Method for preparing water-phase graphene dispersion liquid by employing ultrasonic stripping

A graphene dispersion and ultrasonic stripping technology, which is applied in the field of ultrasonic stripping to prepare high-concentration aqueous graphene dispersion and aqueous graphene dispersion, can solve technical difficulties, easy agglomeration, large specific surface area of graphene, etc. , to achieve the effect of improving hydrophobicity, less structural defects, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]Add 1 part by mass of graphite to 1000 parts by mass of sodium lignosulfonate (molecular weight 1000Da-2500Da) and CTAB non-covalent bond modified sample aqueous solution with a mass concentration of 1g / L, and then use ultrasonic A cleaning machine (200w) was used for ultrasonic stripping for 100 hours; then centrifuged at a centrifugal acceleration of 3000g and a centrifugation time of 40min to obtain a graphene dispersion.

[0038] Using a UV spectrophotometer, using the absorbance at 660nm, according to Lambert-Beer's law A / l=α 660 ·C G (wherein A is the absorbance at 660nm, C G is the graphene concentration, α 660 =2460, l=0.01), the concentration C of graphene can be obtained by conversion G 0.15g / L.

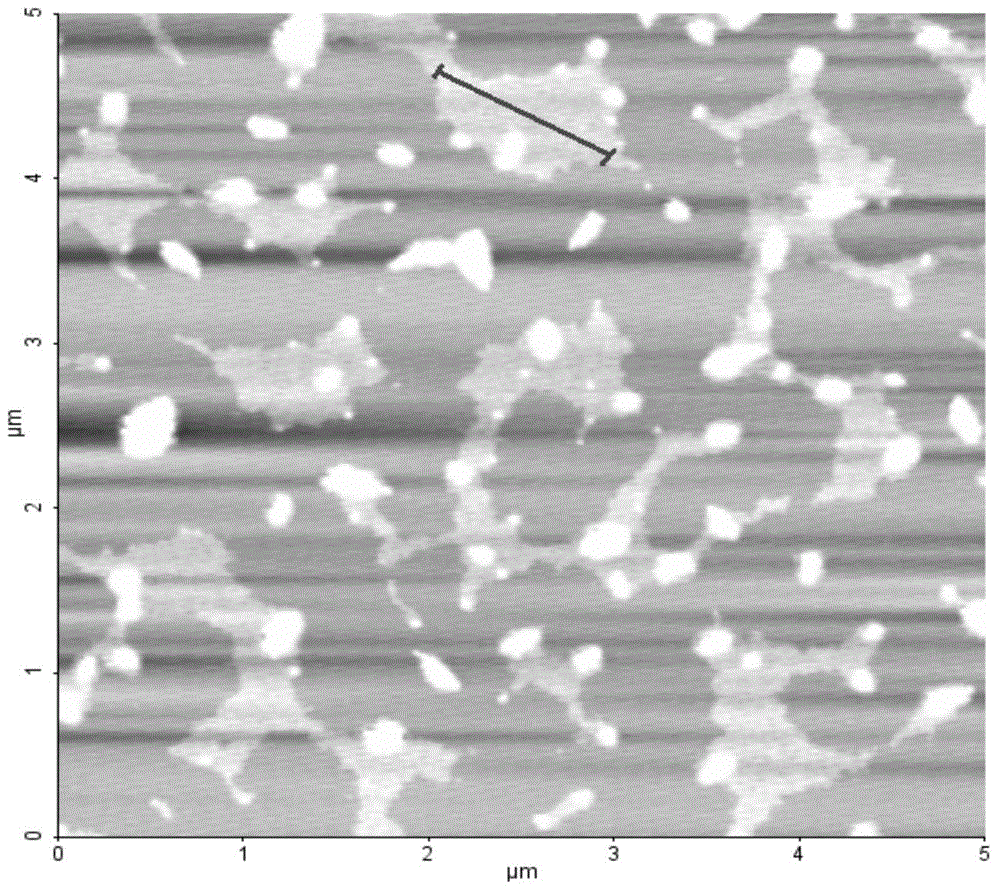

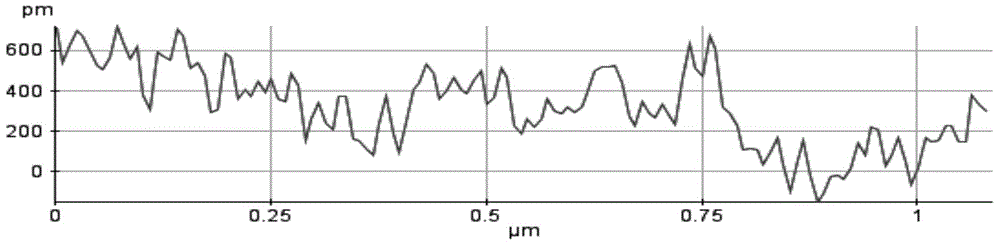

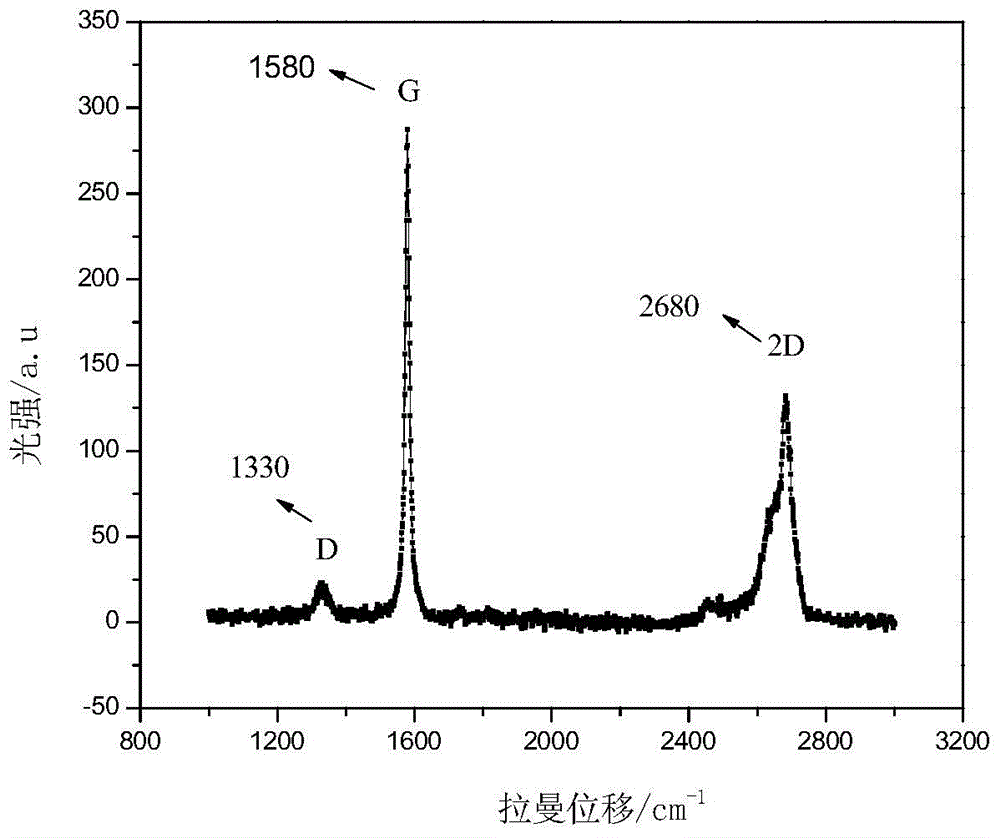

