Patents

Literature

35results about How to "Keep excellent performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

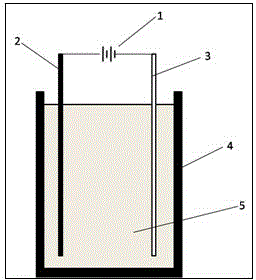

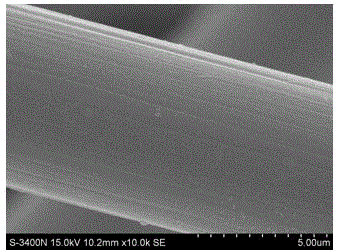

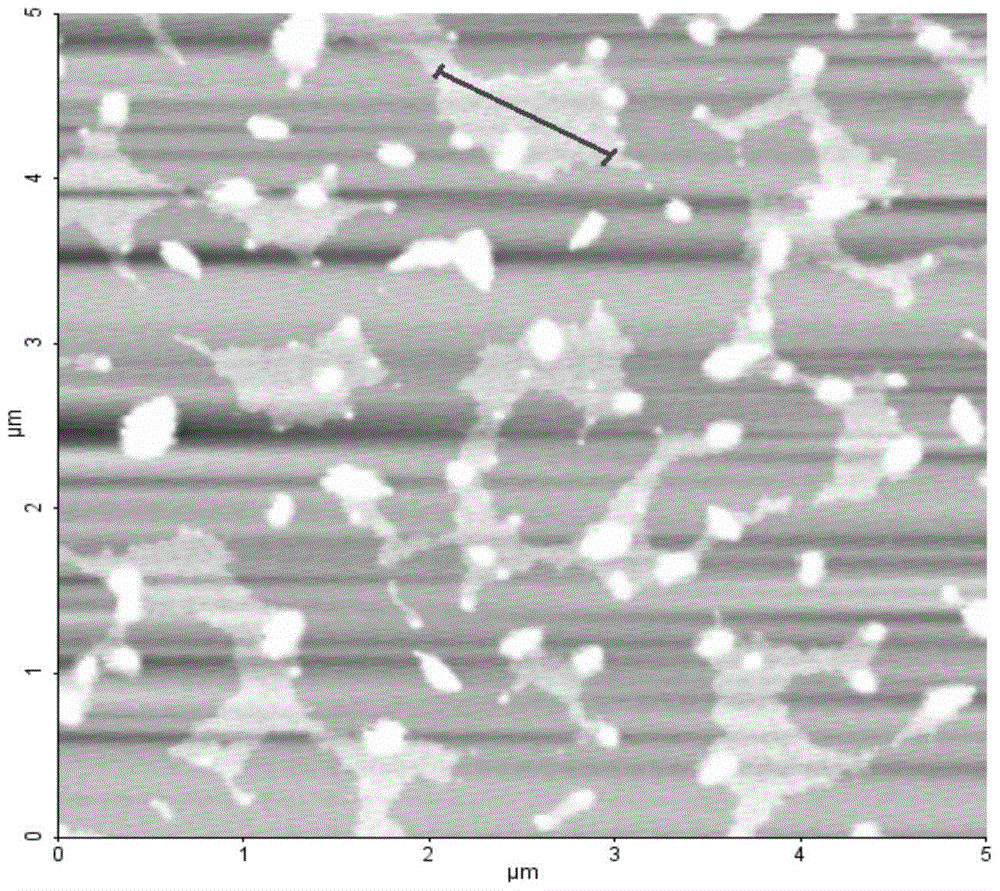

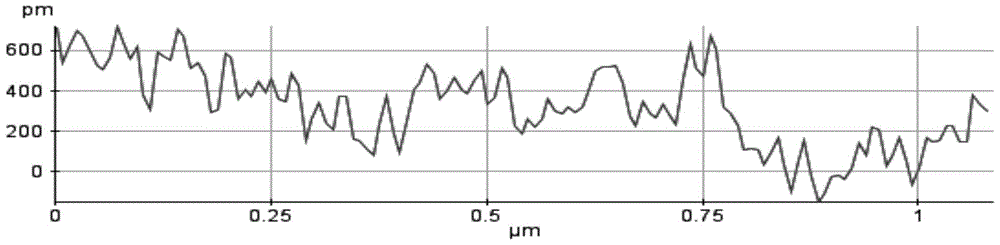

Preparation method of graphene/carbon fiber composite

ActiveCN103614902A2D structure retentionKeep excellent performanceCarbon fibresElectrophoretic coatingsElectrophoresesOrganosolv

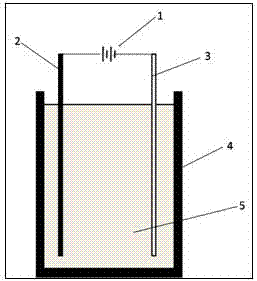

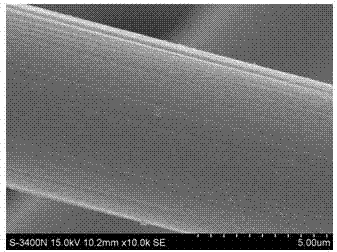

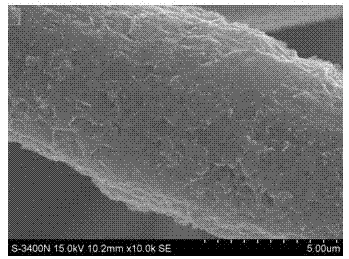

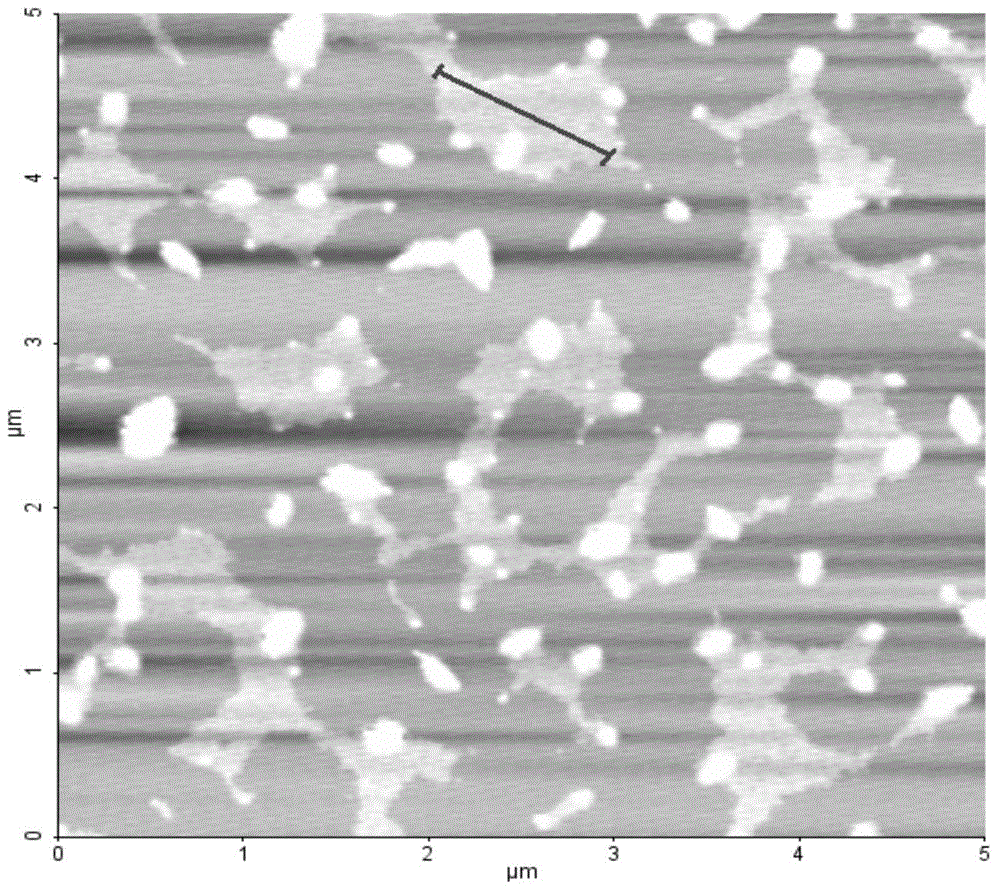

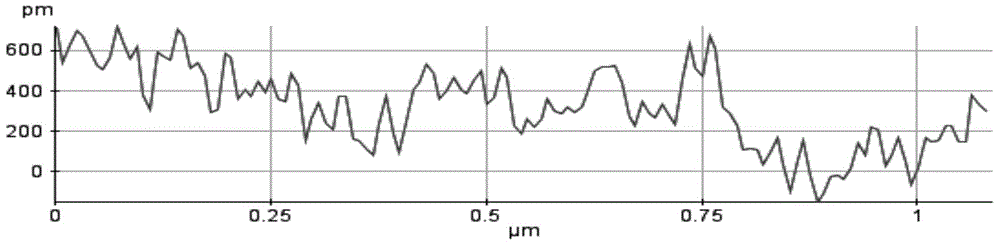

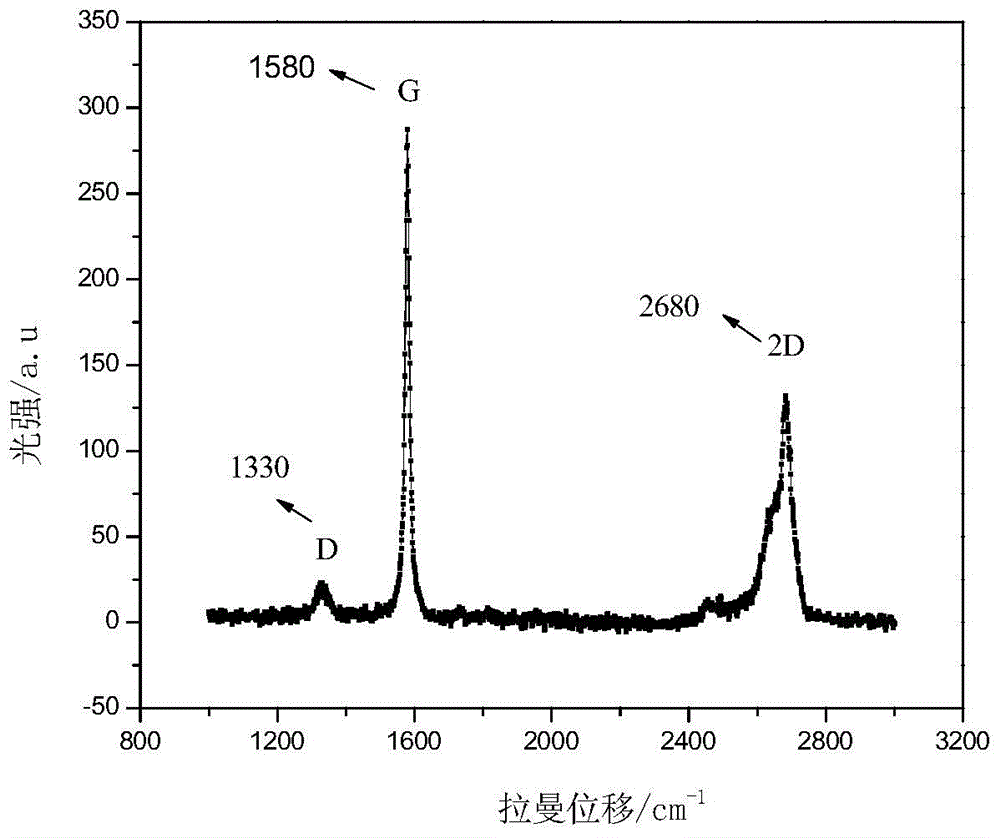

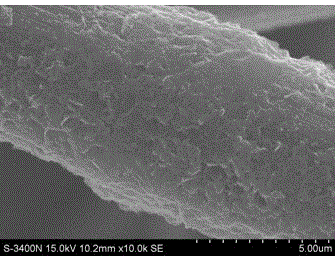

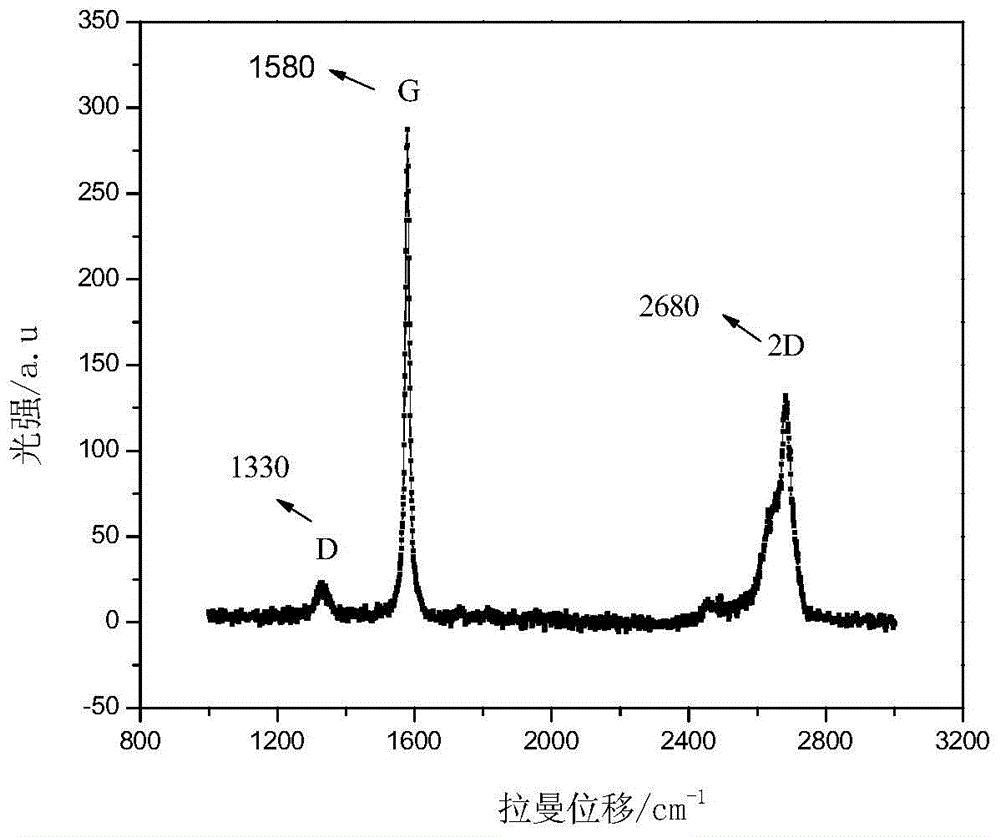

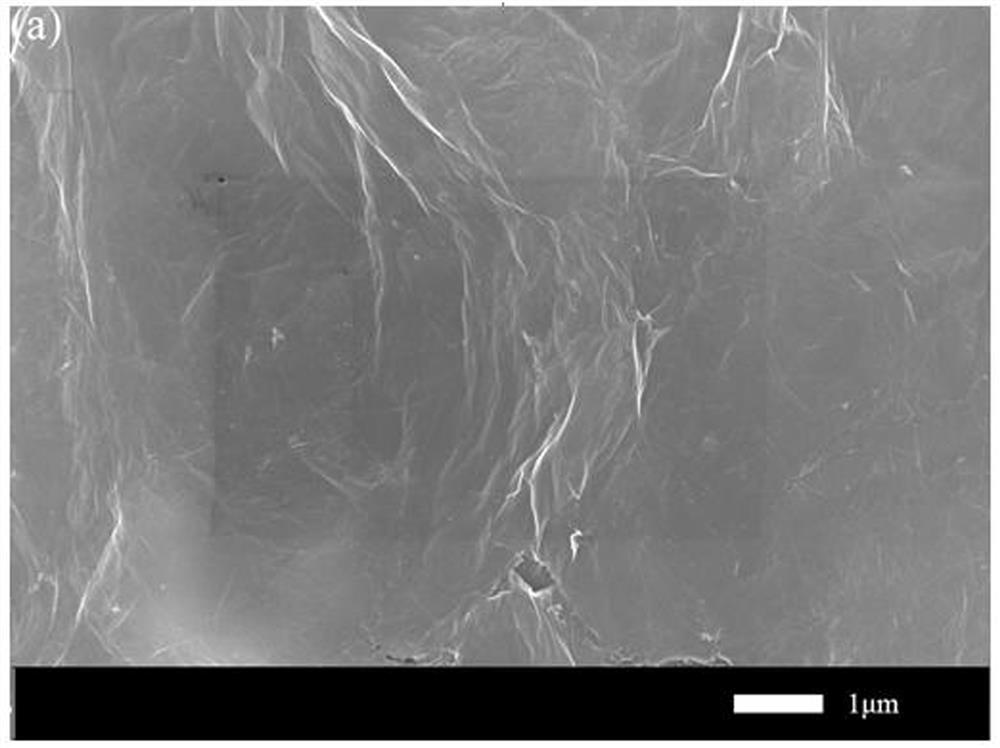

The invention discloses a preparation method of a graphene / carbon fiber composite. The preparation method comprises the steps: firstly, with graphite powder or natural flake graphite as the raw material, directly and ultrasonically stripping the graphite powder or natural flake graphite in an organic solvent to prepare a graphene dispersing solution; then, adding an organic amine salt with aromatic groups into the obtained graphene dispersing solution to enable the graphene to have positive charges because of adsorbing organic amine ions; next, depositing the graphene with the positive charges on carbon fiber or a carbon fiber product under the action of an external electric field to form the graphene / carbon fiber composite with the organic amine salt; and finally, removing the organic amine salt through thermal treatment to obtain the graphene / carbon fiber composite, wherein the organic amine salt is deposited in an electrophoresis deposition process. The method has the advantages of simplicity in operation, low cost, good uniformity of the graphene / carbon fiber composite, easiness for control and the like.

