Method for preparing graphene by combining ultrasonic peeling and jet flow peeling

An ultrasonic exfoliation and graphene technology, applied in the field of graphene functional material preparation, can solve the problems of low conversion rate of raw materials, long reaction time, low equipment requirements, etc., and achieve the effects of high concentration, few structural defects and few production steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. Prepare 0.5g / L sodium dodecylbenzenesulfonate aqueous solution and stir at high speed for 30 minutes;

[0037] 2, the purity is 99.90wt%, and the graphite whose median particle diameter (D50) is 10 μm is added in the sodium dodecylbenzenesulfonate aqueous solution of step 1, and graphite concentration is 25g / L, stirs at high speed for 30 minutes;

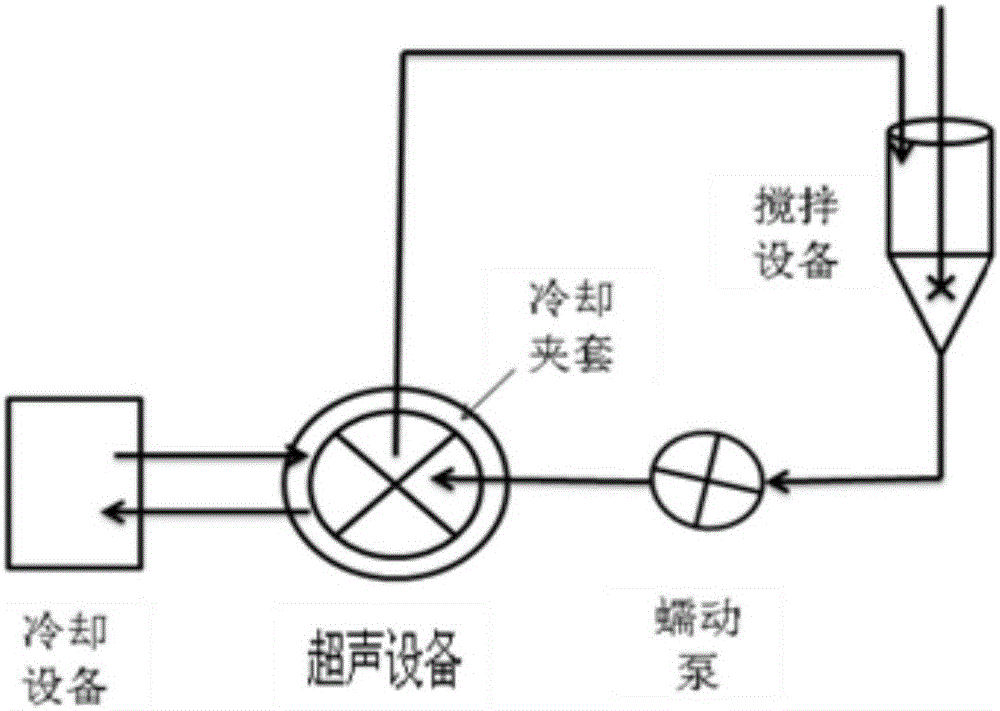

[0038] 3. Press figure 1 Schematic diagram of ultrasonic peeling device for ultrasonic peeling, where the ultrasonic power is 300W and the ultrasonic time is 12 hours;