[0039] The graphene dispersion liquid that above-mentioned preparation obtains is analyzed and observed, and the results are shown in Figure 1~5 . in, figure 1 For using atomic force microscope (manufacturer: South Korea Park company, model: XE100) the topogra...

Embodiment 2

[0045] Add 1 mass part of graphite to 1500 mass parts of sodium lignosulfonate (molecular weight 2500Da ~ 10000Da) and bromotetradecane covalently modified sample aqueous solution with a mass concentration of 2g / L, and then in 30 ℃ Ultrasonic peeling was carried out using an ultrasonic cleaning machine (200w) for 100 hours; then centrifuged, the centrifugal acceleration was 2000g, and the centrifugation time was 30min to obtain the graphene dispersion. Using an ultraviolet spectrophotometer, using the absorbance at 660nm, according to Lambert-Beer's law, the concentration C of graphene can be obtained. G It is 0.13g / L.

Embodiment 3

[0047] Add 1 mass part of graphite to 5000 mass parts of sodium lignosulfonate (molecular weight: 1000Da-2500Da) aqueous solution with a mass concentration of 8g / L, and then use an ultrasonic cleaning machine (200w) at 20°C for ultrasonic peeling for 10 hour; then carry out centrifugation, the centrifugal acceleration is 5000g, and the centrifugation time is 10min, and the graphene dispersion can be obtained. Using an ultraviolet spectrophotometer, using the absorbance at 660nm, according to Lambert-Beer's law, the concentration C of graphene can be obtained. G It is 0.12g / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com