Sunroom skylight system and manufacturing method thereof

A sun room and skylight technology, applied in skylights/domes, windows/doors, building structures, etc., can solve problems such as insufficient thermal insulation effect, unprotected rotating shaft parts, and easily affected skylight glue. Achieve the effect of avoiding accelerated aging, fast assembly, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Such as Figure 1-9 shown.

[0059] A skylight system for a sunshine room, including a frame profile 1, a fan profile, glass 9 and a water draping plate 6,

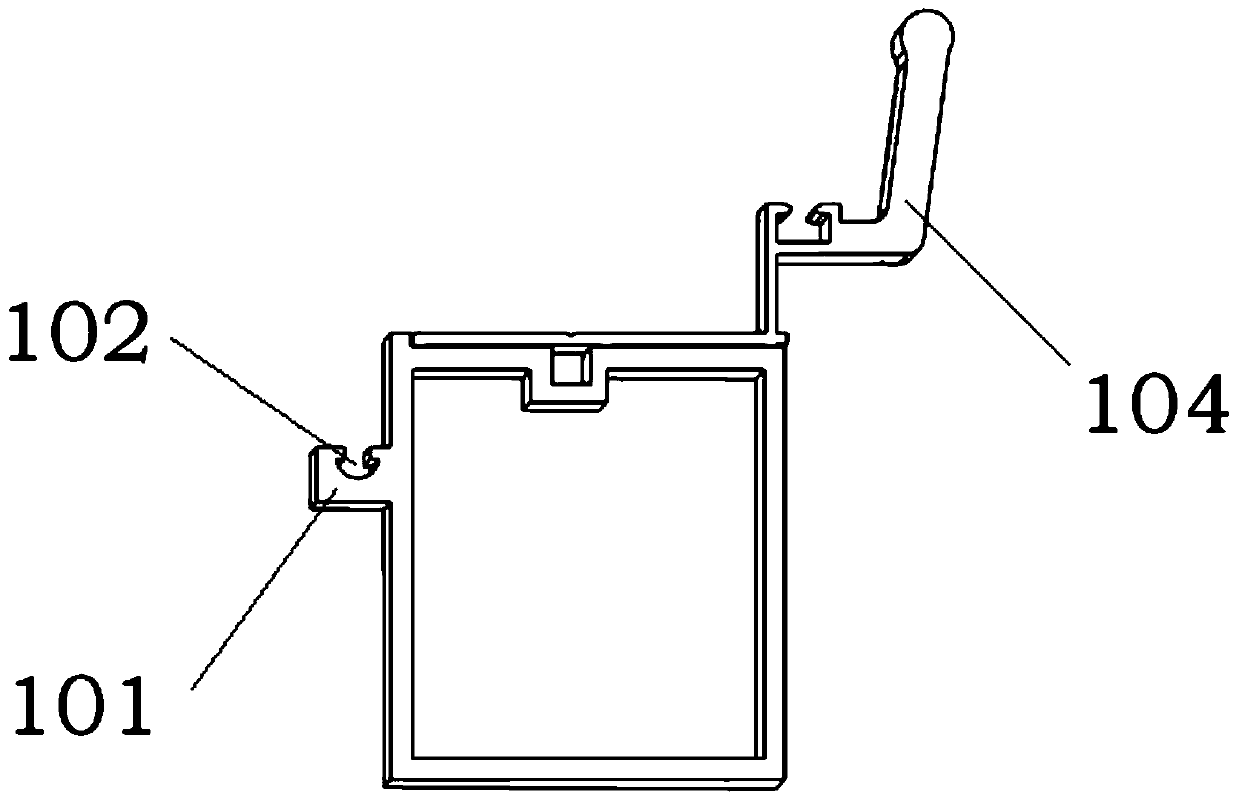

[0060] One end of the frame profile 1 is provided with a frame rotating shaft 104, the surface of one end of the frame rotating shaft 104 is arc-shaped, the frame profile 1 is provided with a boss 101, and the frame rotating shaft 104 is lapped on the aluminum plate;

