Nanofiber yarn and continuous yarn forming method thereof

A nanofiber and yarn technology, applied in fiber processing, filament/thread forming, yarn, etc., can solve problems such as poor mechanical strength and easy hairiness, achieve good elastic recovery rate, avoid hairiness, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This example provides a nanofiber yarn and a continuous yarn forming method thereof. The raw material used in this example is polysulfone (PSF) particles (purchased from Dongguan Chuanao Engineering Plastic Materials Co., Ltd., trade name: P-1710).

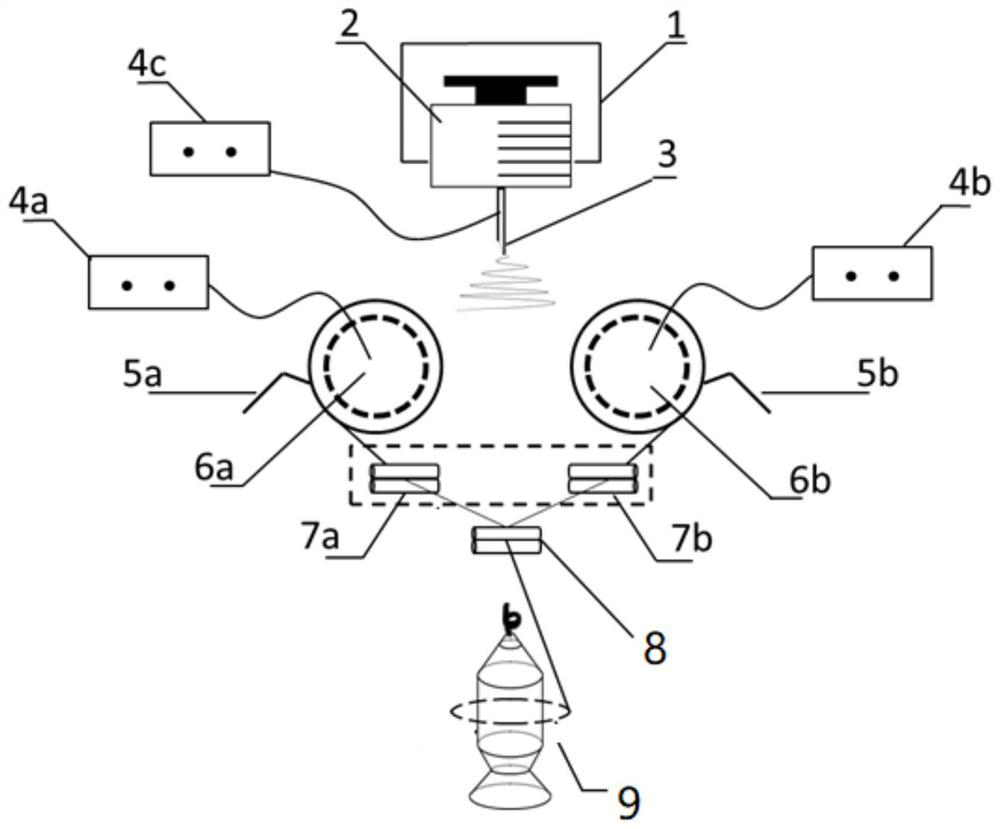

[0039] In this example, the continuous yarn-forming method includes the following steps: using electrospinning to spin out nanofibers, so that the spun nanofibers are split into 2 parts under the action of 2 electric fields during the movement;

[0040] Further, the electrospinning stock solution used in electrospinning was prepared by the following method: 10 g of polysulfone (PSF) particles were dissolved in 90 g of dimethylacetamide (DMAc) to obtain a mixed solution, which was placed in a magnet and placed in a container. It is sealed and placed in a water bath for high temperature heating. The temperature of the water bath is 80 °C and the heating time is 2 hours. After heating, take it out and let it stand for 0.5 hour...

