Steel hot molten slag mineral cotton and its making method

A technology of hot slag and mineral wool, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problem that heat cannot be recycled, achieve good economic and social benefits, save energy, and have a wide acidity coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A kind of iron and steel hot slag mineral wool, its raw material composition mass percentage is:

[0046] Liquid blast furnace slag 70%

[0047] Conditioner 30%

[0048] The particle size of the conditioning material is 40-80 mesh; the conditioning material is composed of albite and silica sand.

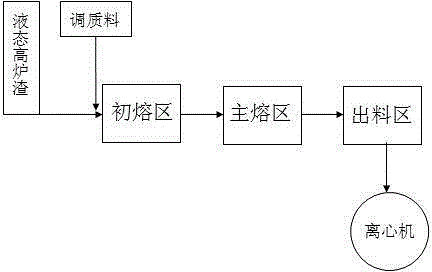

[0049] A method for preparing iron and steel hot slag mineral wool (for the process flow, see image 3 ), the steps are:

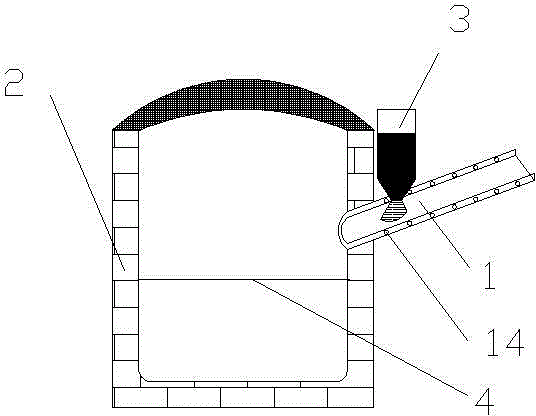

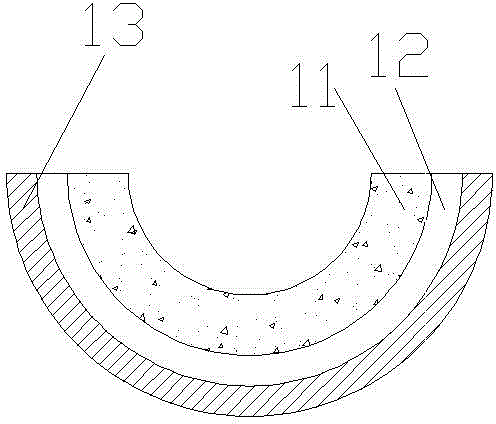

[0050] ①Introduce the hot blast furnace slag directly into the primary melting zone of the slag furnace 2 through the slag tank 1, place the hopper 3 above the junction of the slag tank 1 and the slag furnace 2, and install the conditioning material in the hopper 3, and the conditioning material Together with the hot blast furnace slag, it enters into the initial melting zone of the slag furnace 2 (see figure 1 ). Such as figure 2 As shown, the cross-section of the slag tank 1 is semicircular, and the slag tank 1 is a composite structu...

Embodiment 2

[0057] A kind of iron and steel hot slag mineral wool, its raw material composition mass percentage is:

[0058] Liquid blast furnace slag 80%

[0059] Conditioner 20%

[0060] The particle size of the tempering material is 40-60 mesh; the tempering material is composed of albite, silica sand and basalt.

[0061] A method for preparing iron and steel hot slag mineral wool, the steps are:

[0062] ①Introduce the hot blast furnace slag directly into the primary melting zone of the slag furnace 2 through the slag tank 1, place the hopper 3 above the junction of the slag tank 1 and the slag furnace 2, and install the conditioning material in the hopper 3, and the conditioning material Together with the hot blast furnace slag, it enters into the initial melting zone of the slag furnace 2 (see figure 1 ). Such as figure 2 As shown, the cross-section of the slag tank 1 is semicircular, and the slag tank 1 is a composite structure. The slag tank 1 includes a refrac...

Embodiment 3

[0069] A kind of iron and steel hot slag mineral wool, its raw material composition mass percentage is:

[0070] Liquid blast furnace slag 85%

[0071] Conditioner 15%

[0072] The particle size of the tempering material is 40-80 mesh; the tempering material is composed of albite and basalt.

[0073] A method for preparing iron and steel hot slag mineral wool, the steps are:

[0074]①Introduce the hot blast furnace slag directly into the primary melting zone of the slag furnace 2 through the slag tank 1, place the hopper 3 above the junction of the slag tank 1 and the slag furnace 2, and install the conditioning material in the hopper 3, and the conditioning material Together with the hot blast furnace slag, it enters into the initial melting zone of the slag furnace 2 (see figure 1 ). Such as figure 2 As shown, the cross-section of the slag tank 1 is semicircular, and the slag tank 1 is a composite structure. The slag tank 1 includes a refractory material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com