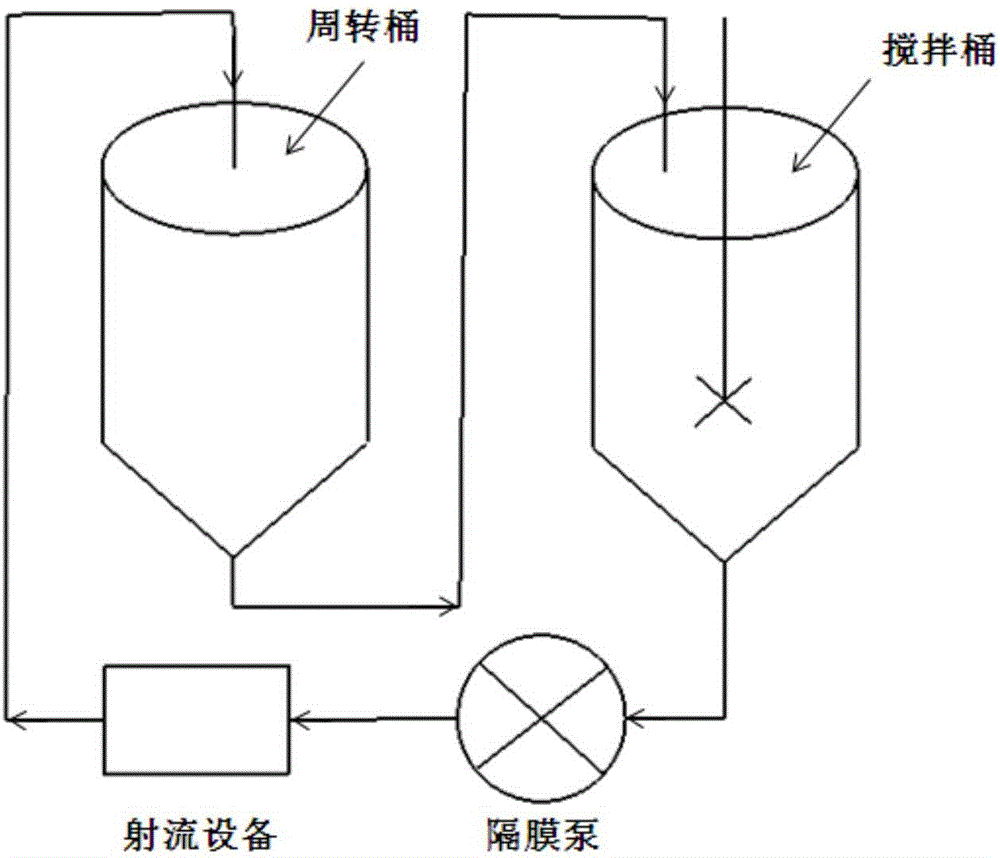

[0039] 4. Press figure 2 Schematic diagram of the jet stripping device for jet stripping, where the flow rate is 300L / h, the feed pump pressure is 2bar, the outlet temperature is 56°C, the nozzle pressure is 300bar, and the number of cycles is 8;

[0040] 5. Vacuum drying to obtain graphene, wherein the drying temperature is 80° C., and the drying time is 6 hours.

Embodiment 2

[0042] 1. Prepare 1.0g / L cetyltrimethylammonium bromide aqueous solution and stir at high speed for 30 minutes;

[0043] 2. Add the graphite with a purity of 99.90wt% and a median particle size (D50) of 60 μm to the cetyltrimethylammonium bromide aqueous solution in step 1, the graphite concentration is 50 g / L, and stir at high speed for 30 minutes;

[0044] 3. Press figure 1 Schematic diagram of ultrasonic peeling device for ultrasonic peeling, where the ultrasonic power is 500W and the ultrasonic time is 10 hours;

[0045] 4. Press figure 2 Schematic diagram of the jet stripping device for jet stripping, where the flow rate is 350L / h, the feed pump pressure is 3bar, the outlet temperature is 58°C, the nozzle pressure is 500bar, and the number of cycles is 7;

[0046] 5. Vacuum drying to obtain graphene, wherein the drying temperature is 80° C., and the drying time is 6 hours.

Embodiment 3

[0048] 1. Prepare 2.0g / L sodium lauryl sulfate aqueous solution and stir at high speed for 30 minutes;

[0049] 2. The graphite with a purity of 99.95wt% and a median particle size (D50) of 50 μm is added to the sodium lauryl sulfate aqueous solution of step 1, and the graphite concentration is 50 g / L, and stirred at high speed for 30 minutes;

[0050] 3. Press figure 1 Schematic diagram of ultrasonic peeling device for ultrasonic peeling, where the ultrasonic power is 750W and the ultrasonic time is 8 hours;

[0051] 4. Press figure 2 Schematic diagram of the jet stripping device for jet stripping, where the flow rate is 350L / h, the feed pump pressure is 3bar, the outlet temperature is 57°C, the nozzle pressure is 700bar, and the number of cycles is 5;

[0052] 5. Vacuum drying to obtain graphene, wherein the drying temperature is 80° C., and the drying time is 5 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com