Solvent-free epoxy joint mixture and preparation method thereof

A solvent-free, caulking technology, applied in the field of epoxy caulking, can solve the problems of air bubbles, affecting the use and appearance of caulking, and sticking to sponges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

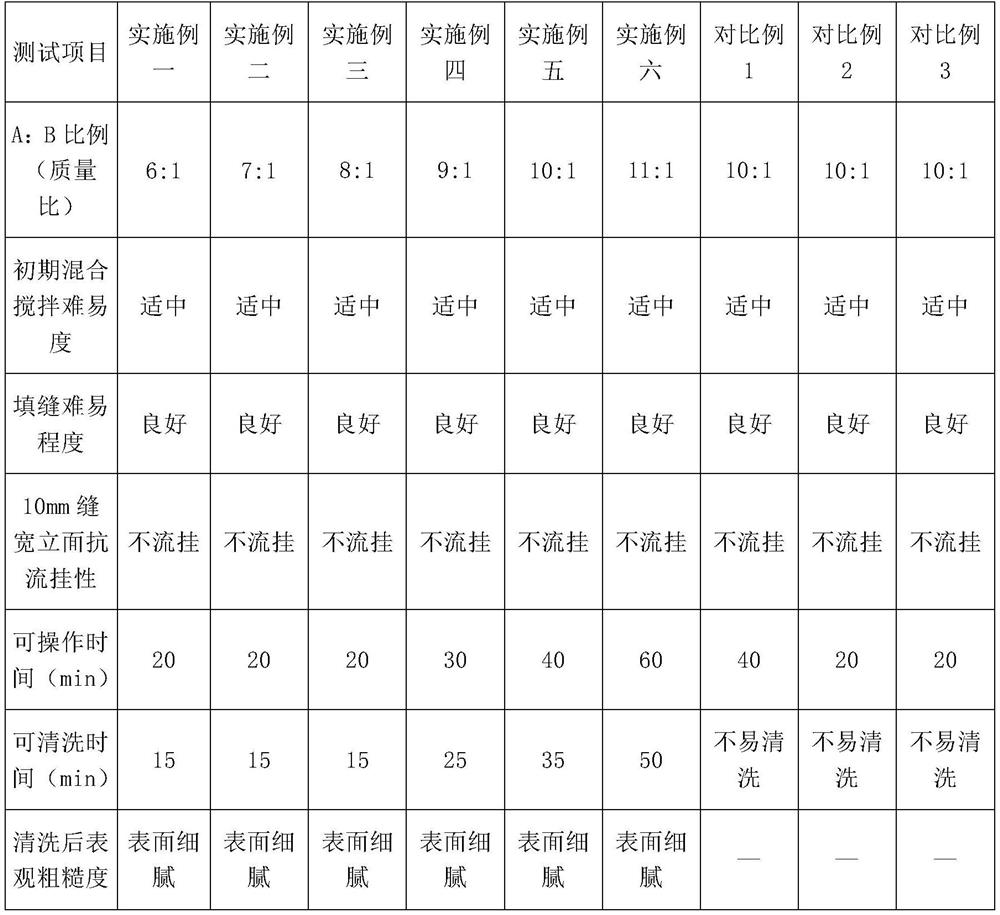

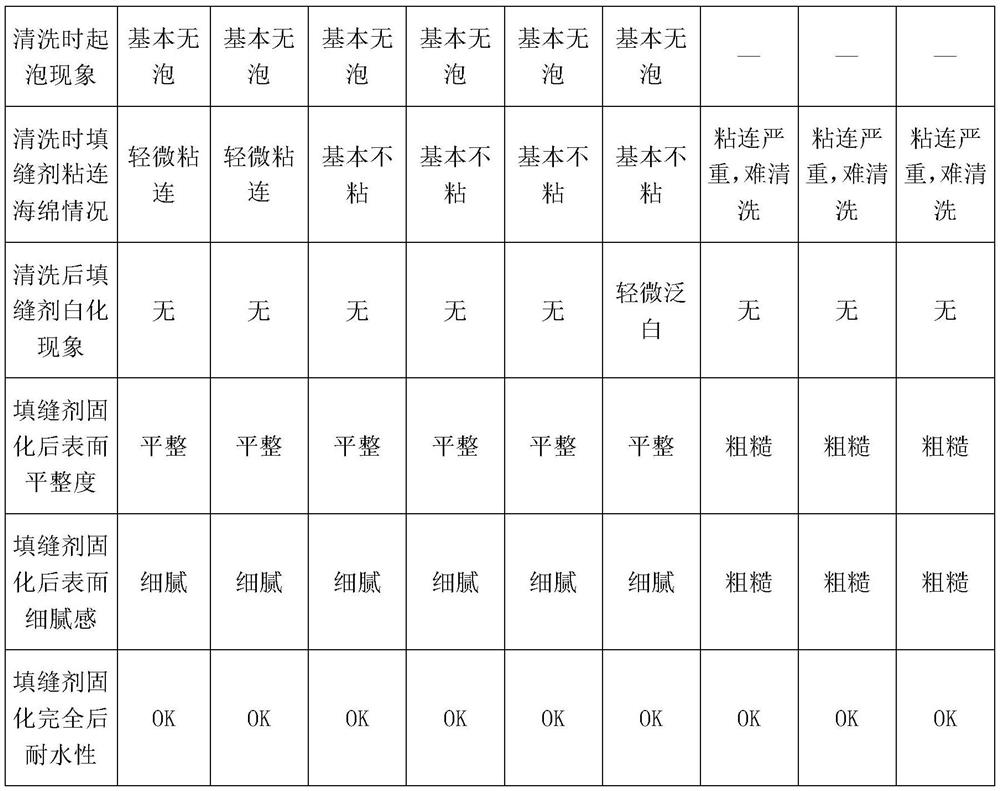

Examples

Embodiment Construction

[0039] An object of the present invention is to provide a solvent-free epoxy caulking agent and a preparation method thereof, wherein the solvent-free epoxy caulking agent maintains good crack resistance and waterproof properties, is not easy to absorb water, is anti-fouling and mildew-proof, and has good strength. While high wear resistance, it also has good yellowing resistance, aging resistance, construction convenience, odor, stain resistance, construction operation time, cleaning performance, anti-sag, safety, environmental protection, etc.

[0040] An object of the present invention is to provide a solvent-free epoxy caulking agent and a preparation method thereof, wherein compared with the existing epoxy caulking agent, the solvent-free epoxy caulking agent of the present invention can not only Zero VOC environmental protection requirements, and avoid the collapse and shrinkage caused by solvent or moisture volatilization during the curing and drying process of the caulk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com