Method for preparing graphene powder and dispersion thereof from fluorine-containing hyperbranched polyethylene copolymers

A hyperbranched polyethylene and graphene dispersion technology, which is applied in the direction of graphene, chemical instruments and methods, carbon compounds, etc., can solve the problems of poor stability of modified structure, low preparation efficiency, and graphene structure damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Embodiment 1, comparative example 1

[0071] 1. Sample preparation

[0072] (1) The preparation of embodiment 1 sample is carried out as follows:

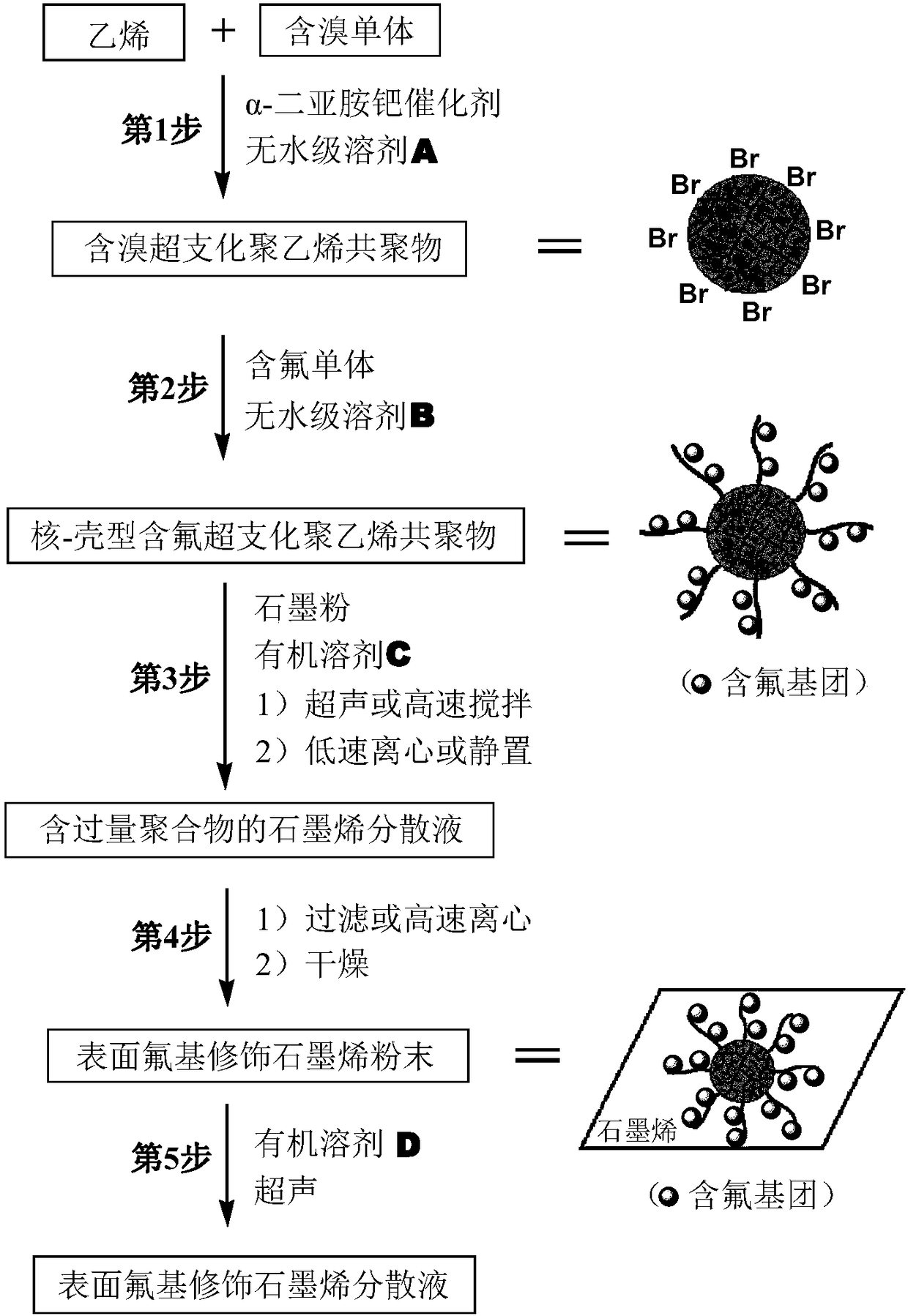

[0073] Step 1: Under the protection of ethylene, 2.12g of bromine-containing monomer BIEA (feeding concentration is 0.4 mol / L), 0.2g of acetonitrile-based α-diimine palladium catalyst 1 (feeding concentration is 12.0mmol / L) and 20mL Anhydrous grade dichloromethane was added to a 50 mL dry Schlenk bottle, and the polymerization was continued for 24 h with stirring at a constant temperature of 25 °C and a stable ethylene pressure of 0.1 MPa. After the end of the polymerization, the ethylene gas source was turned off, and the solvent and residual ethylene gas were removed by blowing cold wind at room temperature to obtain the initial polymerization product. Further dissolve it in 10 mL of tetrahydrofuran, add a small amount of hydrochloric acid and hydrogen peroxide (3 to 5 drops each), stir for 3 h to dissolve the palladium ...

Embodiment 2

[0083] Embodiment 2, comparative example 2

[0084] 1. Sample preparation

[0085] (1) The preparation of embodiment 2 sample is carried out as follows:

[0086] Step 1: Same as Step 1 of Example 1.

[0087] Step 2: Same as Step 2 of Example 1.