Owner:SHANGHAI INST OF TECH

Production of aromatic copolymide fiber dissolving pulp

InactiveCN1456719AAchieve reuseNo protection issuesArtificial filament recoveryPlastic recyclingDissolving pulpAramid

Owner:上海依极科技有限公司

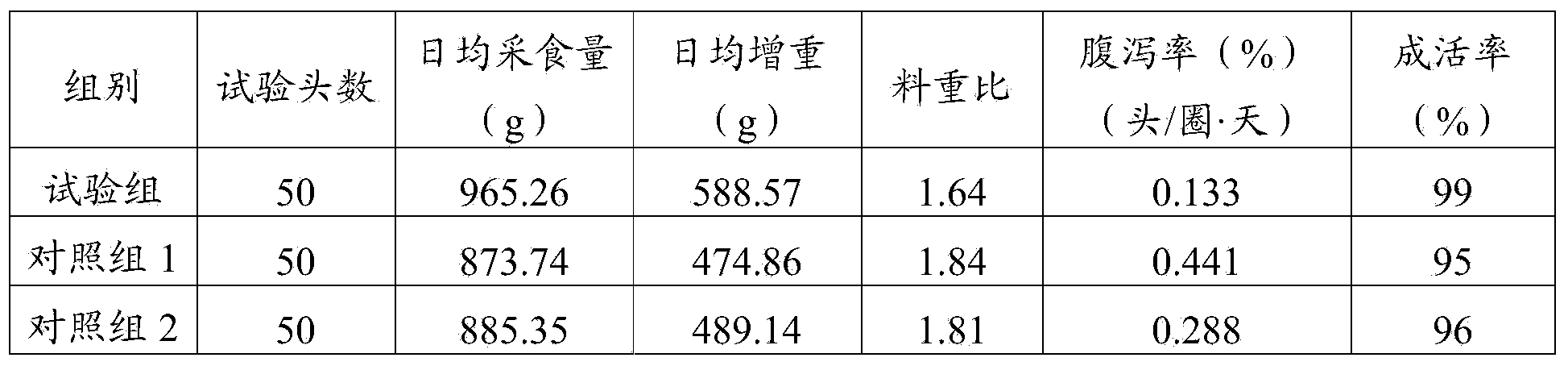

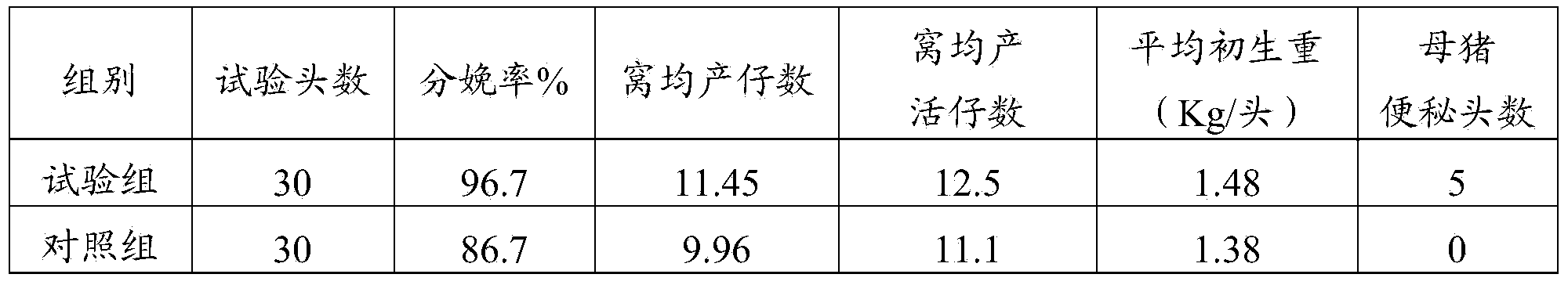

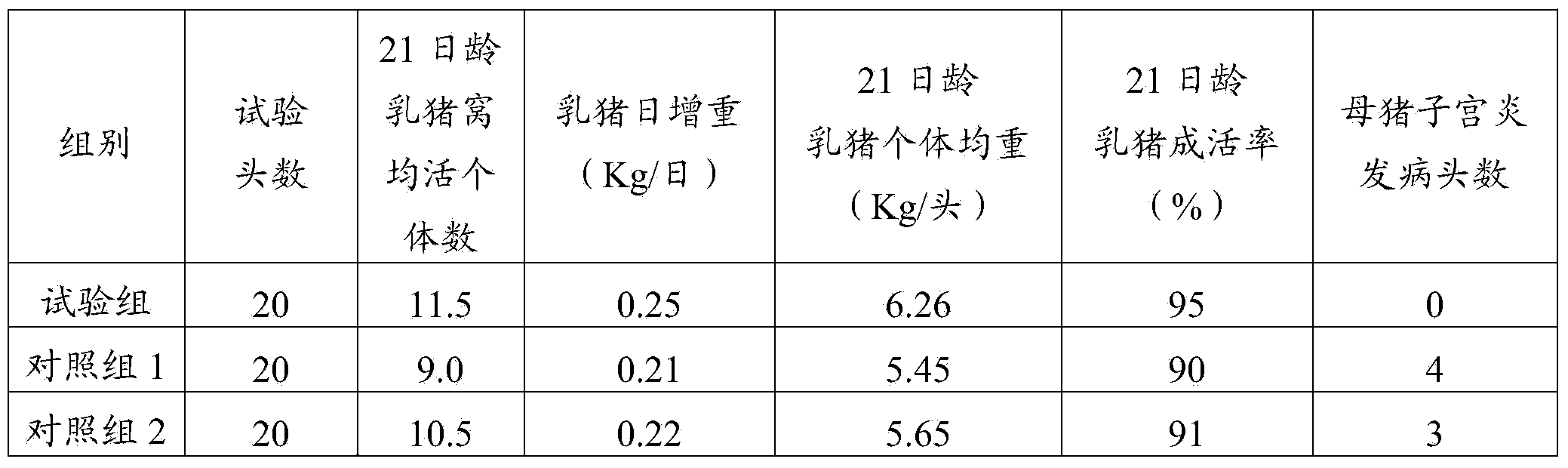

Biological fermentation active carrier type composite premix feed as well as preparation method and application thereof

InactiveCN103907749APromote reproductionLittle impact on growth and metabolismAnimal feeding stuffMetaboliteCulture fluid

The invention provides biological fermentation active carrier type composite premix feed as well as a preparation method and an application thereof. The preparation method comprises the following steps: preparing probiotics biological fermentation active carriers, to be specific, respectively carrying out liquid fermentation cultivation by using lactobacillus acidophilus LA0912, enterococcus faecalis EF1109, bacillus subtilis BS0903 and saccharomyces cerevisiae SC1203, mixing obtained liquid according to a volume ratio being 1: 1: 1: 1, then carrying out solid fermentation cultivation, drying an obtained solid fermentation culture at lower temperature and grinding so as to obtain the biological fermentation active carriers; compounding the biological fermentation active carriers with vitamins, amino acids, minerals, organic trace elements, choline chloride and table salt so as to obtain the biological fermentation active carrier type composite premix feed suitable for pigs at different stages. The biological fermentation active carrier type composite premix feed gives play to the health function of probiotics, makes the best of multiple biological activity effects of probiotics fermentation metabolites and can meet the physiologic nutritional requirements of pigs at different stages.

Owner:李德元 +1

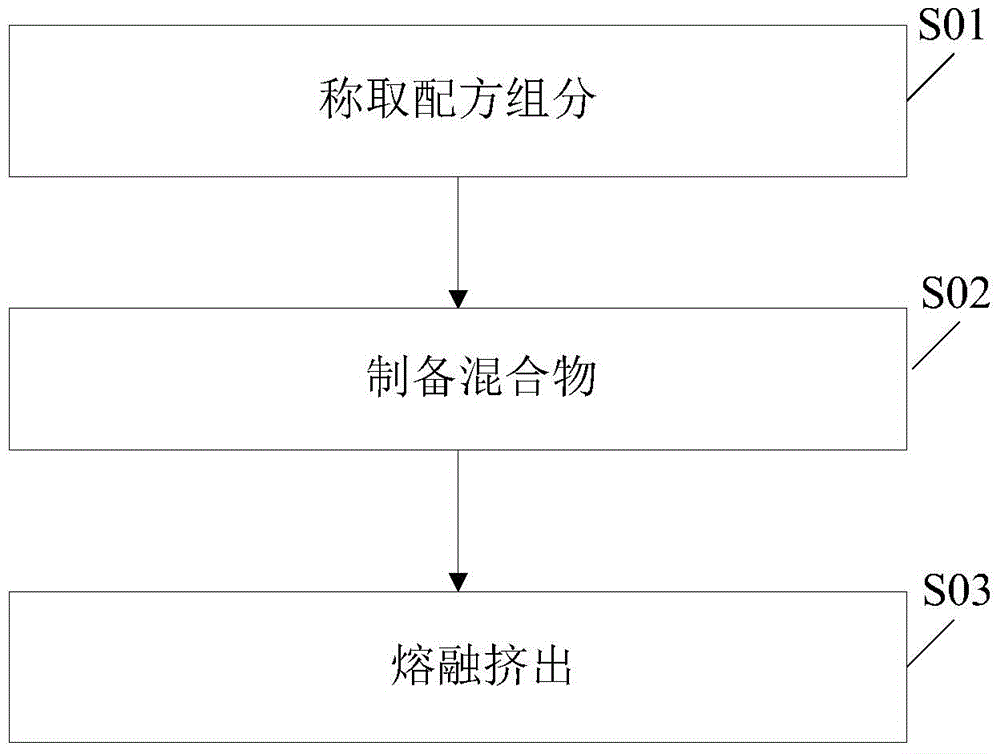

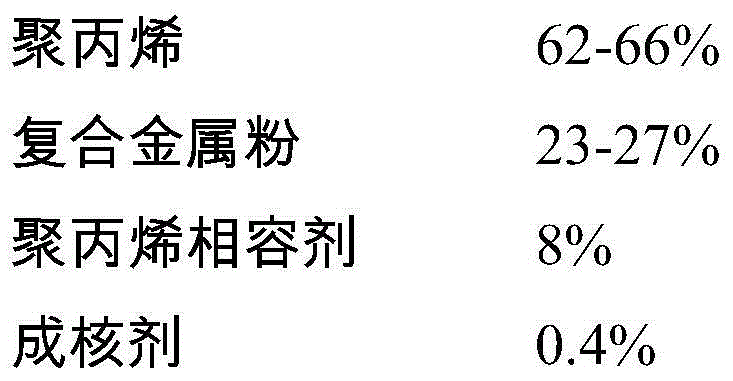

Spray-free baking varnish metal-like polypropylene material and preparation method thereof

InactiveCN104479229AKeep excellent performanceBeautiful imitation metal effectPolymer scienceAntioxidant

The invention belongs to the technical field of modification of high polymer materials, and provides a spray-free baking varnish metal-like polypropylene material and a preparation method thereof. The spray-free baking varnish metal-like polypropylene material is prepared from the following raw materials in percentage by weight: 62-66% of polypropylene, 23-27% of composite metal powder, 8% of polypropylene compatilizer, 0.4% of nucleator, 2% of lubricant and 0.6% of antioxidant. The polypropylene is used as the substrate, composite metal powder for endowing the material with spray-free baking varnish metal-like properties is used as the main component, and the polypropylene compatilizer, nucleator, lubricant and antioxidant are proportionally used as the auxiliary materials; the proportions of appropriate resin raw material, various other assistants and the composite metal powder are selected to obtain the spray-free baking varnish metal-like polypropylene material. The spray-free baking varnish metal-like polypropylene material maintains excellent properties of the propylene, and can have the beautiful metal-like effect under the condition of no spraying of baking varnish, thereby overcoming the defect that the metal-like effect can only be obtained by spraying the baking varnish in the traditional polypropylene.

Owner:ANHUI KEJU NEW MATERIALS

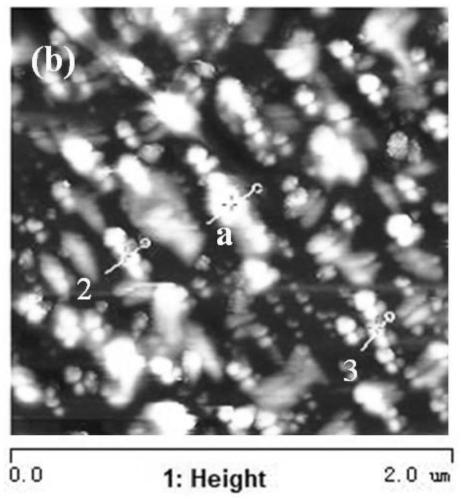

Method for preparing water-phase graphene dispersion liquid by employing ultrasonic stripping

The invention discloses a method for preparing a water-phase graphene dispersion liquid by employing ultrasonic stripping. The method comprises the following steps: adding 1 part of graphite to 500-10,000 parts of a lignin amphiphilic polymer solution with the mass concentration of 0.1-10g / L; carrying out ultrasonic stripping at 20-60 DEG C for 10-100 hours by virtue of an ultrasonic cleaning machine; and then centrifugally separating to obtain the graphene dispersion liquid. According to the method disclosed by the invention, a lignin amphiphilic polymer is adopted as a natural polymer dispersant of water-phase graphene for the first time; the graphene in the prepared dispersion liquid is few in structure defect and few in layers; the lowest concentration is 0.1g / L; the excellent performance of the graphene is well reserved; the method can be widely applied to the fields such as catalysts, sensors and conducting materials; the method disclosed by the invention is economical and environment-friendly; the utilization rate of raw materials is improved; and the industrialization cost is reduced.

Owner:SOUTH CHINA UNIV OF TECH

Polylactic acid/nucleating agent modified cellulose nanocrystalline composite material and method

The invention discloses a polylactic acid / nucleating agent modified cellulose nanocrystalline composite material and a method. The preparation method is characterized by comprising the following steps: modifying cellulose nanocrystals by using a polyamides nucleating agent with a self-assembly capability to obtain modified cellulose nanocrystals with a needle-like or rod-like self-assembly structure, and compounding the modified cellulose nanocrystals with polylactic acid to obtain the polylactic acid / cellulose interface structure with a shish-kebab form. The nucleating agent with self-assembly capability and capable of forming rod-like and needle-like structures is selected, and hydroxyl of cellulose and amino of the nucleating agent form hydrogen-bond interaction, so that adsorption of the nucleating agent on the surface of the cellulose is realized, damage to a cellulose structure is avoided, and excellent performance of the cellulose is reserved to the greatest extent.

