A spherical automatic machine tool

A technology of automatic machine tools and manipulators, which is applied in the direction of metal processing machinery parts, turning equipment, feeding devices, etc., can solve the problem of not developing a complete set of spherical automatic machine tools, achieve precise control of spherical turning trajectory, improve processing quality, and be universal strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

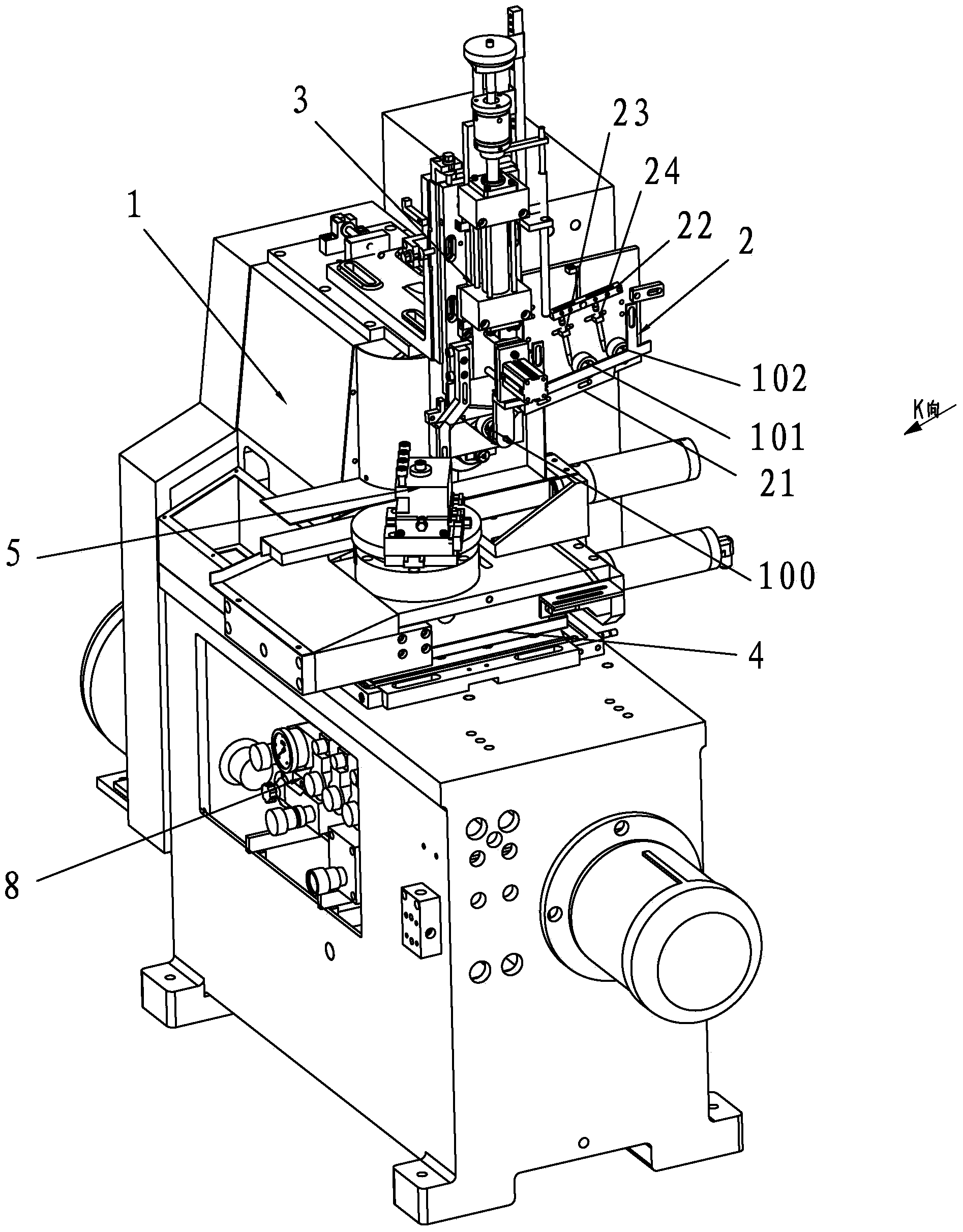