[0088] Step 3: Same as Step 3 of Example 1, except that the solvent was changed from chloroform to tetrahydrofuran.

[0089] (2) The preparation of comparative example 2 sample is carried out as follows:

[0090] Step 1: Same as Step 1 of Comparative Example 1.

[0091] Step 2: Same as Step 2 of Comparative Example 1.

[0092] Step 3: Same as step 3 of Comparative Example 1, except that the solvent is changed from toluene to n-heptane.

[0093] 2. Comparison and analysis of test results

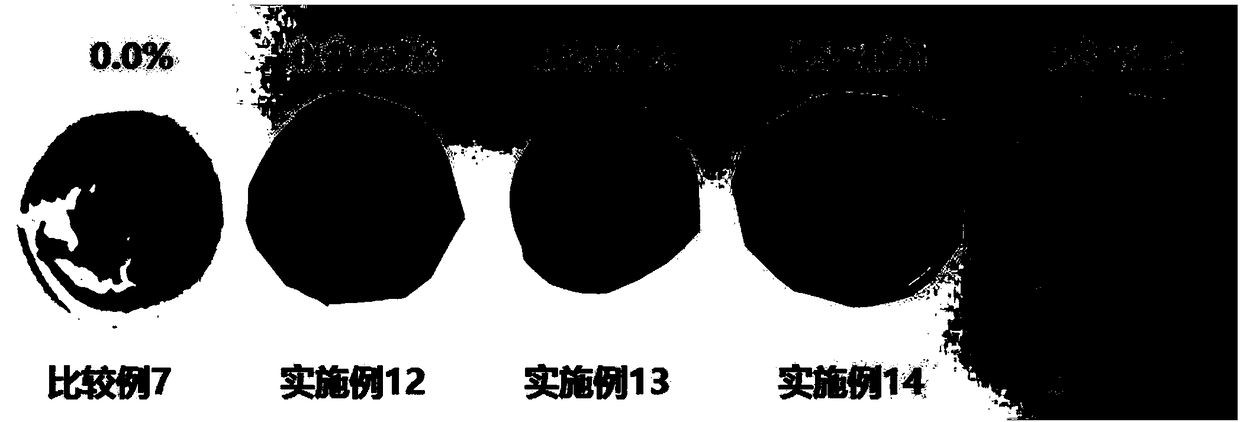

[0094] In Example 2 and Comparative Example 2, the fluorine-containing hyperbranched polyethylene copolymer is synthesized by the same steps, and each process parameter is also consistent (see steps 1 and 2 of the two), and both liquid phase e...

Embodiment 3

[0096] Embodiment 3, comparative example 3

[0097] 1. Sample preparation

[0098] (1) The preparation of embodiment 3 sample is carried out as follows:

[0099] Step 1: Same as Step 1 in Example 1.

[0100] Step 2: Same as step 2 in Example 1, except that the polymerization time is changed from 24h to 12h.

[0101] The 3rd step: with embodiment 1 step 3.

[0102] (2) The preparation of comparative example 3 sample is carried out as follows:

[0103] Step 1: Add natural phosphorus flake graphite powder with an average particle size of about 500 mesh and analytically pure chloroform into a test tube with a capacity of 25 mL (wherein the feeding concentration of graphite powder is 2.0 g / L, fluorine-containing hyperbranched polyethylene copolymer The mass ratio to graphite powder is 0), sealed and placed in a 250W ultrasonic cell at room temperature for 48 hours of continuous ultrasonication; the resulting product was centrifuged at 4000rpm at a low speed for 45min to remove ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com