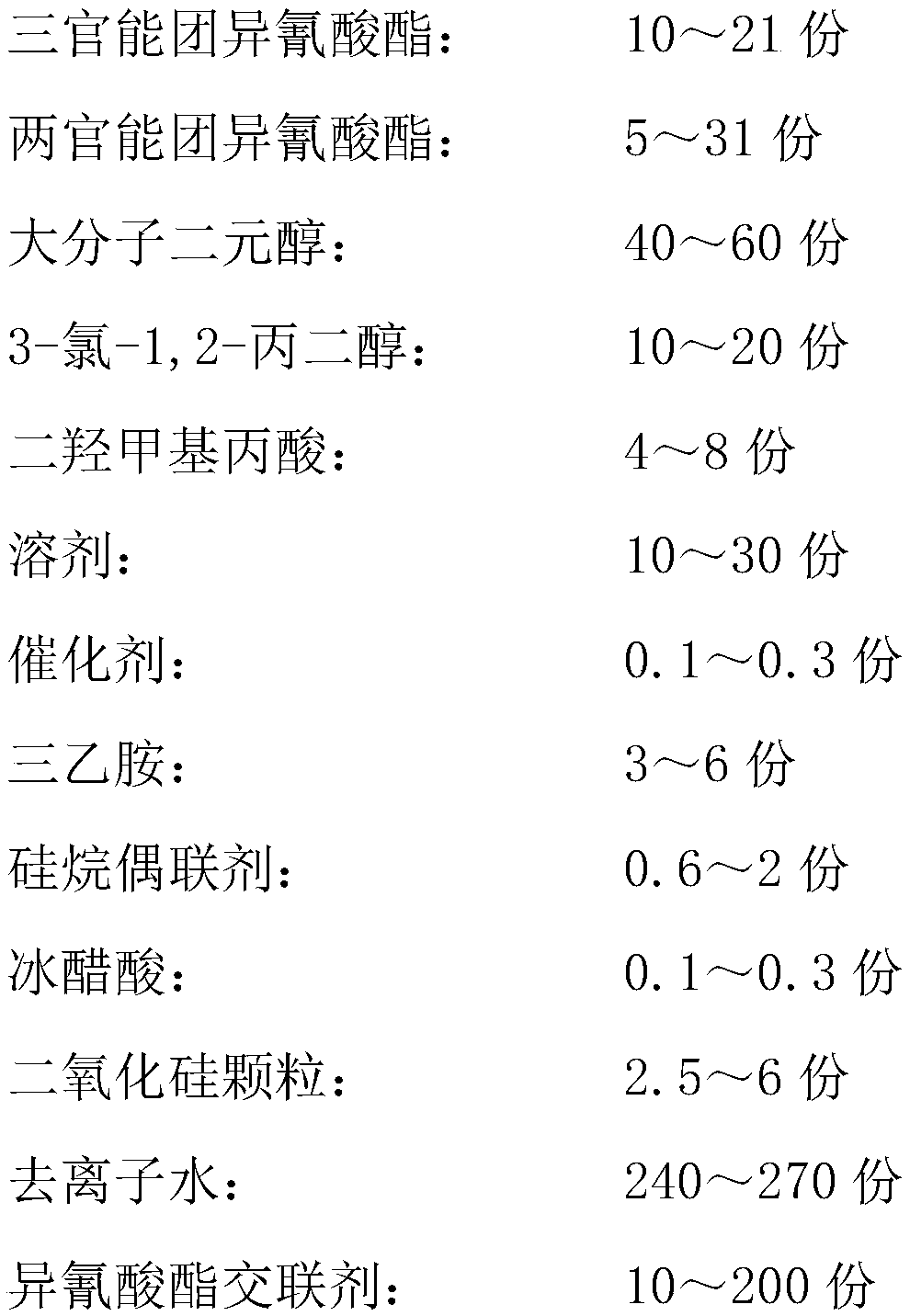

[0059] Under nitrogen atmosphere, in the reaction vessel that stirrer and reflux condenser are equipped with, add 16 parts of hexamethylene diisocyanate trimers, 5 parts of hexamethylene diisocyanates, 5 parts of isophorone diisocyanates, 25 parts of poly 2,4-dichloro-1,6-adipic acid-1,6-hexanediol ester diol with a number average molecular weight of 4000, 26 parts of poly 2,4-diol with a number average molecular weight of 6000 Chloro-1,6-adipic acid-1,3-propylene glycol ester glycol, 8 parts of dimethylol butyric acid, 30 parts of dimethyl carbonate, and 0.1 part of dibutyltin dilaurate are mixed evenly, and the control The temperature is 90°C, react for 3 hours, cool down to 40°C, add 6 parts of triethylamine and stir evenly to obtain polyurethane prepolymer; under nitrogen environment, add 270 parts of deionized water, 1 part of γ-aminopropyltriethoxysilane, 0.2...

Embodiment 3

[0068] (1) Prepare the emulsion required for the connection layer, composite glue, back glue A and back glue B

[0069] Under nitrogen atmosphere, in the reaction vessel that stirrer and reflux condenser are equipped with, add 16 parts of hexamethylene diisocyanate trimers, 5 parts of hexamethylene diisocyanates, 5 parts of isophorone diisocyanates, 25 parts of poly 2,4-dichloro-1,6-adipic acid-1,6-hexanediol ester diol with a number average molecular weight of 4000, 26 parts of poly 2,4-diol with a number average molecular weight of 6000 Chloro-1,6-adipic acid-1,3-propylene glycol ester glycol, 8 parts of dimethylol butyric acid, 30 parts of dimethyl carbonate, and 0.1 part of dibutyltin dilaurate are mixed evenly, and the control The temperature is 90°C, react for 3 hours, cool down to 40°C, add 6 parts of triethylamine and stir evenly to obtain polyurethane prepolymer; under nitrogen environment, add 270 parts of deionized water, 1 part of γ-aminopropyltriethoxysilane, 0.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com