Embodiment 2

[0059] This example provides a nanofiber yarn and a continuous yarn forming method thereof, which is basically the same as that of Example 1, and the difference is only:

[0060] (1) The electrospinning stock solution was obtained by the following method: 10 g of degummed silk fibroin (SF, purchased from Beijing Yongkang Leye Technology Development Co., Ltd., trade name: SP110) powder was dissolved in 90 g of hexafluoropropanol (HFIP) , get the mixed solution, put it into the magnet, place it in a container for sealing treatment and heat it in a water bath. The temperature of the water bath is 40°C, and the heating time is 5h. After heating, take it out and let it stand for 1h to obtain a mass fraction of 10wt % transparent and homogeneous solution;

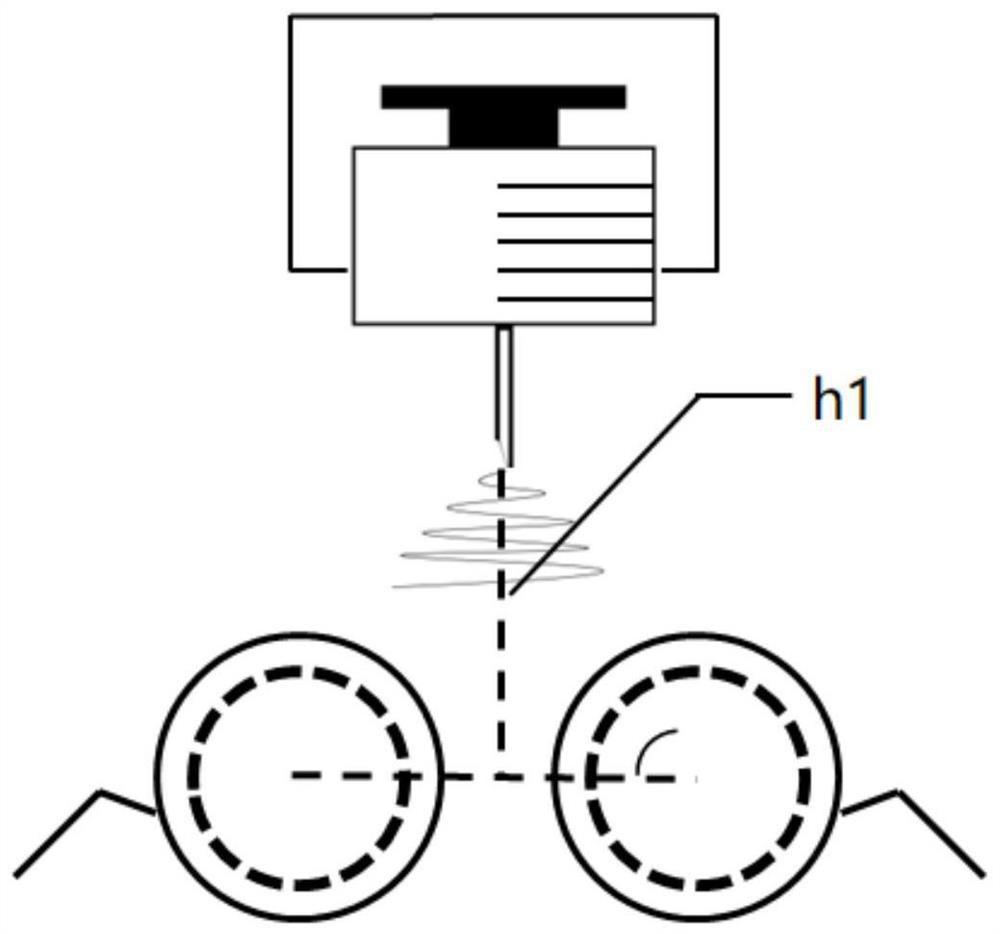

[0061] (2) Electrospinning conditions: the voltage is 20kV, the nozzle aperture is 0.4mm, the solution flow rate is 0.5mL / h, and the spinning distance h1 is 25cm;

[0062] (3) The temperature of the two primary-twisting work rol...

Embodiment 3

[0066] This example provides a nanofiber yarn and a continuous yarn forming method thereof, which is basically the same as that of Example 1, and the difference is only:

[0067] (1) The electrospinning stock solution was obtained by the following method: 10 g of polyacrylonitrile (PAN, purchased from Shanghai Aladdin Biochemical Technology Co., Ltd., trade name: P303197) powder was dissolved in 90 g of dimethylformamide (DMF) to obtain Mix the solution, put it into the magnet, seal it in a container and heat it in a water bath at a high temperature. The temperature of the water bath is 70°C, and the heating time is 5h. Transparent and homogeneous solution;

[0068] (2) Electrospinning conditions: the diameter of the nozzle is 0.4mm;

[0069] (3) The rotational speed of the left cluster guide wheel is 200r / min, and the radius of the conductive metal ring is 5cm;

[0070] The speed of the right cluster guide wheel is 100r / min, and the radius of the conductive metal ring is 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com