Owner:SHANDONG UNIV OF SCI & TECH

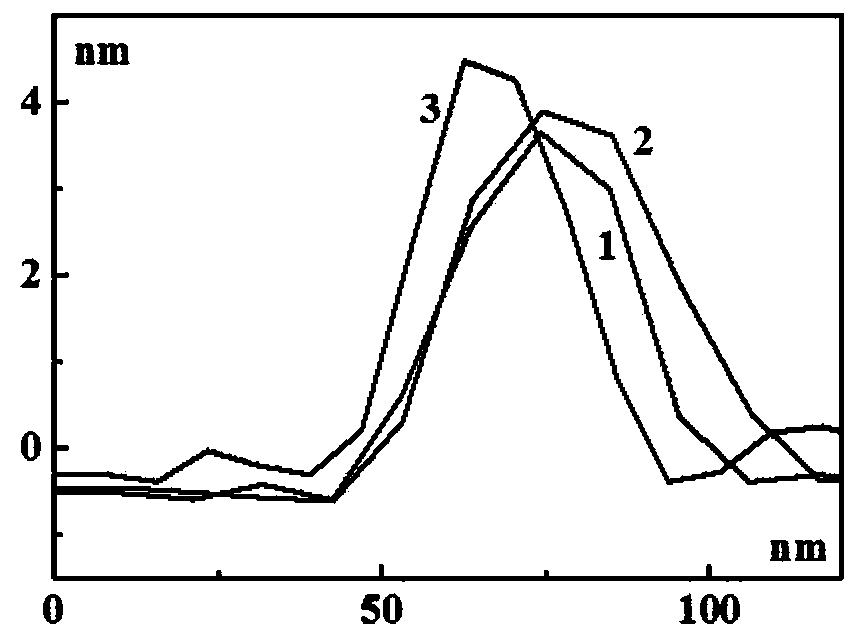

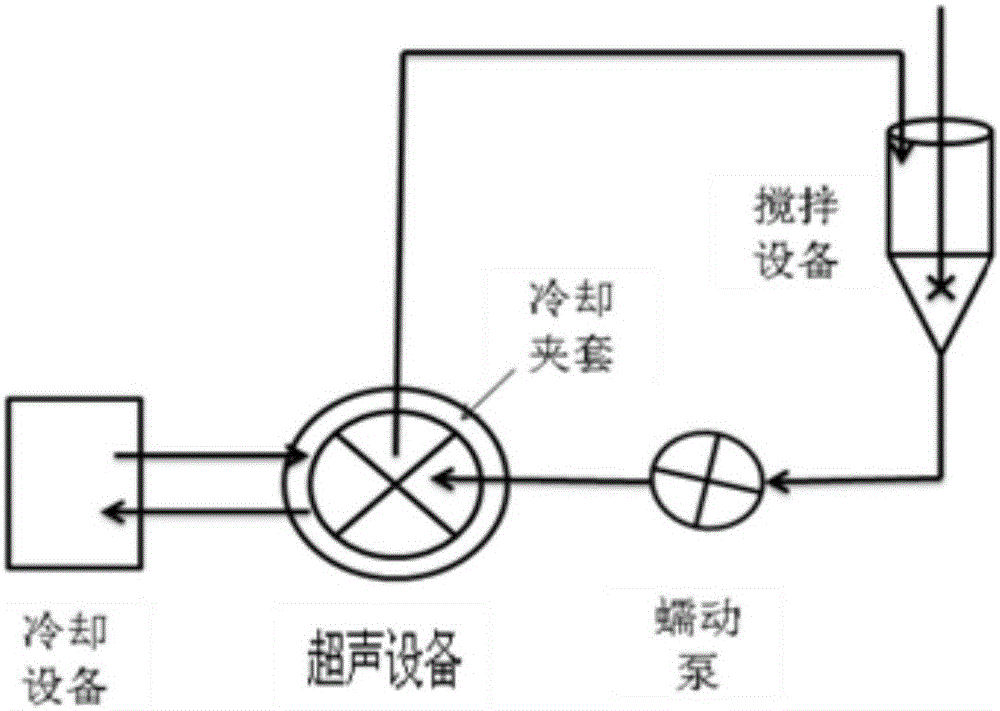

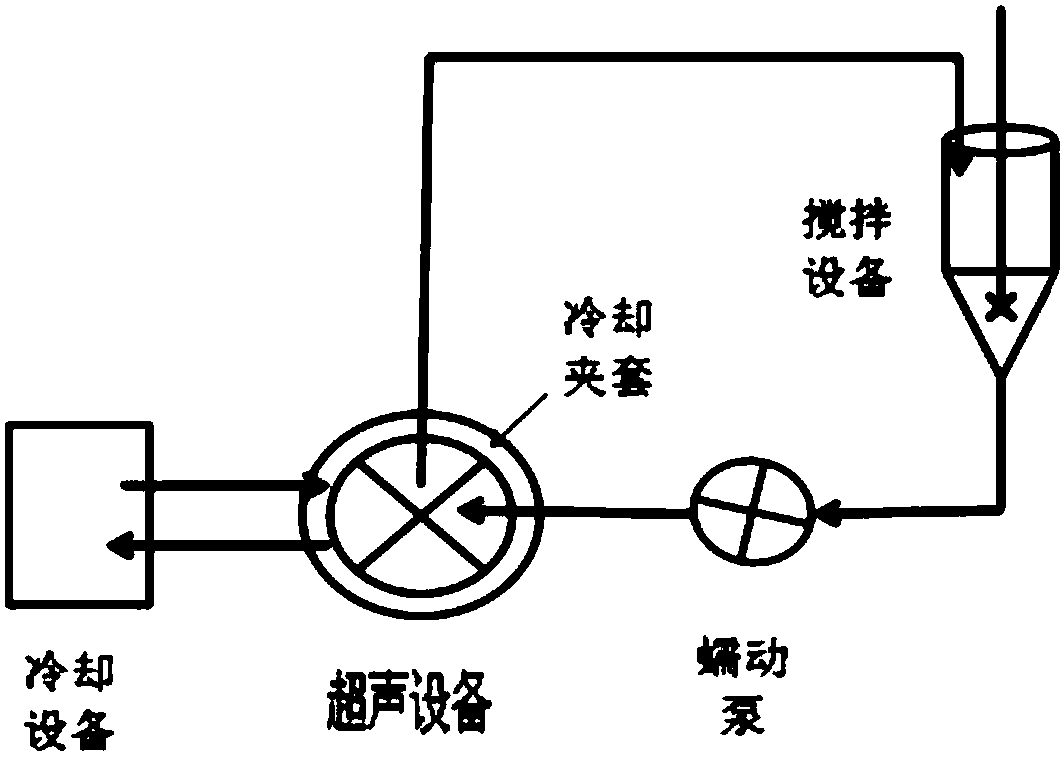

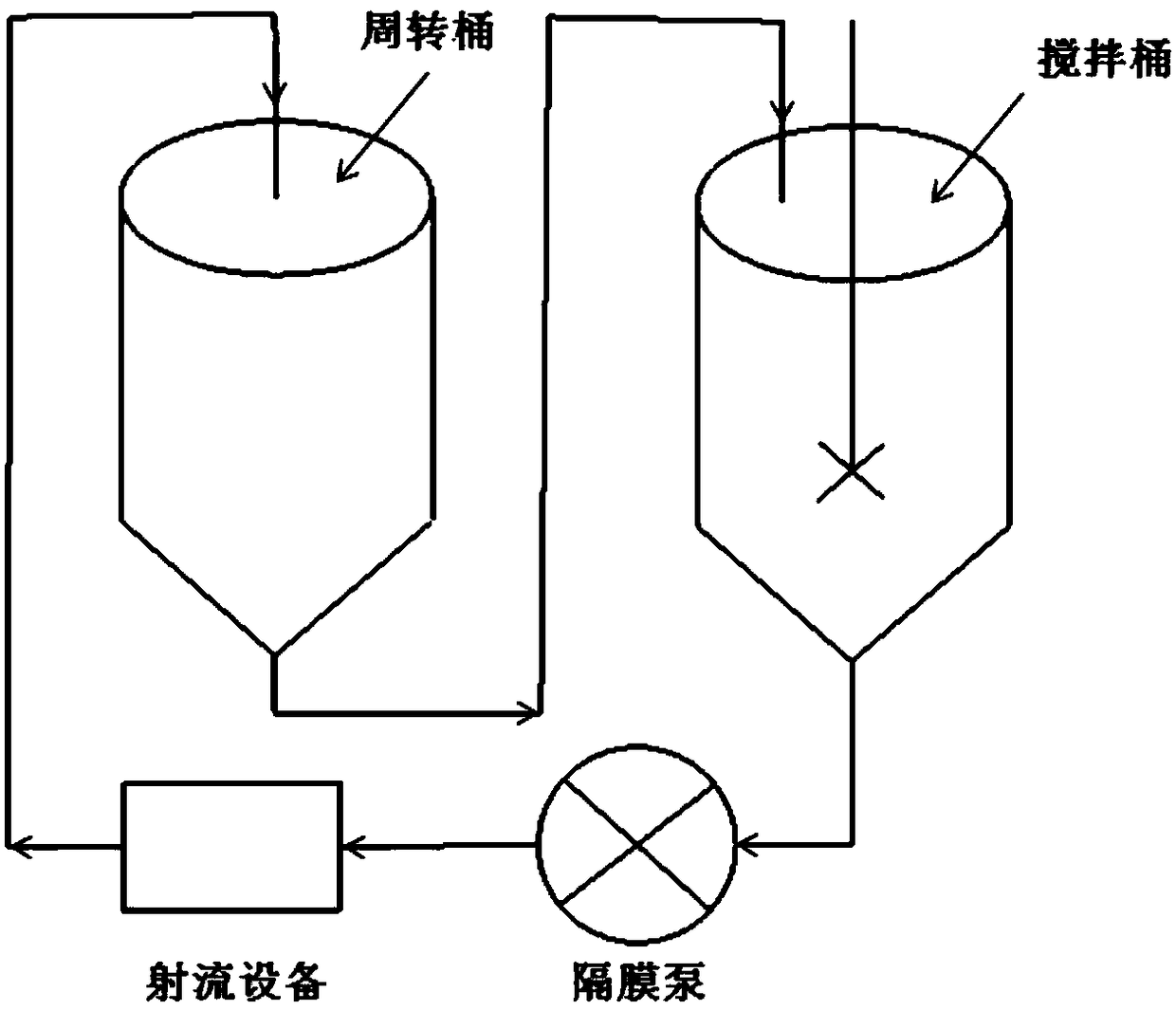

Method for preparing graphene by combining ultrasonic peeling and jet flow peeling

The invention discloses a method for preparing graphene by combining ultrasonic peeling and jet flow peeling. The method comprises the steps that firstly, graphite is dispersed in an aqueous surfactant solution; secondly, the mixed liquid obtained in the first step is subjected to ultrasonic peeling, and multilayer graphene dispersion liquid is obtained; thirdly, the multilayer graphene dispersion liquid obtained in the second step is subjected to jet flow peeling, and monolayer graphene dispersion liquid is obtained; fourthly, the monolayer graphene dispersion liquid obtained in the third step is dried, and the graphene is obtained. According to the preparation method, the ultrasound and jet flow combined peeling mode is adopted for the first time, the obtained graphene in the dispersion liquid has few structural defects and layers and high concentration, the excellent performance of graphene is retained very well, and the graphene can be widely applied to the fields of automotive parts, sensors, conductive materials, heat conduction materials and the like. The method is economical and environmentally friendly, the raw material utilization rate is increased, and the industrialization cost is reduced.

Owner:SHANGHAI LEVSON ENTERPRISE GRP

Novel epoxy-polyacrylate core-shell emulsion and preparation method thereof

The invention discloses a novel epoxy-polyacrylate core-shell emulsion and a preparation method thereof. Aqueous epoxy resin is generally an emulsion, a water dispersing body or an aqueous solution formed by dispersing micro particles, liquid drops or colloid into a water phase; the emulsion, the water dispersing body and the aqueous solution are different in particle sizes of epoxy resin dispersing phases. The preparation method for the novel epoxy-polyacrylate core-shell emulsion comprises the steps of (1) emulsifying the epoxy resin emulsion prepared by a phase inversion method and 1 / 3 of acrylate mixed monomers under the temperature of 20-40 DEG C for 0.5 hour; (2) adding an initiator into a reaction system, adding the residual acrylate mixed monomers drop by drop under the temperature of 80-90 DEG C for 3-4 hours, and preserving the heat for 1-5 hours; and (3) cooling the mixture to be below 50 DEG C, and discharging. The novel epoxy-polyacrylate core-shell emulsion disclosed by the invention is used as paint or a paint base material.

Owner:HARBIN UNIV OF SCI & TECH

Method for preparing graphene powder and dispersion thereof from fluorine-containing hyperbranched polyethylene copolymers

