Connecting wire device of wire-changing power strip

A connection line and wireless plug-in technology, which is applied to the parts, connections, coupling devices, etc. of the connection device, can solve the problems of long lines, damage to the plug-in strip, and failure to restore the original state, etc., to achieve friendly application environment, convenient installation and use, The effect of a broad market prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

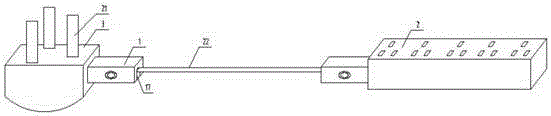

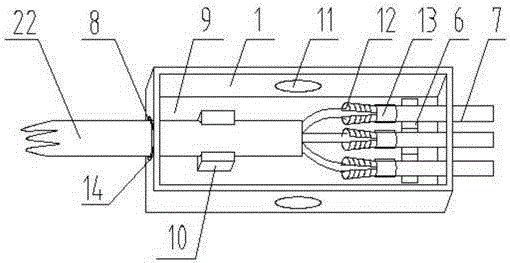

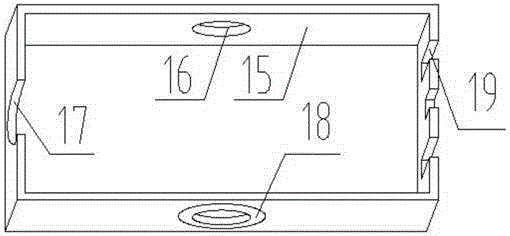

[0017]The main structure of the connecting line device related to the present embodiment includes: a connecting plug 1, a wireless socket 2, a wireless socket 3, a first connecting jack 4, a second connecting jack 5 and a connecting wire 22; the connecting plug The main structure of 1 includes: pin support seat 6, pin 7, wire inlet hole 8, box body 9, fixing block 10, bump 11, fixing piece 12, fixing bolt 13, T-shaped sealing rubber sleeve 14, box cover 15 , bump fixing hole 16, U-shaped groove 17, sealing rubber sleeve 18, latch groove 19 and pull button 20, the cuboid box body 9 of engineering plastic material with high temperature resistance and high flame retardancy is a pentahedron structure with an opening on the top surface, two Protrusions 11 are respectively placed at the center of the long sides, and the protrusions 11 are round cap-shaped structures protruding outwards. The latch 7 is made up of three elongated metal strips that pass horizontally through the right si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com