Low-cost preparation process for preparing three-dimensional porous graphene

A three-dimensional porous, preparation process technology, applied in the field of carbon nanomaterials, can solve the problems of expensive carbon powder and rising prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0035] Process for preparing a three-dimensional porous graphene produced at low cost, comprises the steps of:

[0036] Step 1, selected from the gangue anthracite, bituminous, sub-bituminous, lignite one kind of coal or coal residues in various combinations source.

[0037] Step 2, the selected source coal gangue residues mechanically pulverized coal.

[0038] Step 3, the organic component is separated from the mineral components and residual flotation of coal pulverized coal source.

[0039] The wet powder grinding step 4 the organic component, the isolated to 200-500 mesh.

[0040] Step 5, adding nanoscale organic component catalyst blend milled to obtain a homogeneous mixture wherein the mass ratio of the catalyst with the organic component is 0.1: 1.

[0041] Step 6, the above-described mixture was treated at a high temperature 2000-3000 ℃ 1-24h, processing charged purity nitrogen or high purity argon shielding gas, it graphitization.

[0042] Step 7, 1 part by mass of an orga...

Example Embodiment

[0052] Example 1.

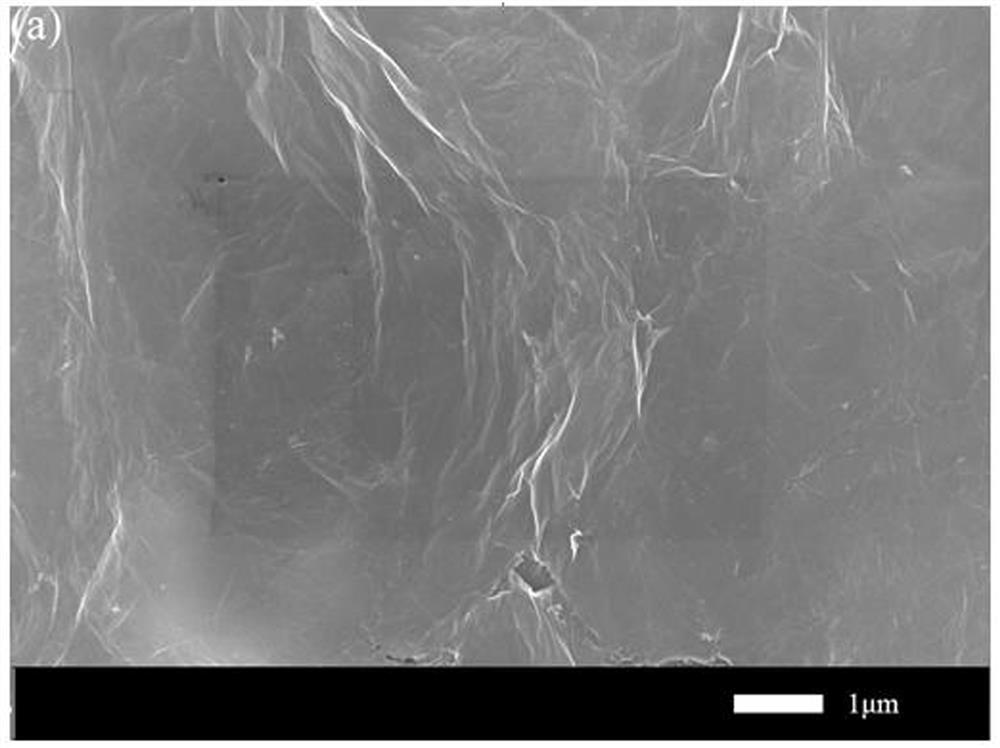

[0053] Anthracite after taking the residue after mechanical comminution selected organic and mineral components float with carbon tetrachloride, the organic component of the obtained wet ground to 500 mesh powder without added iron powder catalyst 1: 0.1 mixed mass ratio of ball milling. Then placed in a graphite furnace temperature of 9h 2000 ℃. Take 40g 1g graphitized material and the concentrated sulfuric acid, concentrated phosphoric acid 6g, was stirred under ice-cooling conditions, mix well, then add 30g of potassium permanganate, the reaction 90min at 30 deg.] C environment. 50g of deionized water was added, the reaction was continued at 90 ℃ 15min, followed by addition of 7g of hydrogen peroxide, stir until golden brown, washing it by centrifugation, and broken by the ultrasonic shear graphene oxide to obtain a uniform suspension. The graphene oxide, the graphene oxide powder solution was dried in vacuo for 24h to obtain a sieve of 500 mesh to obtain. T...

Example Embodiment

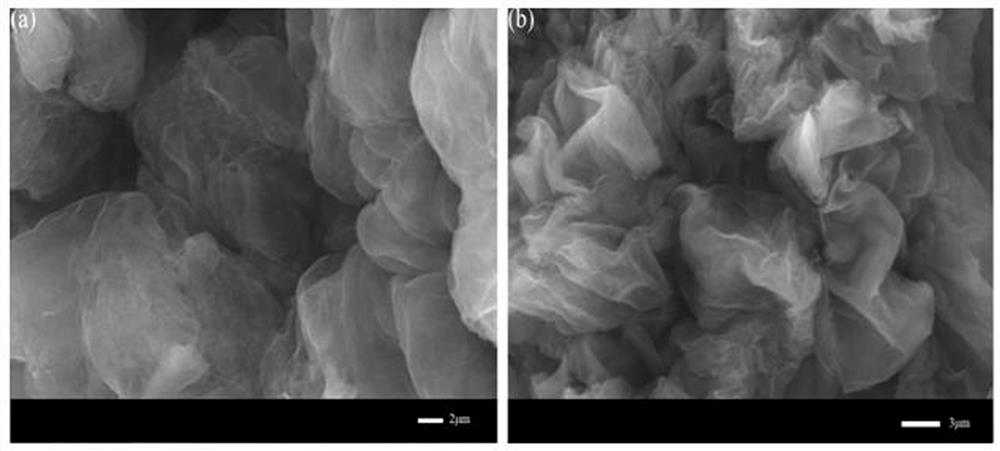

[0054] Example 2.

[0055] After the organic and mineral components selected after mechanical pulverization residue was taken with chloroform floating bituminous, wet ground to 500 mesh powder to the organic component obtained without addition of the catalyst, the iron to 1: 0.1 by mass ratio mixed by a ball mill. Then placed in a graphite furnace temperature of 9h 2000 ℃. Take 50g 1g graphitized material and the concentrated sulfuric acid, 8g concentrated phosphoric acid, stirred under ice-cooling conditions, mix well, then add 40g of potassium permanganate, the reaction 90min at 40 ℃ environment. 50g of deionized water was added, the reaction was continued at 90 ℃ 15min, then 9g of hydrogen peroxide, stir until golden brown, washing it by centrifugation, and broken by the ultrasonic shear graphene oxide to obtain a uniform solution. The obtained graphene oxide through 500 mesh sieve to obtain graphene oxide powder after drying in vacuo 24h. Weigh 0.3g graphene oxide powder, 0.45...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com