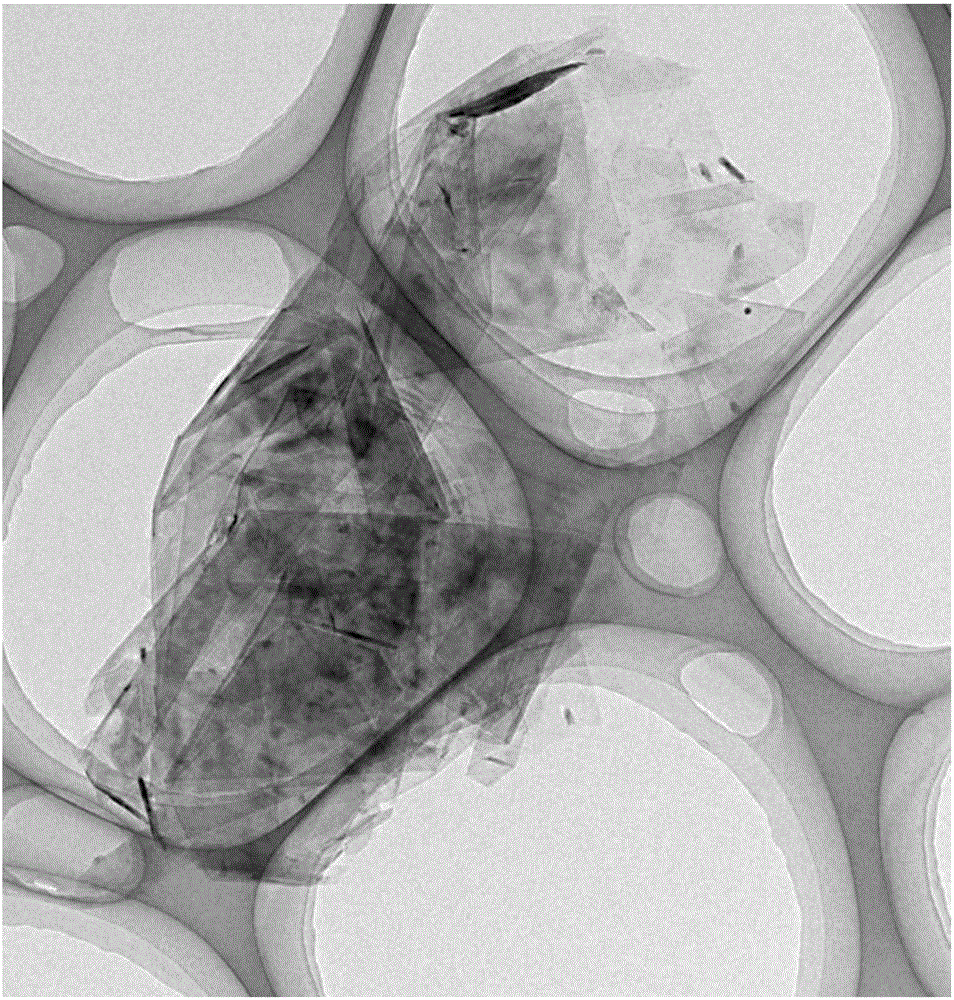

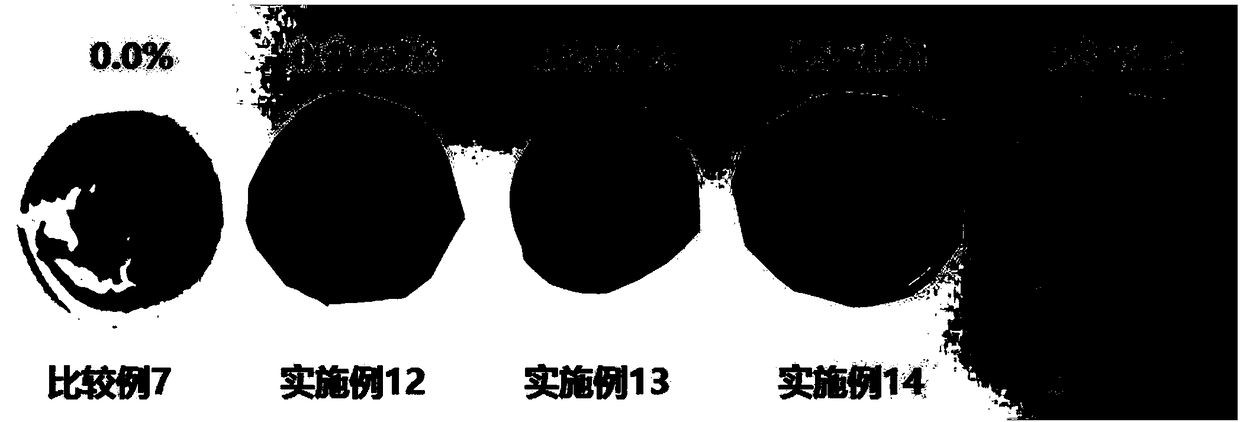

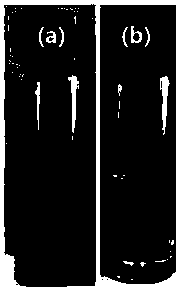

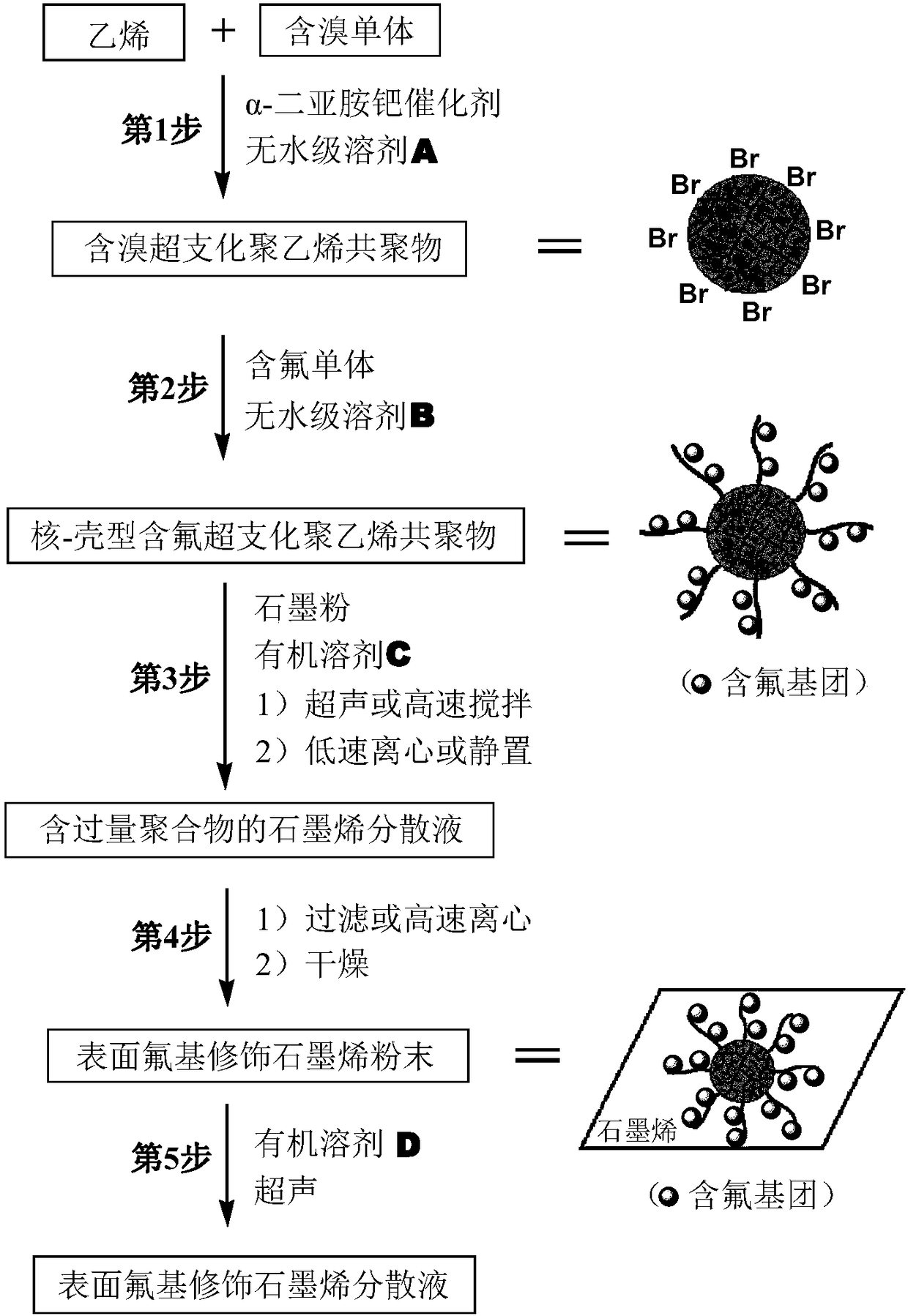

The invention discloses a method for preparing graphene powder and dispersion thereof from fluorine-containing hyperbranched polyethylene copolymers. The method includes catalyzing bromine-containingmonomers and ethylene by the aid of alpha-diimine palladium catalysts to carry out copolymerization so as to obtain bromine-containing hyperbranched polyethylene copolymers; initiating fluorine-containing monomers by the aid of the obtained bromine-containing hyperbranched polyethylene copolymers to carry out copolymerization at terminals of hyperbranched polyethylene branch chains so as to obtainthe fluorine-containing hyperbranched polyethylene copolymers; exfoliating graphite powder in organic solvents by means of ultrasonic or high-speed stirring by the aid of the obtained fluorine-containing hyperbranched polyethylene copolymers which are used as stabilizers so as to obtain graphene dispersion; removing free polymers in the graphene dispersion by means of vacuum suction filtration orcentrifugation to obtain the graphene powder with the surfaces modified by fluorine-containing polymers and ultrasonically dispersing the graphene powder in appropriate organic solvents to obtain graphene dispersion with surfaces modified by the fluorine-containing polymers. The method has the advantages that the method is high in preparation efficiency, graphene has few structure defects, and processes are simple and are easy to scale up; the graphene obtained by the aid of the method has a broad application prospect in the field of fluorine-containing polymer composite modification.

