A kind of preparation method of graphene/carbon fiber composite material

A composite material and carbon fiber technology, used in carbon fiber, fiber treatment, electrolytic coatings, etc., can solve the problems of small specific surface area, less active carbon atoms at the edge, and inert carbon fiber surface, and achieve large specific surface area, avoid damage, and large reactions. The effect of the active site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

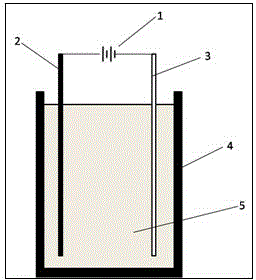

[0046] A preparation method of graphene / carbon fiber composite material, specifically comprising the following steps:

[0047] (1) Preparation of graphene dispersion

[0048] Take 1g of natural flake graphite passed through a 32-mesh sieve, add 1L of 1-methyl-2-pyrrolidone, place it in an ultrasonic instrument, control the temperature at 20-40°C, and perform ultrasonication at 200W for 10 hours to obtain a dispersion;

[0049] Then, the dispersion liquid obtained above is centrifuged under the condition of 4000r / min for 1h, and the supernatant liquid obtained is the graphene dispersion liquid, and the solid content in the graphene dispersion liquid is 0.02g / L;

[0050] (2) According to the ratio of organic amine salt: 1-methyl-2-pyrrolidone of 1g:1L, dissolve 0.005g of organic amine salt in 5ml of 1-methyl-2-pyrrolidone to obtain an organic amine salt solution. The organic amine salt is aniline hydrochloride;

[0051] Add the organic amine salt solution obtained above to 50ml ...

Embodiment 2

[0060] A preparation method of graphene / carbon fiber composite material, specifically comprising the following steps:

[0061] (1), the preparation process of the graphene dispersion is the same as in Example 1;

[0062] (2), the preparation process of the positively charged graphene dispersion is the same as in Example 1;

[0063] (3), in the electrophoretic deposition tank, the positively charged graphene dispersion obtained in step (2) is used as the electrolyte of the electrophoretic deposition tank;

[0064] The stainless steel sheet that was polished and washed with sandpaper and then dried was used as the positive electrode sheet;

[0065] Use carbon fiber products, that is, carbon fiber paper, as the negative pole piece for electrophoretic deposition;

[0066] During the above electrophoretic deposition process, the distance between the positive and negative electrodes was controlled to be 15mm, the applied DC voltage was 90V, the electrophoretic deposition time was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com