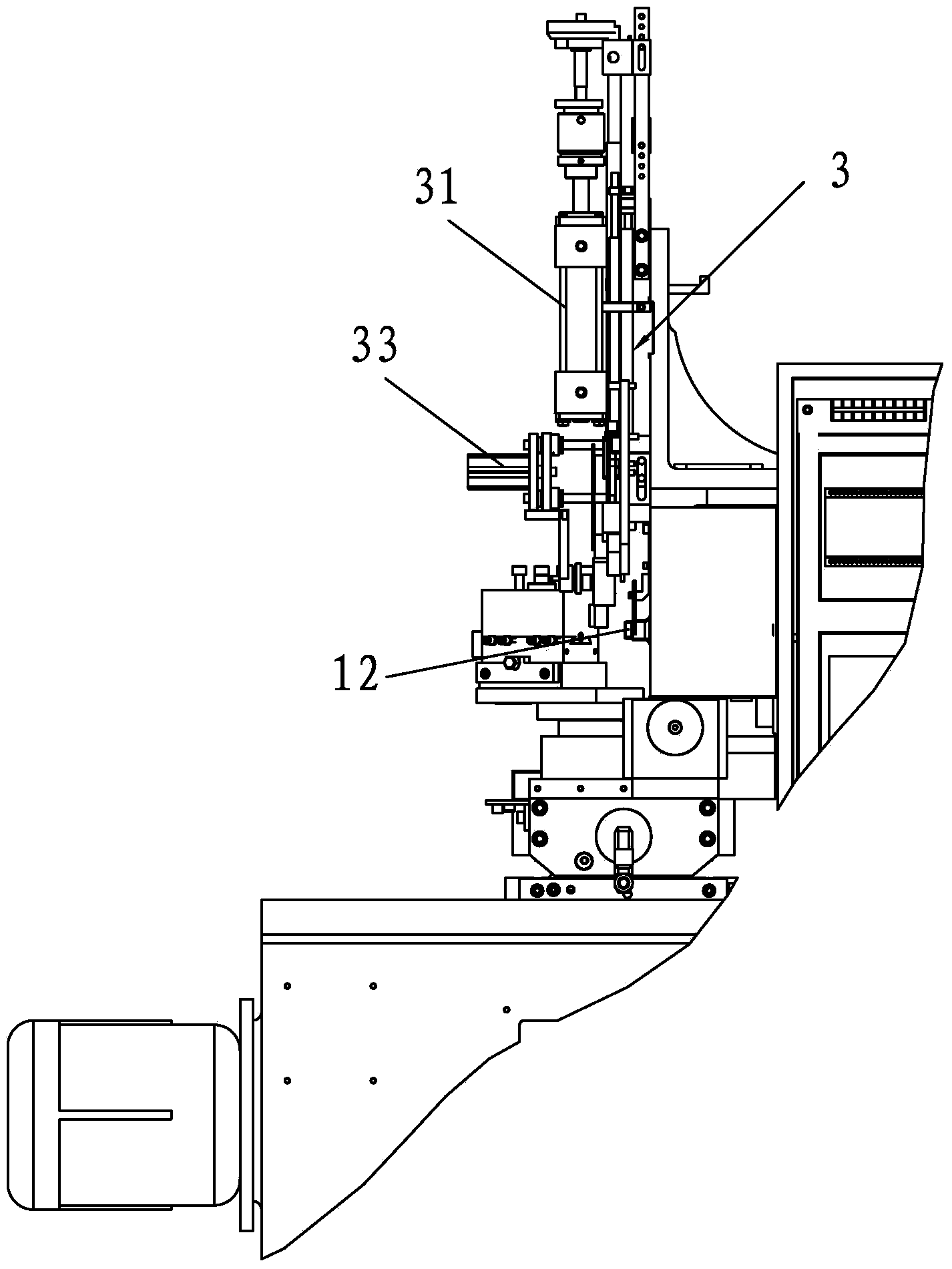

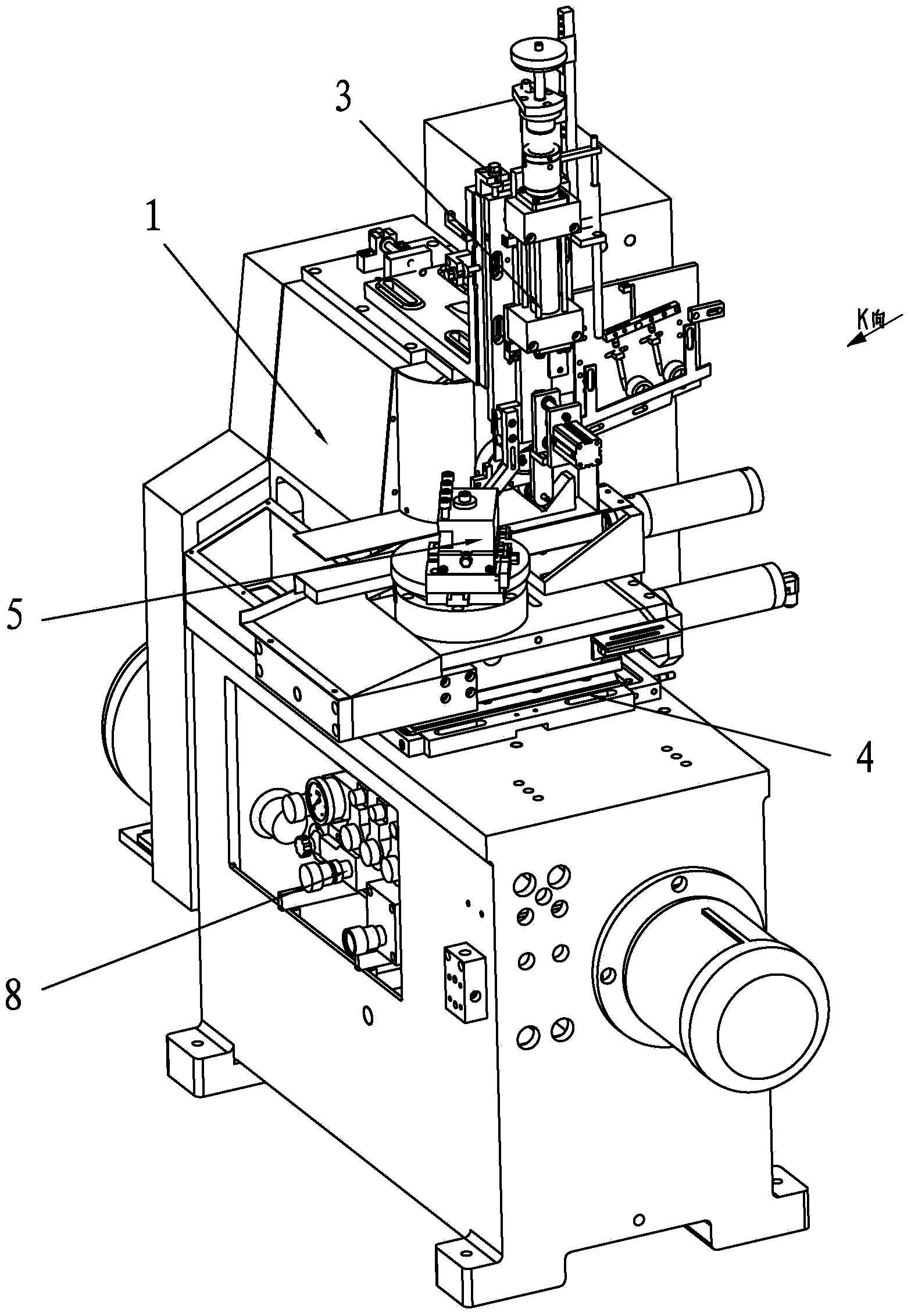

[0040] A spherical automatic machine tool, the main components include: a spindle mechanism 1, a feeding track 2, a manipulator mechanism 3, a carriage mechanism 4, a tool 5, and a material return mechanism 6.

[0041] The main working process of the present invention is that the main shaft mechanism 1 provides the power for bearing rotation, the product to be processed is fed from the feed rail 2, and is installed on the main shaft mechanism 1 through the manipulator mechanism 3, and then the carriage mechanism 4 drives the tool 5 to feed Turning action, after the processing is completed, the carriage mechanism 4 drives the tool 5 to withdraw the tool, and the material withdrawal mechanism 6 withdraws the processed bearing product from the spindle mechanism 1, and completes a product processing. The specific structures and principles o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com