Owner:ZHEJIANG UNIV OF TECH

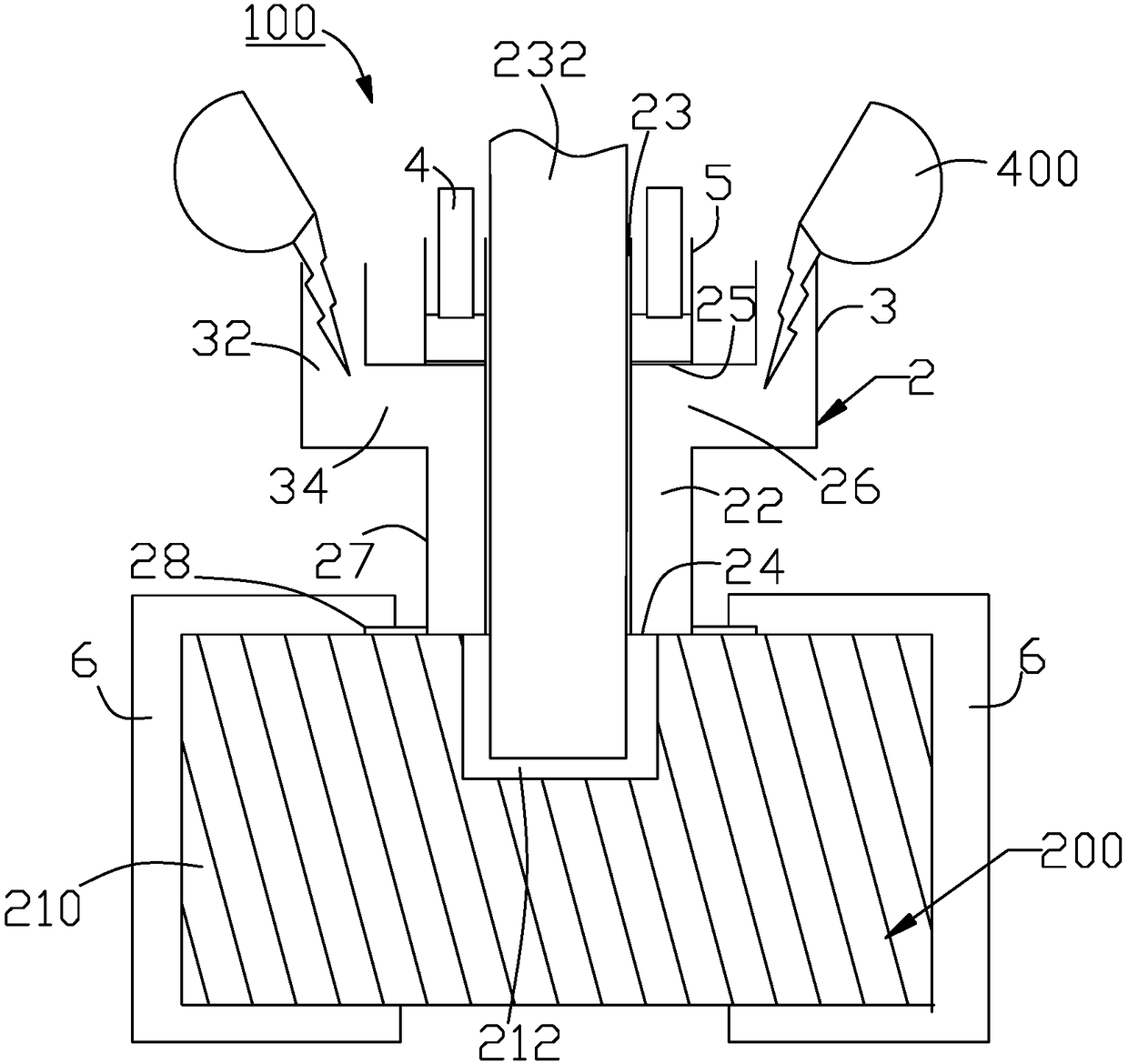

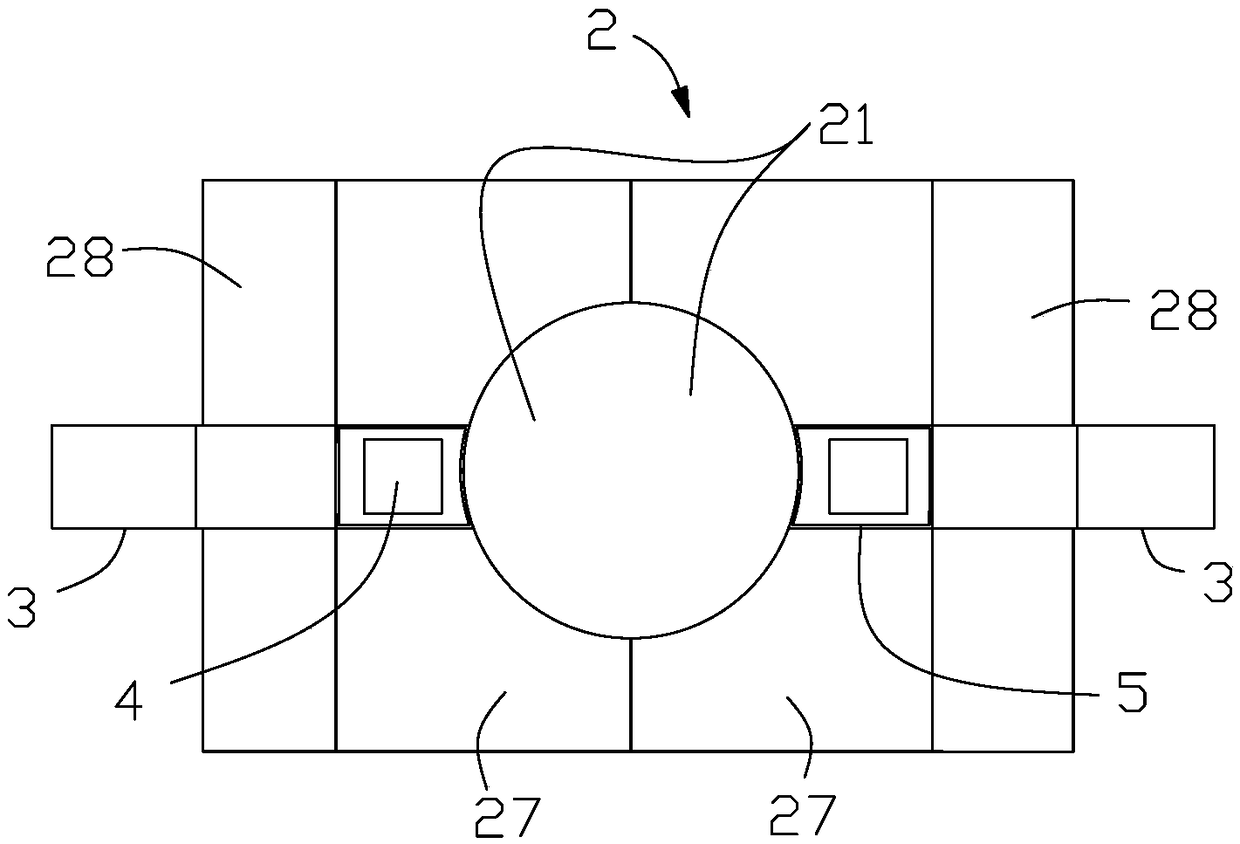

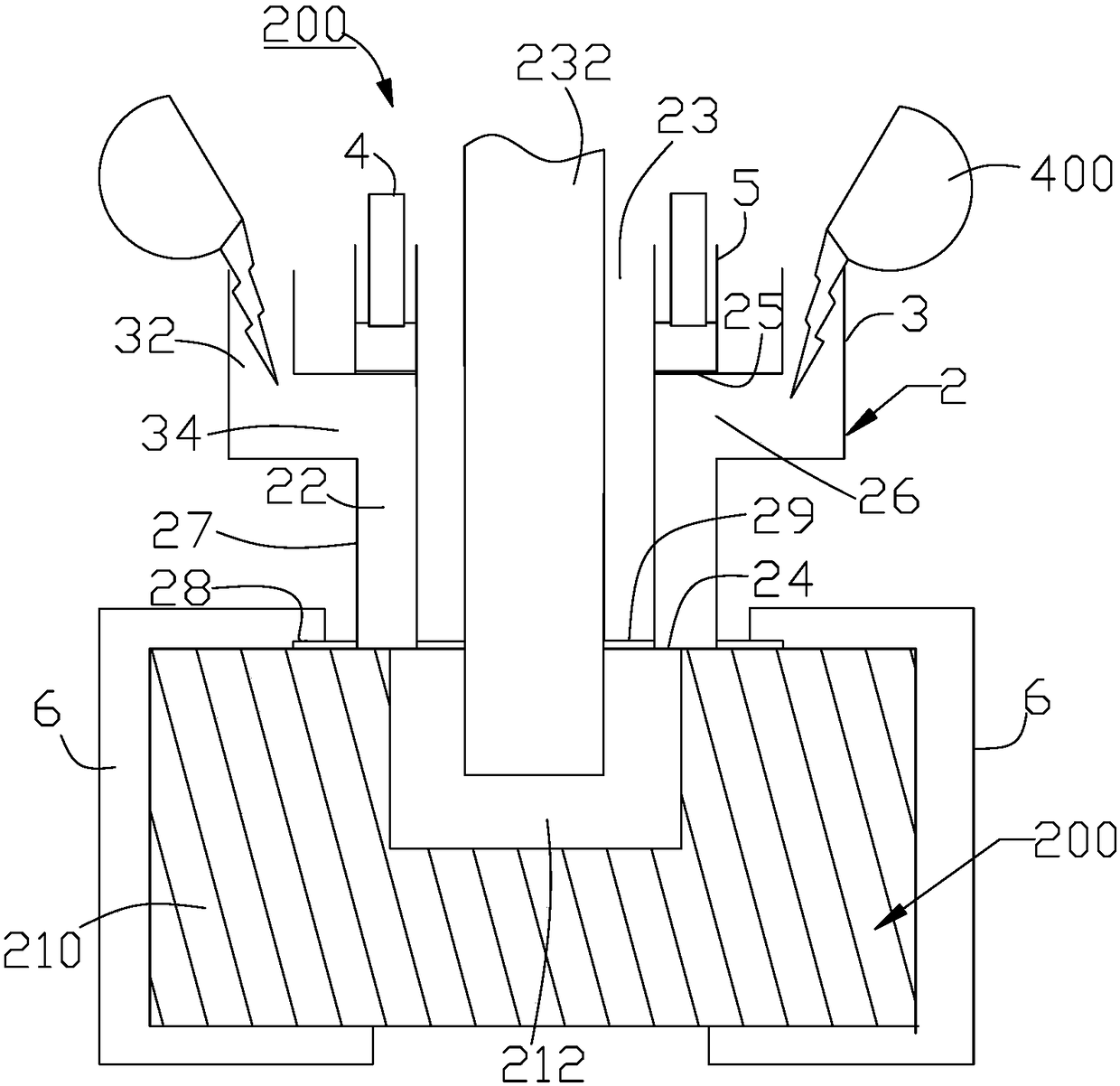

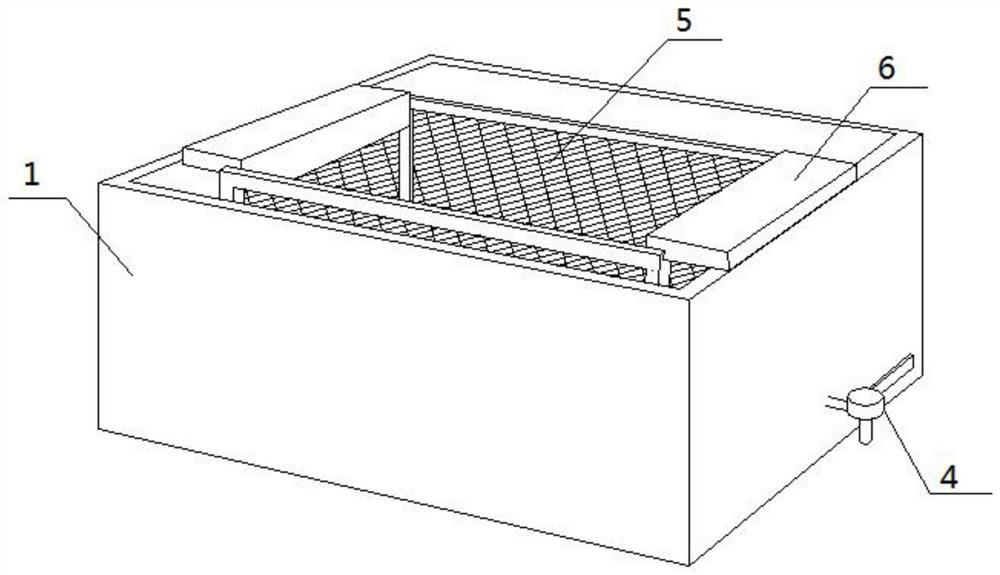

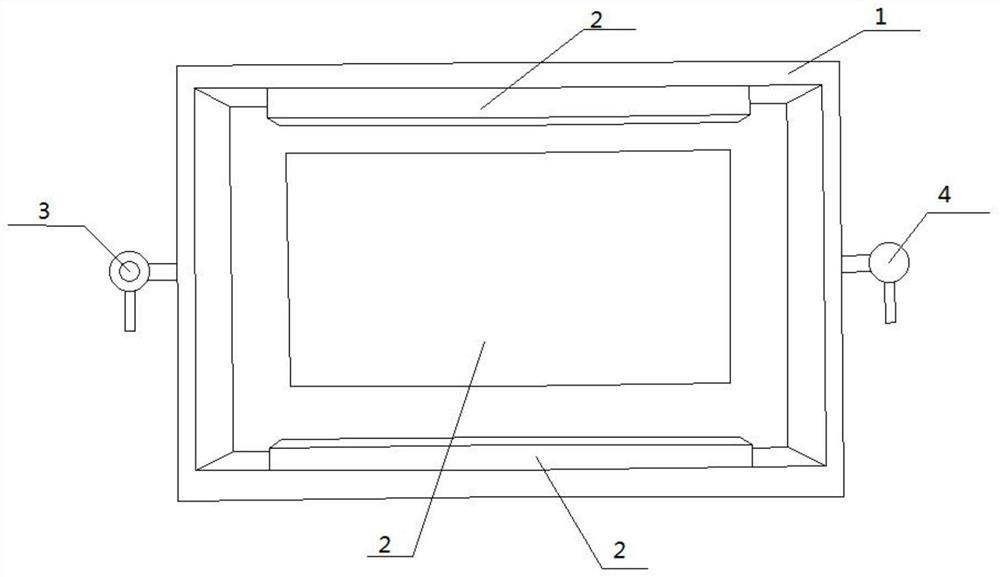

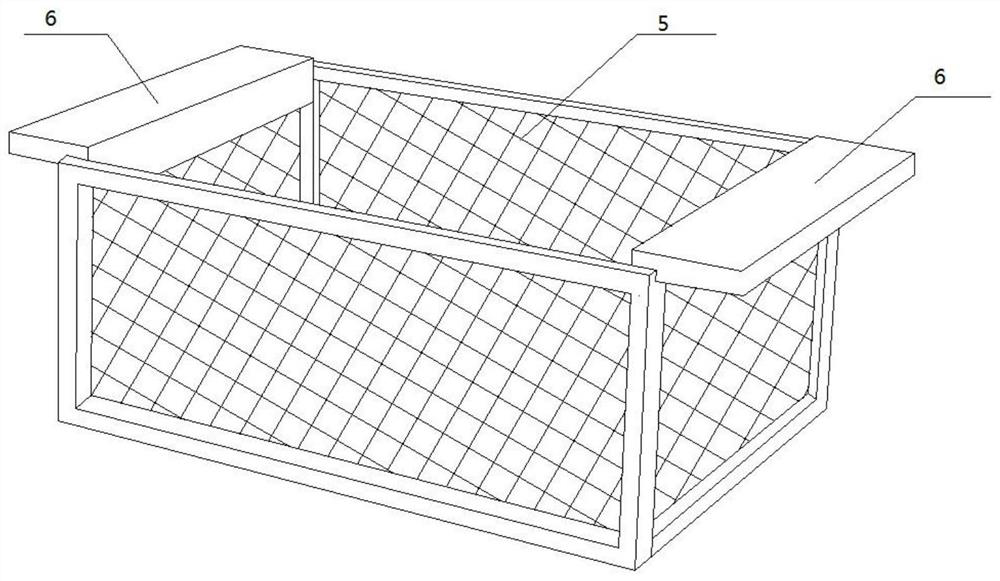

Pressure pouring device for phosphoric pig iron for assembling prebaked anode and pouring method of pressure pouring device

The invention provides a pressure pouring device for phosphoric pig iron for assembling a prebaked anode. An opening of a carbon bowl is closed through a pouring mold so that the carbon bowl can be inthe closed state; and the liquid phosphoric pig iron is pressure-poured into the portion, between the prebaked anode and a steel claw, of the carbon bowl through a pressure jet punch so that the mold-filling capacity of the liquid phosphoric pig iron can be improved, close connection between the prebaked anode and the steel claw can be achieved, the tension resistance can be improved, and connection pressure reduction can be lowered. The invention further provides a pouring method of the pressure pouring device for the phosphoric pig iron for assembling the prebaked anode.

Owner:BAISE UNIV

Production of aromatic copolymide fiber dissolving pulp

InactiveCN1191397CAchieve reuseNo protection issuesArtificial filament recoveryPlastic recyclingDissolving pulpAramid

Owner:上海依极科技有限公司

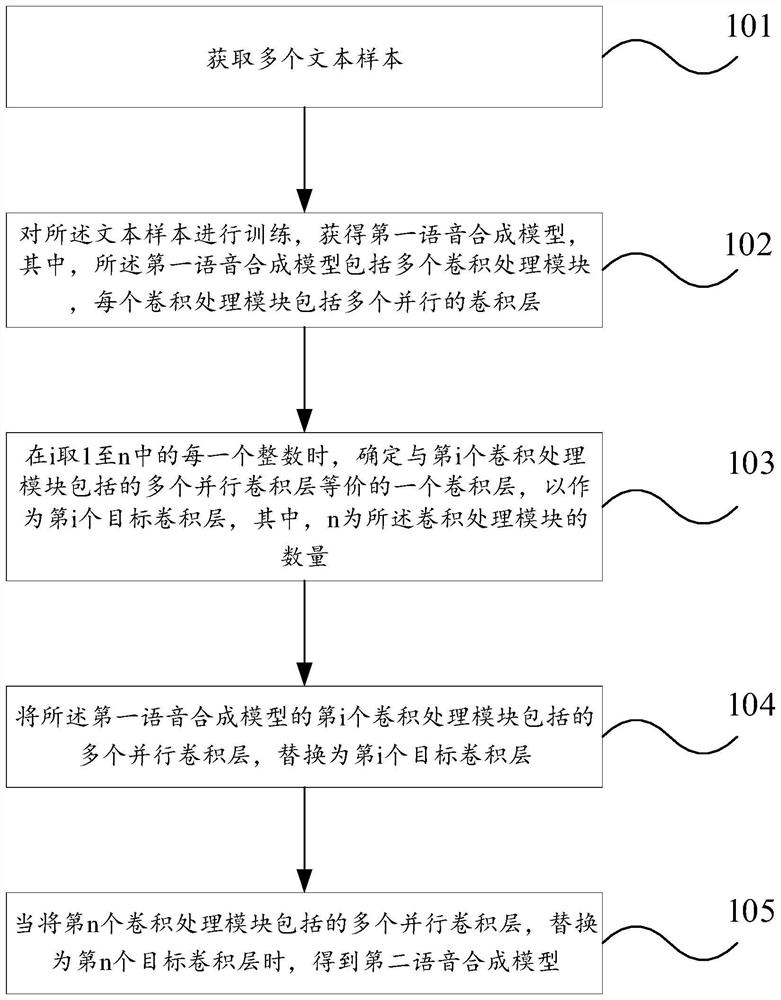

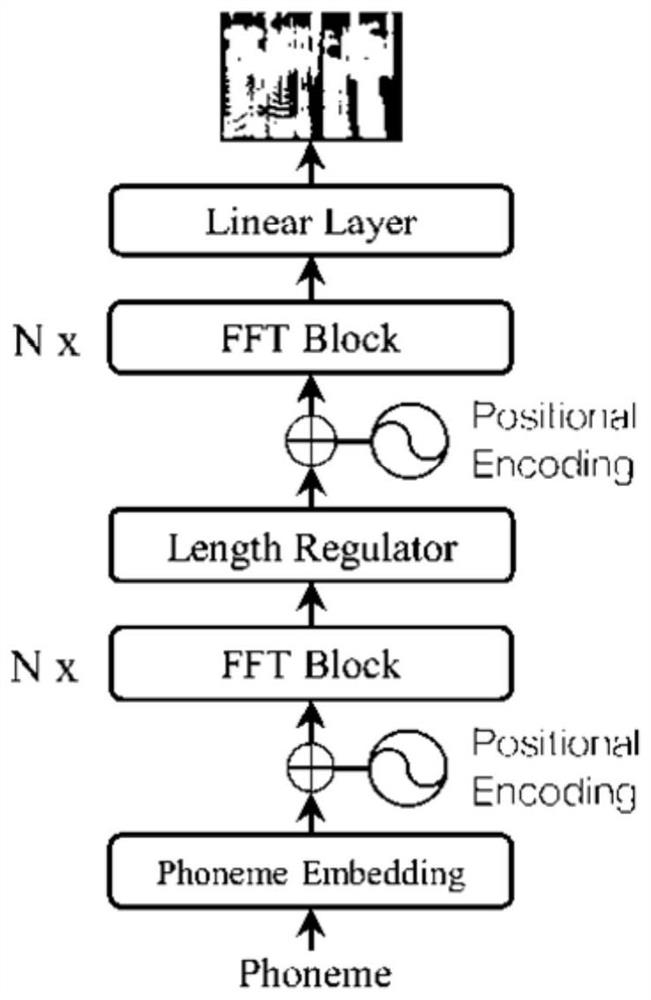

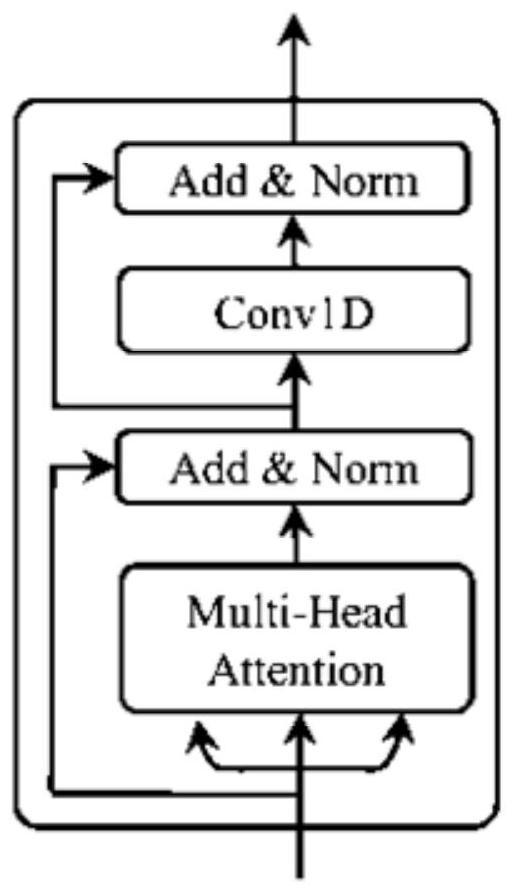

Speech synthesis model generation method and device and electronic equipment

PendingCN114220456AFast convergenceSolve the problem of large memory usageSpeech synthesisTheoretical computer scienceAcoustics

Embodiments of the invention provide a speech synthesis model generation method and apparatus, and an electronic device. The method comprises the steps of obtaining a plurality of text samples; the text sample is trained, a first speech synthesis model is obtained, the first speech synthesis model comprises a plurality of convolution processing modules, and each convolution processing module comprises a plurality of parallel convolution layers; when i is an integer from 1 to n, determining a convolution layer equivalent to the plurality of parallel convolution layers included in the ith convolution processing module as an ith target convolution layer; replacing a plurality of parallel convolution layers included in an ith convolution processing module of the first speech synthesis model with an ith target convolution layer; and when a plurality of parallel convolution layers included in the nth convolution processing module are replaced by the nth target convolution layer, a second speech synthesis model is obtained. Therefore, the second speech synthesis model is obtained by equivalently transforming the target convolutional layer, so that the memory of the model in later application is saved.

Owner:BEIJING SINOVOICE TECH CO LTD

A kind of preparation method of graphene/carbon fiber composite material

ActiveCN103614902B2D structure retentionKeep excellent performanceCarbon fibresElectrophoretic coatingsElectrophoresesOrganic solvent

The invention discloses a preparation method of a graphene / carbon fiber composite material, that is, firstly, graphite powder or natural flake graphite is used as a raw material, and a graphene dispersion liquid is prepared by direct ultrasonic peeling in an organic solvent, and then added to the obtained graphene dispersion liquid Organic amine salts containing aromatic groups. Graphene absorbs organic amine ions and is positively charged. Then, under the action of an external electric field, the positively charged graphene is deposited on carbon fibers or carbon fiber products to form organic amine salts. The graphene / carbon fiber composite material, and finally the organic amine salt deposited in the electrophoretic deposition process is removed by heat treatment to obtain the graphene / carbon fiber composite material. The method has the advantages of simple operation, low cost, good product uniformity, easy control and the like.

Owner:SHANGHAI INST OF TECH

Hyperbranched polysulfone with controllable branching degree and preparation method thereof

ActiveCN111410746AHydrodynamic small sizeReduce melt viscosityHydrocarbon solventsAqueous solubility

The invention discloses hyperbranched polysulfone with controllable branching degree and a preparation method thereof. The method comprises the following steps: 1) generating bisphenol salt from an organic bisphenol compound and a salt-forming agent in a non-water-soluble hydrocarbon solvent; 2) adding a solution of 4, 4'-dichlorodiphenyl sulfone / aprotic polar solvent into a bisphenol salt system,and carrying out condensation polymerization under the catalytic action of a condensation polymerization catalyst to generate linear polysulfone; 3) adding a chloromethylated polysulfone / aprotic polar solvent solution into the system, and reacting to generate hyperbranched polysulfone; and 4) separating out the product in a precipitation agent, and carrying out a post-treatment process to obtainhyperbranched polysulfone powder. Compared with a traditional method for preparing hyperbranched polysulfone, the method has the advantages that expensive polyfunctional monomers do not need to be adopted, so that the cost is greatly reduced; the molecular weight distribution of the obtained product is narrow, the gelation phenomenon is avoided, the branching degree can be controlled by selectingpolysulfones with different chloromethylation degrees, and the method is simple and easy to operate.

Owner:WANHUA CHEM GRP CO LTD

Preparation method of bamboo-based hybrid fiber felt for VARTM molding composite material

PendingCN113529494AReduce bamboo fiber damageProtect excellent performanceFibreboardPaper/cardboardFiberCompositermes

The invention provides a preparation method of a bamboo-based hybrid fiber felt for a VARTM molding composite material. The method comprises the following steps: firstly, putting bamboo fibers into a distilled water solution, stirring until the bamboo fibers are dispersed, and sorting out standard bamboo fibers; uniformly dispersing the standard bamboo fibers in a sieve, placing the sieve in a wet-process layer laying device, and immersing the sieve in an ultrasonic device filled with different solvents for treatment; adding one or more other fibers into the sieve, carrying out ultrasonic treatment, standing, pre-pressing, evaporating the solvent in the fibrofelt, and taking out the formed bamboo-based hybrid fibrofelt; and repeating the above steps on bamboo fibers and other fibers which are equal in mass to obtain a plurality of formed bamboo-based hybrid fiber felts, sequentially stacking and pressing the fiber felts in the sieve to obtain a bamboo-based hybrid fiber felt, and naturally airing and drying the bamboo-based hybrid fiber felt to obtain a bamboo-based hybrid fiber felts for the VARTM formed composite material. The process steps are simple and convenient, the bamboo fibers and other fibers can be uniformly mixed and dispersed, and damage in the mixing preparation process of different fibers is also avoided.

