Hydrophobic organic polysilazane as well as preparation method and application thereof

A polysilazane and organic technology, applied in the field of hydrophobic organopolysilazane and its preparation, can solve the problems of hydrophobic failure, difficult batch operation, cumbersome operation, etc., and achieve simple production process, improved hydrophobicity, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

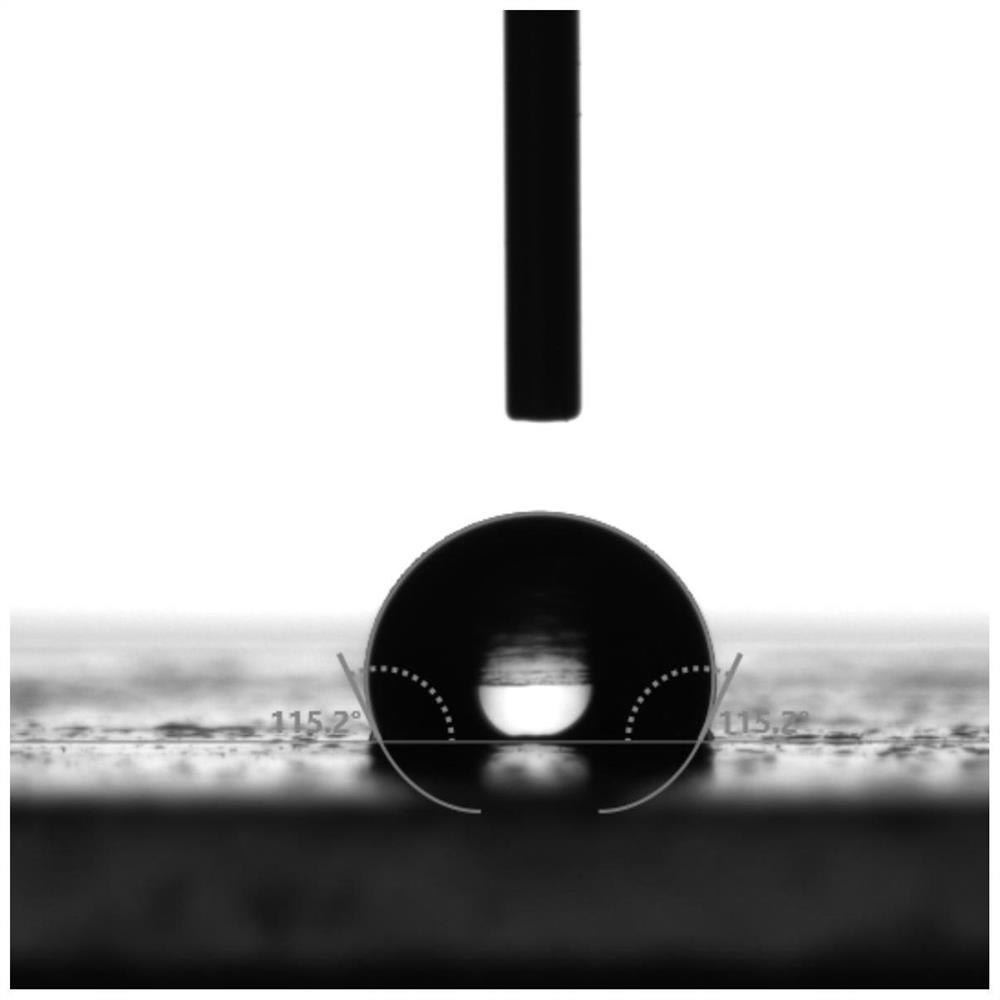

Embodiment 1

[0052] A preparation method of hydrophobic organopolysilazane, the specific steps of the method are as follows:

[0053] (1) carry out dehydration treatment with pentane, hexane and pyridine, make its water content no more than 5ppm, with 99.9% argon purging 1000mL three-necked round-bottomed flask 30min, ensure that the reaction vessel is anhydrous and oxygen-free;

[0054] (2) 200mL of solvent and 0.2mL of pyridine after dehydration treatment in step (1) were added to a 1000mL three-necked round-bottomed flask, wherein the volume ratio of pentane and hexane was 1:2, and then 60mL of perfluorooctylmethyl dichloride was added. Silane and 40 mL of methyldichlorosilane, the volume ratio of perfluorooctylmethyldichlorosilane to methyldichlorosilane is 6:4, and the volume of the catalyst is 0.2% of the sum of the volume of fluorochlorosilane and chlorosilane, After mixing uniformly, the ammonia gas with a purity of 99.999% was introduced for the reaction, stirred at -10°C for 8 ho...