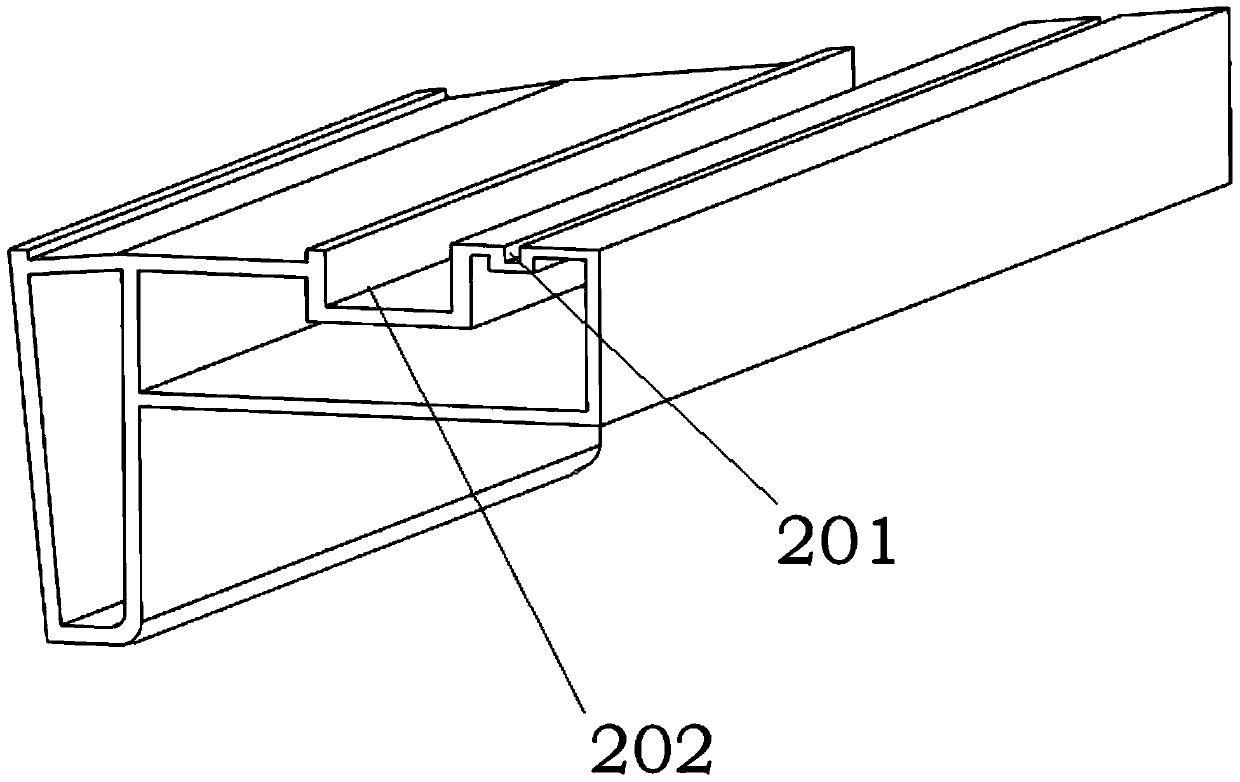

[0061] The fan profile includes a lower support seat 2, an upper support seat 4, and a T-shaped rotating member 3; the lower supporting seat 2 and the T-shaped rotating member 3 are arranged side by side, and the upper supporting seat 4 is arranged on the lower supporting seat 2 and the T-shaped rotating member 3 Above, one end of the T-shaped rotating member 3 is provided with an arc-shaped groove 302, the arc-shaped groove 302 is matched and connected with the frame shaft 104, and the lower support seat 2 is connected with the boss 101;

[0062] ...

Embodiment 2

[0072] A manufacturing method for the sunshine room skylight system described in Embodiment 1, comprising the following steps:

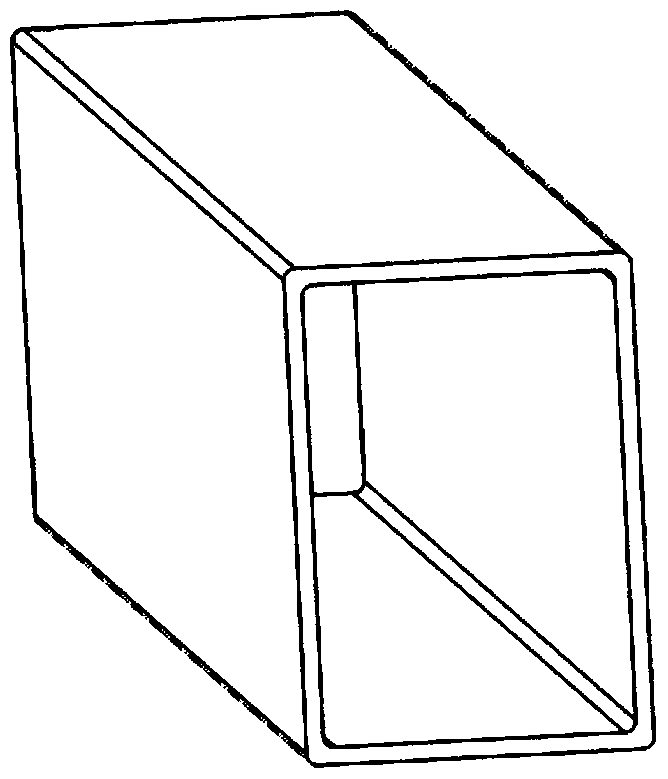

[0073] (1) Carry out blanking and cutting in the workshop, assemble the material plates into a frame profile 1 by welding, fix the frame steel lining 103 inside the frame profile 1; assemble the material plates into a lower support seat 2 and an upper support seat 4 by welding , the T-shaped rotating part 3 is obtained by non-welding, directly processing the material plate;

[0074] (2), the frame rotating shaft 104 is fixed on the frame profile 1 by self-tapping screws;

[0075] (3) Lap the T-shaped rotating part 3 with the lower supporting seat 2, and then place the upper supporting seat 4 so that the upper supporting seat 4 presses the T-shaped rotating part 3, and place the glass 9 on the upper supporting seat 4 , and then apply silicone structural sealant between the upper support seat 4 and the glass 9;

[0076] (4), place the end cover plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com