Owner:ZHEJIANG FORESTRY ACAD

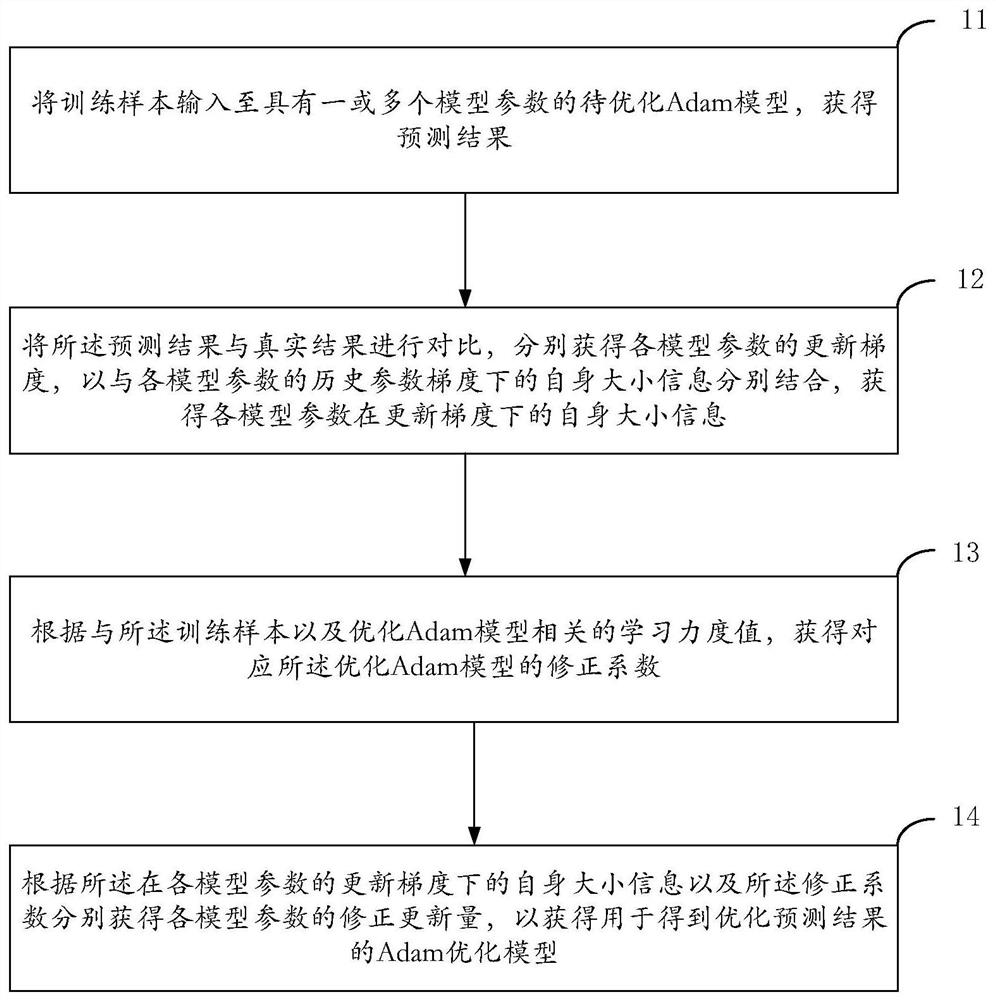

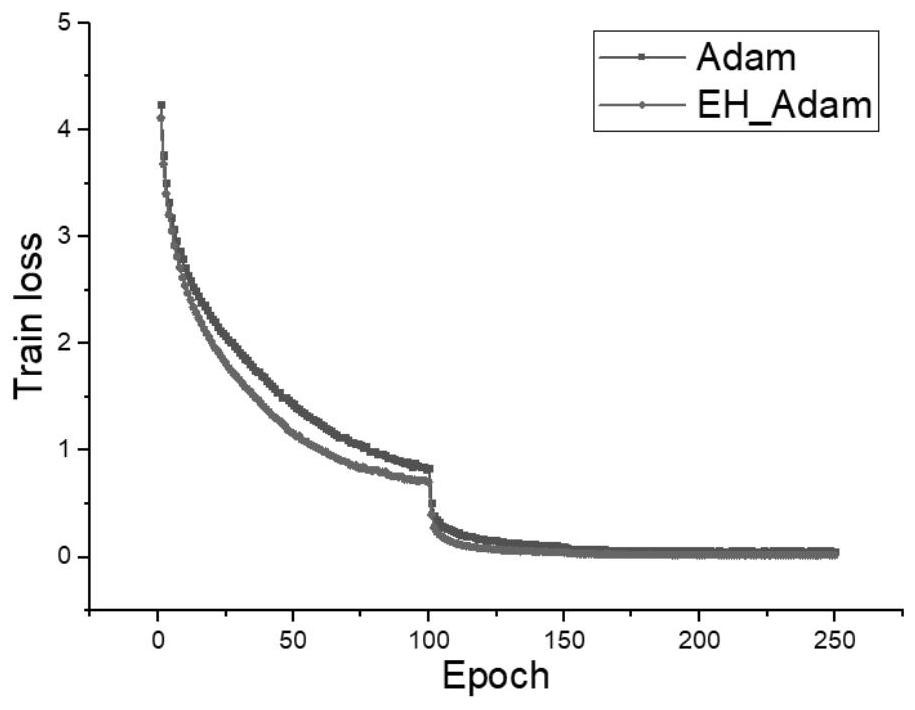

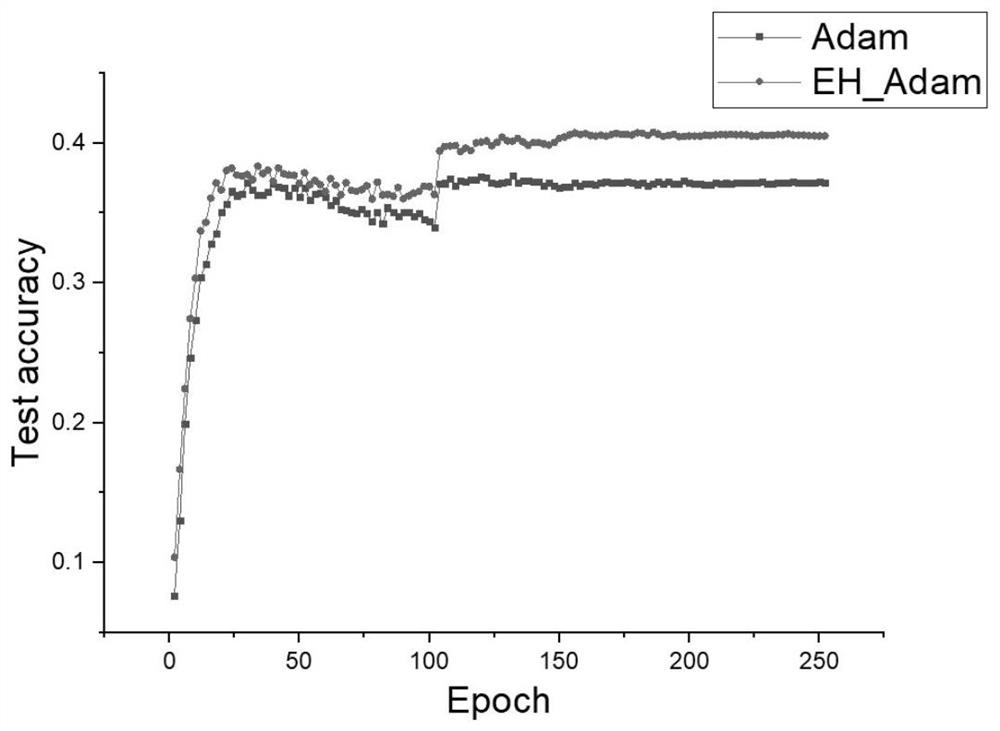

Adam-based optimization method, system and terminal

PendingCN111931422AKeep excellent performanceFast convergenceDesign optimisation/simulationNeural learning methodsAlgorithmData mining

The invention discloses an Adam-based optimization method, system and terminal. The method comprise the following steps: inputting a training sample into a to-be-optimized Adam model with one or moremodel parameters to obtain a prediction result; comparing the prediction result with the real result, and respectively combining the prediction result with the size information of each model parameterunder the historical parameter gradient to obtain the size information of each model parameter under the updated gradient; obtaining a correction coefficient corresponding to the optimized Adam modelaccording to the training sample and the learning intensity value related to the optimized Adam model; obtaining a correction update amount of each model parameter so as to obtain an Adam optimization model used for obtaining an optimization prediction result. The method is used for solving the problem that the requirements of high accuracy and higher convergence rate of an algorithm cannot be met in the prior art for huge data volume. According to the method, model parameters are improved on the basis of an Adam model, and the convergence rate and the final accuracy are further remarkably improved while the excellent performance of the Adam is reserved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

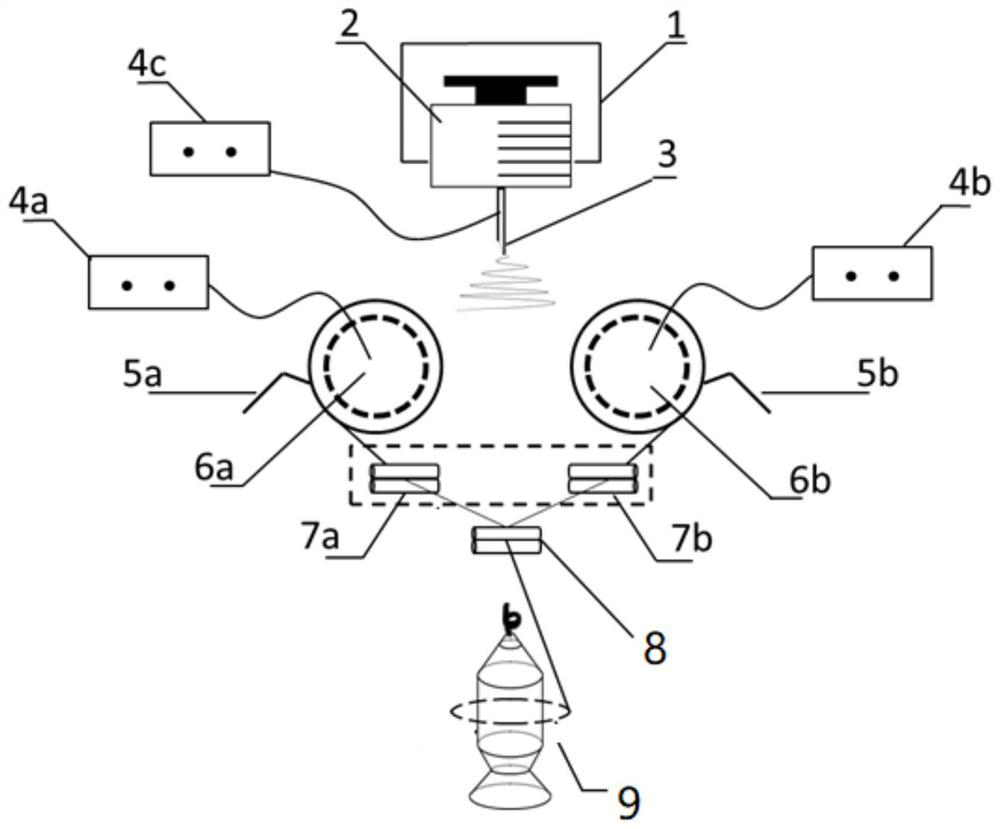

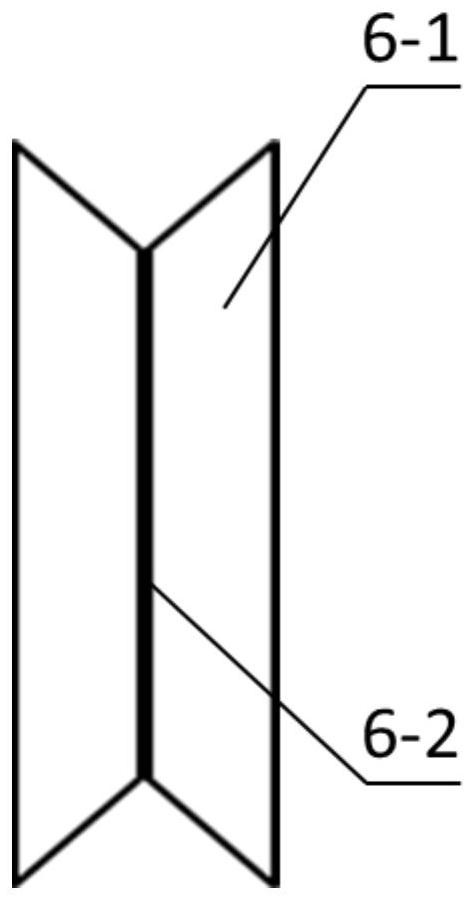

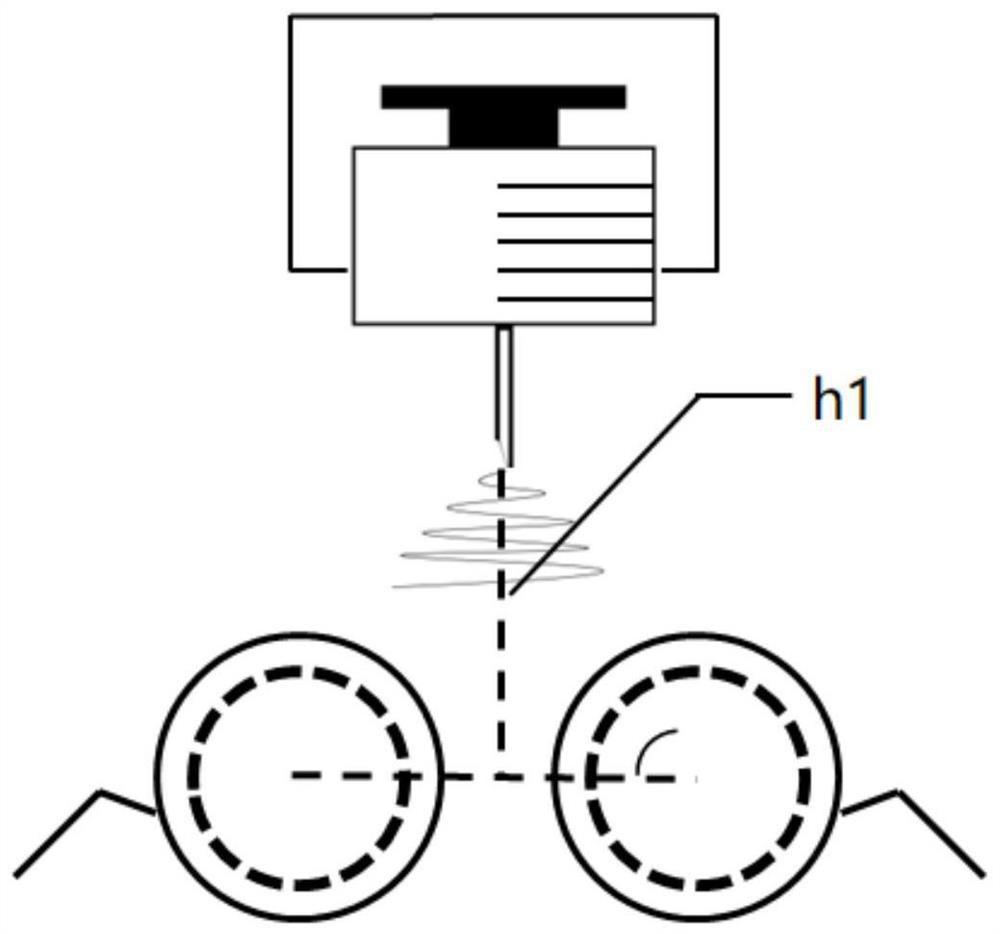

Nanofiber yarn and continuous yarn forming method thereof

ActiveCN114717669AIncrease productivityRealize continuous productionNew-spun product collectionFilament/thread formingYarnFiber

The invention discloses a nanofiber yarn and a continuous yarn forming method thereof.The continuous yarn forming method comprises the steps that nanofibers are spun through an electrostatic spinning method, and the spun nanofibers are split into n parts under the action of n electric field forces in the movement process; a plurality of bundling guide wheels capable of rotating respectively are adopted to independently collect each part of corresponding nanofiber, and each part of nanofiber is oriented and drafted under the action of the bundling guide wheels to form a nanofiber aggregate attached to the bundling guide wheels; according to the method, a continuous nanofiber cluster is pulled out from a corresponding nanofiber aggregate under the action of external force, the nanofiber clusters are independently subjected to preliminary twisting and then are subjected to mixed twisting, and the nanofiber yarn is obtained. In addition, the prepared nanofiber yarn well retains the excellent performance of the nanofiber, and the problems that hairiness is likely to be generated in the yarn forming process of existing nanofiber, and the mechanical strength is poor are solved.

