A kind of rapid preparation method of c/c composite material

A composite material and fast technology, which is applied in the field of rapid preparation of C/C composite materials, can solve the problems of high mold requirements for grouting equipment, unfavorable product diversification production, and poor controllability of material structure, so as to improve universal applicability, The effect of shortening the later densification time and shortening the preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

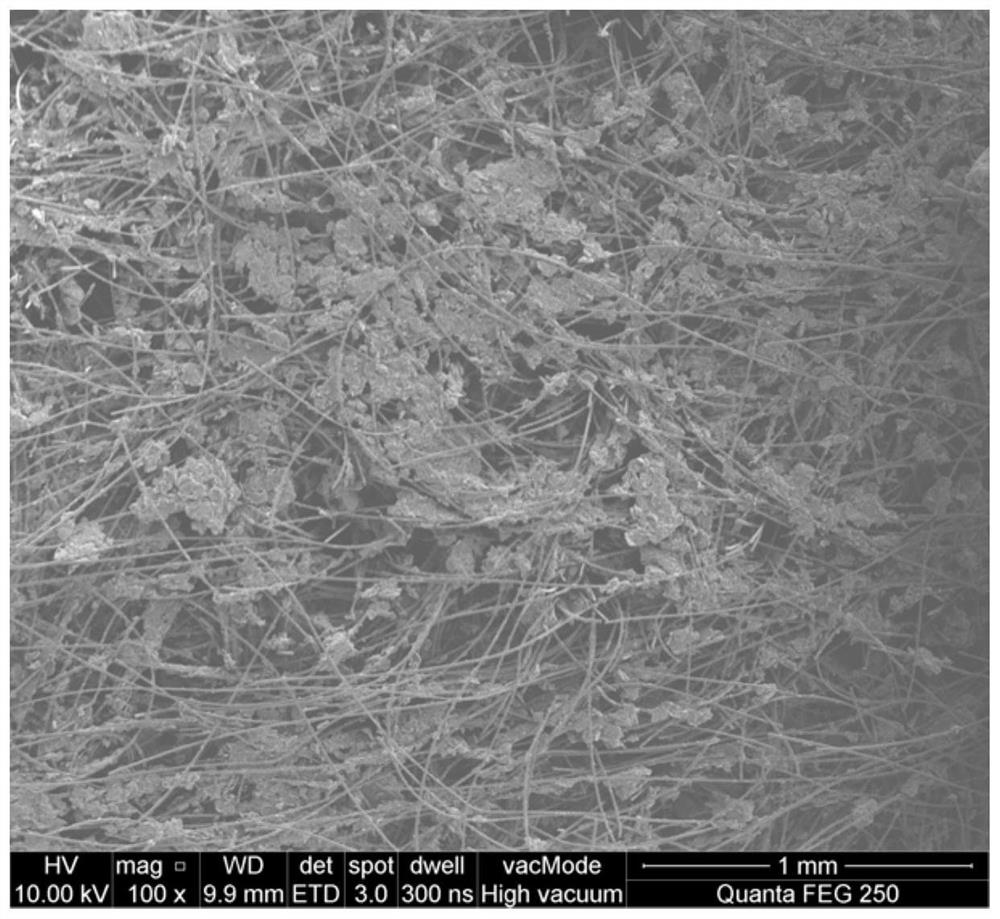

Image

Examples

Embodiment 1

[0049] The invention provides a kind of rapid preparation method of C / C composite material, comprising the following steps:

[0050] (1) A 2.5D carbon fiber prefabricated body is prepared by needle punching, with a thickness of 100mm;

[0051] (2) Put the above-mentioned carbon fiber prefabricated body into a vacuum heating furnace for heat treatment, the heating temperature is 1100°C, the heating time is 1.5h, and the pressure is controlled within 300pa to obtain a degummed prefabricated body;

[0052] (3) Preparation of water-based graphite slurry: Flake graphite powder (800 mesh), sodium carboxymethyl cellulose (dispersant), epoxy resin aqueous solution, and deionized water are in a mass ratio of 15:2:20:63 Configured as graphite water-based slurry, mechanically stirred for 30 minutes and then ball milled, the ball milling time was 2 hours, and the ball milling speed was 200r / min;

[0053] (4) Slurry injection: Utilize the injection method to inject the water-based graphit...

Embodiment 2

[0059] The invention provides a kind of rapid preparation method of C / C composite material, comprising the following steps:

[0060] (1) 2.5D pre-oxidized polyacrylonitrile fiber prefabricated body is obtained by acupuncture, and the thickness is 50mm;

[0061] (2) Put the above-mentioned pre-oxidized polyacrylonitrile fiber prefabricated body into a vacuum heating furnace for slow heating and heat treatment. The body is carbonized to obtain a carbon fiber prefabricated body;

[0062] (3) Preparation of water-based graphite slurry: flake graphite powder (800 mesh), sodium carboxymethyl cellulose (dispersant), epoxy resin aqueous solution, and deionized water are in a mass ratio of 20:1:15:65 Configured as graphite water-based slurry, mechanically stirred for 30 minutes and then ball milled, the ball milling time was 2 hours, and the ball milling speed was 200r / min;

[0063] (4) Slurry injection: Utilize the injection method to inject the water-based graphite slurry into the ...

Embodiment 3

[0069] The invention provides a kind of rapid preparation method of C / C composite material, comprising the following steps:

[0070] (1) A 3D carbon fiber prefabricated body is prepared by three-dimensional puncture, with a thickness of 50mm;

[0071] (2) Put the above-mentioned carbon fiber prefabricated body into a vacuum heating furnace for heat treatment, the heating temperature is 1000° C., the heating time is 1 h, and the pressure is controlled within 300 Pa to obtain a degummed prefabricated body;

[0072] (3) Preparation of water-based graphite slurry: flake graphite powder, sodium carboxymethylcellulose+polyethylene glycol (composite dispersant, mass ratio 3:1), epoxy resin aqueous solution, and deionized water are mixed according to the mass ratio 20:2:15:63 to configure graphite water-based slurry, the graphite powder used is 500 mesh and 1000 mesh, and the mass ratio is 3:7. After mechanical stirring for 30 minutes, ball milling is carried out. The ball milling tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com