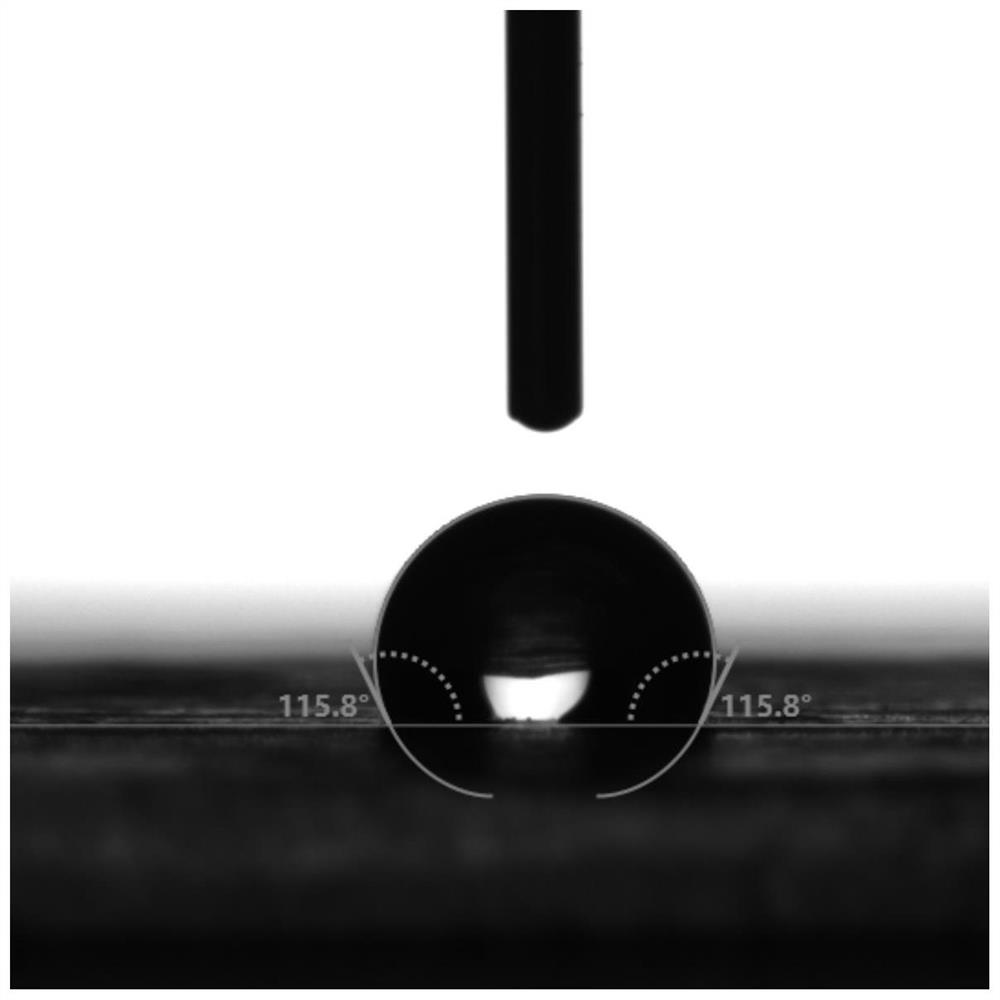

Embodiment 2

[0059] A preparation method of hydrophobic organopolysilazane, the specific steps of the method are as follows:

[0060] (1) dehydration of methylcyclopentane, methylcyclohexane and pyridine so that the water content is no more than 5ppm, purging a 1000mL three-necked round-bottomed flask for 30min with argon with a purity of 99.9% to ensure that the reaction vessel has no water without oxygen;

[0061] (2) Into a 1000mL three-necked round-bottomed flask, add 500mL of the solvent and 0.3mL of pyridine after dehydration in step (1), wherein the volume ratio of methylcyclopentane to methylcyclohexane is 3:1, and then add 2.5mL Perfluorohexyltrichlorosilane and 47.5mL methyltrichlorosilane, perfluorohexyltrichlorosilane:methyltrichlorosilane=5:95, the catalyst volume is 0.6% of the sum of the volume of fluorochlorosilane and chlorosilane, After mixing evenly, introduce ammonia gas with a purity of 99.999% for the reaction, stir at -10°C for 10 hours, add 100 mL of the solvent af...