Owner:NANTONG TEXTILE & SILK IND TECH RES INST +1

A method for preparing aqueous graphene dispersion by ultrasonic exfoliation

InactiveCN104876210BReduce damageReduce the number of layersGraphenePolymer scienceMegasonic cleaning

The invention discloses a method for preparing a water-phase graphene dispersion liquid by employing ultrasonic stripping. The method comprises the following steps: adding 1 part of graphite to 500-10,000 parts of a lignin amphiphilic polymer solution with the mass concentration of 0.1-10g / L; carrying out ultrasonic stripping at 20-60 DEG C for 10-100 hours by virtue of an ultrasonic cleaning machine; and then centrifugally separating to obtain the graphene dispersion liquid. According to the method disclosed by the invention, a lignin amphiphilic polymer is adopted as a natural polymer dispersant of water-phase graphene for the first time; the graphene in the prepared dispersion liquid is few in structure defect and few in layers; the lowest concentration is 0.1g / L; the excellent performance of the graphene is well reserved; the method can be widely applied to the fields such as catalysts, sensors and conducting materials; the method disclosed by the invention is economical and environment-friendly; the utilization rate of raw materials is improved; and the industrialization cost is reduced.

Owner:SOUTH CHINA UNIV OF TECH

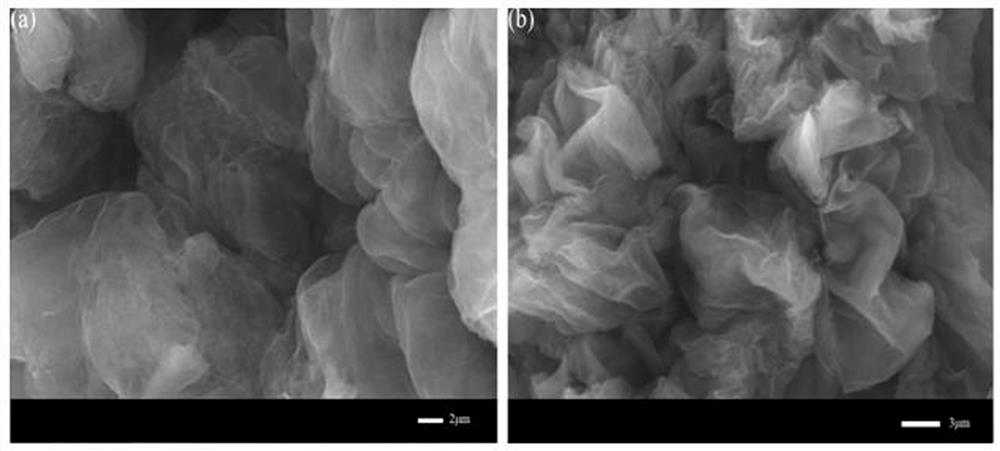

Low-cost preparation process for preparing three-dimensional porous graphene

PendingCN113387351ARealize resource reuseRealize low carbon emissionsPhysical/chemical process catalystsGrapheneChemistryCoal gangue

Owner:辽宁聚泰鑫新材料研究有限公司 +1

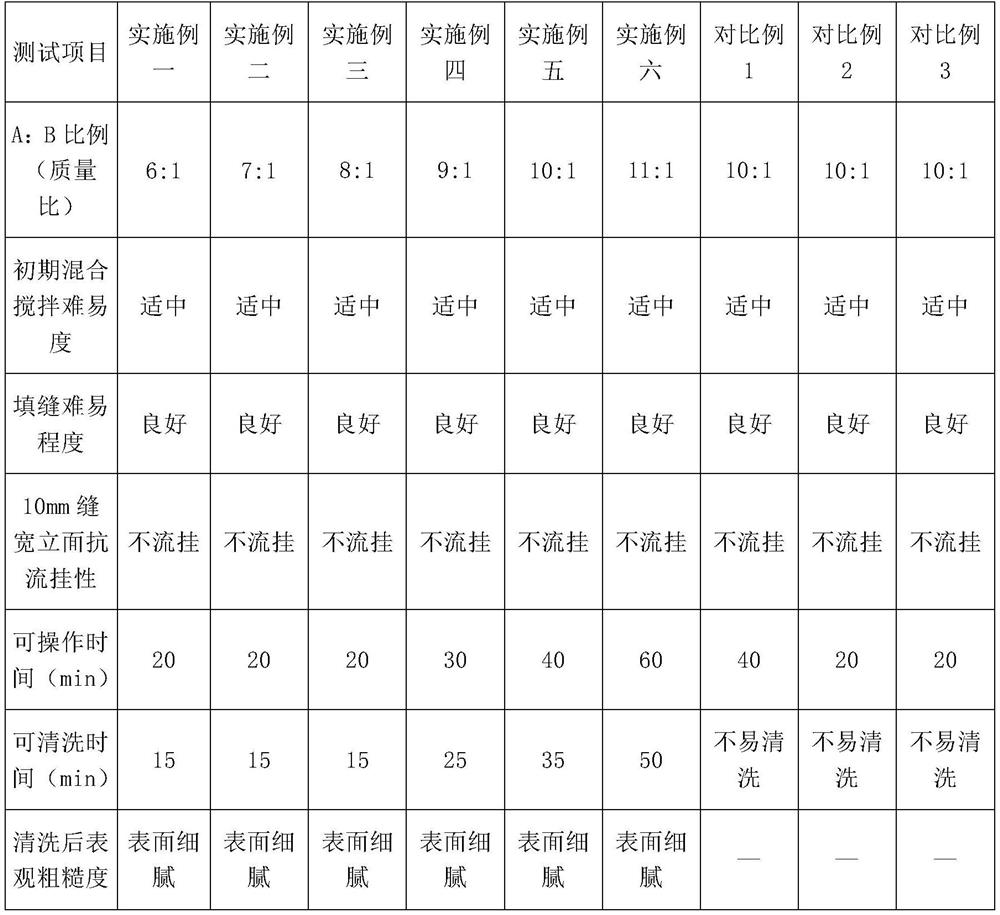

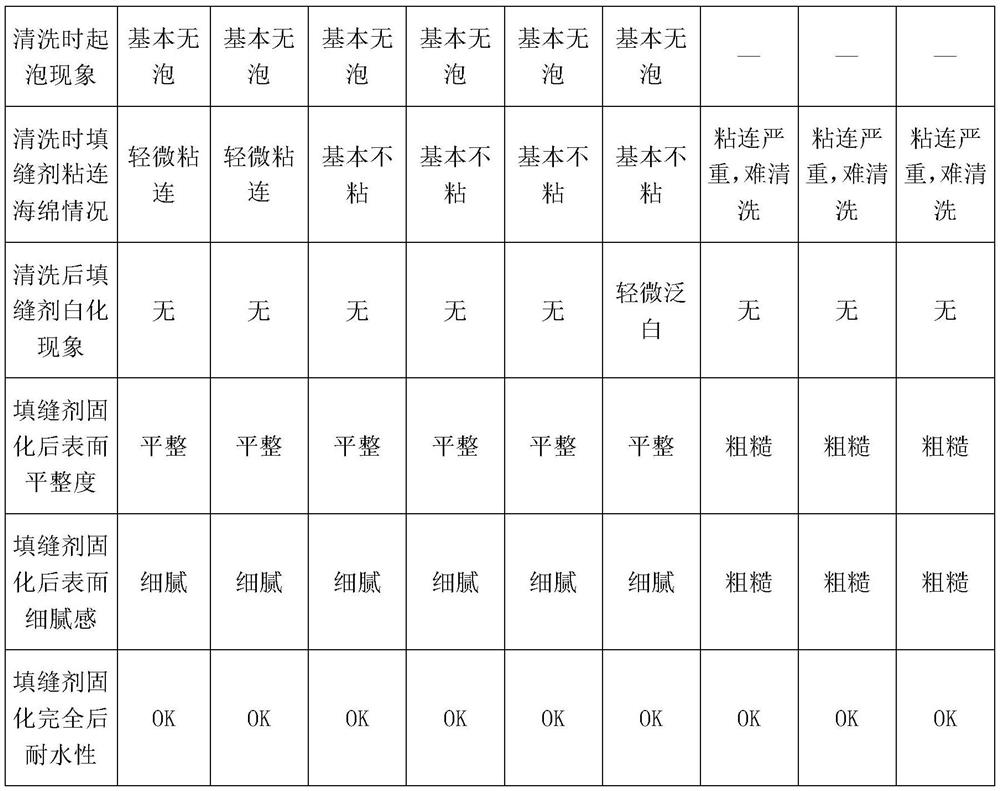

Solvent-free epoxy joint mixture and preparation method thereof

The invention discloses a solvent-free epoxy joint mixture and a preparation method thereof. The solvent-free epoxy joint mixture is composed of a component A and a component B, wherein the componentA comprises 10-50% of solvent-free epoxy resin, 50-90% of a pigment filler, 0-20% of talcum powder and 0-20% of calcium powder, and the component B comprises 0-99% of a solvent reaction type emulsifier epoxy curing agent, 0-99% of a solvent-free epoxy curing agent and 0-5% of anhydrous acetic acid.

Owner:雷帝(中国)建筑材料有限公司

A kind of hyperbranched polysulfone with controllable degree of branching and preparation method thereof

The invention discloses a hyperbranched polysulfone with a controllable degree of branching and a preparation method thereof. The method comprises the following steps: 1) generating bisphenol in a water-insoluble hydrocarbon solvent with an organic bisphenol compound and a salt-forming agent salt; 2) adding the solution of 4,4'-dichlorodiphenyl sulfone / aprotic polar solvent into the bisphenoxide system, and polycondensation reaction occurs under the catalysis of polycondensation catalyst to generate linear polysulfone; 3 ) adding a solution of chloromethylated polysulfone / aprotic polar solvent into the system to react to generate hyperbranched polysulfone; 4) precipitating the product in a precipitating agent, and obtaining hyperbranched polysulfone powder through a post-treatment process. Compared with the traditional method for preparing hyperbranched polysulfone, the present invention does not need to use expensive multifunctional monomers, which greatly saves costs; the molecular weight distribution of the obtained product is narrow, and no gelation phenomenon occurs, and it can also be obtained by selecting different chloroforms. The degree of branching is controlled by polysulfone with the degree of radicalization, which is simple and easy to operate.

Owner:WANHUA CHEM GRP CO LTD

A kind of titanium alloy oil pipe short joint surface treatment method

ActiveCN111519231BHigh affinityGood removal effectSurface reaction electrolytic coatingElectrolytic agentMicro arc oxidation

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

A method for preparing graphene by continuous exfoliation in a dry powder state using an alternating electric field

Owner:齐河智谷产业发展有限公司

A method for preparing graphene by combining ultrasonic stripping and jet stripping

The invention discloses a method for preparing graphene by combining ultrasonic peeling and jet flow peeling. The method comprises the steps that firstly, graphite is dispersed in an aqueous surfactant solution; secondly, the mixed liquid obtained in the first step is subjected to ultrasonic peeling, and multilayer graphene dispersion liquid is obtained; thirdly, the multilayer graphene dispersion liquid obtained in the second step is subjected to jet flow peeling, and monolayer graphene dispersion liquid is obtained; fourthly, the monolayer graphene dispersion liquid obtained in the third step is dried, and the graphene is obtained. According to the preparation method, the ultrasound and jet flow combined peeling mode is adopted for the first time, the obtained graphene in the dispersion liquid has few structural defects and layers and high concentration, the excellent performance of graphene is retained very well, and the graphene can be widely applied to the fields of automotive parts, sensors, conductive materials, heat conduction materials and the like. The method is economical and environmentally friendly, the raw material utilization rate is increased, and the industrialization cost is reduced.

