Medical stone and plant fiber composite material and manufacturing process thereof

A composite material and plant fiber technology, applied in the field of medical stone and plant fiber composite materials and their manufacturing processes, can solve problems such as poor toughness of medical stone containers, achieve high product forming rate, reduce production costs, and increase toughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

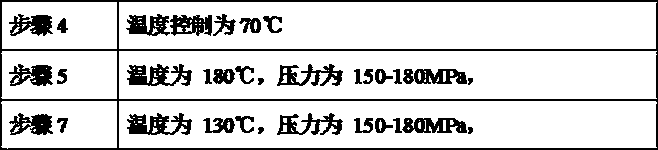

Examples

Embodiment 1

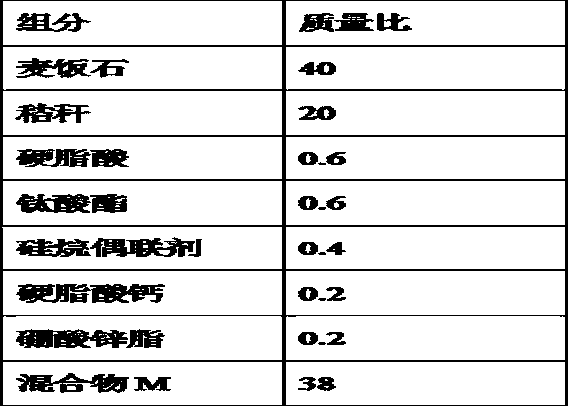

[0027] The weight ratio of each component is as follows

[0028]

[0029] Analysis of the test results: the fluidity of the dispersant of the product is good, the weight of the molded products is between 108-111 grams, the weight of the product increases by about 10%, the specific gravity / density value of the product is 1250, and the stability is relatively good. In the drop test, no damage was found when it was dropped freely from a height of 1.5 meters; it was dropped 5 times from a height higher than 1.5 meters, and there were cracks on the surface.

Embodiment 2

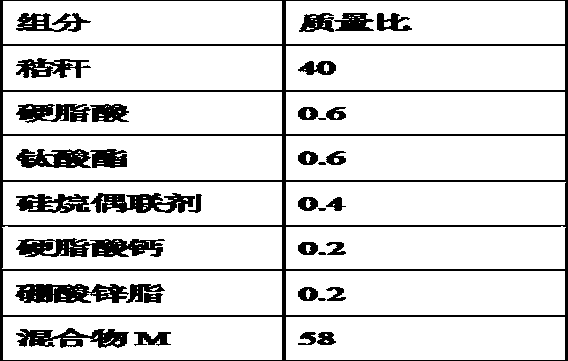

[0031]

[0032] Analysis of the test results: the fluidity of the dispersant of the product is very poor, the weight of the molded product is between 113-116 grams, the weight of the product is about 15%, the specific gravity / density value of the product is 1390, there are agglomerates on the surface, and the hand quality is poor , poor stability. In the drop test, 5 times of free fall at a height of 1.5 meters, 4 times of partial cracking, accompanied by debris.

Embodiment 3

[0034]

[0035] Analysis of the test results: the fluidity of the dispersant of the product is poor, the weight of the molded product is between 110-112 grams, the weight of the product is about 11%, the specific gravity / density value of the product is 1265, and there are a few pits and fine particles on the surface . In the drop test, it was dropped 5 times at a height of 4 meters, and no damage was found; it was dropped 5 times at a height of 1.5 meters, and there were cracks on the surface twice.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com