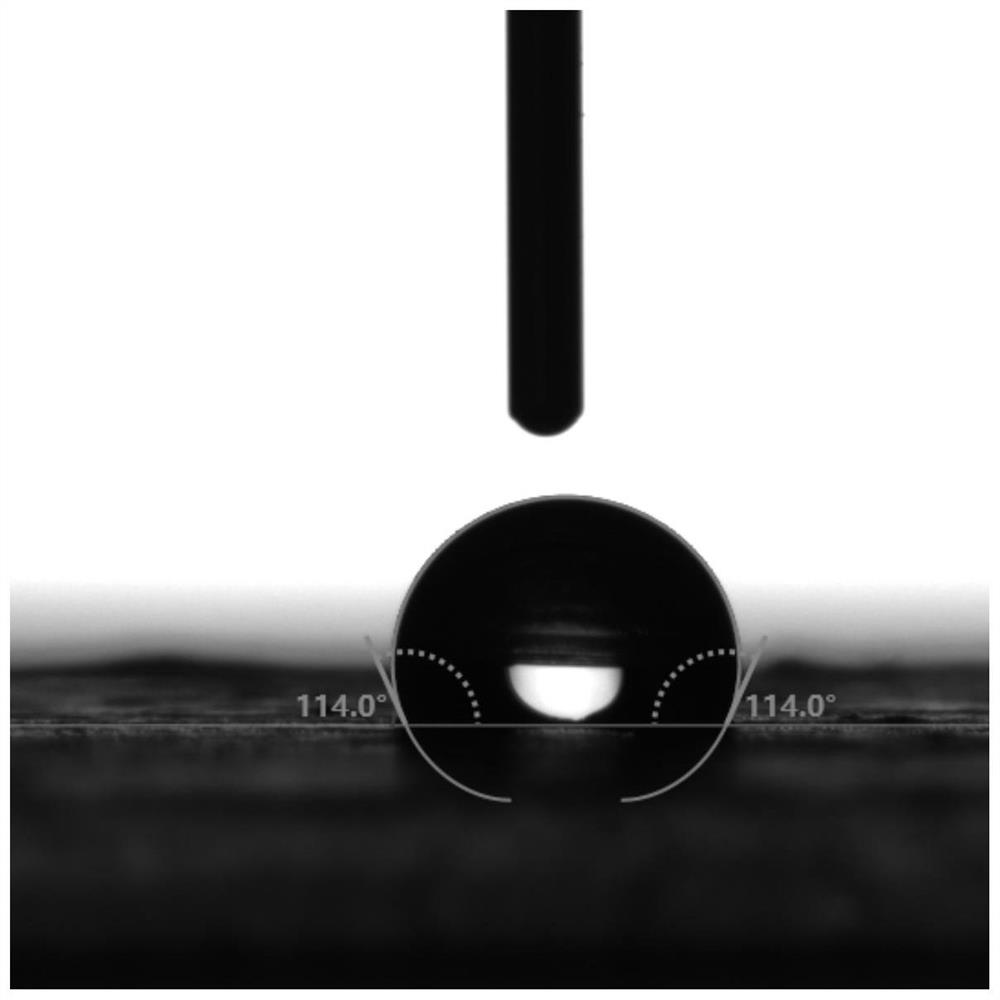

Embodiment 3

[0066] A preparation method of hydrophobic organopolysilazane, the specific steps of the method are as follows:

[0067] (1) toluene and pyridine are dehydrated so that their water content is no more than 5ppm, and a 1000mL three-necked round-bottomed flask is purged for 30min with a purity of 99.9% argon to ensure that the reaction vessel is anhydrous and oxygen-free;

[0068] (2) Into a 1000mL three-necked round bottom flask, add 400mL of toluene solvent and 0.2mL of pyridine after dehydration in step (1), then add 7mL of perfluorohexyltrichlorosilane, 7mL of perfluorodecylmethyldichlorosilane, 56mL of The volume ratio of ethyldichlorosilane, perfluorohexyltrichlorosilane:perfluorodecylmethyldichlorosilane:ethyldichlorosilane is 1:1:8, and the volume of the catalyst is the volume of chlorofluorosilane and chlorosilane. 0.25% of the total and 0.25%, after mixing evenly, introduce ammonia gas with a purity of 99.999% for reaction, stir at -10 °C for 9 h, add 100 mL of the solv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com