Owner:SHANGHAI LEVSON ENTERPRISE GRP

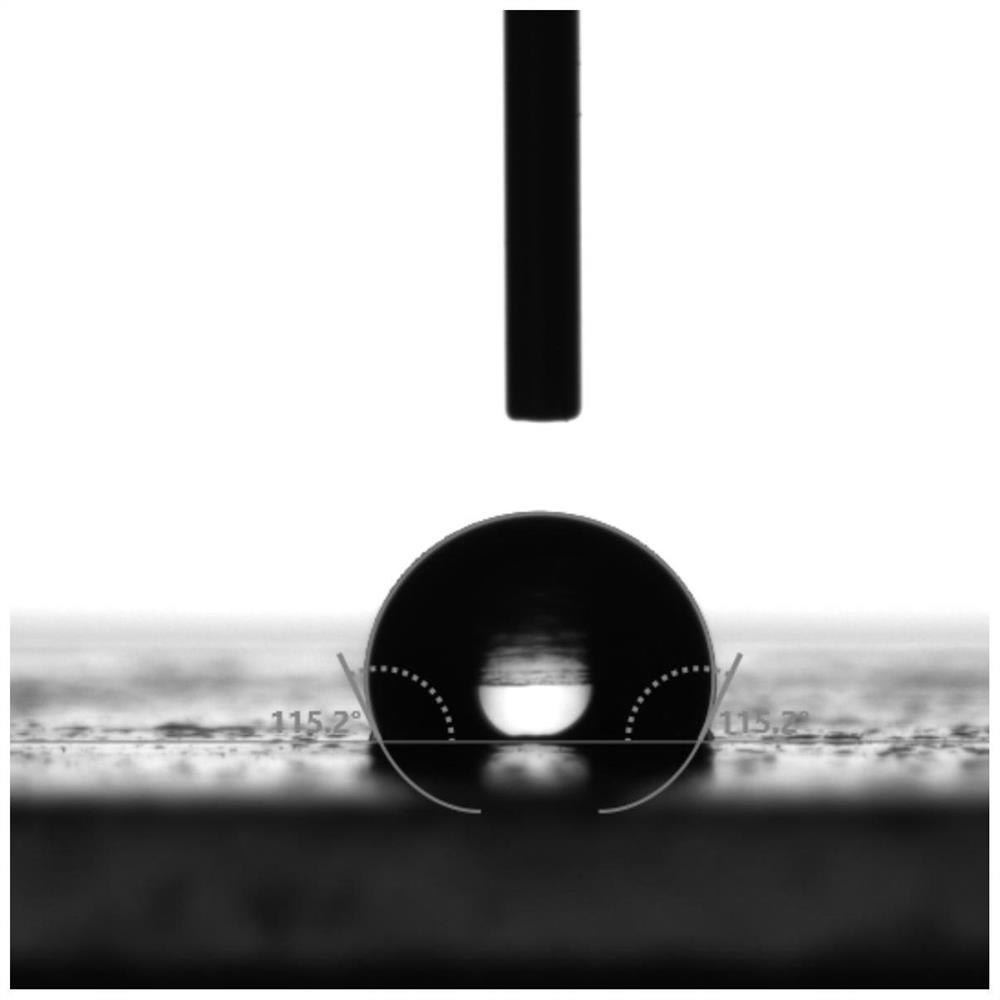

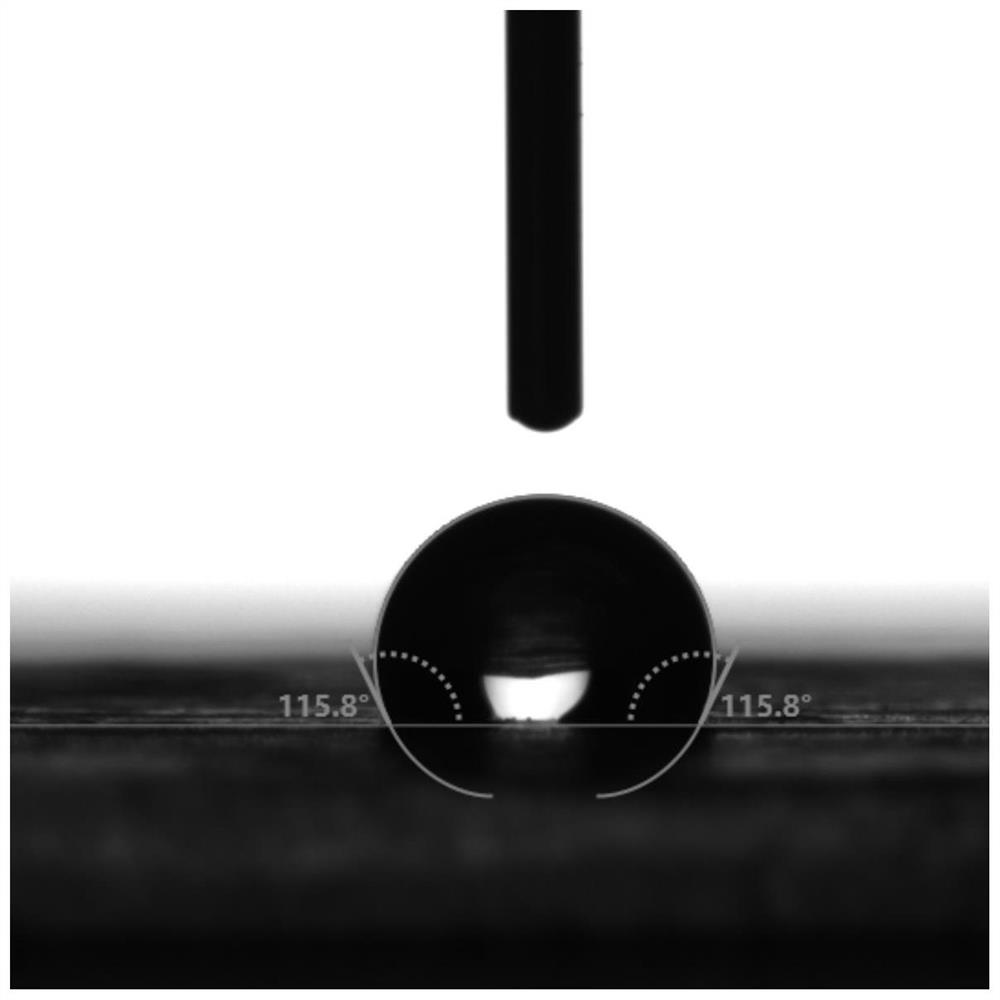

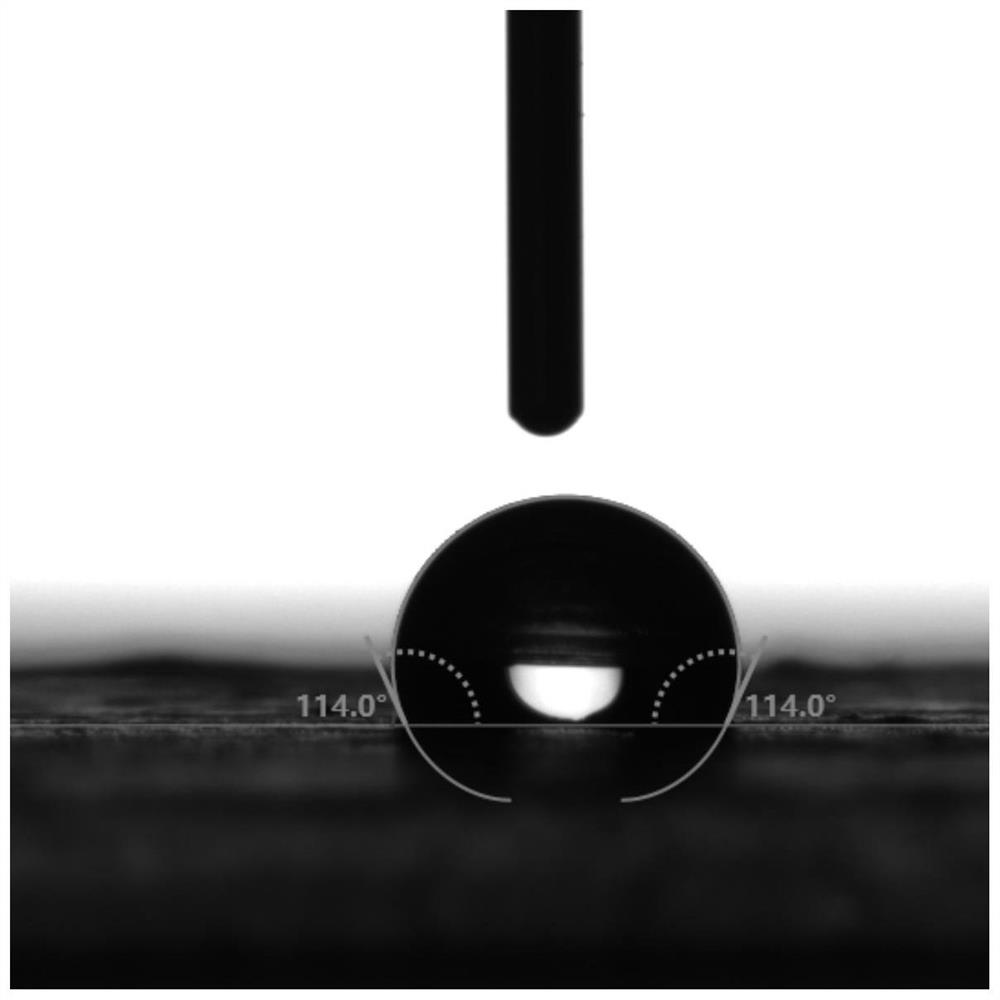

Hydrophobic organic polysilazane as well as preparation method and application thereof

The invention relates to hydrophobic organic polysilazane as well as a preparation method and application thereof, and belongs to the technical field of organic polysilazane preparation. According to the method, fluorochlorosilane with fluorine-containing branched chains and chlorosilane are selected as reaction raw materials, hydrophobic organic polysilazane is synthesized through polycondensation by a one-step method according to the principle of chlorosilane ammonolysis polycondensation, and by means of molecular structure design, the Si-N bond structure of the main chain of a polysilazane molecule is reserved, so that the excellent performance of the polysilazane material is reserved; the fluorine-containing branched chain of the fluorochlorosilane is increased along with the increase of the Si-N main chain in the polycondensation process by controlling parameters such as temperature and reaction time, the branched chain is changed into a hydrophobic group, the hydrophobicity is improved, and the average hydrophobic angle of the polysilazane can reach 114 degrees or above. The polysilazane is colorless transparent liquid and can be self-cured to form a film at room temperature, complex processes such as compounding of various solutions, repeated coating or heat treatment and the like when the coating needs to be used are avoided, the using method is simplified, and the coating is uniform, transparent and high in light transmittance.

Owner:718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

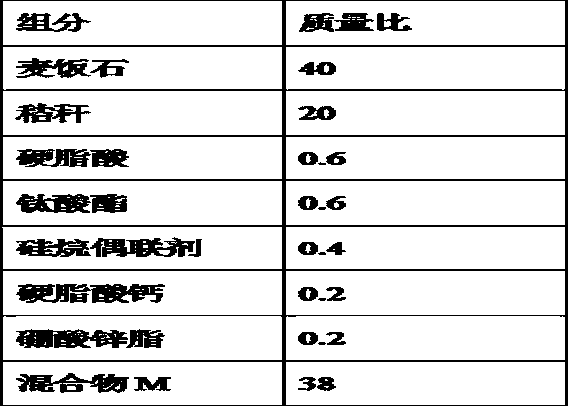

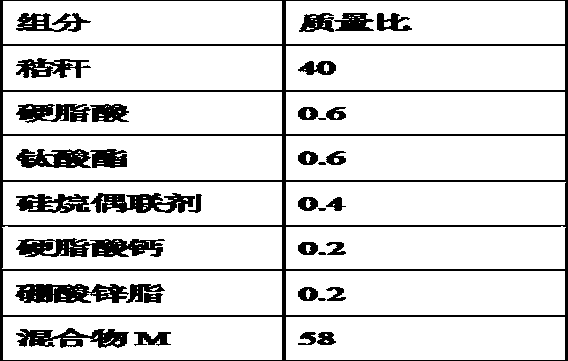

Medical stone and plant fiber composite material and manufacturing process thereof

The invention relates to a medical stone and plant fiber composite material and a manufacturing process thereof, wherein the main materials of the composite material are medical stone and plant fiberpowder, a mixture of stearic acid, titanate, a silane coupling agent, calcium stearate and zinc borate is adopted as a mixed auxiliary agent, the medical stone and the plant fiber powder are subjectedto a mixed reaction by controlling at 60-80 meshes, and mixing and die pressing need to be conducted at a high pressure and a low temperature compared with the conventional thermosetting process. According to the invention, the composite material integrates the two characteristics of medical stone and plant fibers, substantially improve the hydrophobicity of the plant fibers, enhances the toughness of the medical stone, reserves the excellent performance of the melamine resin, reduces the production cost, can release trace elements and negative ions, and is suitable for daily life.

Owner:安徽绿之态秸秆制品有限公司

A kind of short fiber reinforced oriented max phase ceramic matrix composite material and preparation method

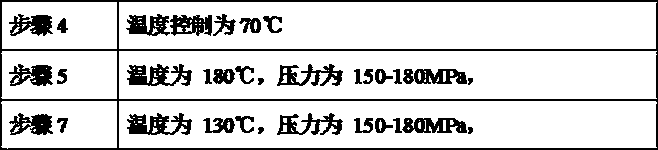

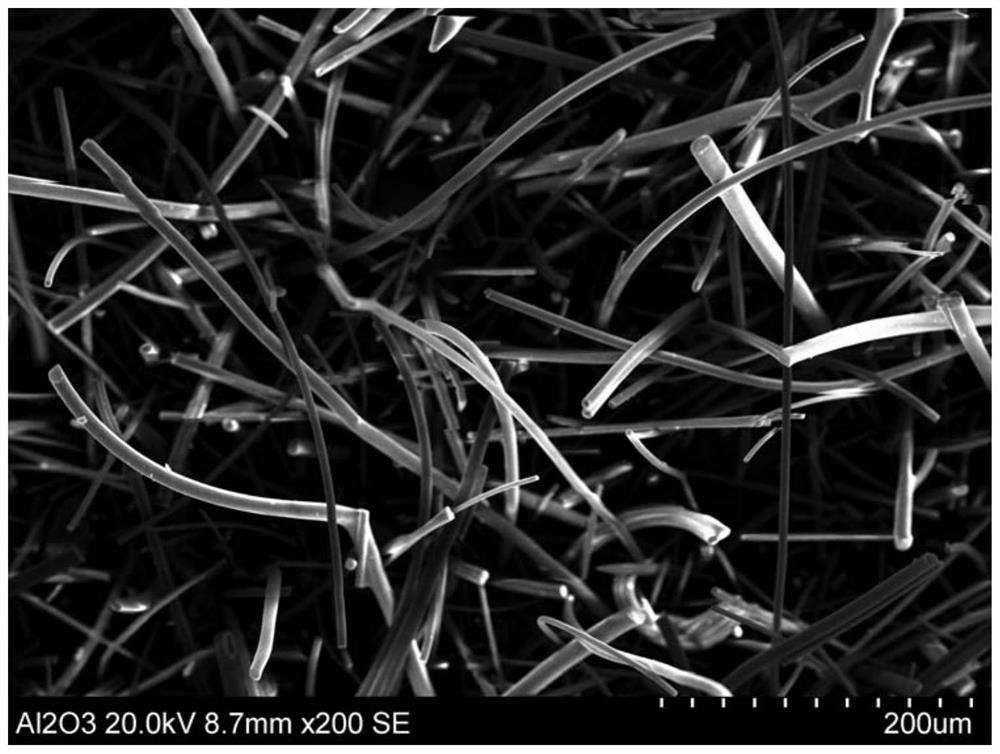

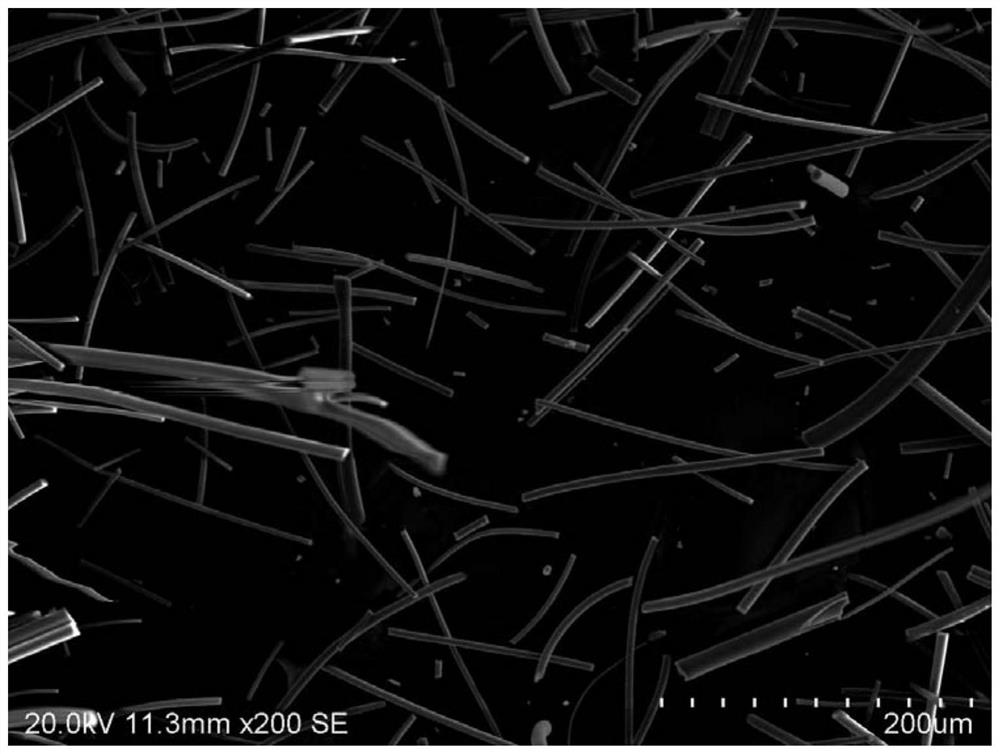

ActiveCN109053206BLow equipment requirementsNo size limitMaterial nanotechnologyUltimate tensile strengthCeramic matrix composite

The invention relates to the field of MAX-phase ceramic-based composite materials, in particular to a short-fiber-reinforced and oriented MAX-phase ceramic-based composite material and a preparation method thereof. A new process of preparing fiber-reinforced MAX phase ceramic matrix composites with fibers, nanosheet layered MAX phase ceramic powder, and other additives is used to prepare a matrix composed of highly oriented lamellar MAX phase ceramics, and the fibers are parallel to the axial direction. A new ternary composite material in which the layered MAX phase ceramics are distributed, and the granular ceramic phase reinforcement phase is dispersed in the matrix. Therefore, the MAX phase ceramic matrix composite material matrix material prepared by the existing method has coarse grains, many internal defects, low strength, and poor fracture toughness; and the reaction sintering temperature is too high, and the chemical and physical damage of the fiber in the substrate causes performance degradation etc. The fiber prepared by the method is suitable for large-scale industrial preparation, and its performance far exceeds any existing known fiber MAX phase composite material.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Epoxy-polyacrylate "core-shell" emulsion and preparation method thereof

Novel epoxy-polyacrylate "core-shell" emulsion and preparation method thereof, water-based epoxy resin usually refers to the emulsion, aqueous dispersion or formed by dispersing epoxy resin in the water phase in the form of particles, droplets or colloids Aqueous solution, the difference between the three lies in the particle size of the dispersed phase of epoxy resin. Novel epoxy-polyacrylate "core-shell" emulsion steps: (1) Emulsify the epoxy resin emulsion prepared by the phase inversion method with one-third of the acrylate mixed monomer at 20°C~40°C for 0.5 (2) Add the initiator into the reaction system, add the remaining acrylate mixed monomer drop by drop at a temperature of 80°C~90°C, finish adding within 3~4 hours, and keep warm for 1~5 hours; (3 ) to cool below 50°C and discharge. The product of the invention is used as paint or paint base material.

Owner:HARBIN UNIV OF SCI & TECH

A kind of industrial synthesis method of branched high-strength polysulfone resin

The invention discloses an industrial synthesis method of branched high-strength polysulfone resin. In the present invention, by controlling the ratio of dichloride and bisphenol monomers, at first, a hydroxyl-terminated polysulfone oligomer is synthesized, and further, the hydroxyl-terminated polysulfone is lowered by a dichloro substitute, a trichloro substitute or a tetrachloro substitute. The high-strength polysulfone resin is prepared by adding low-molecular-weight organic substances containing carbon, silicon, and titanium to the polymer, which not only retains the excellent performance of the original polysulfone resin, but also greatly improves the impact strength and toughness, breaking the application limitations and greatly expanded its field of application.

Owner:GUANGDONG YOUJU ADVANCED MATERIAL RES CO LTD

A kind of cellulose nanocrystal composite material and method modified by polylactic acid/nucleating agent

Owner:SHANDONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com